Patents

Literature

56 results about "Crystal violet lactone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

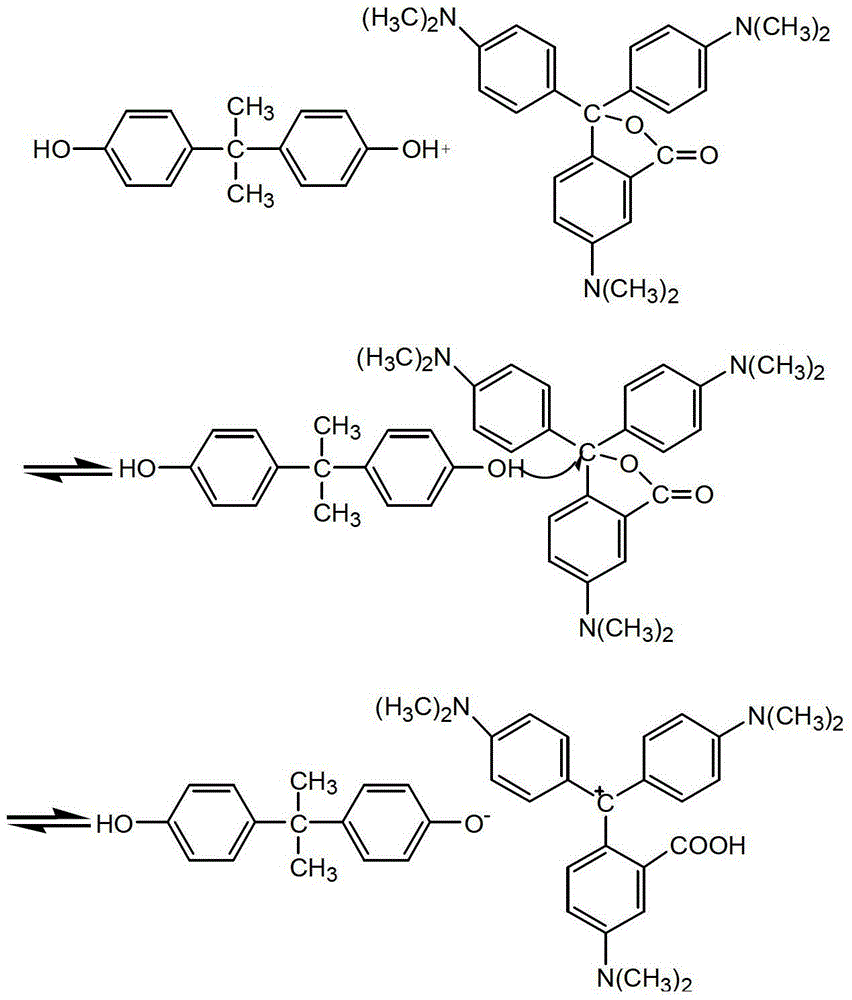

Crystal violet lactone (CVL) is a leuco dye, a lactone derivate of crystal violet 10B. In pure state it is a slightly yellowish crystalline powder, soluble in nonpolar or slightly polar organic solvents.

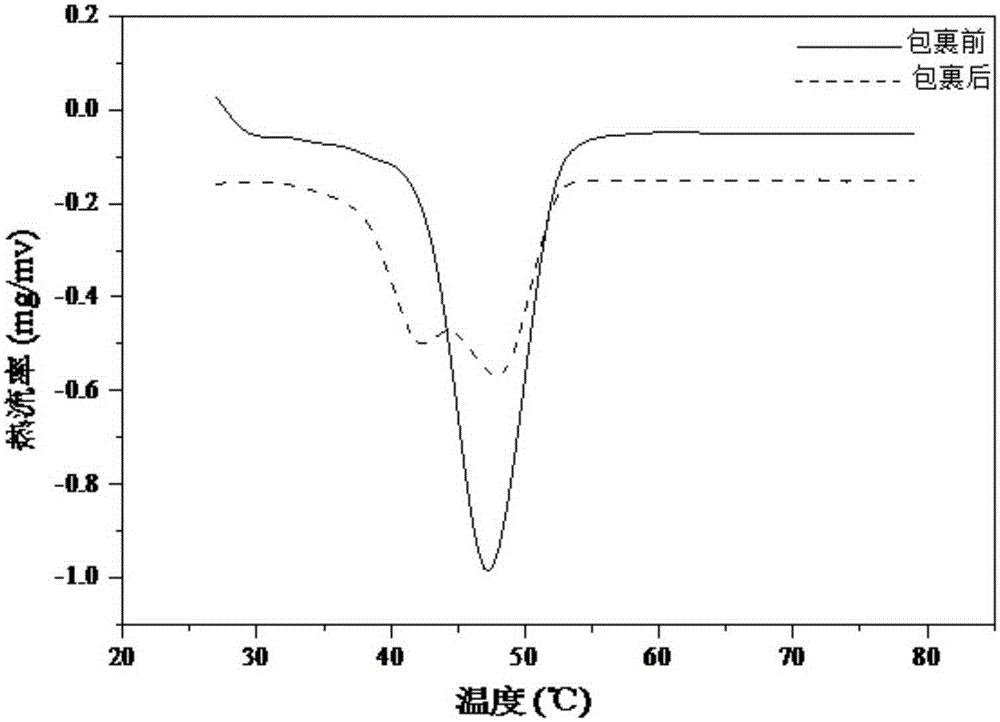

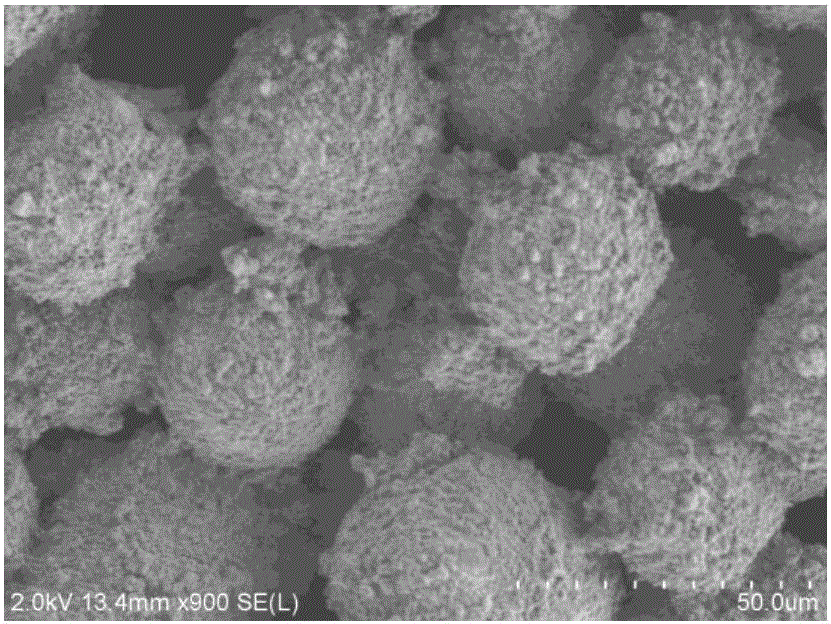

Thermosensitive discoloring energy-storage material and preparation method thereof

InactiveCN102827597AOvercoming the Liquid Leakage Problem of Phase ChangesOvercome the defect of high discoloration temperatureHeat-exchange elementsTenebresent compositionsMelamineStorage material

