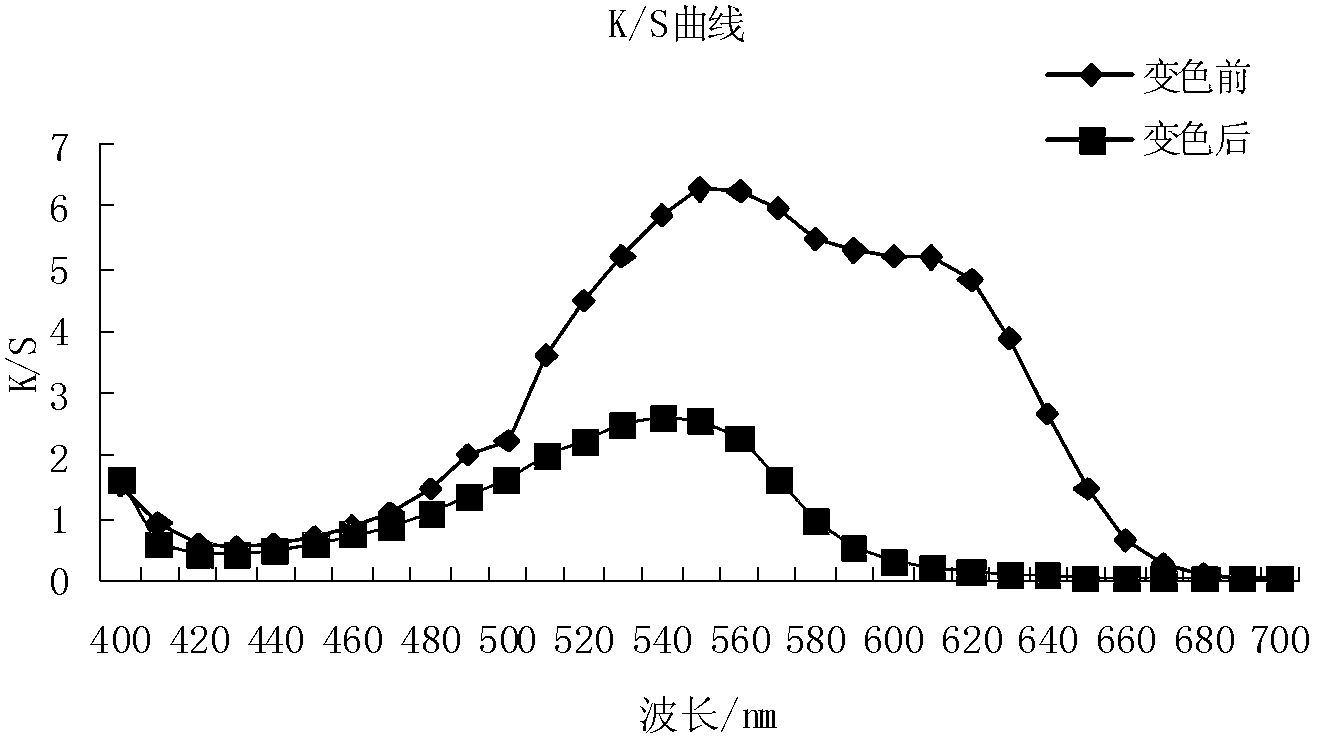

Thermosensitive discoloring energy-storage material and preparation method thereof

A heat-sensitive discoloration and energy storage material technology, applied in the field of energy storage materials and their preparation, and heat-sensitive discoloration, can solve the problems of single color change, easy deterioration of color-changing materials, high discoloration temperature, etc., to overcome the high discoloration temperature and easy The effect of industrialized production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Weigh 8.884g of tetradecyl alcohol and 1.116g of cetyl alcohol as energy storage materials and place them in a container, dissolve them at 80°C, then add 0.2g of dispersed cationic pink, 0.6g of crystal violet lactone and 3.0g of bisphenol A and seal it well, stir in a water bath at 80°C for 60 minutes to make a core material solution;

[0041] (2) Take 2.00g of melamine, 3.86g of formaldehyde solution and 22.5ml of distilled water, mix and stir evenly at a temperature of 70°C, adjust the pH value of the mixture to 8.5-9 with triethanolamine, and then react for 30 minutes until it is colorless and transparent shape, that is, to make a prepolymer, take it out and store it at 50°C for later use;

[0042] (3) Take 1.38g styrene-maleic anhydride copolymer and 25ml distilled water in a three-necked flask, add 0.2gNaOH, mix well, then adjust the pH value of the solution to 4-5 with 10% citric acid, and put Stirring and reacting at a temperature of ℃ for 1 h; then adding ...

Embodiment 2

[0047] (1) Weigh 7.796g of tetradecyl alcohol and 2.204g of cetyl alcohol as the energy storage material and put them in a container, dissolve them at 80°C, then add 0.2g of dispersed cationic bright yellow, 0.6g of crystal violet lactone and 3.0g of bisphenol A and seal it well, stir in a water bath at 80°C for 60 minutes to make a core material solution;

[0048] (2) Take 2.00g of melamine, 3.86g of formaldehyde solution and 22.5ml of distilled water, mix and stir evenly at a temperature of 70°C, adjust the pH value of the mixture to 8.5-9 with triethanolamine, and then react for 30 minutes until it is colorless and transparent shape, that is, to make a prepolymer, take it out and store it at 50°C for later use;

[0049] (3) Take 1.4g styrene-maleic anhydride copolymer and 25ml distilled water in a three-necked flask, add 0.2gNaOH, mix thoroughly, then adjust the pH value of the solution to 4-5 with 10% citric acid, and put Stirring and reacting for 1 h at a temperature of ...

Embodiment 3

[0054] (1) Weigh 6.735g of tetradecyl alcohol and 3.265g of cetyl alcohol as energy storage materials and place them in a container, dissolve them at 80°C, then add 0.2g of dispersed cationic pink, 0.6g of crystal violet lactone and 3.0g of bisphenol A and seal well, stir in 80°C water bath for 60min, thus make core material solution;

[0055] (2) Take 2.00g of melamine, 3.86g of formaldehyde solution and 22.5ml of distilled water, mix and stir evenly at a temperature of 70°C, adjust the pH value of the mixture to 8.5-9 with triethanolamine, and then react for 30 minutes until it is colorless and transparent shape, that is, to make a prepolymer, take it out and store it at 50°C for later use;

[0056] (3) Take 1.37g styrene-maleic anhydride copolymer and 25ml distilled water in a three-necked flask, add 0.2gNaOH, mix thoroughly, and then adjust the pH value of the solution to 4-5 with 10% citric acid. Stirring and reacting at a temperature of ℃ for 1 h; then adding 0.968 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discoloration temperature | aaaaa | aaaaa |

| Discoloration temperature | aaaaa | aaaaa |

| Discoloration temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com