Patents

Literature

118results about How to "Achieve anti-counterfeiting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Handset with built in reader-writer of identifying radio frequency

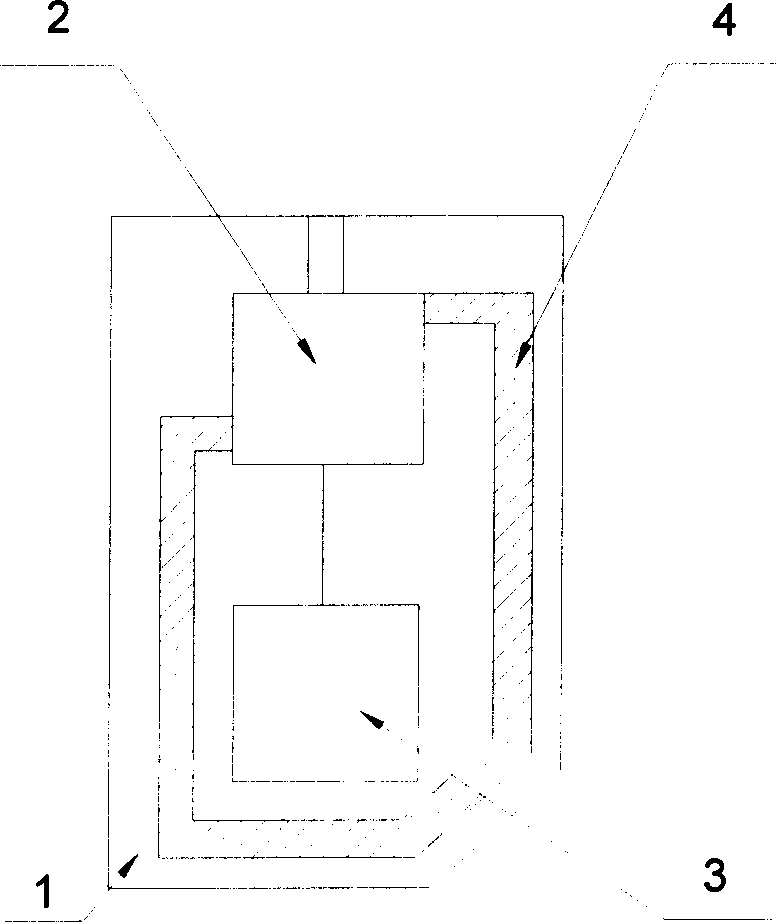

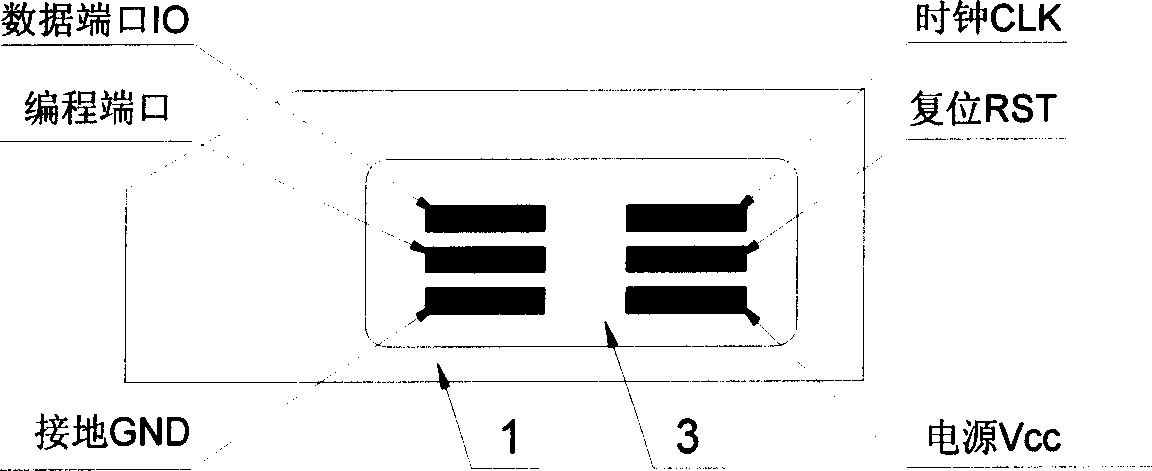

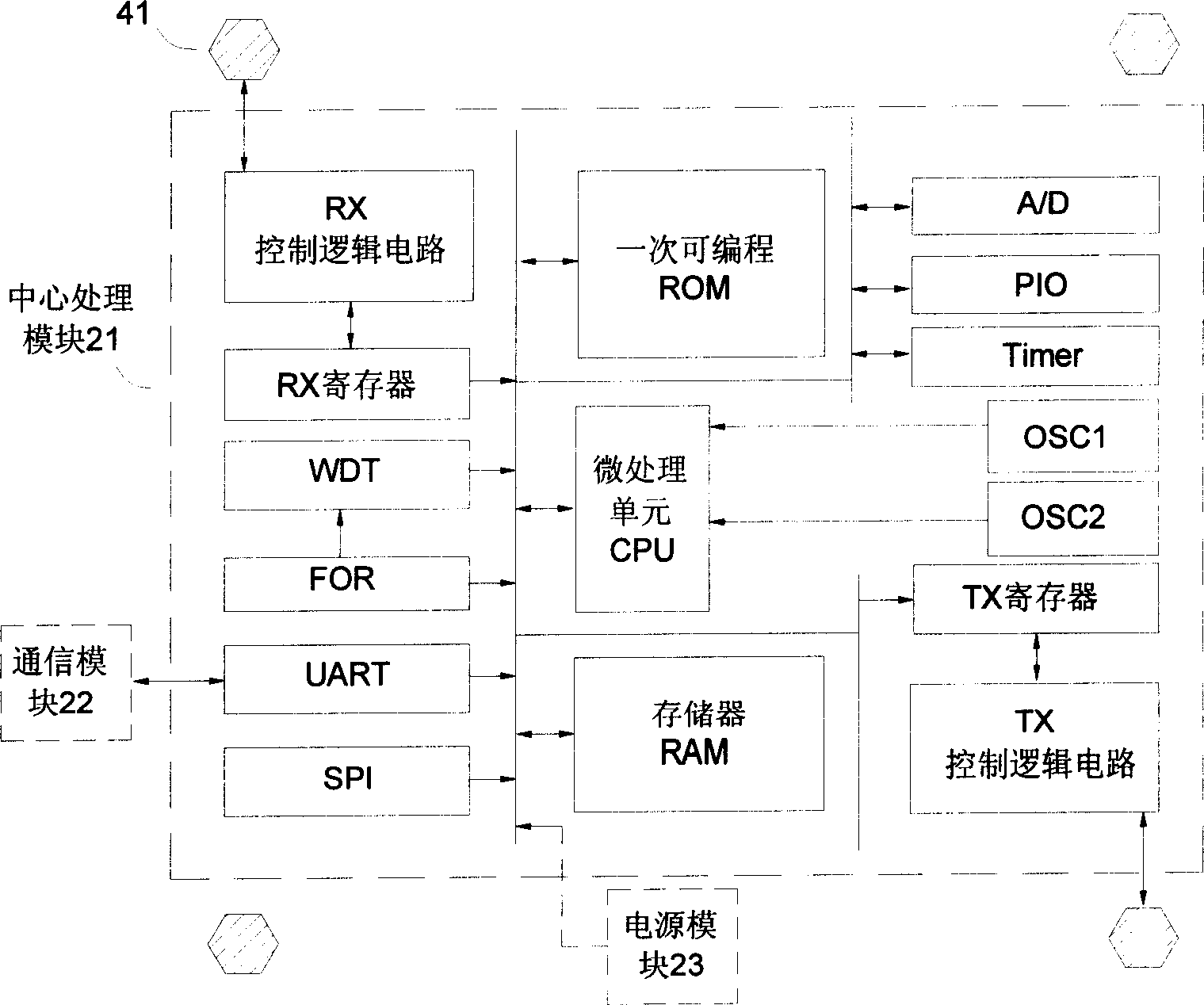

InactiveCN1761342AImprove communication qualityEasily determine authenticityRadio/inductive link selection arrangementsSubstation equipmentRadio frequencyReader writer

The invention combines RFID dedicated read / write device with handset including SIM card. Characters of the invention are as following: RFID read / write chip capable of reading / writing RFID electronic label and external antenna connected to the said RFID read / write chip are setup on card body of SIM card; RFID read / write chip is connected to IC chip in SIM card. The invention makes general handset implement function for reading and writing RFID electronic label so as to constitute handset with RFID reader / writer built in.