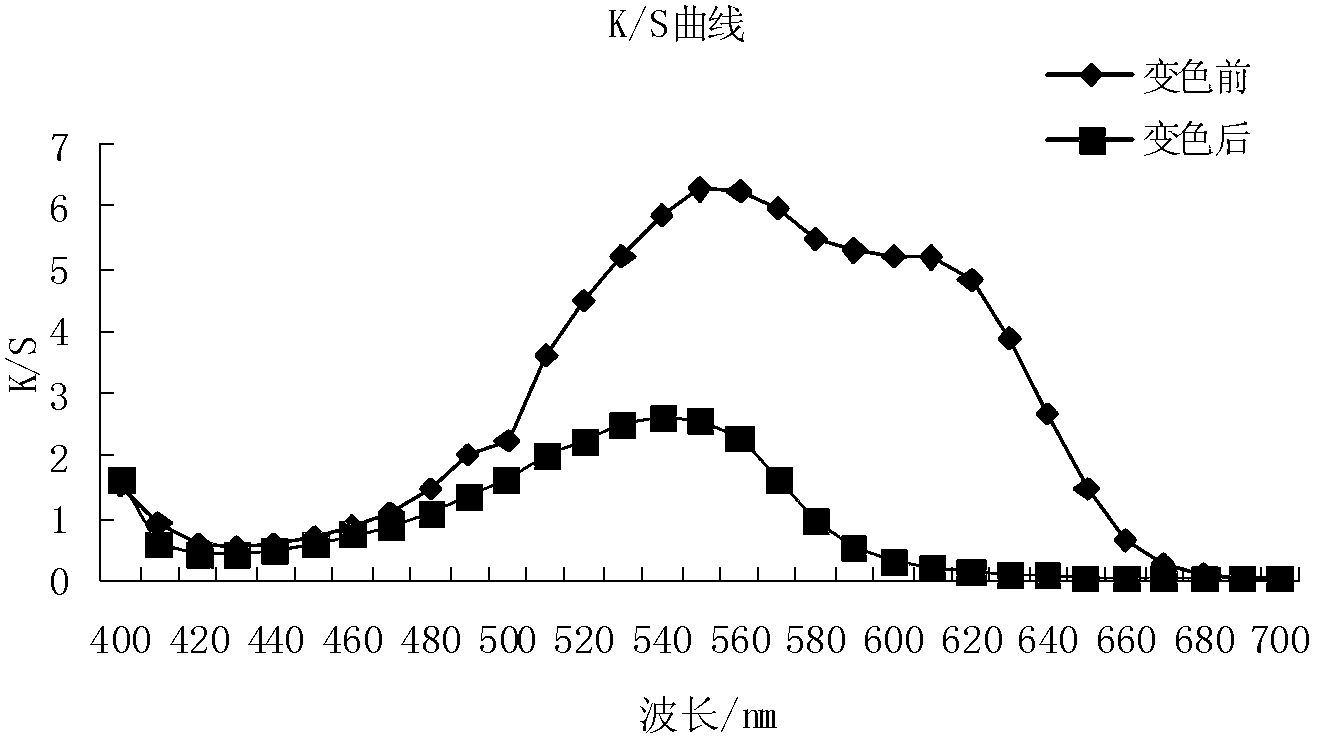

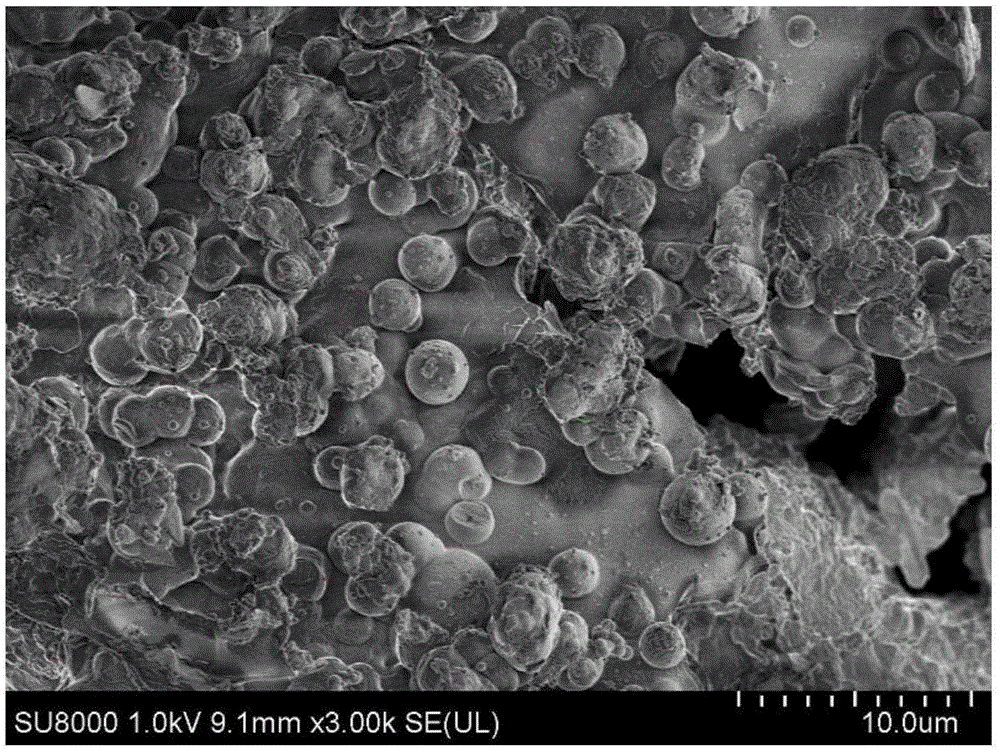

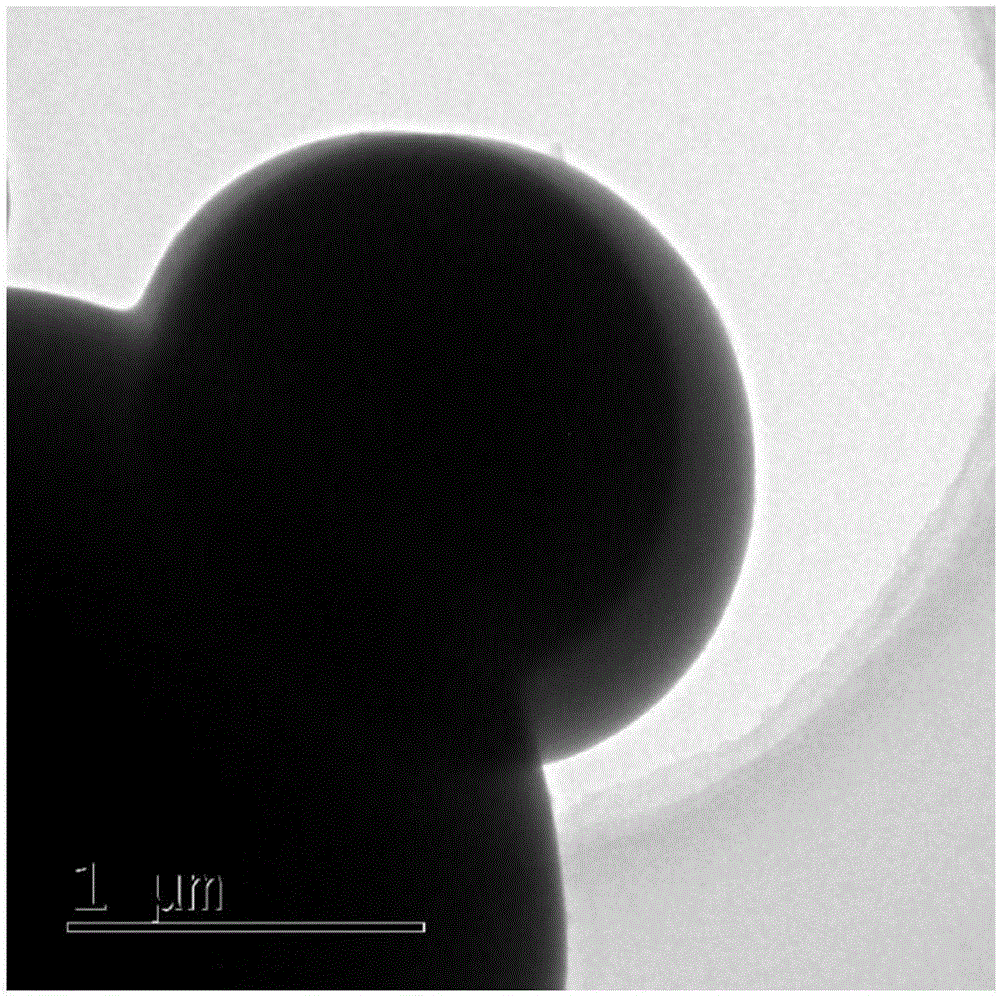

The invention discloses a thermosensitive discoloring energy-storage material and a preparation method of the thermosensitive discoloring energy-storage material, belonging to the field of functional composite materials. The invention aims at solving the technical problem of forming a thermosensitive discoloring energy-storage microcapsule by using crystal violet lactone as a leuco body, using bisphenol A as a color developing agent, and using the compound of tetradecanol and hexadecanol as a solvent; mixing the leuco body, the color developing agent, the solvent and an appropriate amount of dispersant cationic dyes to form a core material; using a melamine resin formed by formaldehyde-melamine as a wall material; and covering the core material by the wall material. The thermosensitive discoloring energy-storage material disclosed by the invention can not only reversibly discolor along with the change of temperature, but also absorb and dissipate energy; and the thermosensitive discoloring energy-storage material is compact in structure, uniform in particle size and long in service life, and can be widely used in the fields of civil textiles, industry cloths, construction and building materials, printing, anti-faking and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of thermochromic phase-change and energy-storage wood taking delignification wood as raw material

InactiveCN107511900AWide variety of sourcesLow costWood treatment detailsHeat-exchange elementsAlcoholSulfite salt

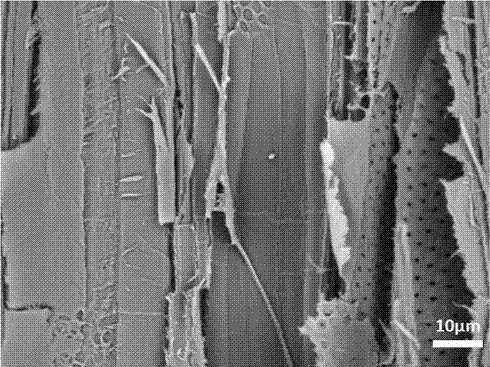

The invention discloses a preparation method of thermochromic phase-change and energy-storage wood taking delignification wood as a raw material. The preparation method comprises the following process steps: (1) adding wood blocks into a mixed solution of sodium hydroxide and sodium sulfite, heating up to a boiling state, keeping the boiling state for a certain time, and then washing the wood blocks with deionized water to obtain the delignification wood; (2) adding the delignification wood into a hydrogen peroxide solution for bleaching, and heating up to a boiling state until the wood becomes white; (3) adding crystal violet lactone and bisphenol A into molten tetradecanol, and carrying out magnetic stirring under the heating condition to obtain a compound; and (4) putting the delignification wood into the compound for dipping, and then putting the delignification wood subjected to dipping into a vacuum drying oven for a certain time to obtain the thermochromic phase-change energy-storage wood. The preparation method has the advantages that the raw material not only retains the original three-dimensional porous structure of the raw wood, but also has a larger adsorption rate than the raw wood, and the prepared thermochromic phase-change energy-storage material is low in cost, simple in method, short in production period, environmentally friendly and thermochromic.

Owner:GUANGDONG YIHUA TIMBER IND +1

Reversible thermochromic microcapsule pigment preparation method

InactiveCN105170041AIncrease coverageImprove stabilityOrganic dyesTenebresent compositionsColor changesFORMALDEHYDE SOLUTION

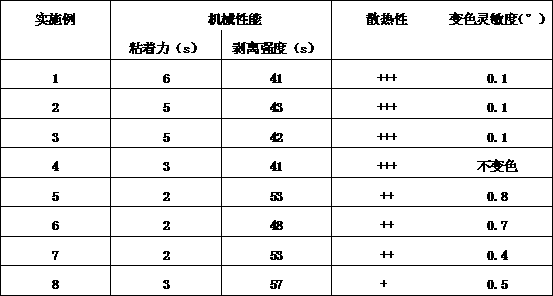

The present invention discloses a reversible thermochromic microcapsule pigment preparation method, which comprises: weighing 0.08-0.1% by mass of crystal violet lactone, 0.4-0.5% by mass of bisphenol A, 3-6% by mass of hexadecanol, 2-4% by mass of melamine, 4.03-5% by mass of a formaldehyde solution, 0.4-0.6% by mass of sodium dodecyl benzene sulfonate, 0.09-0.11% by mass of sodium dodecyl sulfate ammonium, and 87-90% by mass of distilled water, preparing a complex A, preparing an O / W type emulsion and a melamine-formaldehyde pre-polymerization liquid, and carrying out a condensation polymerization reaction to prepare the pigment. According to the present invention, advantages of high color change sensitivity, low color change temperature and good color change stability are provided when the prepared monomer thermochromic material is adopted as the pigment, and the prepared reversible thermochromic microcapsule pigment can be widely used in the fields of anti-counterfeiting inks, temperature showing materials, and the like.

Owner:XIAN UNIV OF TECH

Multifunctional temperature clothes thermochromic material and production method thereof

A multifunctional temperature clothes thermochromic material which has functions of body temperature detection and daily health care and a production method thereof. The technical scheme is as follows: the multifunctional temperature clothes thermochromic material is characterized by comprising the following raw materials of: by weight, 1-3 parts of a shell material, 1-5 parts of a leuco dye, 3-8 parts of a color formation agent, 25-40 parts of a temperature control agent and 50-60 parts of water, wherein the shell material is a melamino-formaldehyde polymer, the leuco dye is 3,3-bis(4-dimethylamino phenyl)-6-dimethylamino benzene peptide(crystal violet lactone), the color formation agent is Bisphenol-A(Bisphenol A, Bisphenol), and the temperature control agent is hexadecanol. The production method of the multifunctional temperature clothes thermochromic material is characterized by weighing each raw material in proportion and producing the microcapsule of the multifunctional temperature clothes thermochromic material by the microcapsule production technology.

