Chinlon 6 for spinning and manufacturing method thereof

A nylon and molecular weight control agent technology, applied in the field of nylon 6 modification, can solve the problems of poor spinnability, low thermal stability of nylon 6, high-speed spinning full roll rate and low heat-resistant dyeing A rate, etc. The effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

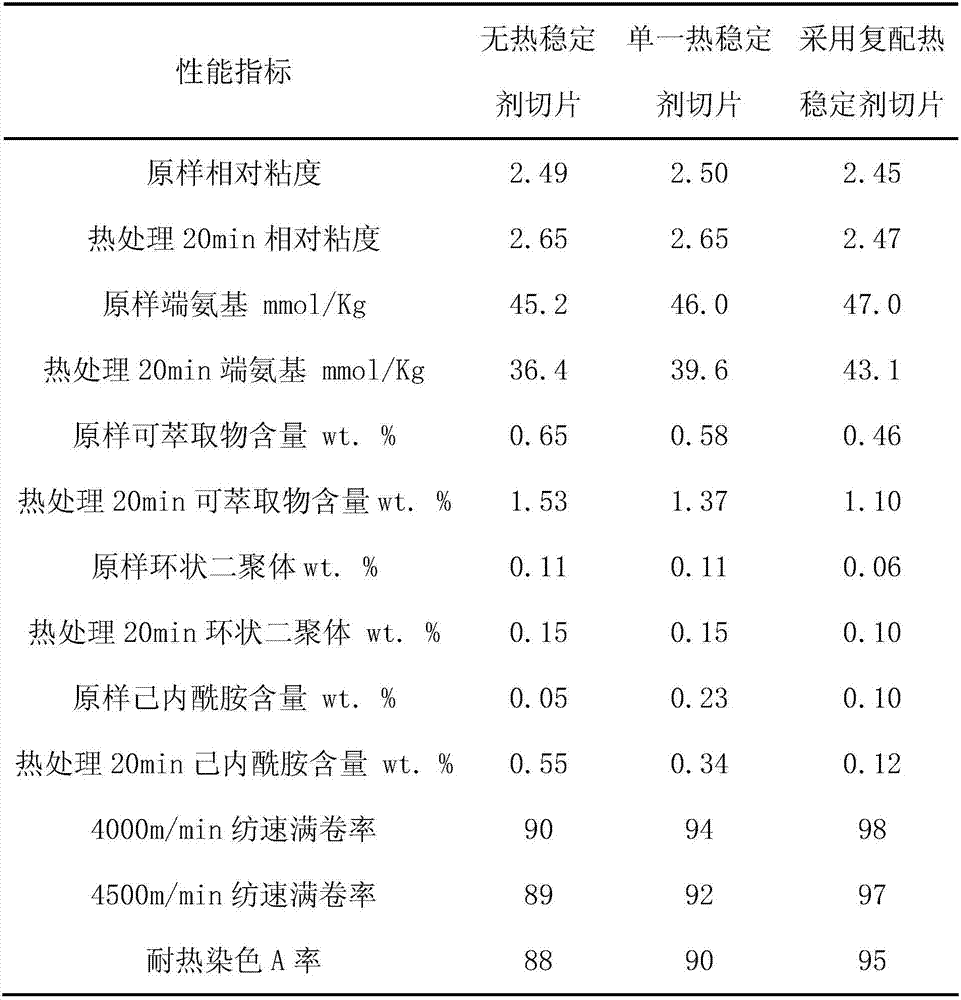

Examples

Embodiment 1

[0033] 480kg caprolactam, 20kg desalted water, 1.4kg terephthalic acid, 10g 4-amino-2,2,6,6-4 methylpiperidine, 240g N,N'-bis(2,2,6,6- Tetramethyl-4-piperidinyl)-1,3-benzenedicarboxamide was put into a static mixer and mixed evenly, and the evenly mixed mixture was put into the prepolymerization tower, and reacted at 0.55MPa and 270°C for 2h, and then Add it into the main polycondensation tower, react at 255°C and 0.15MPa for 7 hours, and finally pelletize, extract with boiling water and dry to obtain high-speed spun chips with a relative viscosity of 2.50 and an amino terminal of 47mmol / kg.

Embodiment 2

[0035] 480kg caprolactam, 20kg desalted water, 1.4kg terephthalic acid, 20g 4-amino-2,2,6,6-4 methylpiperidine and 230g N,N'-bis(2,2,6,6-tetra Methyl-4-piperidinyl)-1,3-benzenedicarboxamide was put into a static mixer and mixed evenly, and the evenly mixed mixture was added to the prepolymerization tower, and reacted at 0.55MPa and 270°C for 2 hours, and then added In the main polycondensation tower, react at 270°C and 0.15MPa for 6 hours, and finally undergo pelletizing, boiling water extraction and drying to obtain high-speed spun chips with a relative viscosity of 2.50 and terminal amino groups of 46mmol / kg.

Embodiment 3

[0037] 480kg caprolactam, 20kg desalted water, 1.4kg terephthalic acid, 10g 4-amino-2,2,6,6-4 methylpiperidine, 340g N,N'-bis(2,2,6,6- Tetramethyl-4-piperidinyl)-1,3-benzenedicarboxamide was put into a static mixer and mixed evenly, and the evenly mixed mixture was put into the prepolymerization tower, and reacted at 0.55MPa and 255°C for 3h, and then Add it into the main polycondensation tower, react at 260°C and 0.10MPa for 10 hours, and finally undergo pelletizing, boiling water extraction and drying to obtain high-speed spun chips with a relative viscosity of 2.50 and terminal amino groups of 48mmol / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com