Spinning polyamide 6 and manufacture method thereof

A manufacturing method, polyamide technology, applied in the direction of single-component polyester rayon, etc., can solve the problems of high fiber strength, low strength, and inflexibility, and achieve strong UV resistance, good thermal stability, and high strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

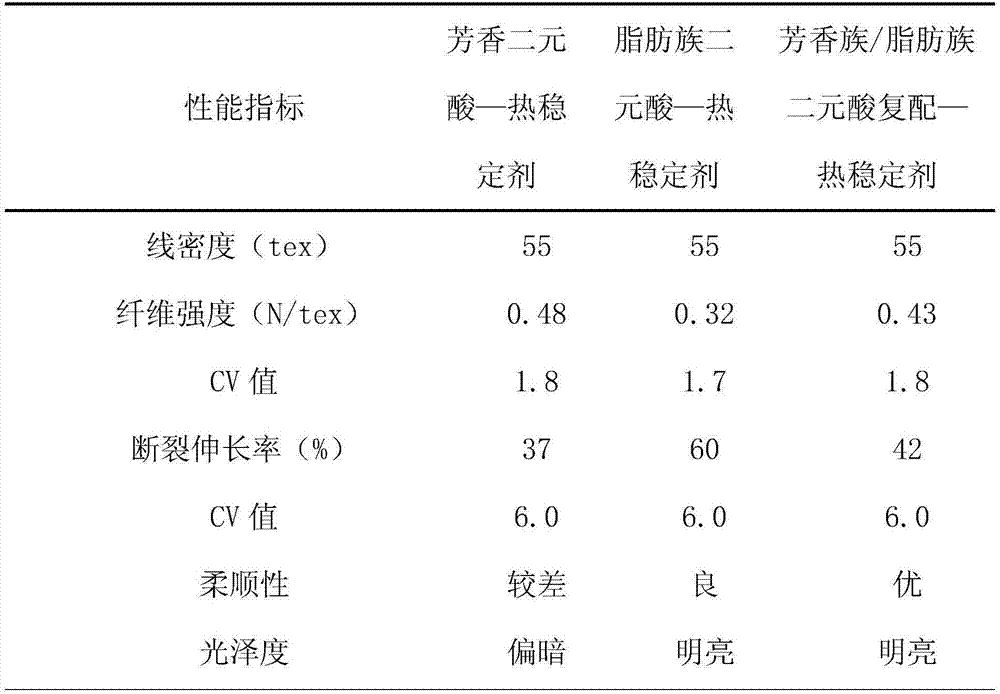

Examples

Embodiment 1

[0032] Put 480kg of caprolactam, 20kg of desalted water, 1300g of adipic acid, 100g of terephthalic acid, and 250g of 4-amino-2,2,6,6-4 methylpiperidine into a static mixer and mix well. Put it into the pre-polymerization tower, react at 0.55MPa and 270°C for 2 hours, then add it to the main polymerization tower and react at 0.15MPa for 7 hours, control the reaction temperature at 250°C, and finally go through pelletizing, boiling water extraction and drying. High-speed spun chips with a relative viscosity of 2.60, 40 mmol / kg of terminal amino groups and 77 mmol / kg of terminal carboxyl groups can be obtained.

Embodiment 2

[0034] Put 480kg of caprolactam, 20kg of desalted water, 1200g of adipic acid, 200g of terephthalic acid and 250g of 4-amino-2,2,6,6-4 methylpiperidine into a static mixer and mix them evenly. Put it into the pre-polymerization tower, react at 0.55MPa and 270°C for 2 hours, then add it to the main polymerization tower and react at 0.15MPa for 6 hours, control the reaction temperature between 270°C, and finally go through pelletizing, boiling water extraction and drying. High-speed spun chips with a relative viscosity of 2.60, 41 mmol / kg of terminal amino groups and 76 mmol / kg of terminal carboxyl groups can be obtained.

Embodiment 3

[0036] 480kg caprolactam, 20kg desalted water, 1100g adipic acid, 300g terephthalic acid and 350g N,N'-bis(2,2,6,6-tetramethyl-4 piperidinyl)-1,3-benzene Diformamide is placed in a static mixer and mixed evenly, and the evenly mixed mixture is added to the prepolymerization tower, reacted at 0.55MPa and 255°C for 3h, and then added to the main polymerization tower for 10h at 0.10MPa, and the reaction temperature is controlled Always between 260°C. Finally, high-speed spinning chips with a relative viscosity of 2.60, 42 mmol / kg of terminal amino groups and 77 mmol / kg of terminal carboxyl groups can be obtained through pelletizing, boiling water extraction and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com