Method for preparing high-purity dicyclopentadiene

A technology for dicyclopentadiene and cyclopentadiene, which is applied in the field of preparing high-purity dicyclopentadiene, can solve the problem of inability to take into account the degree of depolymerization of dicyclopentadiene and the continuity of the production process, and the device Unable to run for a long time, accumulation of coking of polymers, etc., to avoid coking of tower kettle, low price and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

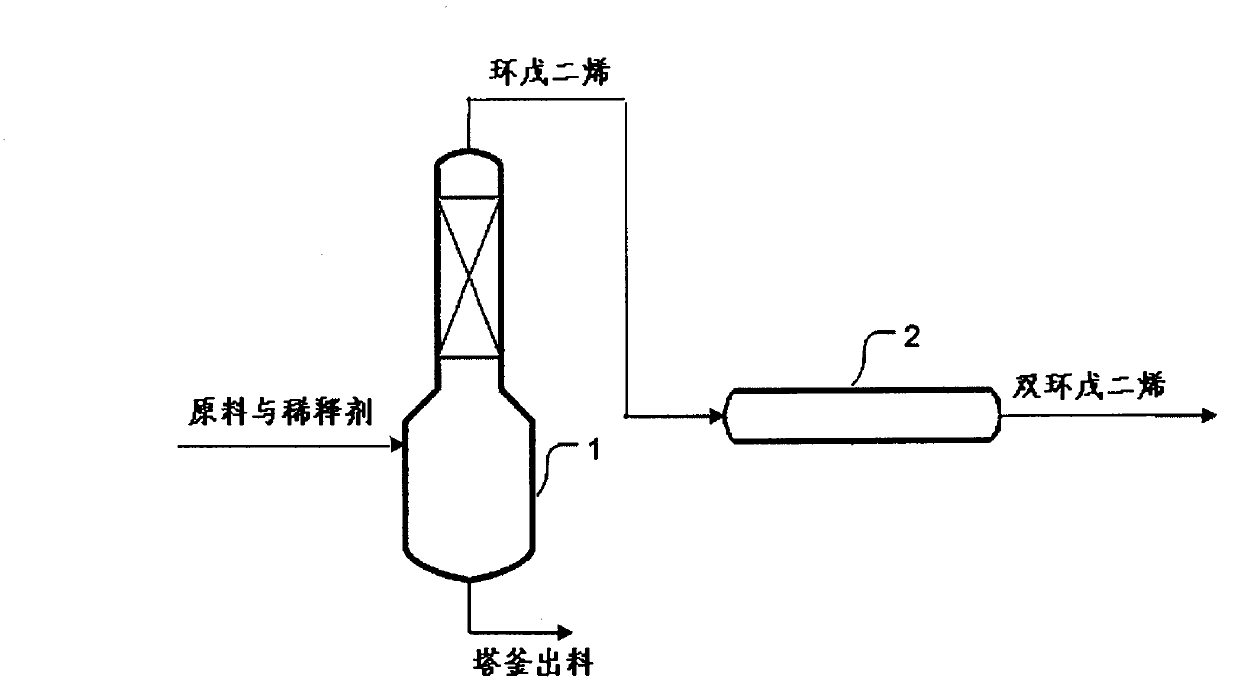

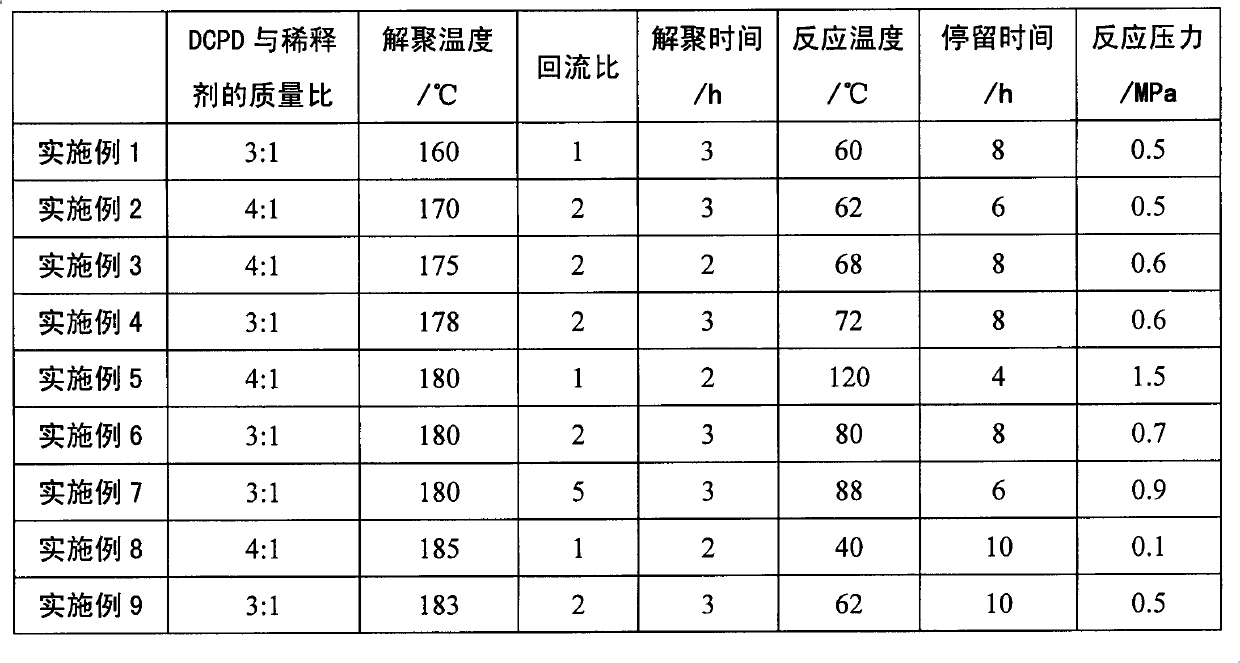

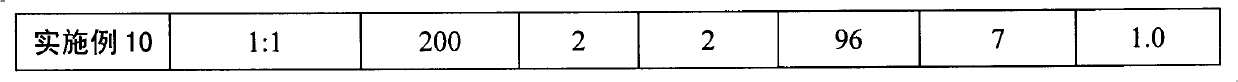

[0027] The process flow of Examples 1 to 10 is shown in the accompanying drawings. The raw material is crude dicyclopentadiene obtained by pyrolysis and thermal dimerization of C5, and its composition is shown in Table 1.

[0028] Add crude dicyclopentadiene and diluent in a certain proportion into the mixing tank, and the diluted dicyclopentadiene raw material is pumped into the reactor of the reactive distillation tower by a metering pump; dicyclopentadiene depolymerizes in the reactor to form ring Pentadiene, the cyclopentadiene generated by depolymerization is rectified and purified in the upper rectification tower, and the high-purity cyclopentadiene product is obtained at the top of the tower, and the liquid in the bottom of the tower is continuously discharged; the cyclopentadiene at the top of the tower is passed through a tube The reactor undergoes a dimerization reaction to generate dicyclopentadiene. See Table 2 for the operating conditions of the depolymerization r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com