Owner:马洪会

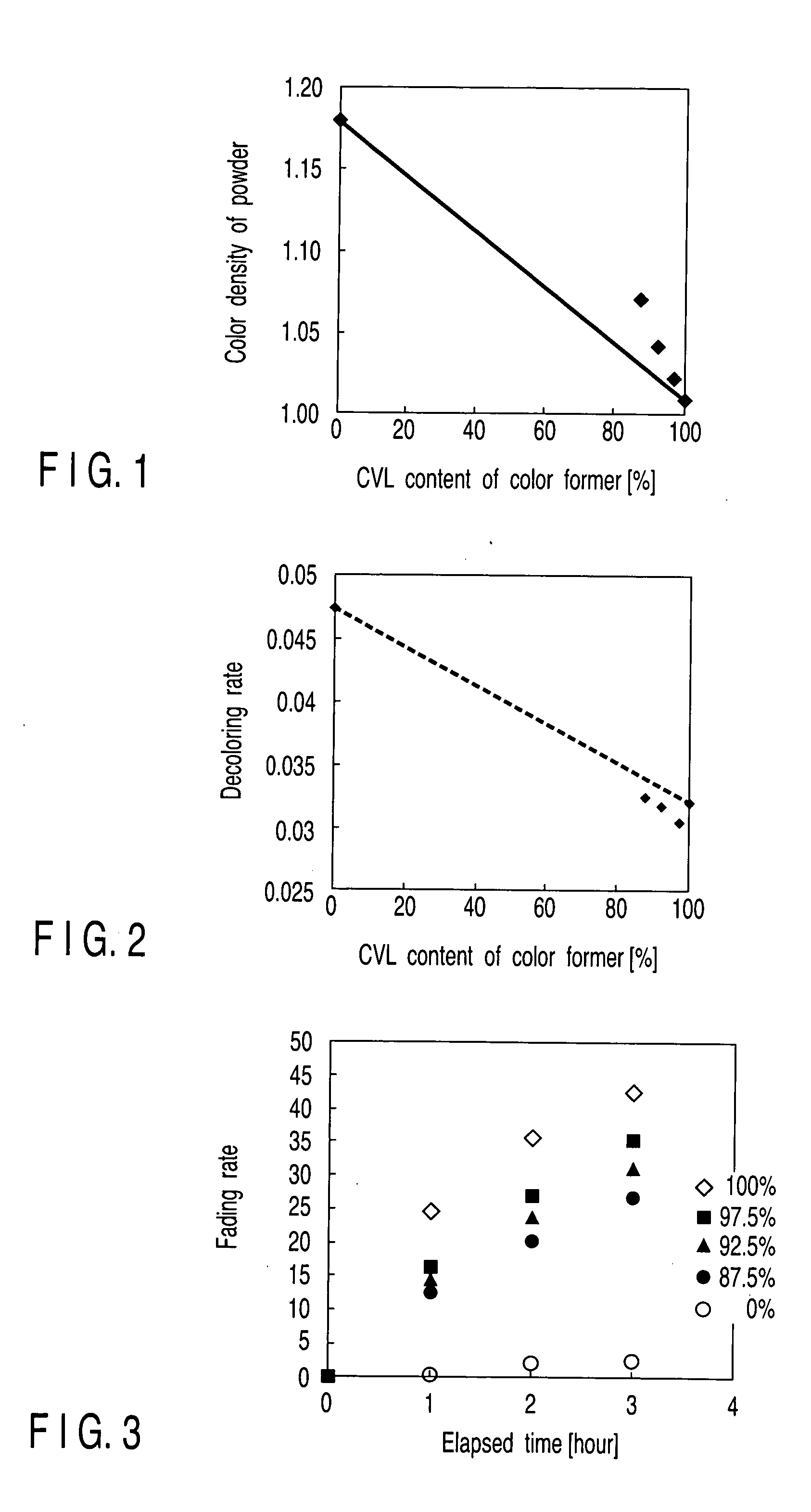

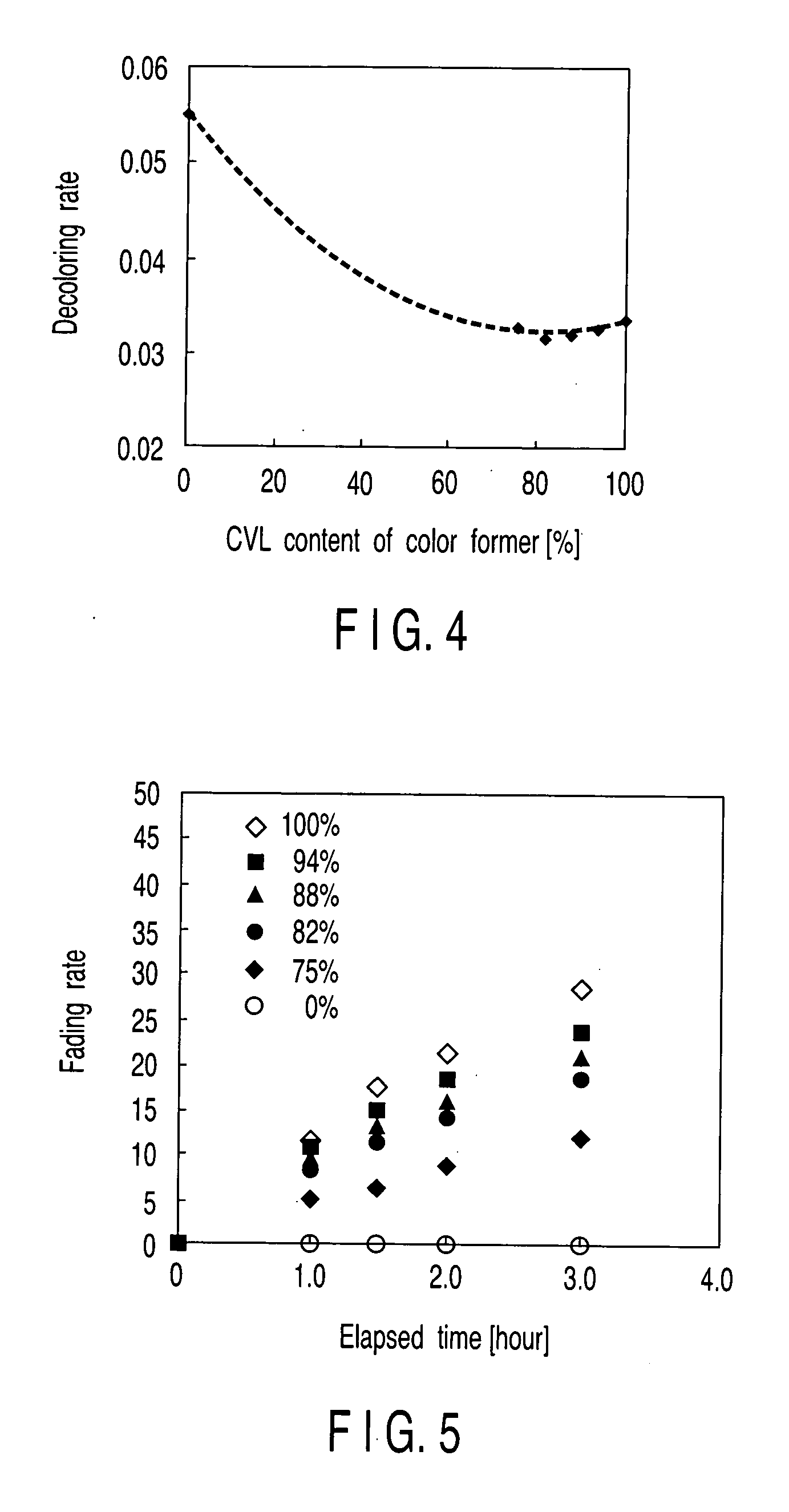

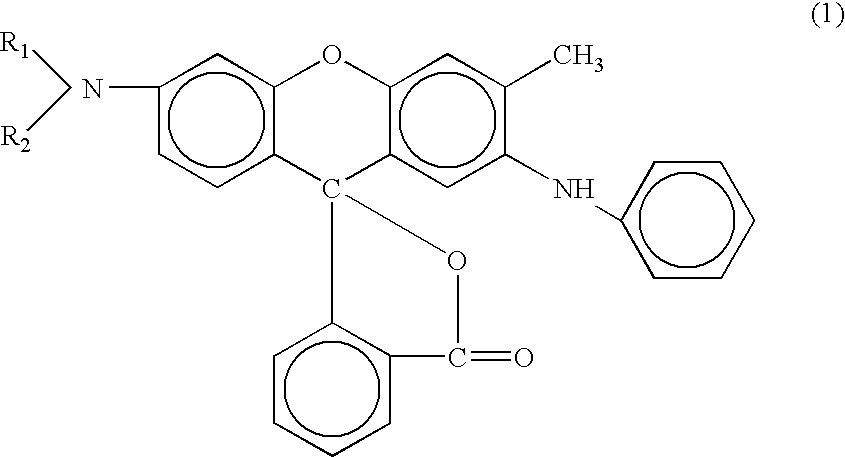

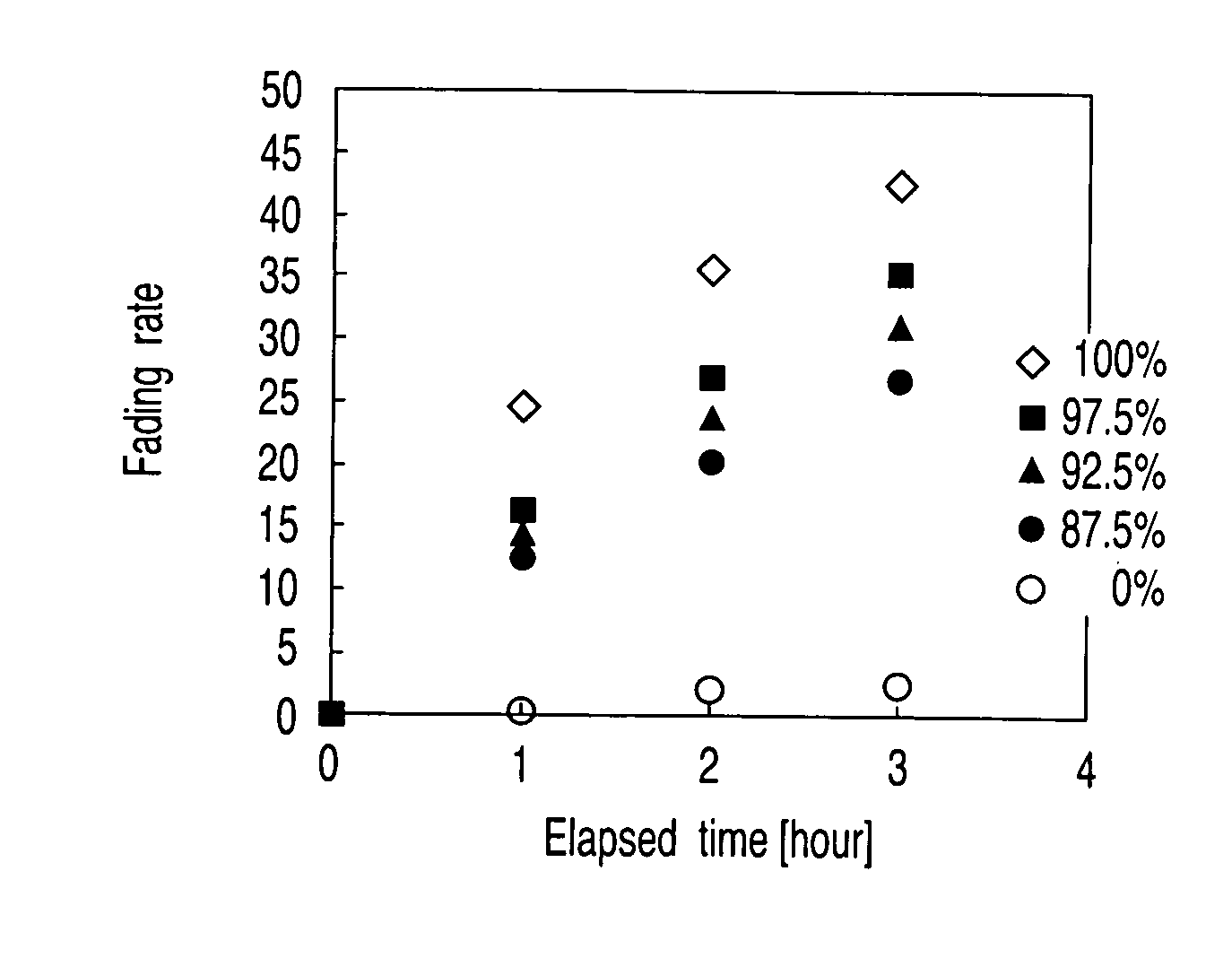

Erasable image forming material

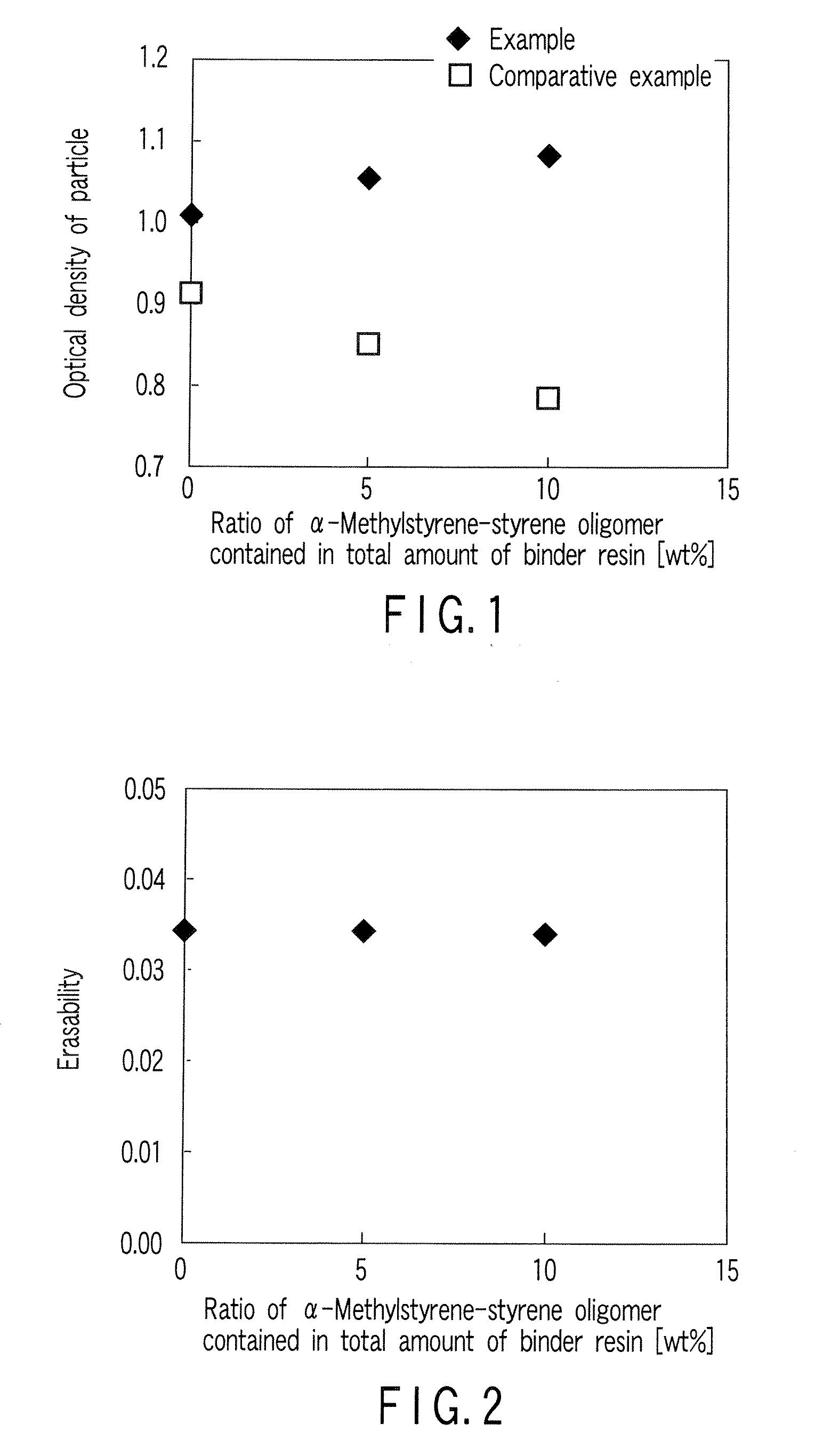

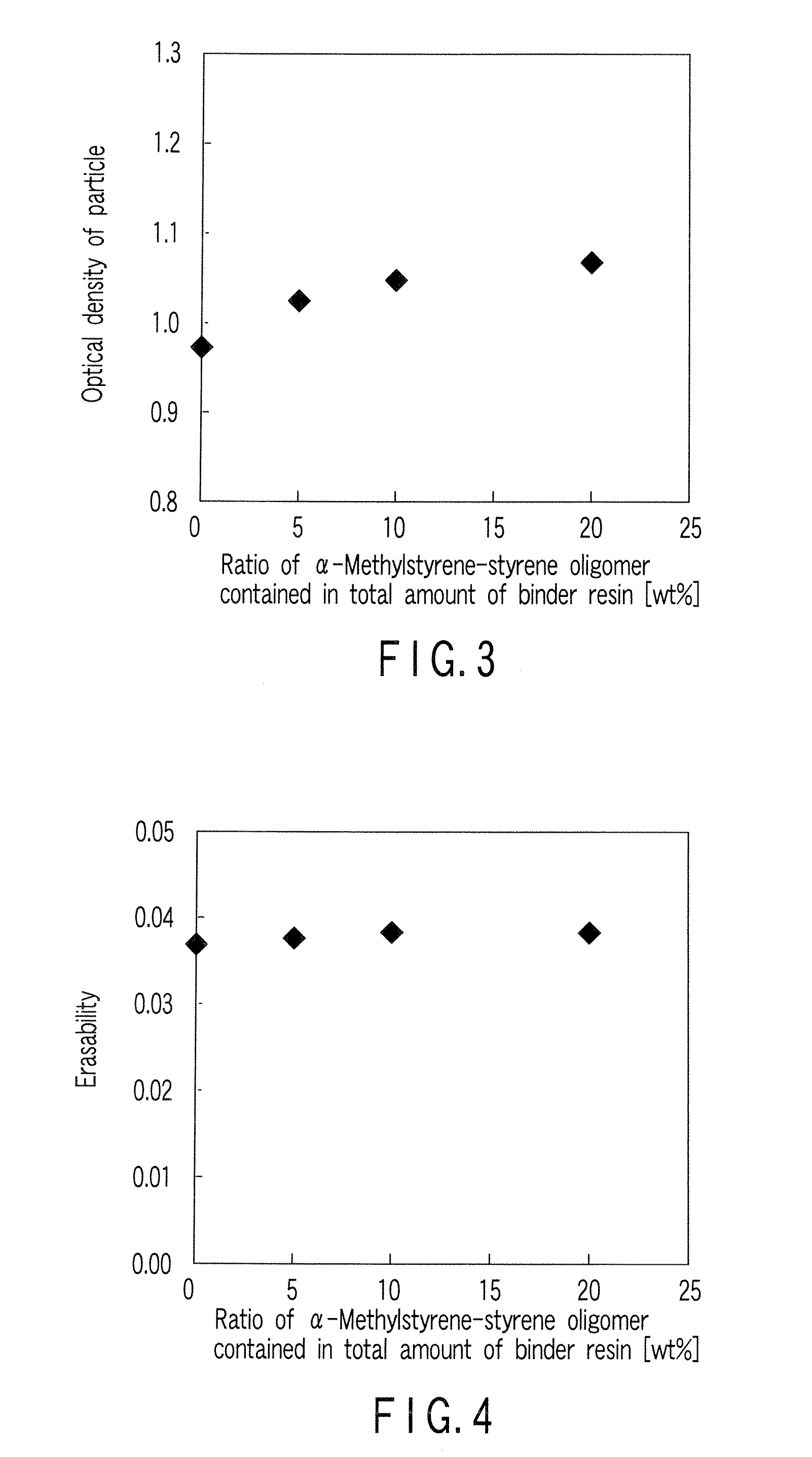

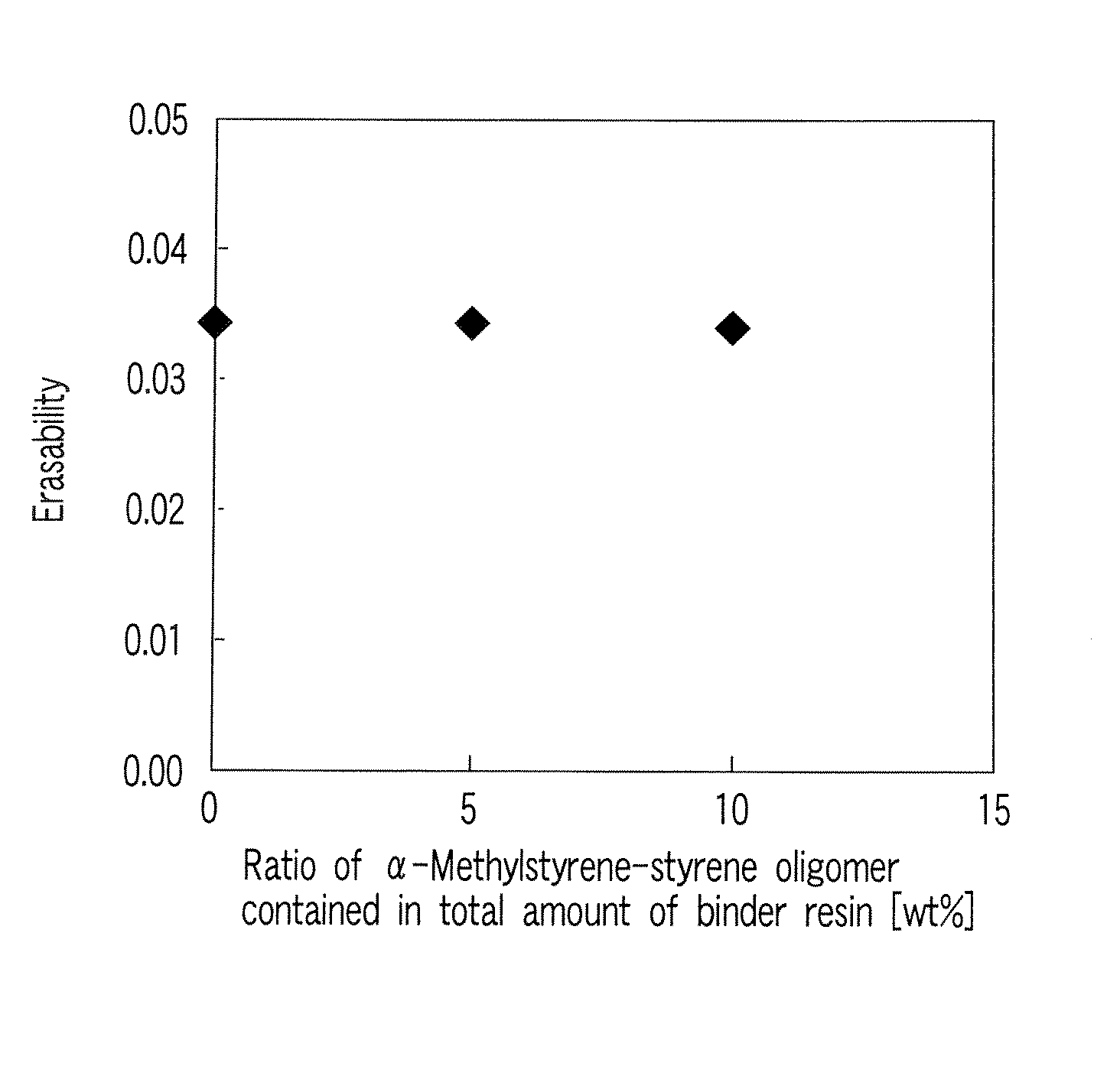

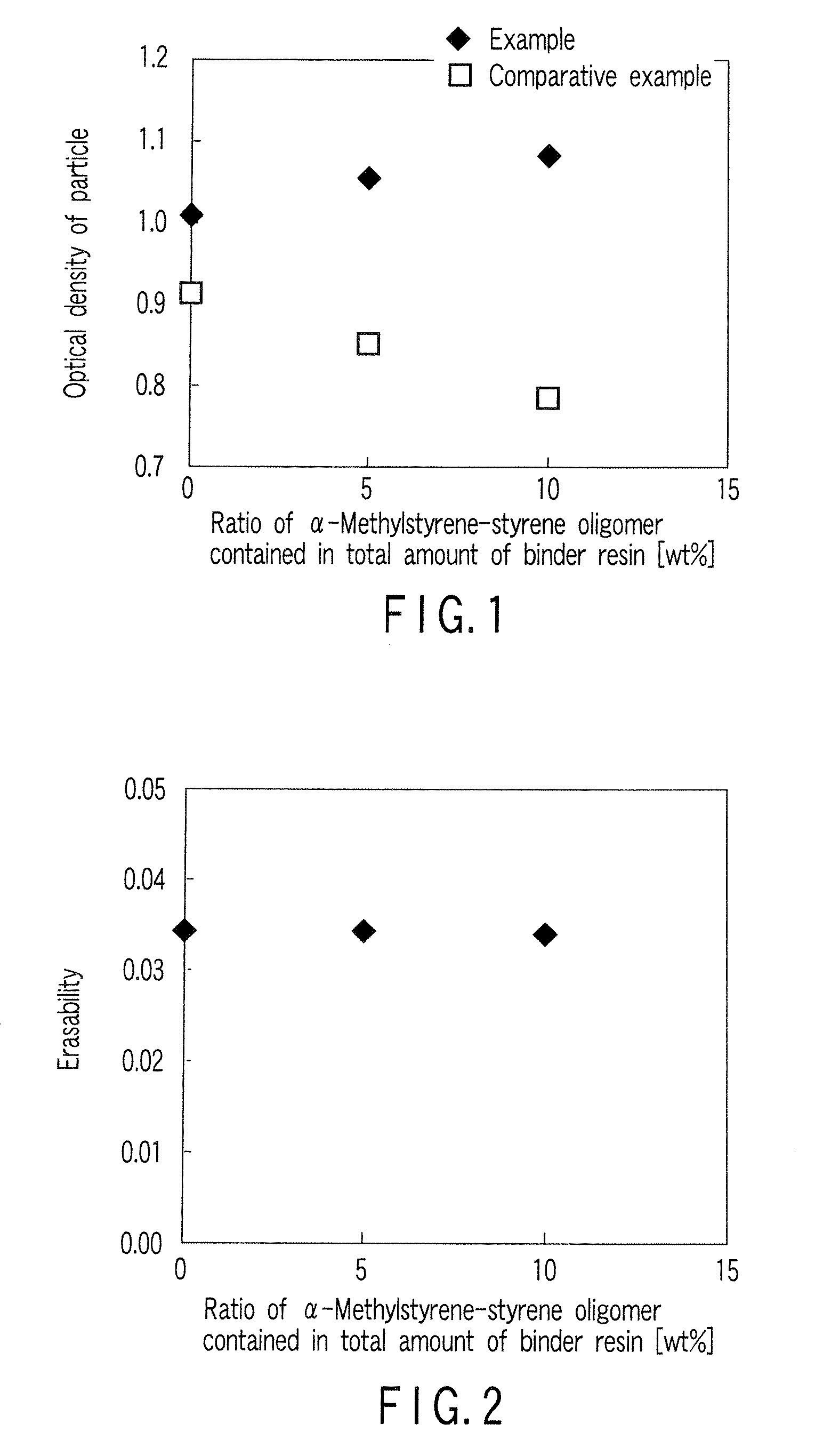

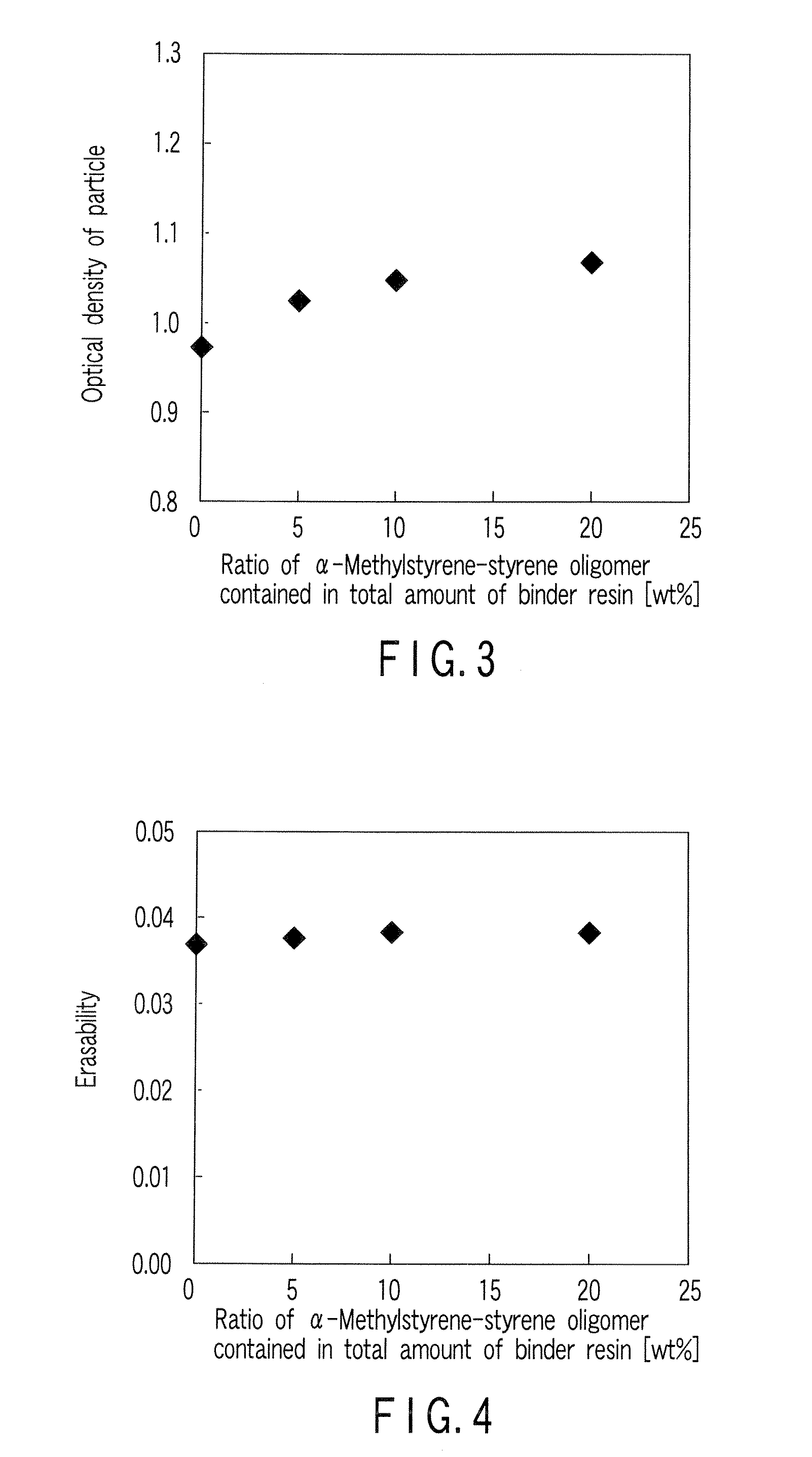