Owner:PEKING UBIQUITOUS IC TAG TECH

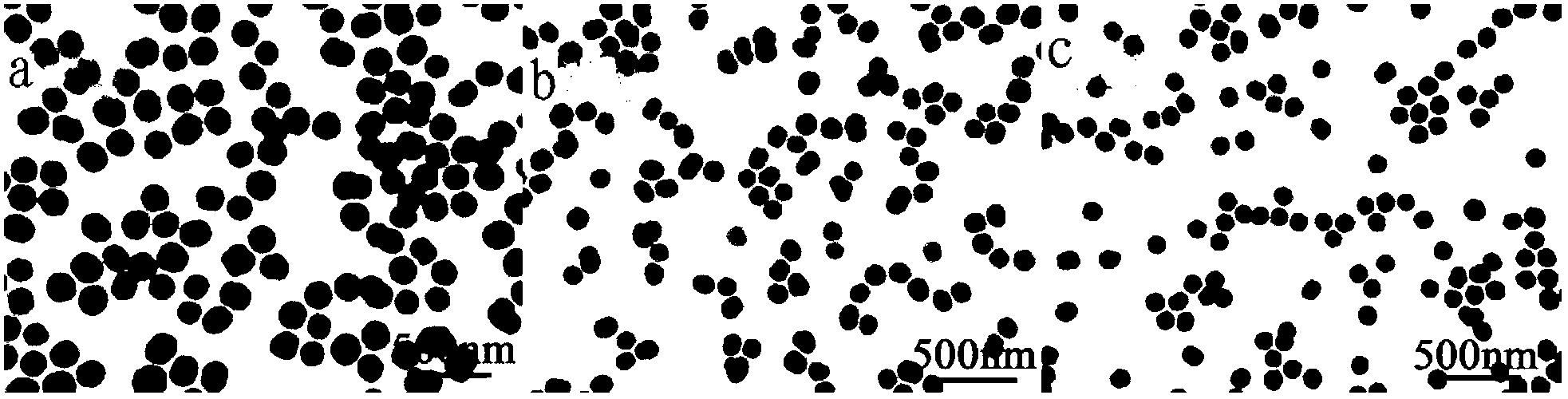

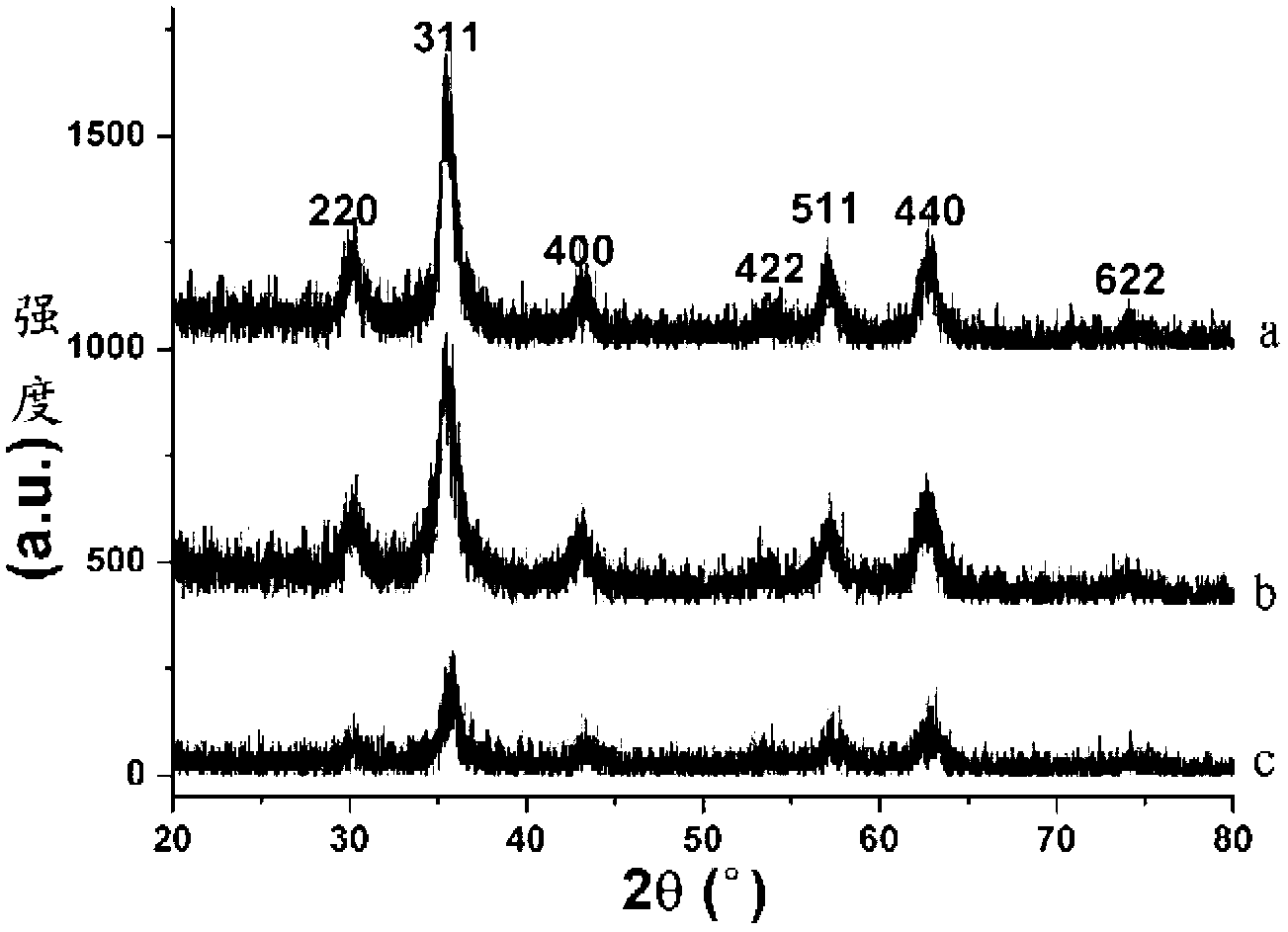

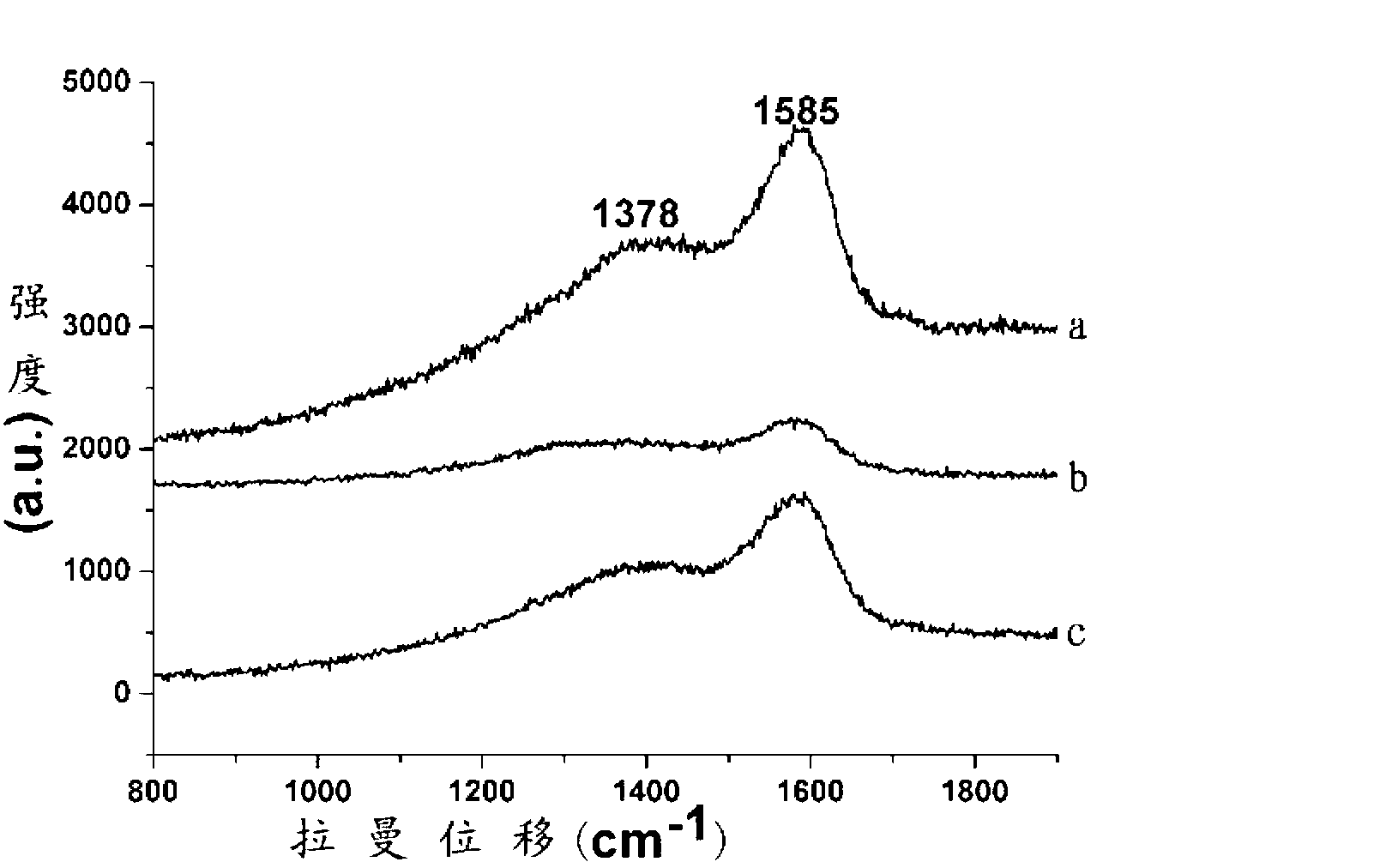

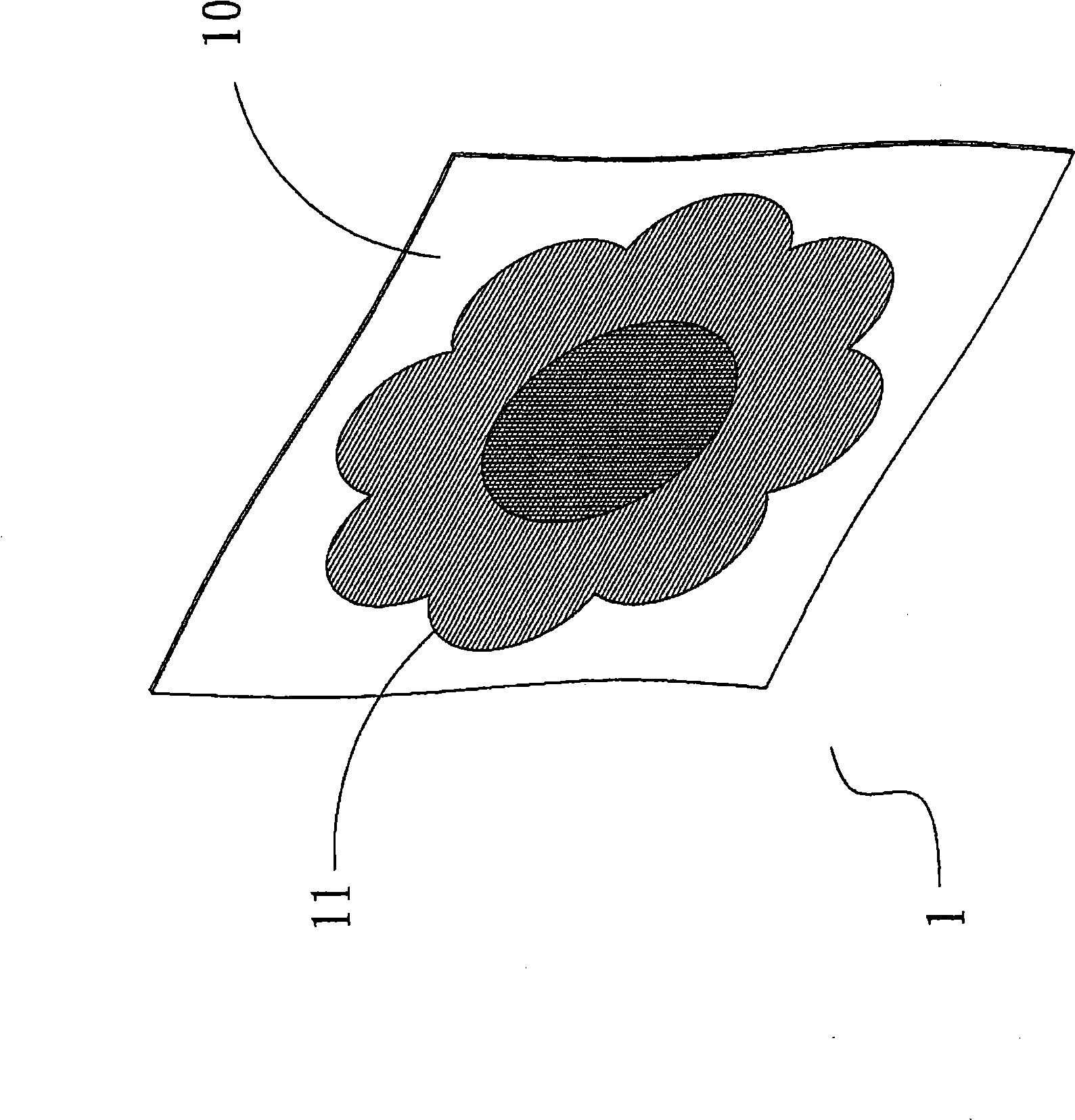

Magnetic response photonic crystal anti-fake label and manufacturing method thereof

InactiveCN102708773ALarge induced magnetic momentThe induced magnetic moment is sufficientStatic indicating devicesSuperparamagnetismMagnetic response

The invention provides a magnetic response photonic crystal anti-fake label and a manufacturing method thereof. The magnetic response photonic crystal anti-fake label provided by the invention comprises a plurality of patterns, wherein the patterns comprise polymer substrates and ethylene glycol micro droplets which contain carbon-coated superparamagnetism ferroferric oxide colloidal nanometer particles and are encapsulated in the polymer substrates; single pattern among the patterns at least comprises two kinds of carbon-coated superparamagnetism ferroferric oxide colloidal nanometer particles of different particle diameters. In the magnetic response photonic crystal anti-fake label provided by the invention, the carbon-coated superparamagnetism ferroferric oxide colloidal nanometer particles of different particle diameters are self-assembled respectively to acquire a multi-photon band gap structure under the action of magnetic fields, so that visible light of different wavelengths can be reflected and is superposed to acquire a new colour; and the color can not be copied by common pigment or dye color, has a good anti-fake effect and good color adjustability, and is beneficial to application.

