Reversible thermochromic functional composite phase change material as well as preparation method and application thereof

A composite phase change material and thermochromic technology, applied in the direction of color-changing fluorescent materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor shape-setting packaging effect, low cost, and lack of color memory function, etc., to achieve Good anti-leakage effect and high phase change enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

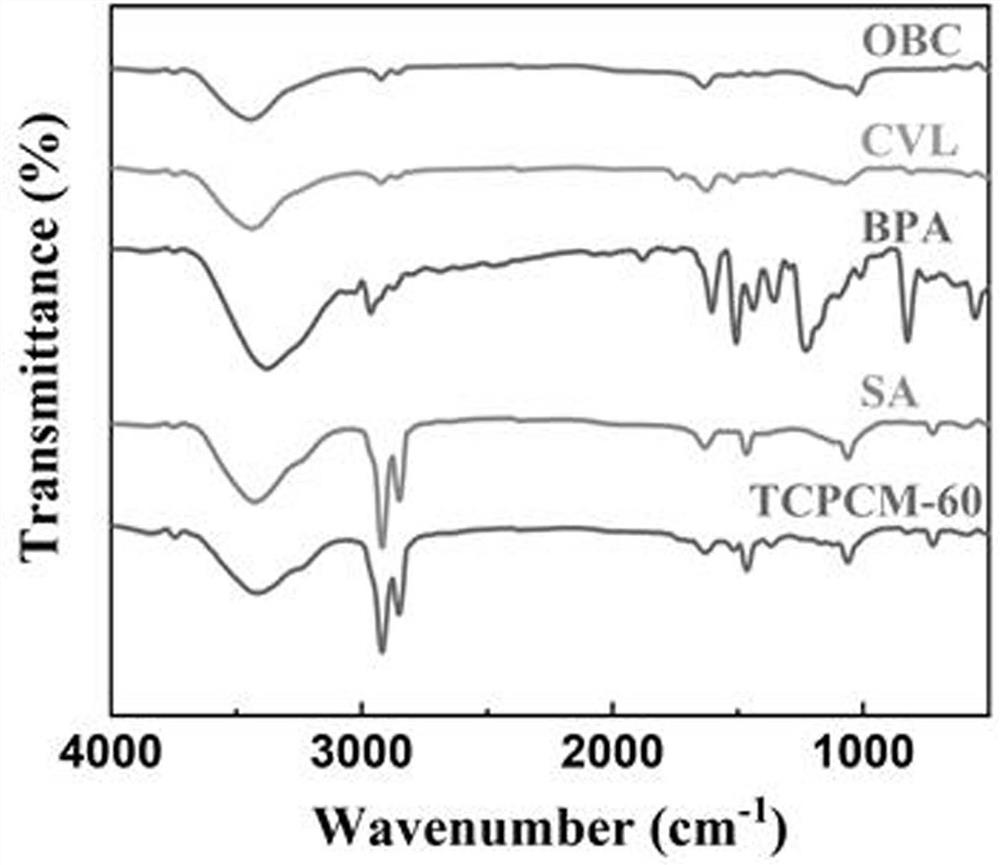

[0048] A preparation method of a reversible thermochromic functional composite phase change material, comprising the following steps:

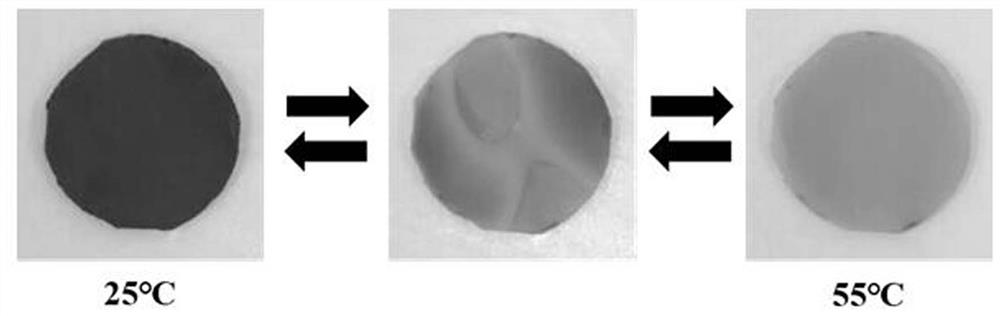

[0049] Step 1, preparation of the reversible thermochromic blend, the operation of step 1 was carried out under the condition of maintaining 60 ° C, firstly 3.48 g of stearyl alcohol was melted into a liquid state, and then, under stirring conditions, 0.17 g of crystal violet was added to the solution. The ester was added to the liquid stearyl alcohol and stirred for 10 min until the crystal violet lactone was completely dissolved. Then, 0.35 g of bisphenol A was added and stirred for 10 min until the bisphenol A was completely dissolved. The addition was stopped and cooled to 25°C naturally. , 4 g of reversible thermochromic blends with dark blue color at 25 °C can be obtained;

[0050] Step 2, the preparation of the reversible thermochromic functional composite phase change material, using a hot pressing method, under the condition of a hot ...

Embodiment 2

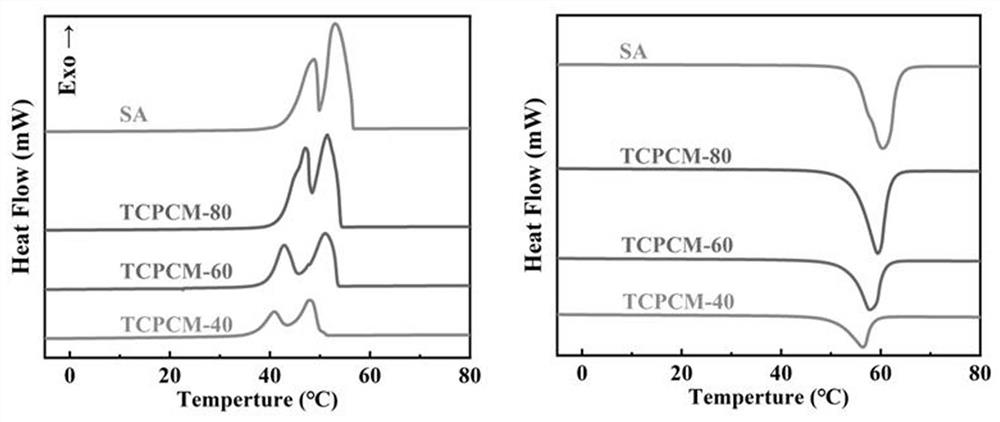

[0078] A preparation method of a reversible thermochromic functional composite phase change material with a stearyl alcohol content of 40%, the specific steps are the same as in Example 1, except that the addition of the stearyl alcohol in the step 1 is: 2.32 g, the added amount of olefin block copolymer OBC was 3.02 g, and the obtained sample was named TCPCM-40.

[0079] The phase change heat storage performance test results of TCPCM-40 are as follows image 3 As shown, the phase transition temperature of TCPCM-40 is 33.7-51.5°C, and the phase transition enthalpy value is 99.7-101.2 J / g. The phase transition enthalpy is lower than that of TCPCM-60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com