Method for separating and cracking cyclopentadienyl from carbon 5 fraction

A technology for separating cyclopentadiene and cyclopentadiene, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of not being an economical implementation, increasing production costs, etc., and reducing polymerization. The reaction occurs and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Utilize the cracking C5 fraction in Table 1 below, and use the method for separating and cracking cyclopentadiene in the C5 fraction of the present invention to remove cyclopentadiene.

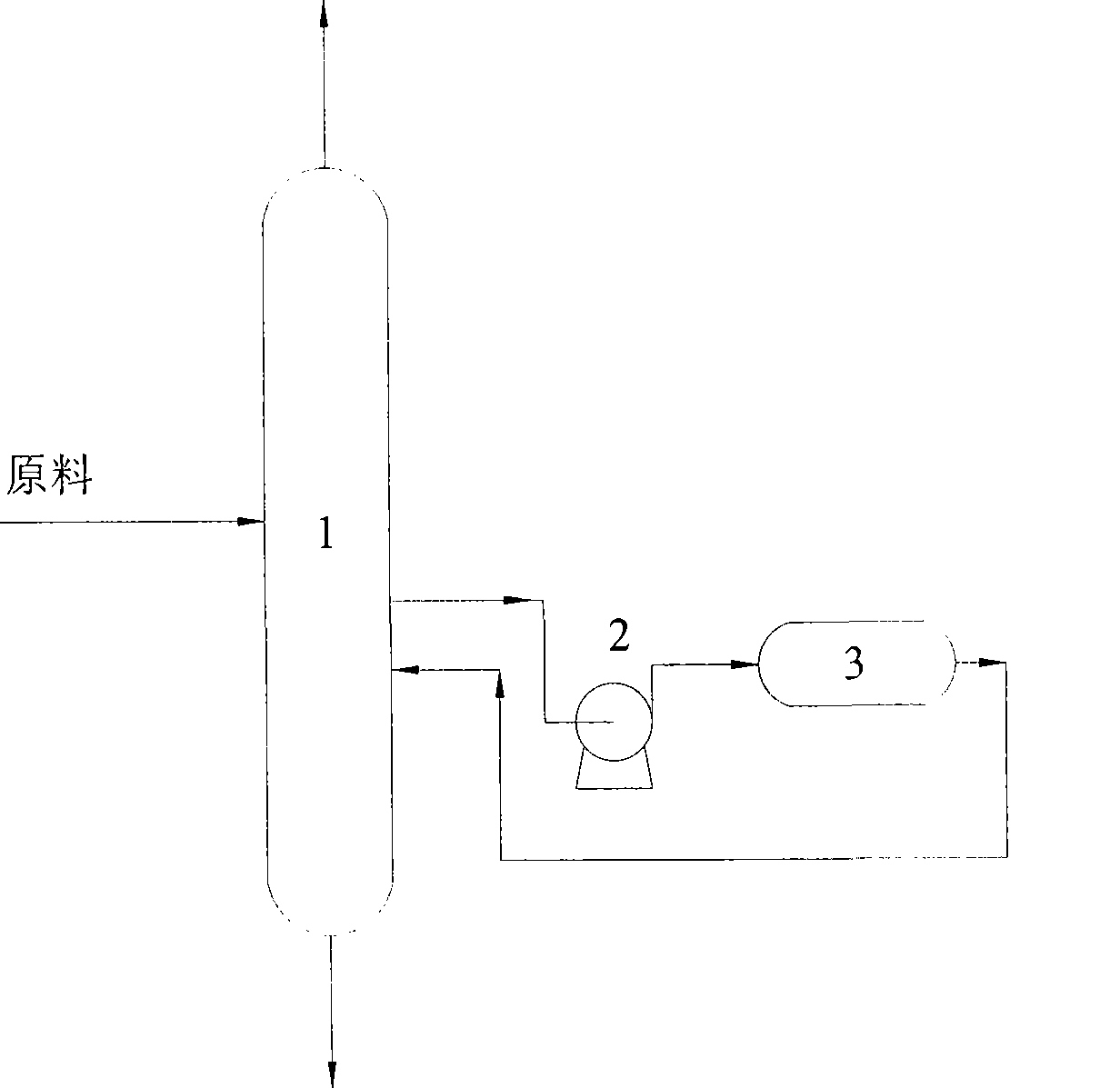

[0032] First, the cracked C5 fraction enters the rectification tower, the number of theoretical plates of the rectification tower is 60, the feed inlet is on the 30th plate, the temperature at the top of the tower is 45°C, the pressure at the top of the tower is 2.5MPa, and the reflux ratio is 5 . The output at the top of the tower is 50% (mass) of the feed amount. From the 35th plate, the liquid phase stream is drawn, and the drawn amount is 10% (mass) of the feed amount, and is sent to the suspended dimerization reactor with a pump, so that the residence time in the dimerization reactor is 1.5 hours, The reactor does not use an external heater, but uses the temperature of the material itself, and then sends the material to the rectification column from the 40th plate. According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com