Ultrahigh-molecular-weight polyethylene catalyst as well as preparation method and application thereof

A technology of ultra-high molecular weight and catalyst, applied in the field of ultra-high molecular weight polyethylene catalyst and its preparation, can solve the problems of low viscosity-average molecular weight, unfavorable processing, large particle size, etc., and achieve excellent mechanical properties, good impact resistance, and friction The effect of a small coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

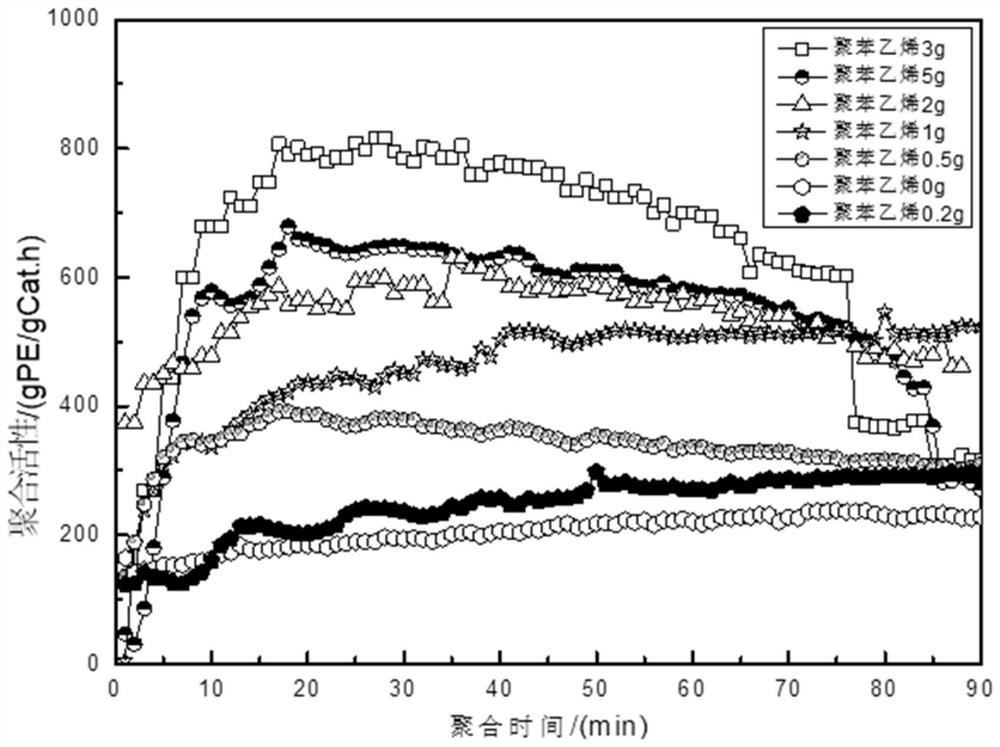

Image

Examples

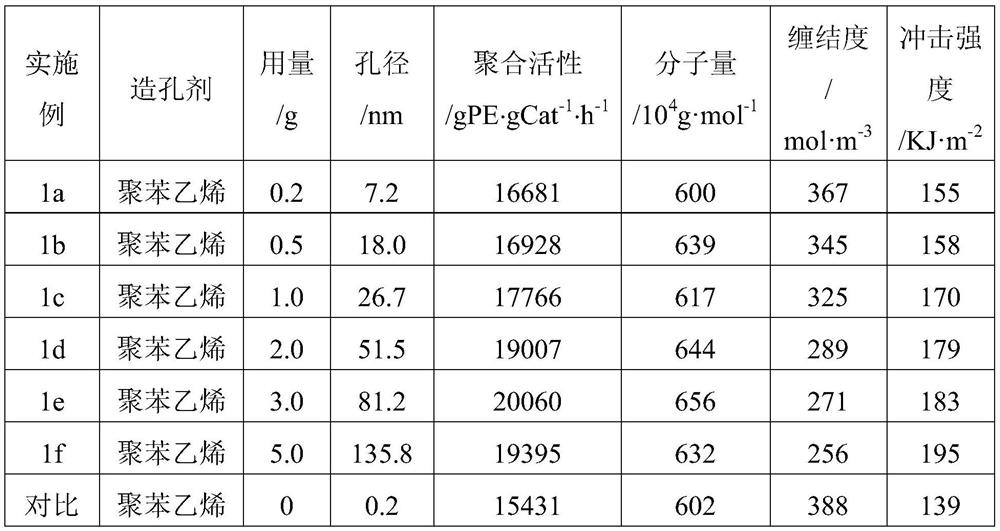

Embodiment 1a

[0049] (1) 2g SiO 2 , 1g NaAlO 2 Add 20ml of mass fraction of 10% N,N-dimethylacetamide solvent, after ultrasonic dispersion for 4h, add 15ml of tetrapropylammonium hydroxide (TPAOH) templating agent with mass fraction of 20% in the resulting solution, stir After aging for 1 day, react under hydrothermal conditions at 150°C for 24 hours, collect the precipitated product, wash with deionized water until neutral, and dry at 150°C to obtain molecular sieve seed crystal powder;

[0050] (2) Take 2g of the above-mentioned molecular sieve seed crystal powder and add it to 15ml of N,N-dimethylacetamide solvent with a mass fraction of 10%, stir for 4h, add 0.2g of pore-forming agent polystyrene to the resulting solution, and ultrasonically disperse After 4h, add 10ml of high molecular weight polyvinylpyrrolidone (PVP) auxiliary agent with a mass fraction of 10%, and continue to stir for 12h to obtain an electrospinning precursor solution;

[0051] (3) The obtained electrospinning pr...

Embodiment 1b

[0056] The difference from Example 1a is that the amount of pore-forming agent polystyrene is increased to 0.5 g. Polymerization was carried out following the same procedure as Example 1a. Table 1 lists the pore size of the carrier and the performance of the polyethylene resin tested by the above test method.

Embodiment 1c

[0058] The difference from Example 1a is that the amount of pore-forming agent polystyrene was increased to 1.0 g. Polymerization was carried out following the same procedure as Example 1a. Table 1 lists the pore size of the carrier and the performance of the polyethylene resin tested by the above test method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com