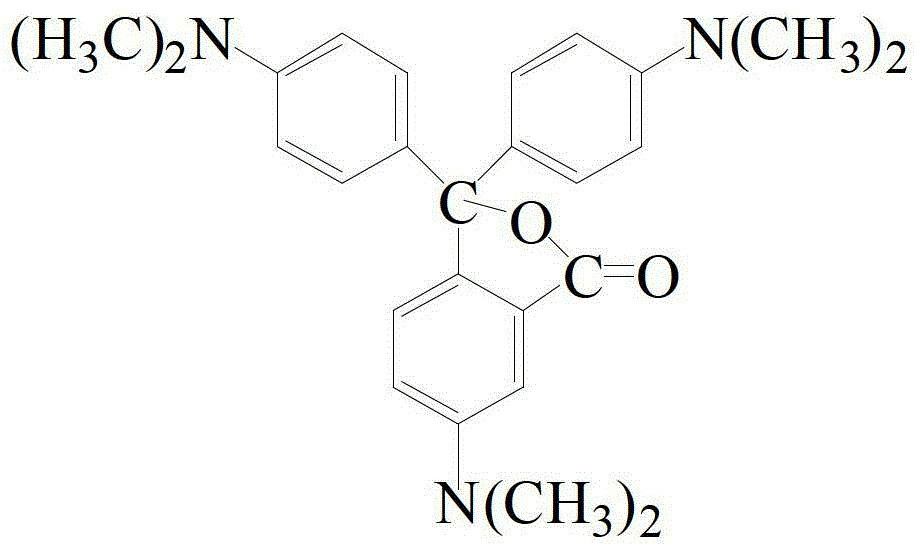

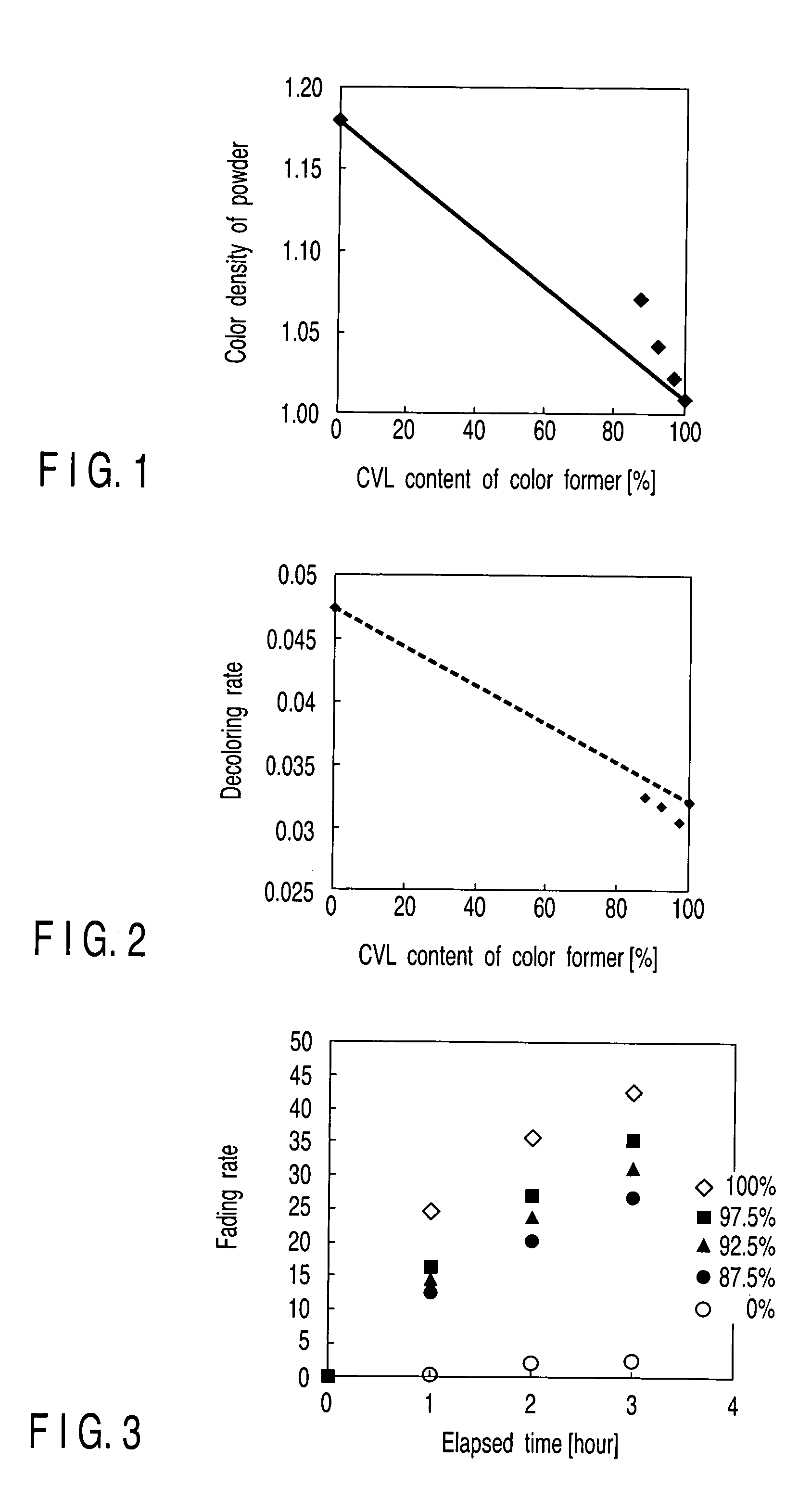

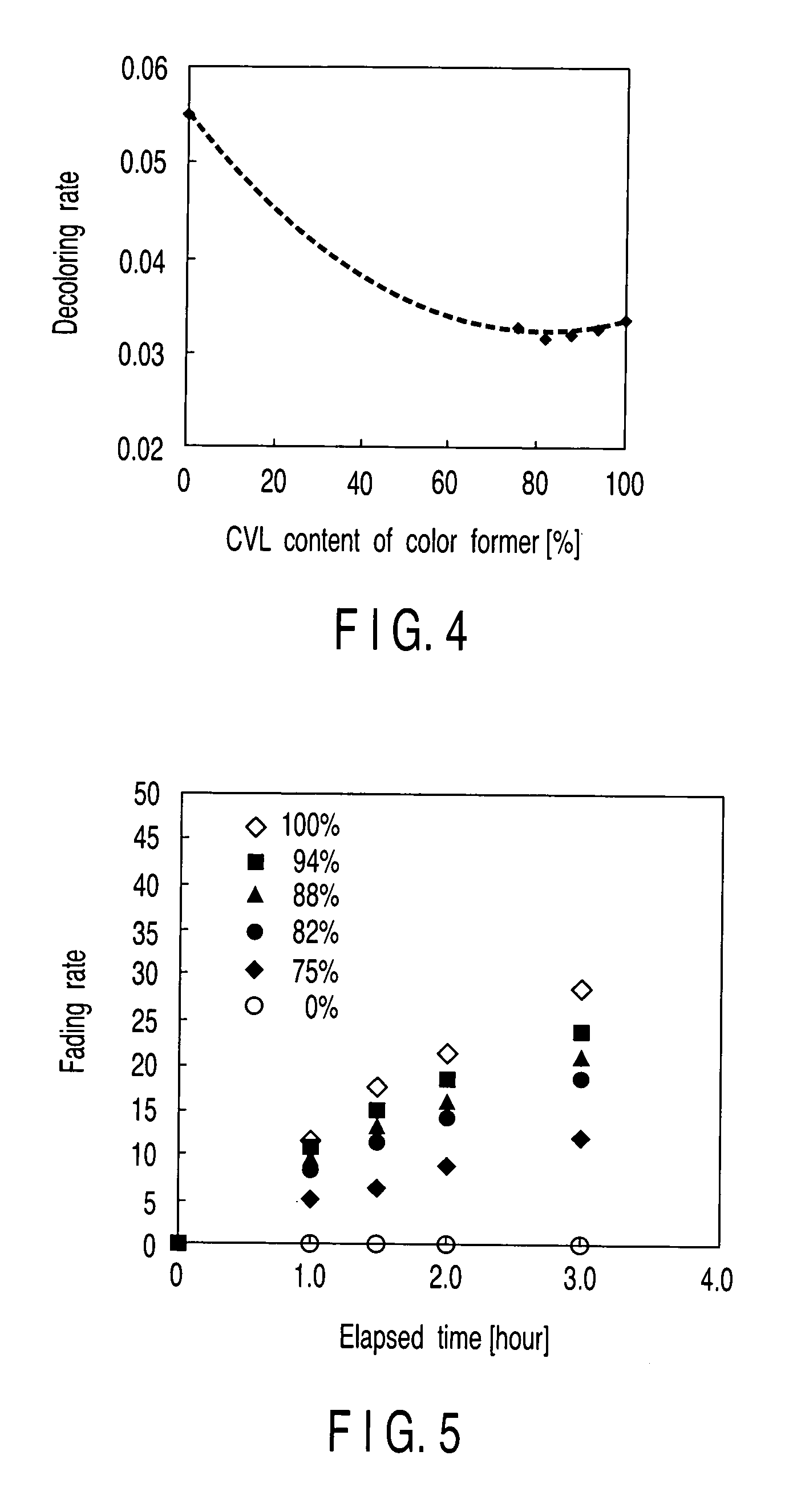

An erasable image forming material includes a color former containing crystal violet lactone, a developer, a first binder resin of styrene-butadiene copolymer and a second binder resin of a styrene-based resin containing a-methylstyrene, the first and second binder resins being in a compatible state.

Owner:KK TOSHIBA

Erasable image forming material

InactiveUS7354885B2Ablative recordingDuplicating using pressureButadiene-styrene rubberCrystal violet lactone

An erasable image forming material includes a color former containing crystal violet lactone, a developer, a first binder resin of styrene-butadiene copolymer and a second binder resin of a styrene-based resin containing a-methylstyrene, the first and second binder resins being in a compatible state.

