Alpha-methyl styrene selective hydrogenation method

A methylstyrene, selective technology, used in chemical instruments and methods, hydrogenation to hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc. to achieve good anti-interference performance and good low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

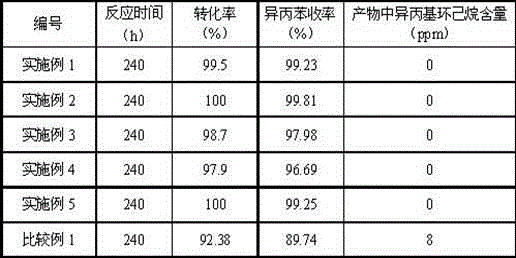

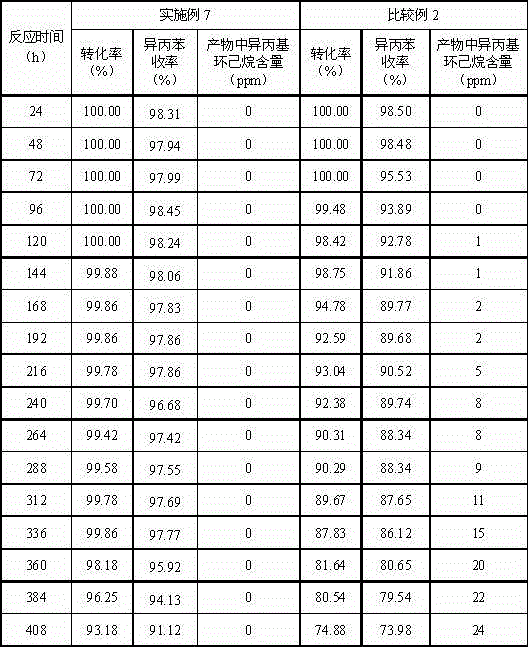

Examples

Embodiment 1

[0020] Weigh 300 grams of pseudo-boehmite and 9 grams of fennel powder, mix them, and then add 12 grams of polyvinyl alcohol solution (5% mass concentration), 4.0 grams of nitric acid, 2.2 grams of phosphoric acid with a concentration of 85%, potassium nitrate 2.3 grams, 270 milliliters of an aqueous solution of 12 grams of magnesium nitrate, extruded into a clover with a diameter of 2.5 mm, and the wet strip was dried at 50°C for 24 hours and then calcined at 1000°C for 4 hours to obtain the carrier Z1. Take 100 g of the carrier to pre-soak the carrier with deionized water, then drain the water, and place the carrier in 0.3L PdCl 2 Impregnation was carried out in the impregnation solution (the mass concentration of Pd was 1g Pd / L) until the impregnation solution was colorless, drained, dried at 120°C for 4 hours, and calcined at 450°C for 4 hours to obtain Pd-based catalyst C1. The catalyst composition, specific surface area and pore volume are shown in Table 1.

[0021] Tak...

Embodiment 2

[0024] Weigh 300 grams of pseudo-boehmite, 9 grams of scallop powder, mix, then add 12 grams of polyvinyl alcohol solution (5% mass concentration), 4.0 grams of nitric acid, 1.2 grams of barium nitrate, 0.1 grams of silver nitrate, 25 270 ml of aqueous solution of 120 g of silica sol, extruded into a clover with a diameter of 2.5 mm, dried at 90°C for 8 hours and then calcined at 900°C for 4 hours to obtain alumina carrier Z2. Take 100 g of the carrier, pre-soak the carrier with deionized water, then drain the water, and place the carrier in 0.5 L PdCl 2 Impregnation was carried out in the impregnation solution (the mass concentration of Pd was 1g Pd / L) until the impregnation solution was colorless, drained, dried at 120°C for 4 hours, and calcined at 450°C for 4 hours to obtain Pd-based catalyst C2. The catalyst composition, specific surface area and pore volume are shown in Table 1.

[0025] Take 100 ml of C2 catalyst and reduce it for 8 hours under the conditions of hydrog...

Embodiment 3

[0028]Weigh 300 grams of pseudo-boehmite, 9 grams of scallop powder, mix, then add 12 grams of polyvinyl alcohol solution (5% mass concentration), 4.0 grams of nitric acid, 9.0 grams of calcium nitrate, and 85% phosphoric acid 270 milliliters of 5.6 grams of aqueous solution was extruded into a clover with a diameter of 2.5 mm, and the wet strip was dried at 90° C. for 8 hours and then calcined at 1050° C. for 4 hours to obtain alumina carrier Z3. Take 100 g of the carrier, pre-soak the carrier with deionized water, then drain the water, and dissolve the carrier in 0.3 L PdCl 2 The impregnating solution (where the mass concentration of Pd is 0.5 g Pd / L) was impregnated until the impregnating solution was colorless, drained, dried at 120°C for 4 hours, and calcined at 450°C for 4 hours to obtain Pd-based catalyst C3. The catalyst composition, specific surface area and pore volume are shown in Table 1.

[0029] Take 100 ml of C3 catalyst and reduce it for 8 hours under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com