Method for preparing potassium hexatitanate whisker

A potassium hexatitanate whisker and purpose technology, which is applied in the field of preparation of potassium hexatitanate whisker, can solve problems such as long production cycle, high fuel consumption, complex process flow, etc., to improve product yield and purity, improve Purity and yield, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The method for preparing potassium hexatitanate whiskers of the present invention includes the following steps:

[0029] a. The -100 mesh titanium-containing raw material and potassium-containing raw material are in accordance with TiO 2 : K 2 O=3~6 molar ratio and mix well;

[0030] b. Place the uniformly mixed materials in step a for sintering in a temperature environment of 1100 to 1300°C for 1 to 5 hours to fully react the materials;

[0031] c. The sintered material in step b is rapidly cooled, and then the cooled material is fully dissociated with water in a constant temperature environment of 60-80°C, and finally filtered and dried to obtain the product potassium hexatitanate whiskers.

[0032] The particle size of the raw material of the invention is -100 mesh, so that the loose volume of the titanium-containing raw material and the potassium-containing raw material is basically the same, which is beneficial to uniform mixing and sufficient contact of the raw materials. ...

Embodiment 1

[0040] -100 mesh anatase titanium dioxide and anhydrous potassium carbonate are 2 : K 2 Weigh with a molar ratio of O=5.5 and mix the two evenly;

[0041] Put the above mixed raw materials into a crucible of appropriate size, and put the crucible into a high temperature box-type resistance furnace at 1150℃ for 3 hours;

[0042] Take out the above sintered product and immediately put it into a water container to cool;

[0043] After the product has cooled down, take the product out of the water, put the product in the crucible into a beaker containing 400ml of water, and put the beaker into a water bath set at a temperature of 70℃, and stir the product in the beaker to make a whisker product Fully dissociated, the dissociation time is 2h;

[0044] After the above-mentioned dissociated product is suction filtered, it is put into an oven at 90°C and dried to be the finished product.

