Method for producing a propylene polymer having a very high melt flowability

一种丙烯聚合物、丙烯聚合的技术,应用在全同立构丙烯聚合物领域,能够解决氢气反应性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] [Preparation of main catalyst component]

[0032] Into a fully nitrogen-purged 1 L glass reactor equipped with a stirrer was added 200 ml of toluene and diethoxymagnesium (25 g, 0.219 mol) and stirred at 250 rpm while maintaining the temperature at 10°C. Add 75ml of titanium tetrachloride to it within 30 minutes, then raise the temperature of the reactor to 110°C at a rate of 0.5°C per minute, during the temperature rise, when the temperature reaches 25°C, further add 7.5ml of phthalic acid Diisobutyl ester (DIBP) (0.028 mol). The resulting mixture was reacted at 110° C. for 1 hour with stirring, and then left without stirring to precipitate a solid product. The supernatant was removed therefrom and 250 ml of fresh toluene was added to wash the precipitate and stirred for 15 minutes. Repeat the same washing steps again.

[0033] Add 200ml of toluene again to the solid product obtained, and then add 75ml of titanium tetrachloride and 5.0ml of DIBP continuously therein...

Embodiment 2~5

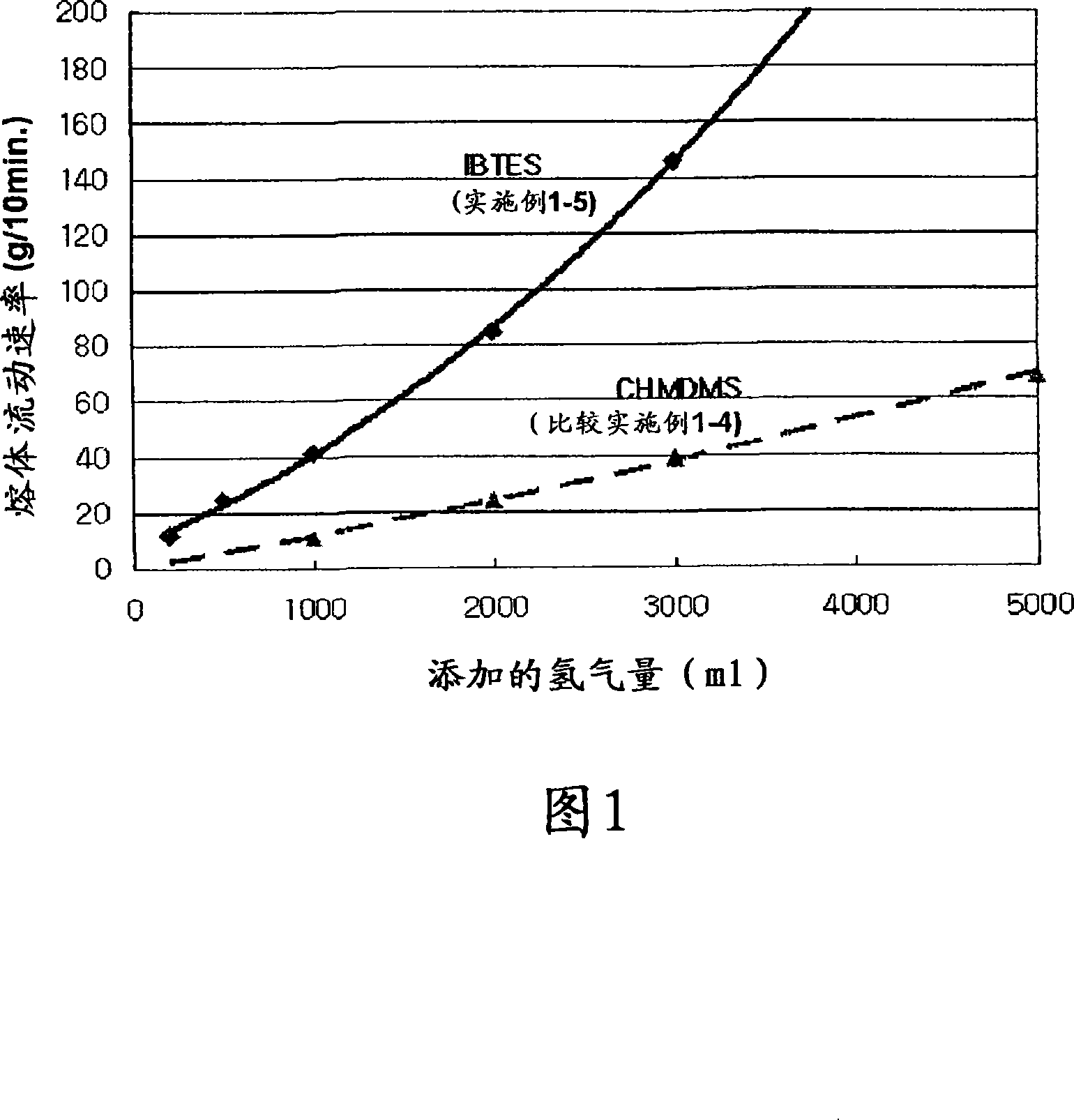

[0048] Propylene polymers were produced by using the same catalyst system and the same method as in Example 1 above, except that the amount of hydrogen used in the [propylene polymerization] step was changed to 200ml, 500ml, 2000ml and 3000ml, respectively.

[0049] For each of the obtained propylene polymers, the polymerization activity, isotactic index, melt flow rate and melting point were measured by the same method as in Example 1 above, and the results are shown in Table 1 below.

Embodiment 6~8

[0051] By using the same catalyst system and the same method as in Example 1 above to prepare a propylene polymer, except changing the amount of hydrogen to 500ml in the [propylene polymerization] step, isobutylethoxysilane (IBTES) as an external electron donor The amount of was changed to 0.3mmol, 0.5mmol and 1.4mmol respectively.

[0052] For each of the obtained propylene polymers, the polymerization activity, isotactic index, melt flow rate and melting point were measured by the same method as in Example 1 above, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of tacticity | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

| degree of tacticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com