Owner:KK TOSHIBA

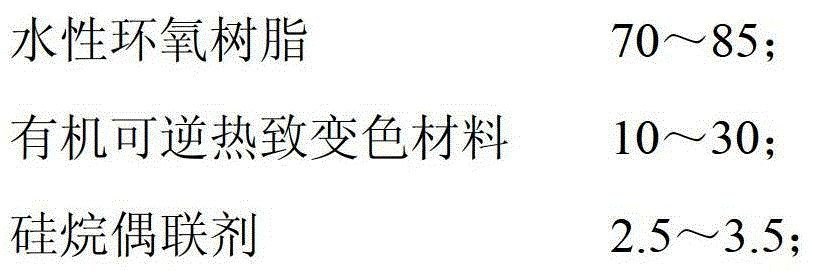

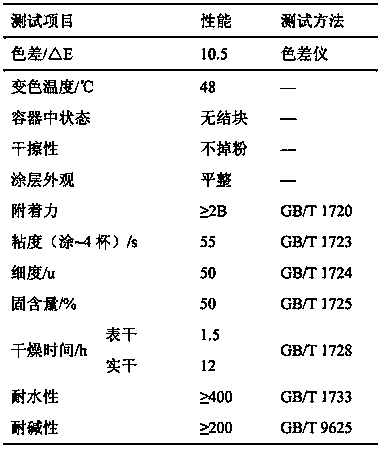

Low temperature organic irreversible thermochromic paint, preparation method and application thereof

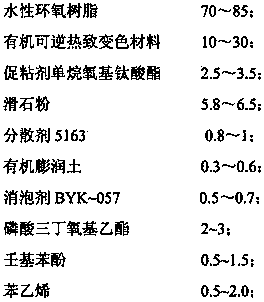

The invention discloses a low temperature organic irreversible thermochromic paint and a preparation method thereof. By weight part, the paint consists of: 70-85 of waterborne epoxy resin; 10-30 of an organic reversible thermochromic material; 2.5-3.5 of a silane coupling agent; 5.8-6.5 of talcum powder; 0.8-1 of a dispersant; 0.3-0.6 of an anti-settling agent; and 0.5-0.7 of a defoaming agent. Specifically, the organic reversible thermochromic material is prepared by reaction of crystal violet lactone and bisphenol A in fatty alcohol. In the invention, by modifying the organic reversible thermochromic material, the low temperature organic reversible thermochromic material is transformed into the low temperature irreversible thermochromic material, which is especially suitable for automatic lineation, automatic printing and other fields.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Reversible thermochromic fabric

InactiveCN106521973AFast coloringNon-sublimableHeating/cooling textile fabricsThermosensitive paintsFluorocarbonPolymer emulsion

The invention provides a reversible thermochromic fabric, and relates to the technical field of functional fabrics; the reversible thermochromic fabric is composed of a basic fabric and a functional coating layer, wherein the functional coating layer includes the following substances in parts by weight: 50-60 parts of a high-molecular polymer emulsion, 30-40 parts of crystal violet lactone microcapsules, 10-15 parts of a discoloring additive, 5-8 parts of a fluorocarbon surfactant, 3-8 parts of a crosslinking agent, 3-5 parts of a penetrating agent, and 3-8 parts of silica. The reversible thermochromic fabric can show different colors at different temperatures, is beautiful and fashionable, also is used as a sensor, can help people perceive changes of the environment in time, and has the advantages of simple preparation method, stable performance and long service life.

Owner:ZHEJIANG KEYI TEXTILE

Synthetic method for crystal violet lactone

ActiveCN106565650AAvoid generatingEmission reductionOrganic chemistryTriarylmethane dyesDimethylaniline N-oxideCatalytic oxidation

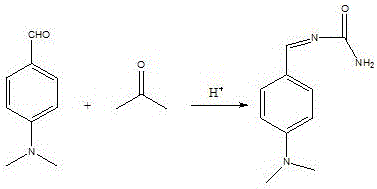

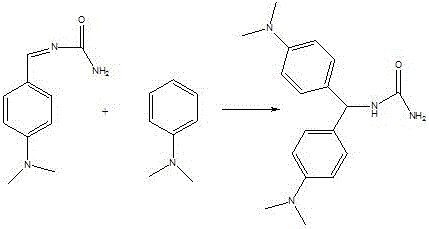

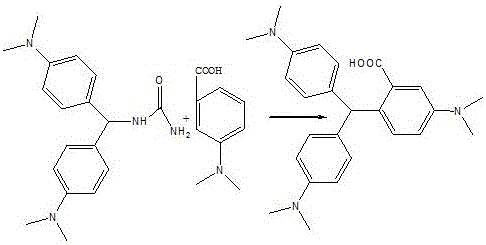

The invention discloses a synthetic method for crystal violet lactone and relates to a synthetic method for a thermal-pressure sensitive dye. The crystal violet lactone is synthesized through a Schiff base stage, a urea intermediate stage, a colorless crystal violet stage and a final oxidation reaction stage by taking substances such as urea, dimethylaniline, dimethylaminobenzoic acid and paradimethylaminobenzaldehyde as raw materials. The synthetic method comprises the following stages: (1) the Schiff base stage: performing a reaction on paradimethylaminobenzaldehyde and urea to generate Schiff base; (2) the urea intermediate stage: performing a reaction on the product generated in the previous stage and dimethylaniline to obtain a urea intermediate; (3) the colorless crystal violet stage: performing a reaction on the product generated in the previous stage and dimethylaminobenzoic acid as the raw materials to generate colorless crystal violet; and (4) the oxidation reaction stage: performing catalytic oxidation on the colorless crystal violet to generate the crystal violet lactone. The method is the synthetic method which avoids generation of impurities, so that the product yield is improved, and meanwhile, discharge of solid wastes is reduced.

Owner:NANJING JINHAO MEDICAL TECH CO LTD

Preparation method of temperature-controlled color-variable ink

ActiveCN107216718AImprove anti-counterfeiting performanceImprove internal heatInksChemical recyclingEpoxyTemperature control

The invention discloses a preparation method of temperature-controlled color-variable ink. The preparation method of the ink comprises the following steps: synthesizing a novel sensitive color-variable material by utilizing an eutectic reagent as a solvent and adopting crystal violet lactone and stearic acid as a raw material, preparing a thermosensitive material into a microcapsule by utilizing a microcapsulation technology, preparing heat-resistant resin by utilizing epoxy resin and organic silicon, and finally mixing the thermosensitive microcapsule, resin, pigments, resin, catalyst, a drier and an antioxidant to obtain the htermosensitive color-variable ink. The method for preparing the thermosensitive material is green and environment-friendly; and the prepared ink has thermoesensitive stability, good heat resistance and can be rapidly dried. The obtained ink has good anti-counterfeit printing effect.

Owner:广东泰金智能包装有限公司

Reversible color-changing material and reversible temperature-indicating coating, and preparation methods and applications thereof

InactiveCN111218147AAppropriate temperature indication rangeHigh temperature pointThermosensitive paintsStearic acidColor changes

The invention relates to a reversible color-changing material and a reversible temperature-indicating coating, and preparation methods and applications thereof. The reversible color-changing materialcomprises crystal violet lactone, bisphenol A and a color developing agent, and the color developing agent is stearic acid or naphthalene. According to the reversible color-changing material, the combination of crystal violet lactone, bisphenol A and the specific color developing agent is innovatively adopted, so that the reversible color-changing material has a proper temperature indicating range, is high in temperature indicating temperature point, obvious in color change and single in color changing, and can be recognized by naked eyes to achieve the purpose of warning temperature. The color of the temperature-indicating coating is reversible, so that the temperature-indicating coating can be repeatedly used, the reversible color-changing material has few raw materials, the economic cost can be saved, the effect is obvious, and the practicability is higher.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

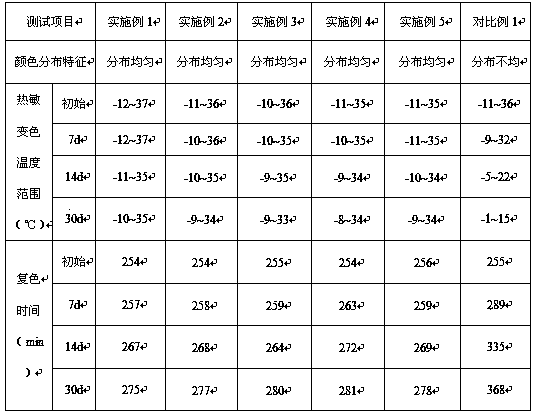

Color-changable architectural decorative diatomite dry powder coating and preparation method thereof

InactiveCN108864776AFast coloringHigh chromaPowdery paintsThermosensitive paintsEmulsionColor changes

The invention discloses a color-changable architectural decorative diatomite dry powder coating and a preparation method thereof. The diatomite dry powder coating is prepared by the following steps: a, mixing crystal violet lactone, bisphenol A, with higher fatty alcohol to obtain a complex color developing agent; b, adding an emulsifier into the complex color developing agent, homogenizing, and shearing, to obtain a complex emulsion; c, adding the precursor liquid of hydroxypropyl-beta-cyclodextrin capsule and a dispersing agent into the complex emulsion to prepare a transparent microcapsulewrapped with the color developing agent; and d, uniformly mixing the transparent microcapsule with diatomite, inorganic fillers, rubber powders and auxiliary agents, to prepare color-changable architectural decorative diatomite dry powder coating. The method has the following advantages: through adopting hydroxypropyl-beta-cyclodextrin to wrap the complex color developing agent to prepare the transparent microcapsule, the coating formed by construction is uniform in color distribution. The transparent microcapsule is used to wrap and protect the developing agent, without affecting color development, and the color-changable architectural decorative diatomite dry powder coating effectively prolongs the service life of the color developing agent, has a wide temperature range of thermosensitive color change, and has a good decorative effect at the same time.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

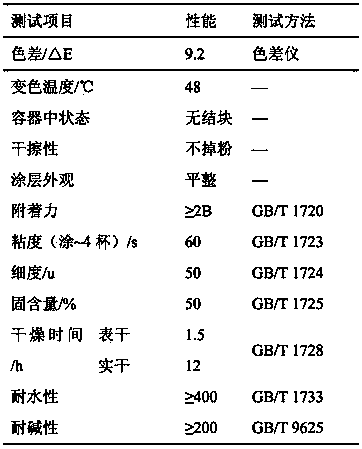

Overstable thermotropic color-changing coating and preparation method thereof

The invention discloses an overstable thermotropic color-changing coating and a preparation method thereof. The overstable thermotropic color-changing coating is prepared from the following components in parts by weight: 70-85 parts of water-borne epoxy resin, 10-30 parts of organic reversible thermotropic color-changing material, 2.5-3.5 parts of silane coupling agent, 5.8-6.5 parts of talcum powder, 0.8-1 part of dispersing agent, 0.3-0.6 parts of organic bentonite, 0.5-0.7 parts of deforming agent, 2-3 parts of tributoxyethyl phosphate, 0.5-1.5 parts of nonylphenol and 0.5-2.0 parts of styrene, wherein the reversible thermotropic color-changing material is prepared from crystal violet lactone and bisphenol A which react in fatty alcohol. The organic reversible thermotropic color-changing material is modified so as to be transformed into the low-temperature overstable thermotropic color-changing material.

Owner:珠海市誉达伟业科技有限公司

Thermosensitive three-stage color-changing medical antipyretic patch and preparation method thereof

InactiveCN109223297AHigh sensitivity to discolorationAchieve three-level color changeDiagnostic recording/measuringSensorsCarrageenanMedicine

The invention discloses a novel medical antipyretic patch, in particular to a thermosensitive three-stage color-changing medical antipyretic patch and a preparation method thereof, wherein the thermosensitive three-stage color-changing medical antipyretic patch can directly observe the temperature change of a human body according to the color change in the use process. The antipyretic patch comprises a spunlace nonwoven substrate, a thermosensitive hydrogel layer and a PP separating film, wherein the thermosensitive hydrogel is coated on the spunlace nonwoven substrate, and then the PP separating film is coated on the thermosensitive hydrogel. The invention uses the mixture of crystal violet lactone, fatty alcohol and hydrated cobalt salt as the leuco dye, the mixture of tetradecanoic acid, hexadecanoic acid and stearic acid as the electron acceptor material, and optimizes the proportion of the components to effectively improve the color-changing sensitivity of the thermosensitive material; By adding carrageenan, konjac gum and nano-silica into hydrogel, the permeability and mechanical properties of hydrogel can be effectively improved, and the practicability is stronger.

Owner:江西润丰药业有限公司 +1

Preparation method of thermosensitive color-changing organic glass

InactiveCN106519093ASensitive to temperature and color changeGood discoloration effectMicroballoon preparationMicrocapsule preparationBenzoyl peroxidePolymethyl methacrylate

The invention provides a preparation method of thermosensitive color-changing organic glass. The method comprises the following steps of 1 preparation of thermosensitive color-changing microcapsules, wherein crystal violet lactone, stearic acid and tetradecyl alcohol are weighed accurately, stirring and dissolving are conducted, an aqueous solution of Tween 80 is dropwise added, stirring is conducted for 2 h at the temperature of 70 DEG C, a solution A is obtained, methyl methacrylate and benzoyl peroxide are weighed, a stirring reaction is conducted for 30 min at the temperature of 80 DEG C, a solution B is obtained, the solution B is dropwise added into the solution A, reacting is conducted for 30-45 min at the temperature of 80 DEG C, filtering, water washing and drying are conducted, and the color-changing microcapsules are obtained; 2 preparation of thermosensitive color-changing organic glass, wherein methyl methacrylate and benzoyl peroxide are weighed, a stirring reaction is conducted for 30-60 min at the temperature of 85 DEG C, the color-changing microcapsules are added, stirring continues to be conducted for 5 min, rapid cooling is conducted to reach 50 DEG C, standing is conducted for 1 h, the temperature is increased to 70 DEG C, constant temperature treatment is conducted for 2 h, the temperature is increased to 100 DEG C, and constant temperature treatment is conducted for 2-3 h, and the color-changing organic glass is obtained. According to the method, the color-changing organic glass is obtained by conducting bulk polymerization on thermosensitive color-changing microcapsules polymethyl methacrylate in situ, and the product has the advantages of being sensitive in color changing and uniform in color and luster.

