Overstable thermotropic color-changing coating and preparation method thereof

A thermochromic material and thermochromic technology, applied in the field of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

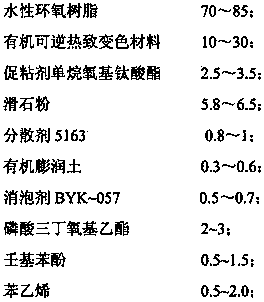

[0014] An ultra-stable thermochromic paint, in parts by weight, it consists of the following components:

[0015]

[0016] The organic reversible thermochromic material is prepared by reacting crystal violet lactone and bisphenol A in fatty alcohol.

[0017] The preparation method of above-mentioned ultra-stable thermochromic coating comprises the following steps:

[0018] (1) Disperse talcum powder and organic reversible thermochromic material in a high-speed disperser to obtain component A;

[0019] (2) Add water-based epoxy resin to component A, and add adhesion promoter monoalkoxy titanate, talc powder, dispersant 5163, organic bentonite, defoamer BYK~057, tributoxyethyl phosphate Esters, nonylphenol and styrene are mixed at high speed, the paint mixture is taken out, ground in a grinder, and the insoluble solid impurities are filtered to obtain a color-changing paint.

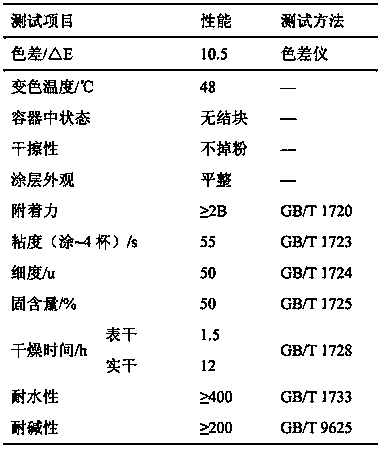

[0020] Embodiment 1 performance measurement result is as following table:

[0021]

Embodiment 2

[0023] An ultra-stable thermochromic paint, in parts by weight, it consists of the following components:

[0024]

[0025] The organic reversible thermochromic material is prepared by reacting crystal violet lactone and bisphenol A in fatty alcohol.

[0026] The preparation method of above-mentioned ultra-stable thermochromic coating comprises the following steps:

[0027] (1) Disperse talcum powder and organic reversible thermochromic material in a high-speed disperser to obtain component A;

[0028] (2) Add water-based epoxy resin to component A, and add adhesion promoter monoalkoxy titanate, talc powder, dispersant 5163, organic bentonite, defoamer BYK~057, tributoxyethyl phosphate Esters, nonylphenol and styrene are mixed at high speed, the paint mixture is taken out, ground in a grinder, and the insoluble solid impurities are filtered to obtain a color-changing paint.

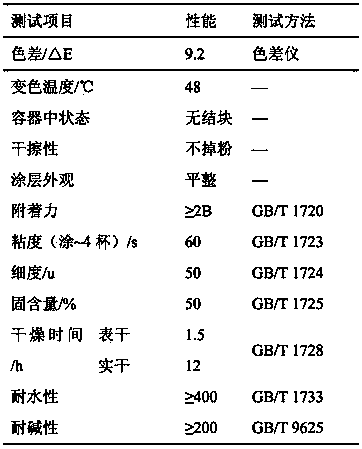

[0029] Embodiment 2 performance measurement result is as follows table:

[0030]

Embodiment 3

[0032] An ultra-stable thermochromic paint, in parts by weight, it consists of the following components:

[0033]

[0034]

[0035] The organic reversible thermochromic material is prepared by reacting crystal violet lactone and bisphenol A in fatty alcohol.

[0036] The preparation method of above-mentioned ultra-stable thermochromic coating comprises the following steps:

[0037] (1) Disperse talcum powder and organic reversible thermochromic material in a high-speed disperser to obtain component A;

[0038] (2) Add water-based epoxy resin to component A, and add adhesion promoter monoalkoxy titanate, talc powder, dispersant 5163, organic bentonite, defoamer BYK~057, tributoxyethyl phosphate Esters, nonylphenol and styrene are mixed at high speed, the paint mixture is taken out, ground in a grinder, and the insoluble solid impurities are filtered to obtain a color-changing paint.

[0039] Embodiment 3 performance measurement result is as follows table:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com