Method for preparing multifunctional acrylic matting resin

A technology of matting resin and acrylic acid, which is applied in coatings, powder coatings, etc., can solve the problems of poor mechanical strength, poor surface scratch resistance, high cost, etc., achieve homopolymerization process improvement, increase mechanical strength and surface abrasion resistance performance, enhance the effect of inherent advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

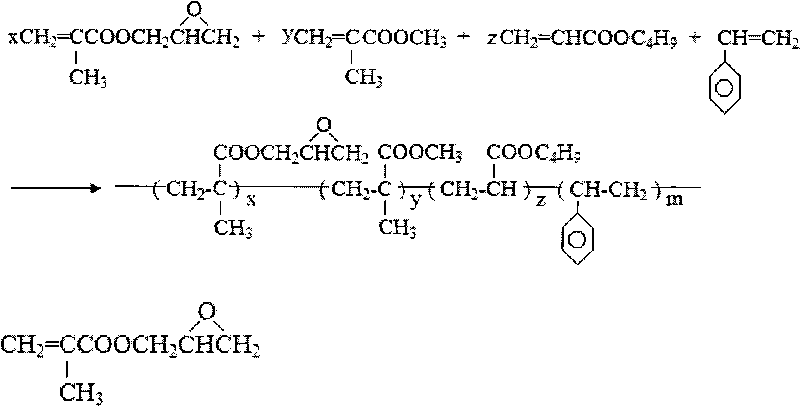

Method used

Image

Examples

Embodiment 1

[0020] Mix 125g of glycidyl methacrylate, 200g of methyl methacrylate, 52g of butyl acrylate, 20g of styrene, 7.94g of azobisethylbutyronitrile, and 3.97g of α-methylstyrene forming dimer in advance , then premix 3.97g of benzoyl peroxide and 79.4g of xylene, add 397g of xylene into a 1000ml four-necked reaction glass bottle and heat it to 110°C, slowly drop the above two components into In the four-necked reaction glass bottle, the dropwise addition time is 1.5 hours, and after the dropwise addition is completed, the temperature is kept at 110° C. for 1 hour. After the heat preservation is over, heat up and under vacuum conditions, slowly distill and recover xylene until no xylene is distilled out, then the distillation can be stopped. Pour the material into the receiving pan for cooling and crystallization. 405 g of crystals were obtained.

[0021] Put 405g of the matting resin synthesized by the first step reaction and 2g of hydroxyalkyl amide, pulverize the mixture on an...

Embodiment 2

[0023] Change methyl methacrylate to 125g, butyl acrylate to 37.5g, azobisethylbutyronitrile to 6.15g, and α-methylstyrene forming dimer to 3.075g and mix evenly. 3.075 g of benzoyl oxide and 61.5 g of xylene were premixed, and 307.5 g of xylene was added to a 1000 ml four-necked reaction glass bottle. The amounts and operating conditions of other substances were consistent with those in Example 1 to obtain 313 g of crystals.

[0024] 313g of the matting resin synthesized by the first step reaction and 1.5g of hydroxyalkylamide are pulverized on an ACM vertical mill, and then packaged. The softening point is 118.6°C, and the minimum extinction degree can reach 5°C.

Embodiment 3

[0026] Change methyl methacrylate to 250g, butyl acrylate to 75g, azobisethylbutyronitrile to 9.40g, and α-methylstyrene dimer to 4.70g and mix evenly, and then mix the 4.70 g of benzoyl and 94.0 g of xylene were premixed, and 470 g of xylene was added to a 1000 ml four-necked reaction glass bottle. The amounts and operating conditions of other substances were the same as those in Example 1 to obtain 480 g of crystals.

[0027] 480 g of the matting resin synthesized by the first step reaction and 2.2 g of hydroxyalkylamide are pulverized on an ACM vertical mill, and then packaged. The softening point is 116.2°C, and the minimum extinction degree can reach 6.2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com