Owner:TIANJIN CHENGJIAN UNIV

Using method of polyimide (PI) ink

ActiveCN102933033AImprove signal stabilityHigh precisionConductive material chemical/electrolytical removalMaterial resourcesCrystal violet lactone

The invention provides a using method of polyimide (PI) ink. The using method comprises the following steps of: mixing the PI ink, printing, pre-baking, aligning and developing. By the method, the problems in the general crystal violet lactone (CVL) production; a new production method is supplied by rationally using the PI ink, so that the precision and the quality of a finished product are effectively improved; various technologies of the finished product are obviously improved; moreover, the production time is saved by fining the production flow, so that labor and material resources are greatly saved; the total production cost is reduced; the production efficiency is promoted and improved; and active and deep benefits in actual production are realized.

Owner:广州源康精密电子股份有限公司

Color-changing silicone cup

InactiveCN104844998AFast coloringHigh chromaTenebresent compositionsDrinking vesselsCrystal violet lactoneLeuco dye

The invention relates to a color-changing silicone cup, the preparation raw materials of which is formed by an A constituent and a B constituent. The A constituent is hydrated silicon dioxide, which accounts for 98-99% by mass percentage; and the B constituent is a mixture, which accounts for 1-2% by mass percentage. The ingredients and parts by weight of the mixture are 60-70 parts of hydroxy acrylic resin, 10-20 parts of butyl acetate, 4-6 parts of silicone oil, 1-2 parts of stearamide, 2-4 parts of benzyl 4-hydroxybenzoate, 2-4 parts of crystal violet lactone, 10-20 parts of ethanol and 5-8 parts of cetanol. The crystal violet lactone is used as leuco dye, and the benzyl 4-hydroxybenzoate is used as a color developing agent, wherein the two ingredients are nontoxic raw materials; the benzyl 4-hydroxybenzoate is mostly used for food flavor; the crystal violet lactone is fast in color development and high in chroma; and sensitivity for thermoinduction is improved.

Owner:TIANJIN YIHAOYONG PRECISION PLASTIC SCI & TECH

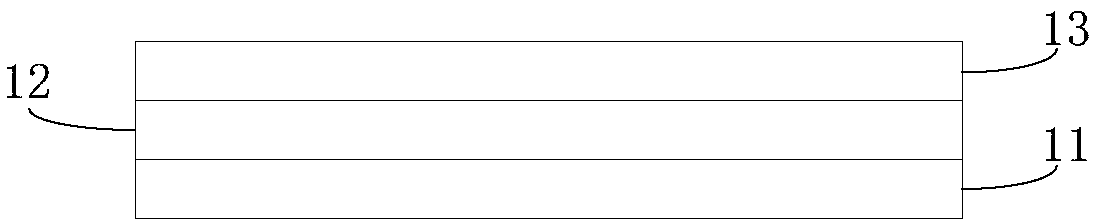

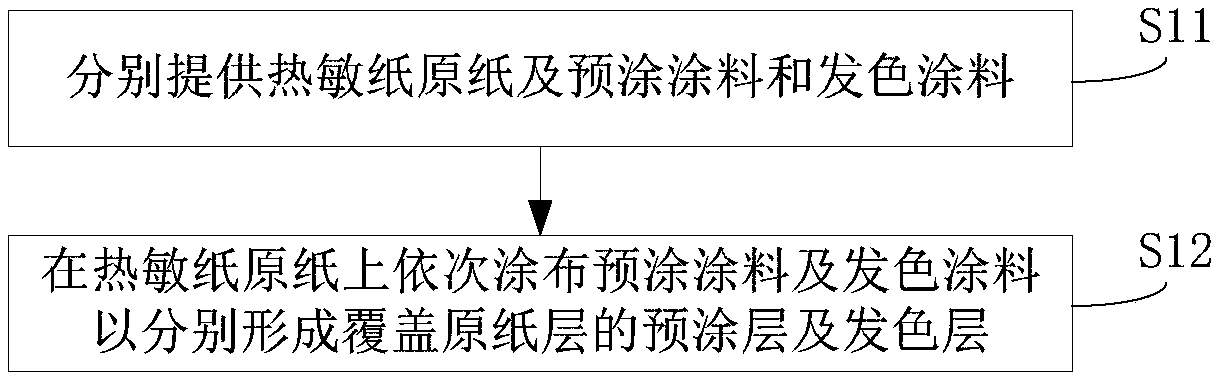

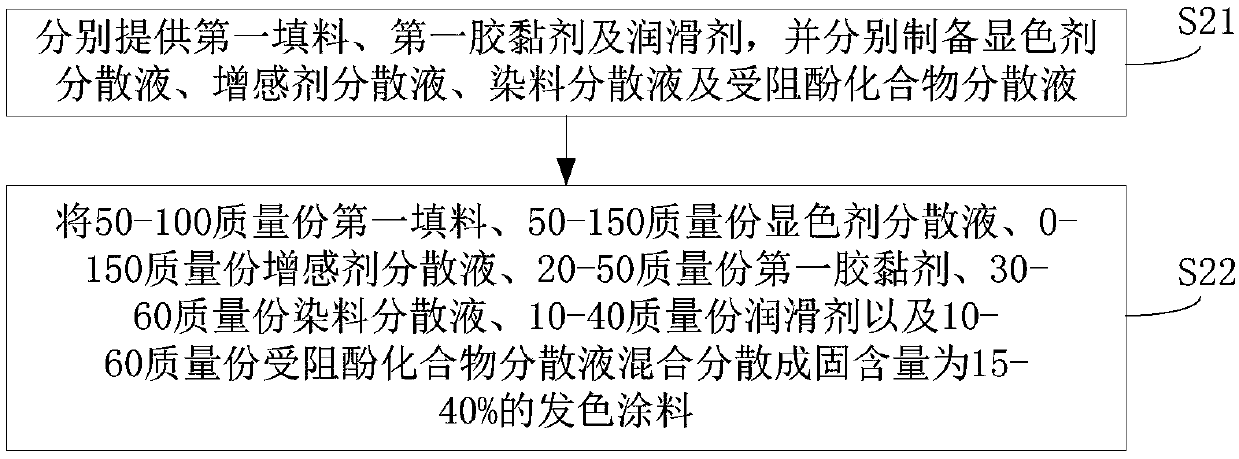

Thermosensitive paper and preparation method thereof

The invention discloses thermosensitive paper and a preparation method thereof. The thermosensitive paper comprises a base paper layer, a precoating layer and a chromogenic layer, wherein the precoating layer and the chromogenic layer are successively formed on the base paper layer; the chromogenic layer is formed by coating with a chromogenic coating, and a chromogenic coating comprises a dye, wherein the dye is at least one of crystal violet lactone, 10-benzoyl-3,7-bis(dimethylamino)phenothiazine, and 7-[4-(diethylamino)-2-(hexyloxy)phenyl]-7-(1-ethyl-2-methyl-1H-indole-3-yl)furano[3,4-B]pyridine-5(7H)-one. Through the method, the amount of a dye and a color developer in the thermosensitive paper can be substantially reduced, and thus adhesion of the dye and the color developer, on a printing head, in the thermosensitive paper in the printing process is reduced, and the printing head is protected to a certain extent.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Reversible thermochromic ink as well as preparation method and application thereof

InactiveCN111196903AImprove thermochromic effectAchieve anti-counterfeiting effectAuxillary controllers with auxillary heating devicesInksThermochromismColor changes

The invention discloses reversible thermochromic ink as well as a preparation method and application thereof. Crystal violet lactone is used as a color former; boric acid is used as a color developingagent to prepare a thermochromic material; the thermochromic material is added into the ink, so that the ink is endowed with a thermochromic effect, is light blue at normal temperature, is grey whiteunder heat sources such as a lighter and the like, the anti-counterfeiting function of the ink is realized, printed images and texts can be subjected to color change through a certain heat source, and the color can be recovered after the heat source is removed for a period of time; the identification method is convenient and rapid, and thermochromism has reversibility.

Owner:HUNAN UNIV OF TECH

Thermochromic fabric

InactiveCN106811997AImprove performanceIncreased sensitivityDyeing processYarnAntioxidantFirming agent

The invention relates to fabric and provides breathable soft thermochromic fabric, comprising a fabric body that is prepared from, by weight, 50-60 parts of silk fiber, 20-30 parts of Lyocell bamboo fiber, 3-5 parts of bisphenol A, 3-8 parts of crystal violet lactone, 5-10 parts of a desensitizer, 5-10 parts of a firming agent, 20-25 parts of a dispersant, 10-15 parts of a wetting agent, 20-30 parts of a color fixing agent, and 5-10 parts of an antioxidant.

Owner:贸盛投资(福建)有限公司

Multifunctional heat dissipation device

InactiveCN105295319AWith thermochromic functionWith heat conduction and heat dissipation functionPolymer scienceMeth-

The invention discloses a multifunctional heat dissipation device. An adopted heat dissipation material is prepared from the following raw materials in parts by weight: 10-15 parts of carbon nanotubes, 3-5 parts of polymethyl methacrylate, 10-12 parts of graphite, 3-5 parts of organic montmorillonite, 3.5-4.5 parts of hydroxyl silicone oil, 2.5-3.5 parts of silicon carbide, 5-6 parts of octamethyl cyclotetrasiloxane, 4-5 parts of PET, 2-3 parts of crystal violet lactone, 4-6 parts of bisphenol A, 8-10 parts of tetradecyl alcohol, 1-2 parts of polyphenylene sulfide, 0.8-1.2 parts of glass fiber, 0.5-0.8 part of a coupling agent and 0.5-0.8 part of a plasticizer. The multifunctional heat dissipation device has the functions of heat conduction, heat dissipation and high-temperature warning.

Owner:TAICANG DOW ELECTRIC

Rolling fingerprint acquisition method based on thermochromic principle

The invention relates to a rolling fingerprint acquisition method based on thermochromic principle, and belongs to the field of materials chemistry. A thermochromic microcapsule is prepared in an in-situ polymerization process by taking a crystal violet lactone compound as the capsule core material and urea-formaldehyde resin as a capsule wall material. The film surface temperature is controlled to obtain a proper rolling fingerprint acquisition condition. The method is easy, feasible, rapid and reliable, a series of problems in traditional rolling fingerprint acquisition can be solved, acquired fingerprint images are clear and reliable, and the method has great significance in establishment of a national fingerprint base.

Owner:JIANGNAN UNIV

A kind of preparation method of temperature-controlled color-changing ink

ActiveCN107216718BImprove anti-counterfeiting performanceImprove internal heatInksChemical recyclingEpoxyStearic acid

The invention discloses a preparation method of temperature-controlled color-variable ink. The preparation method of the ink comprises the following steps: synthesizing a novel sensitive color-variable material by utilizing an eutectic reagent as a solvent and adopting crystal violet lactone and stearic acid as a raw material, preparing a thermosensitive material into a microcapsule by utilizing a microcapsulation technology, preparing heat-resistant resin by utilizing epoxy resin and organic silicon, and finally mixing the thermosensitive microcapsule, resin, pigments, resin, catalyst, a drier and an antioxidant to obtain the htermosensitive color-variable ink. The method for preparing the thermosensitive material is green and environment-friendly; and the prepared ink has thermoesensitive stability, good heat resistance and can be rapidly dried. The obtained ink has good anti-counterfeit printing effect.

Owner:广东泰金智能包装有限公司

Water-based reversible thermochromic ink and preparation method thereof

The invention discloses a water-based reversible thermochromic ink, which is composed of the following components in percentage by mass: 14-25% of thermochromic powder; 9%-11% of polyvinyl alcohol; 65.5% to 74.4% of purified water; and 0.5%-0.6% of a base material wetting agent, wherein the sum of the mass percentages of the components mentioned above is 100%, the thermochromic powder comprises crystal violet lactone, bisphenol A and tetradecyl alcohol; and the mass ratio of crystal violet lactone to bisphenol A to tetradecyl alcohol is 1: (3-4): (10-20). The invention also discloses a preparation method of the water-based reversible thermochromic ink.

Owner:XIAN UNIV OF TECH

Anion environment-friendly wallpaper and preparation method thereof

InactiveCN106085176AFlat surfaceNot easy to moldCovering/liningsPolyurea/polyurethane coatingsLiquid layerIndium

The invention relates to wallpaper and provides anion environment-friendly wallpaper and a preparation method thereof. The problem that wallpaper in the prior art has no color change function is solved. The anion environment-friendly wallpaper comprises a base material layer. The base material layer is soaked in a pretreatment liquid layer. The pretreatment liquid layer is coated with a foaming slurry layer. The surface of the foaming slurry layer is coated with an anion color change paint layer. The anion color change paint layer comprises, by weight, 12-20 parts of polyacrylate, 1-3 parts of polyacrylic acid, 10-20 parts of silver, indium, antimony and tellurium, 20-35 parts of spiropyrane thermosensitive color change organic compound, 30-35 parts of bisphenol A, 16-25 parts of crystal violet lactone, 30-35 parts of fatty acid, 10-15 parts of silicon dioxide, 5-10 parts of tinting pigment, 5-15 parts of ferridravite, 2-6 parts of oxidized dode-carbon tetrade-aluminum and 50-80 parts of water.