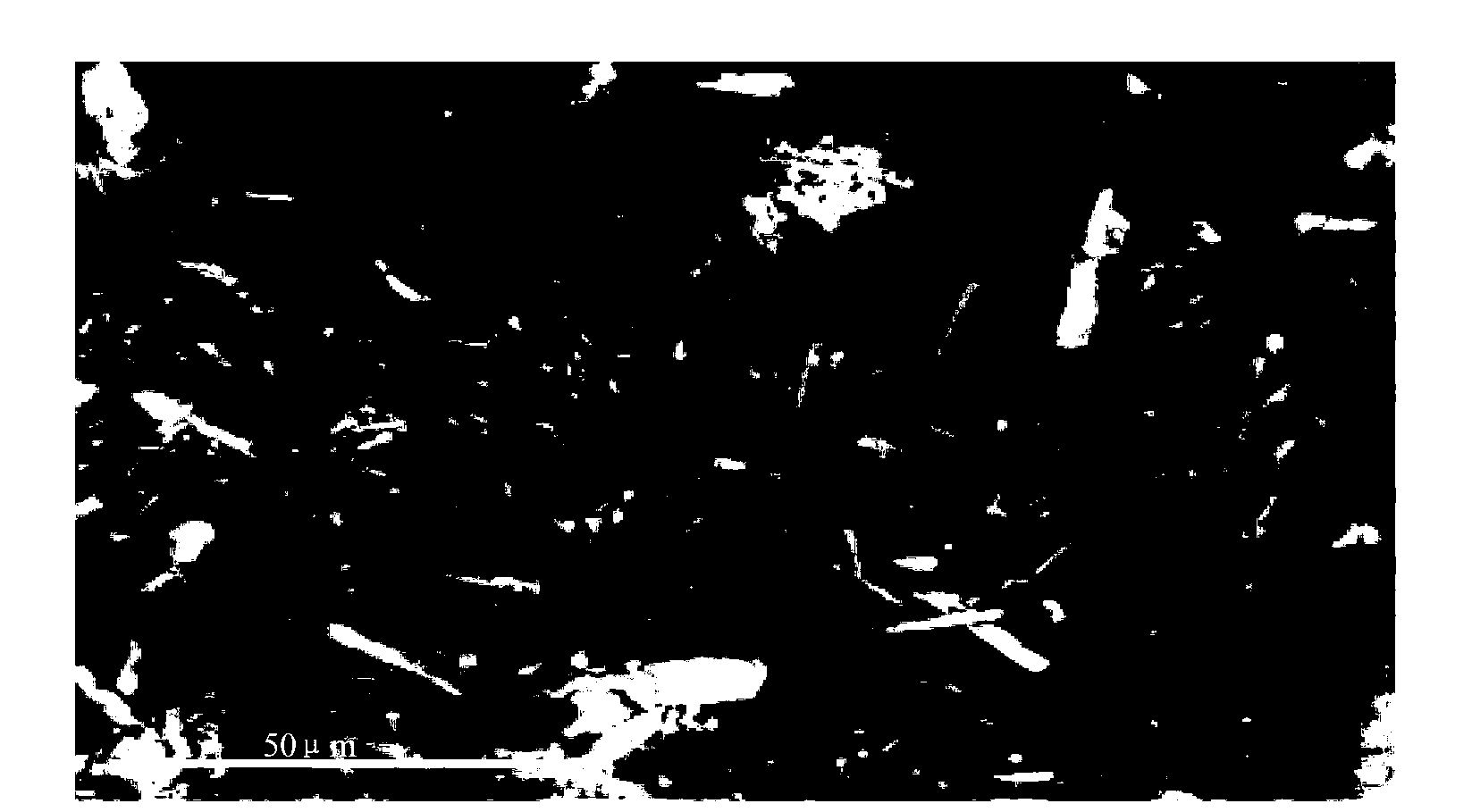

[0045] See the SEM image of the prepared potassium hexatitanate whiskers ( figure 1 ), the length of the ...

Embodiment 2

[0047] -100 mesh anatase titanium dioxide and anhydrous potassium carbonate are 2 : K 2 Weigh with a molar ratio of O=5.5 and mix the two evenly;

[0048] Put the above mixed raw materials into a crucible of appropriate size, and put the crucible into a high temperature box-type resistance furnace at 1200°C for 3 hours;

[0049] Take out the above sintered product and immediately put it into a water container to cool;

[0050] After the product has cooled down, take the product out of the water, put the product in the crucible into a beaker containing 400ml of water, and put the beaker into a water bath set at a temperature of 70℃, and stir the product in the beaker to make a whisker product Fully dissociated, the dissociation time is 2h;

[0051] After the above-mentioned dissociated product is suction filtered, it is put into an oven at 90°C and dried to be the finished product.

