Chromium-zinc modified molecular sieve loaded bimetallic catalyst, preparation thereof and application of chromium-zinc modified molecular sieve loaded bimetallic catalyst in lignin depolymerization

A technology of bimetallic catalyst and molecular sieve is applied in the field of lignin depolymerization research to achieve the effects of reducing cost, simple and convenient preparation process, and increasing the degree of depolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0039] Weigh 1.46g Cr(NO 3 ) 3 ·9H2 O and 0.87 g Zn(NO 3 ) 3 ·6H 2 O Solid in a beaker, to which 15ml of deionized water was added, and then added 5g of all-silicon MCM-41 carrier, wherein the modified amount of metal chromium and zinc are 3.8wt%, ultrasonic shock 25min, stirring for 10h, 110 °C drying for 8h, roasting at 500 °C in the muffle furnace for 5h, wherein the heating rate is 6 °C / min, that is, the modified molecular sieve carrier (Cr-Zn-MCM-41).

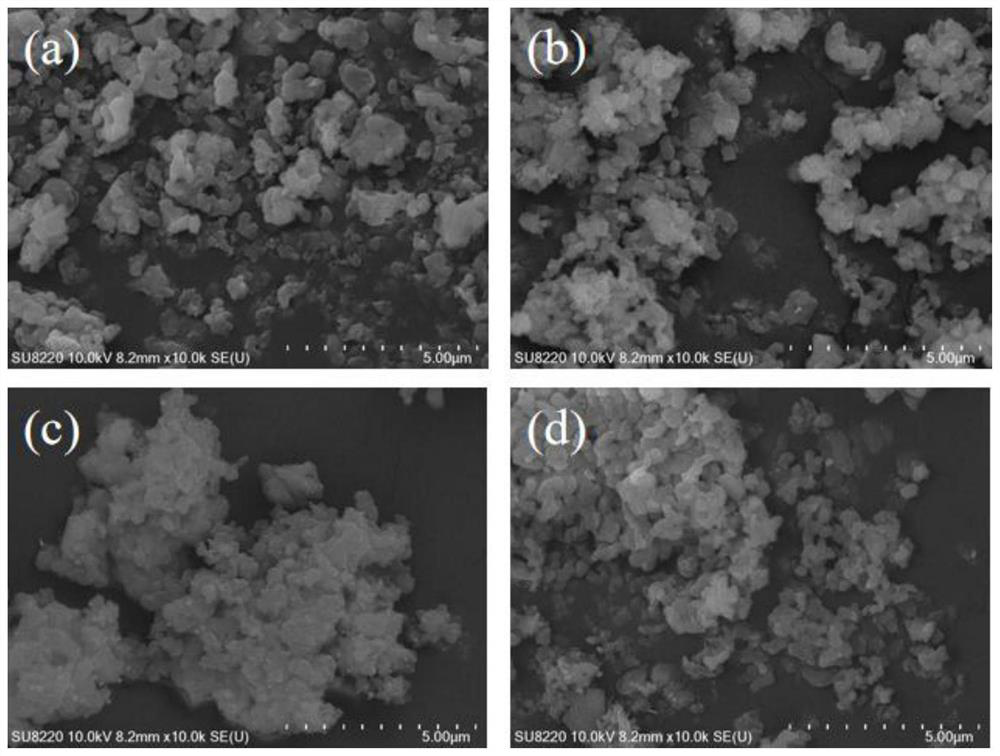

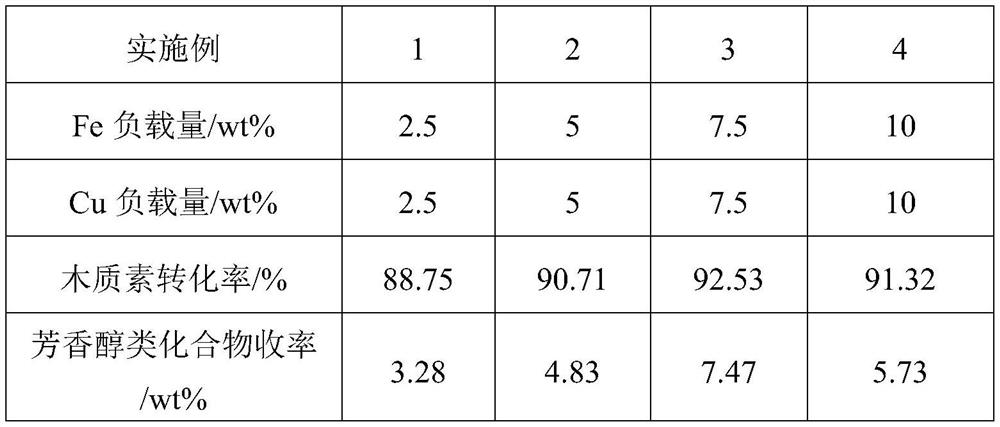

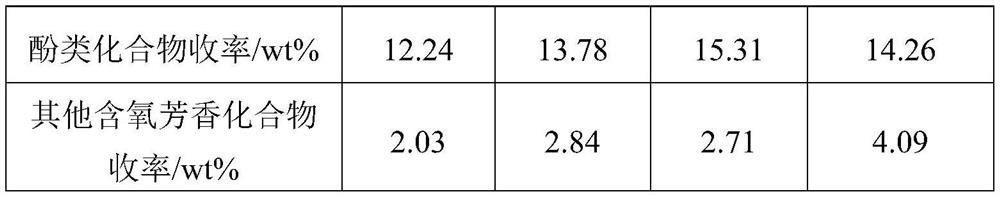

[0040] 0.18g, 0.36g, 0.54g, and 0.72g Fe(NO 3 ) 3 ·9H 2 O and 0.067g, 0.134g, 0.20g, 0.268g CuCl 2 ·2H 2 O, dissolved with 3 ml of deionized water, added 1g modified molecular sieve carrier, ultrasonically shaken for 25min, stirred for 10h, dried at 110 °C for 8h, hydrogen was reduced at 500 °C in a tubular furnace for 4h, wherein the heating rate of hydrogen reduction was 4 °C / min, at N 2 / O 2 Ambient passivation for 30min in a mixed atmosphere, where O 2 The content is 1wt%, N 2 / O 2 The flow rate of the mixture is 40ml / min...

Embodiment 5-7

[0046] Refer to the preparation process of the modified molecular sieve carrier in Example 1-4 to prepare the modified molecular sieve carrier.