Owner:FUJIAN YOUYA ENVIRONMENTAL PROTECTION WALLPAPER CO LTD

Erasable ball pen ink

The invention discloses a pen for writing, and particularly relates to erasable ball pen ink, which is prepared from the following raw materials in part by weight: 10 to 30 parts of phenolic resin, 5 to 25 parts of crystal violet lactone, 20 to 30 parts of benzyl alcohol, 15 to 25 parts of hydroxyethyl phenyl ether, 12 to 26 parts of modified xylene resin, 7 to 20 parts of oleic acid, 0.1 to 1 part of polyvinylpyrrolidone and 3 to 15 parts of fatty acid. A ball pen injected with the ink of the invention can write clear blue letters smoothly like an ordinary ball pen, erase the letters for correction conveniently like a pencil, store the letters permanently after the letters are cured and erase the letters by using an ordinary eraser after the letters are written for several hours, and has good rewriting effect. The erasable ball pen has the advantages of both the ordinary ball pen and the ordinary pencil, overcomes the shortcomings of illegibility and short retention time of the letters written by the pencil, solves the problems of troubles and insanitation caused by pencil sharpening, overcomes the detects of non-erasability of the ordinary ball pen, and has high color fastness.

Owner:冀登昌

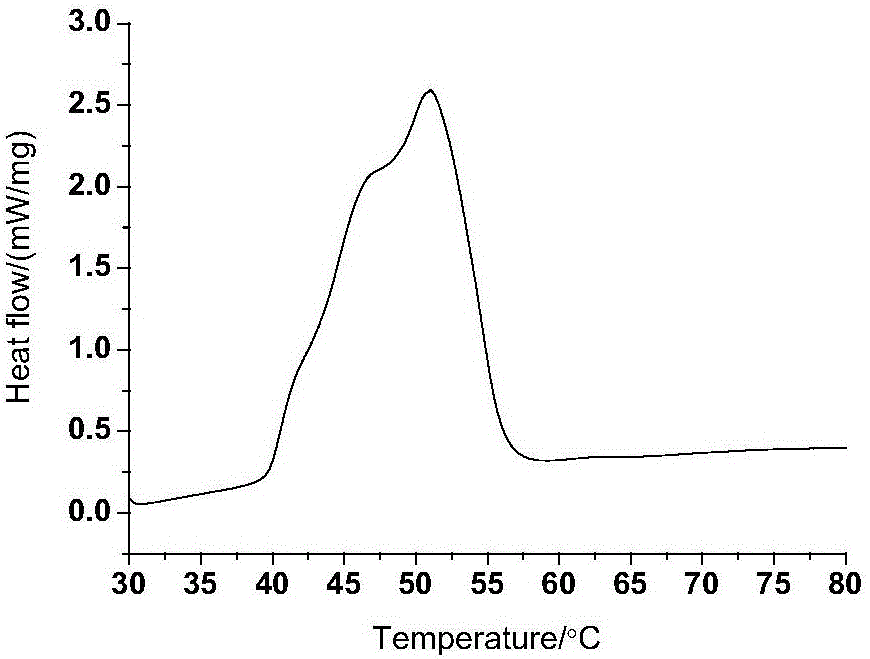

Reversible thermochromic functional composite phase change material as well as preparation method and application thereof

PendingCN114716980ANo chemical reactionProcess reversibleHeat-exchange elementsTenebresent compositionsPolymer chemistryBisphenol

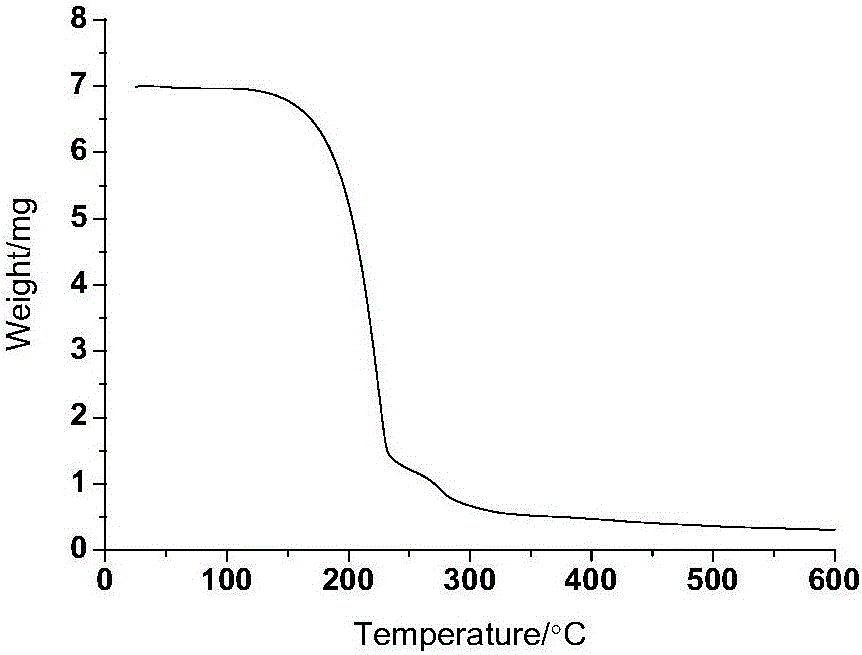

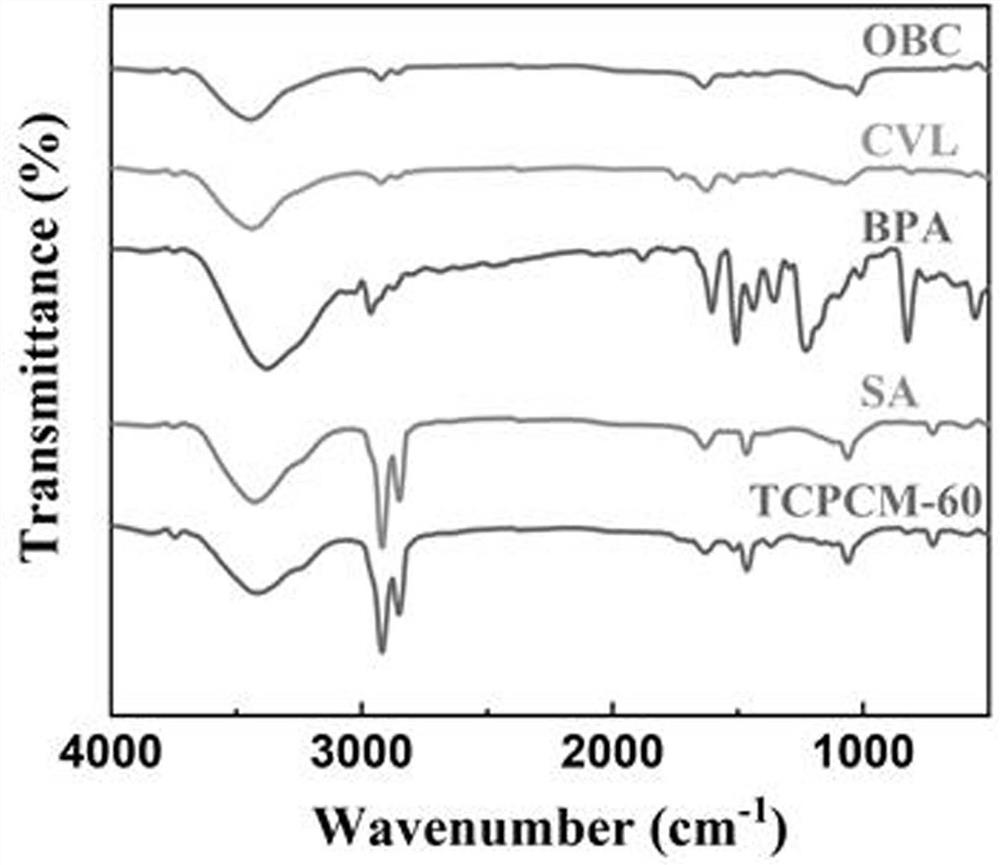

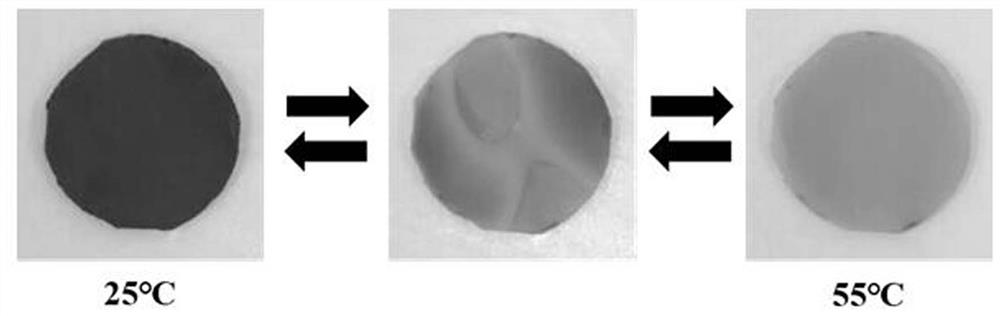

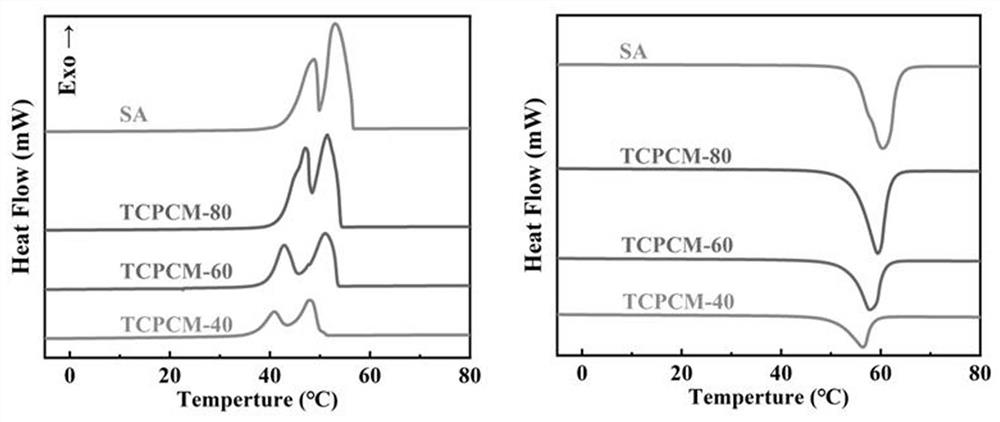

The invention provides a reversible thermochromic functional composite phase change material which is prepared by the following steps: by taking crystal violet lactone, bisphenol A, stearyl alcohol and an olefin block copolymer OBC as raw materials, firstly melting and blending the crystal violet lactone, the bisphenol A and the stearyl alcohol to obtain a reversible thermochromic blend; and carrying out hot press molding on the reversible thermochromic blend and the olefin block copolymer OBC by adopting a hot press method, and naturally cooling to obtain the reversible thermochromic functional composite phase change material which has both the reversible thermochromic function and the phase change function and has the difference between the reversible thermochromic temperature and the phase change temperature less than 5 DEG C. The thermochromism process is a reversible process, crystal violet lactone provides a color-changing color base, bisphenol A causes thermochromism, and stearyl alcohol serves as a cosolvent to adjust the color-changing temperature. The preparation method has the advantages that the phase change material stearyl alcohol is used as a connecting bridge of a color change system and a phase change system, reversible thermochromism and phase change temperature are adjusted, and the phase change heat storage material has the phase change heat storage performance and the photothermal conversion performance at the same time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Microcapsules for carbon-free paper coating achieved through deinked pulp carbon-free raw paper and production technology of microcapsules

InactiveCN106237946ALow costUniform particle sizeNon-fibrous pulp additionMicroballoon preparationPapermakingRaw material

The invention discloses microcapsules for carbon-free paper coating achieved through deinked pulp carbon-free raw paper and a production technology of the microcapsules. The microcapsules are prepared from wall materials, color oil and emulsifying raw materials, wherein the wall materials comprise 110-120 parts of formaldehyde, 35-55 parts of alcohol and 30-50 parts of melamine, the color oil comprises 250-350 parts of solvent oil and 12-22 parts of crystal violet lactone, and the emulsifying raw materials comprise 80-90 parts of an emulsifying agent, 18-30 parts of urea, 1-2 parts of glacial acetic acid and 20-30 parts of alcohol. According to the microcapsules, the microcapsules are blue and white emulsion, the solid content is 40%, the pH value is 8.5, the viscosity is lower than or equal to 100 mpa.s, and the microcapsules can be dispersed in water in any proportion and develop blue or black; a series of technical problems that the finished carbon-free paper is poor in development effect and nonuniform in paper surface coating in the production process that the carbon-free paper is obtained through coating of the deinked pulp papermaking carbon-free raw paper and carbon runs off in the paper cutting and printing process are solved, and compared with originally-used domestic coating microcapsules, the cost per ton is reduced by 2,100 yuan.

Owner:湖北金民纤维材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com