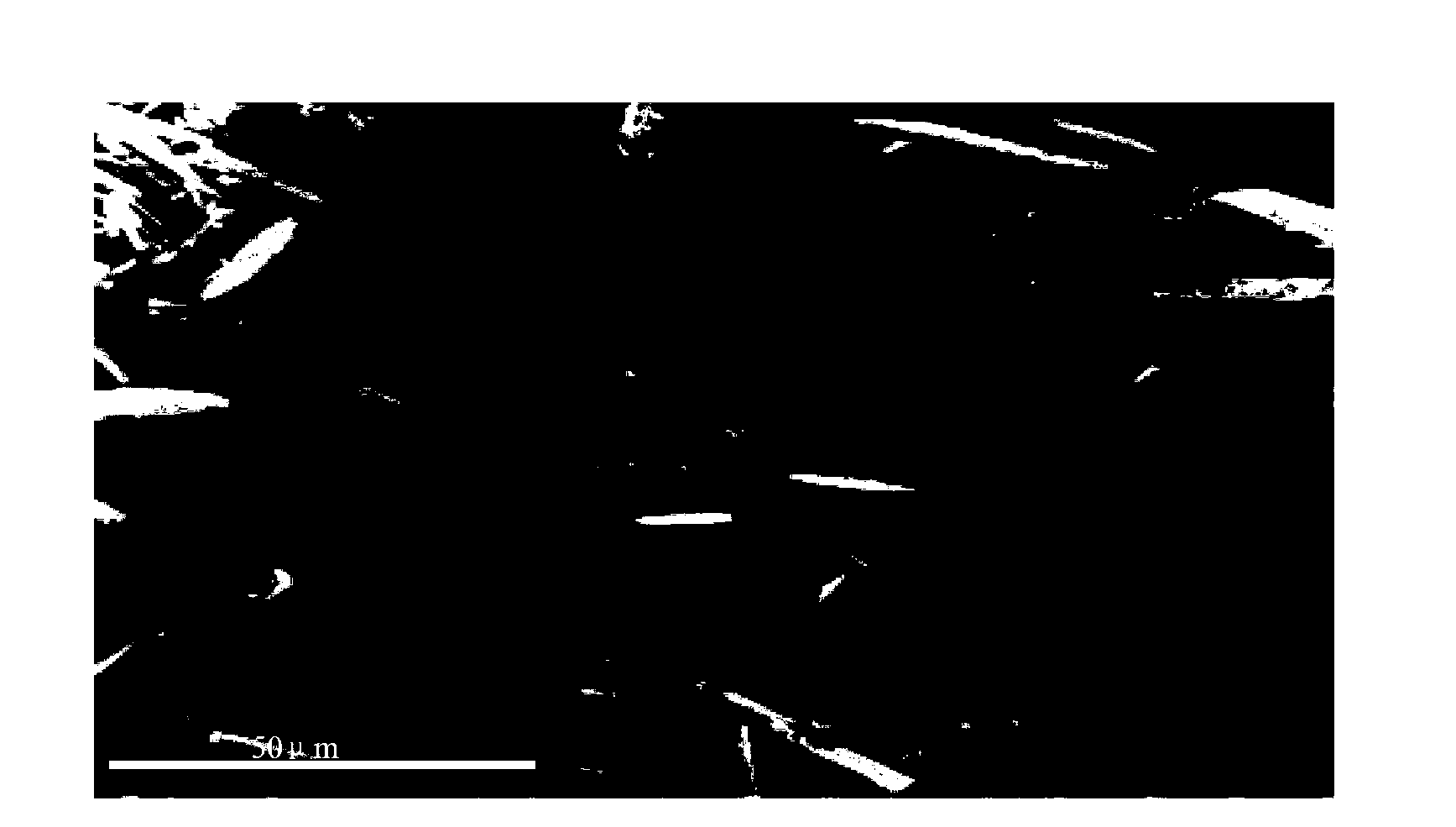

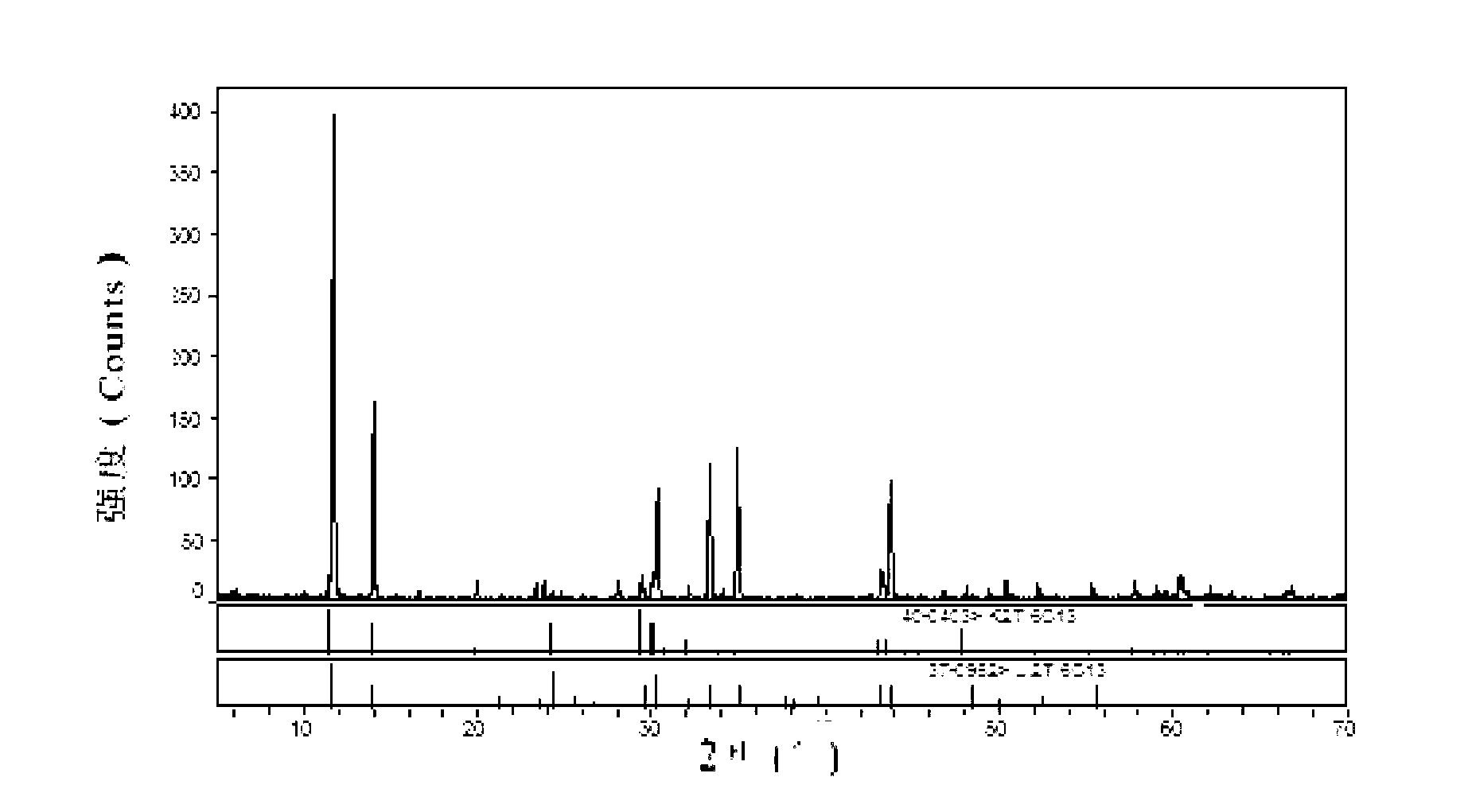

[0052] See the SEM image and XRD image of the prepared potassium hexatitanate whiskers ( figure 2 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com