Novel preparation process of synthetic fatting agent and device

A preparation process and a fatliquor technology are applied in the field of the preparation process and device of a new type of synthetic leather fatliquor, which can solve the problems of inability to accurately and timely control, and achieve excellent fatliquoring performance, convenient operation and simple device structure. Effect

Inactive Publication Date: 2016-09-21

JIAXING ZANYU TECH DEV CO LTD +1

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method can only manually control the feed ratio of raw materials, while the molar ratio of monoester and diester in the product is determined by the reaction situation, which cannot be controlled accurately and in time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

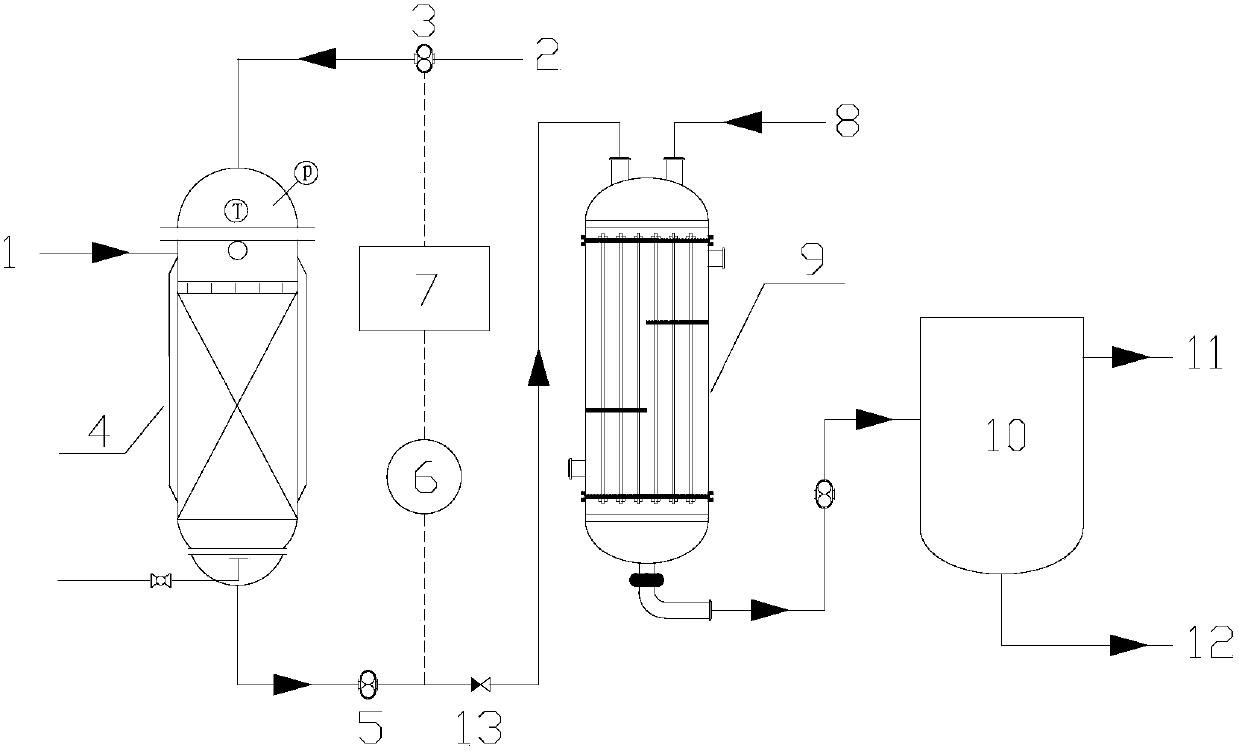

The invention relates to a novel preparation process of a synthetic fatting agent and a device, and aims at achieving the effects that according to the provided process, the sulfonation degree of a final product can be automatically controlled, and the provided device can realize the continuous production of products. The preparation process of the novel synthetic fatting agent has the technical scheme that the novel preparation process of the synthetic fatting agent is performed according to the following steps of (1) synthesizing an oleic acid glycol monoester and diester mixture; (2) measuring the density of an esterification product by an automatic control system; (3) continuously inputting an oleic acid glycol ester mixture into a sulfonator for taking a diaphragm type sulfonation reaction; and (4) obtaining a leather fatting agent product, wherein tail gas is absorbed by a tail gas treatment system. A novel production device of the synthetic fatting agent comprises an esterification reactor, an organic material pump, a back pressure valve, a sulfonation reactor and a gas-liquid separator, wherein the esterification reactor is provided with an oleic acid inlet and a glycol inlet; a measuring instrument is also arranged in a connecting pipeline arranged between the organic material pump and the back pressure valve; and a data converter is communicated with the measuring instrument and a raw material pump.

Description

technical field The invention relates to the technical field of leather chemical industry, in particular to a preparation process and device of a novel synthetic leather fatliquoring agent. Background technique In the field of leather chemical industry, ethylene glycol oleate leather fatliquor, as a newly developed synthetic fatliquor in recent years, shows excellent leather fatliquor performance. The study found that the application of oleic acid ethylene glycol ester synthetic fatliquor to the leather after fatliquoring is soft, the board surface is plump and elastic, the finished product is not greasy, and the grain surface and suede of the leather are shiny; Increase the water absorption and improve the waterproof performance of the leather. Therefore, this type of synthetic fatliquoring agent is more and more widely used in the field of leather chemical industry. In order to better reflect the fatliquoring effect of ethylene glycol oleate on leather, chemical modific...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C14C9/02

CPCC14C9/02

Inventor 钟鸣翔徐坤华余新林葛赞杨春良黄亚茹

Owner JIAXING ZANYU TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com