Polyactic acid/polycarbonate alloy material, and preparation method and application thereof

A technology of alloy materials and polycarbonate, which is applied in the field of polymer processing, can solve the problems of limiting the wide application of alloy materials, slow crystallization rate, and increased processing costs, and achieve good dimensional stability, accelerated crystallization rate, and reduced processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10 and comparative example 3-7

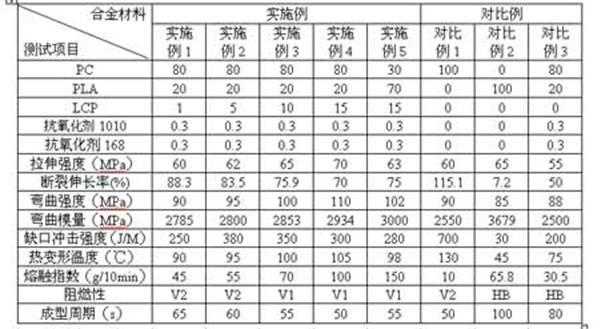

[0052] According to the formula quantity in Table 1 and Table 2, polycarbonate, polylactic acid, liquid crystal polymer, flame retardant, toughening agent, inorganic filler, antioxidant are pre-mixed evenly, and then added to the twin-screw extruder from the main feeding port. Melt blending is carried out in the machine, the temperature of the first zone is 210°C, the temperature of the second zone is 225°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 245°C, and the temperature of the sixth zone is 245°C. The temperature in the seventh zone is 245°C, the temperature in the eighth zone is 245°C, the temperature in the ninth zone is 245°C, the screw speed is 250 rpm, and the residence time is 2 minutes. After extrusion, it is cooled, dried and pelletized to obtain a high-quality High performance, environmentally friendly polylactic acid / polycarbonate alloy. The performance test results of the alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com