[0047] Each is called 0.54g Fe(NO 3 ) 3 ·9H 2 O、0.315g Co(CH 3 COO) 2 ·4H 2 O、0.30g NiCl 2 ·6H 2 O、0.14g(NH 4 ) 6 Mo 7 O 24 ·4H 2 O and four servings of 0.201 g CuCl 2 ·2H 2 O, dissolved with 3ml of deionized water, added 1g modified molecular sieve carrier, ultrasonically shaken for 25min, stirred for 10h, dried at 110 °C for 8h, hydrogen was reduced at 500 °C in a tubular furnace for 4h, wherein the heating rate of hydrogen reduction was 4 °C / min, at N 2 / O 2 Ambient passivation for 30min in a mixed atmosphere, where O 2 The content is 1wt%, N 2 / O 2 The flow rate of the mixture is 40ml / min, and the bimetallic catalyst with a metal Fe, Co, Ni and Mo load of 7.5wt and Cu load of 7.5wt% is obtained, respectively, which is recorded as 7.5X-7.5Cu / Cr-Zn-MCM-41 (X=Fe, Co, Ni, Mo), as shown in Table 2.

[0048] The 0.3 g of lignin obtained by...

Embodiment 8-11

[0053] Referring to Example 6, the 0.3g organic solvent extraction method obtained lignin (obtained using ethanol), 0.15g of 7.5Ni-7.5Cu / Cr-Zn-MCM-41 catalyst and 40ml of solvent (see Table 3) were added to the high-pressure reactor, to which 1MPa N was introduced 2 Replace the air in the kettle, repeat 3 times, exhaust to atmospheric pressure, and fill with 1 MPa H 2 , 280 °C reaction 5h, after the end of the reaction, the reactor with tap water reduced to room temperature, filtering, filter residue with ethyl acetate for washing, and then using methanol volume, take 1ml of extract for gas chromatographic analysis, the yield of the resulting liquid product aromatic alcohols, phenols and other oxygenated aromatic compounds is shown in Table 3.

[0054] Table 3 Effects of different solvents on the depolymerization of organic solvents lignin

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com