Owner:UNIV OF SCI & TECH OF CHINA

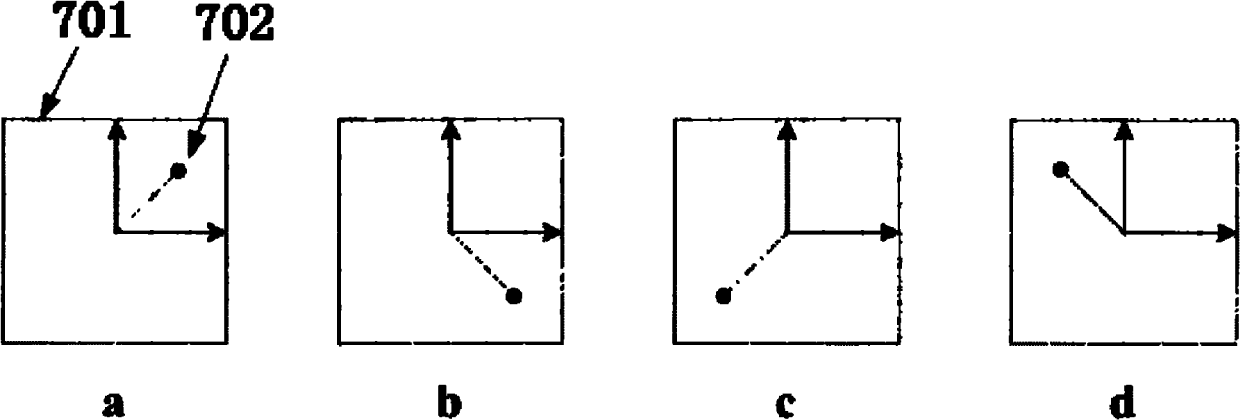

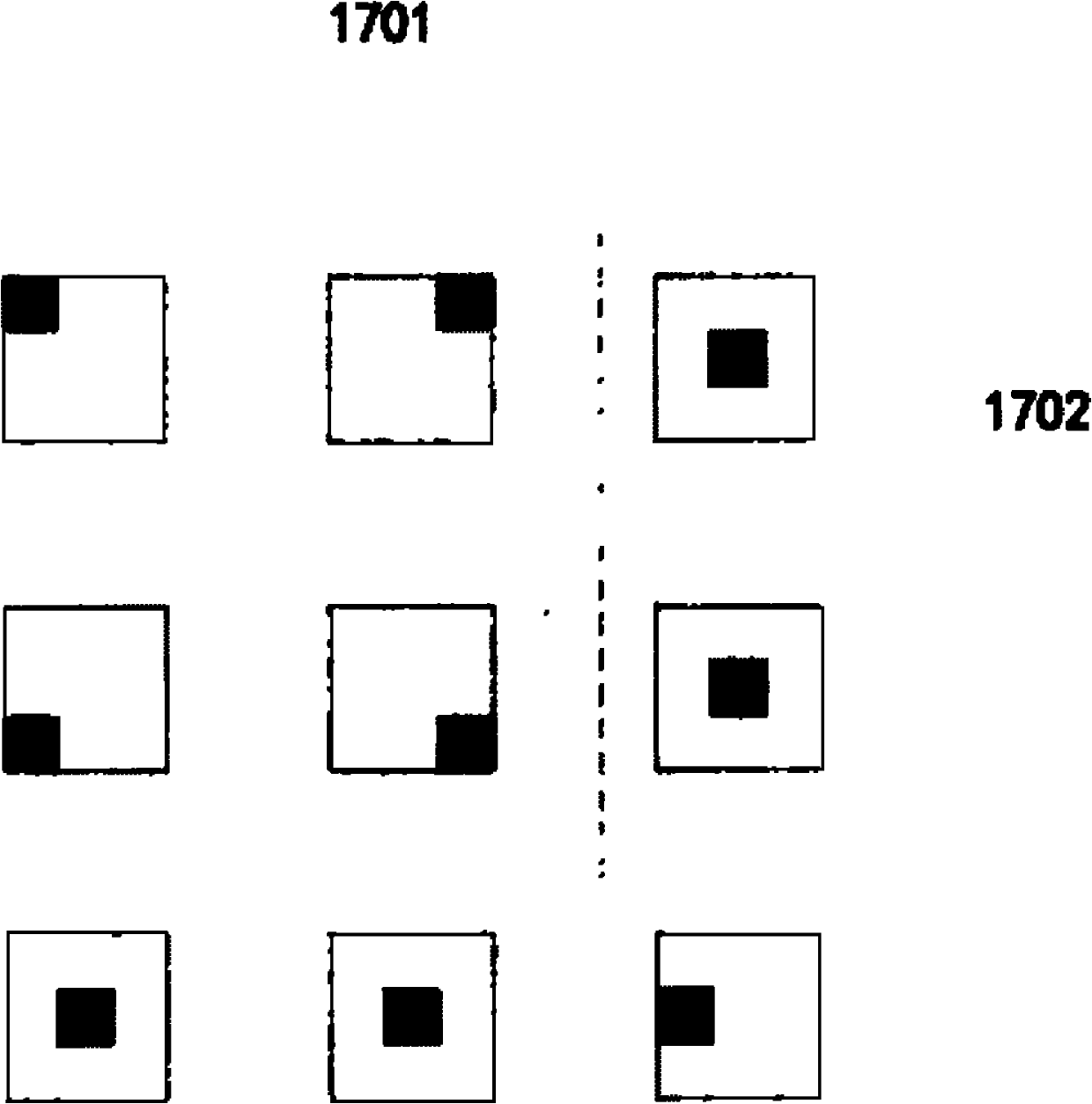

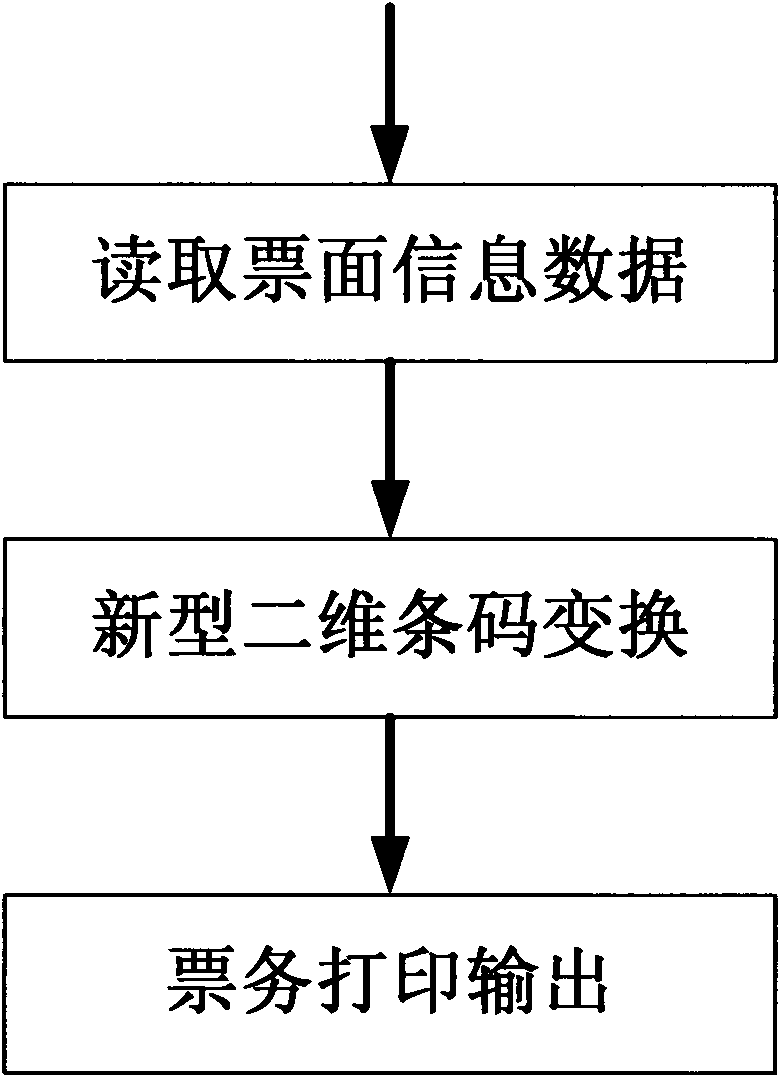

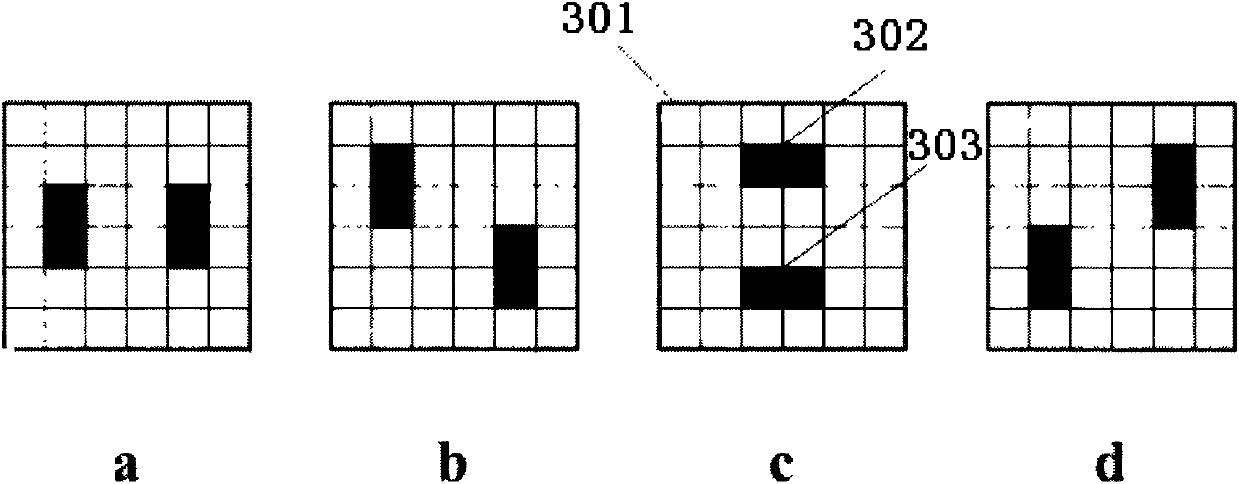

Constituting method of novel two-dimensional bar code

ActiveCN102890787AAchieve anti-counterfeiting effectRecord carriers used with machinesSensing by electromagnetic radiationInformation processingEngineering

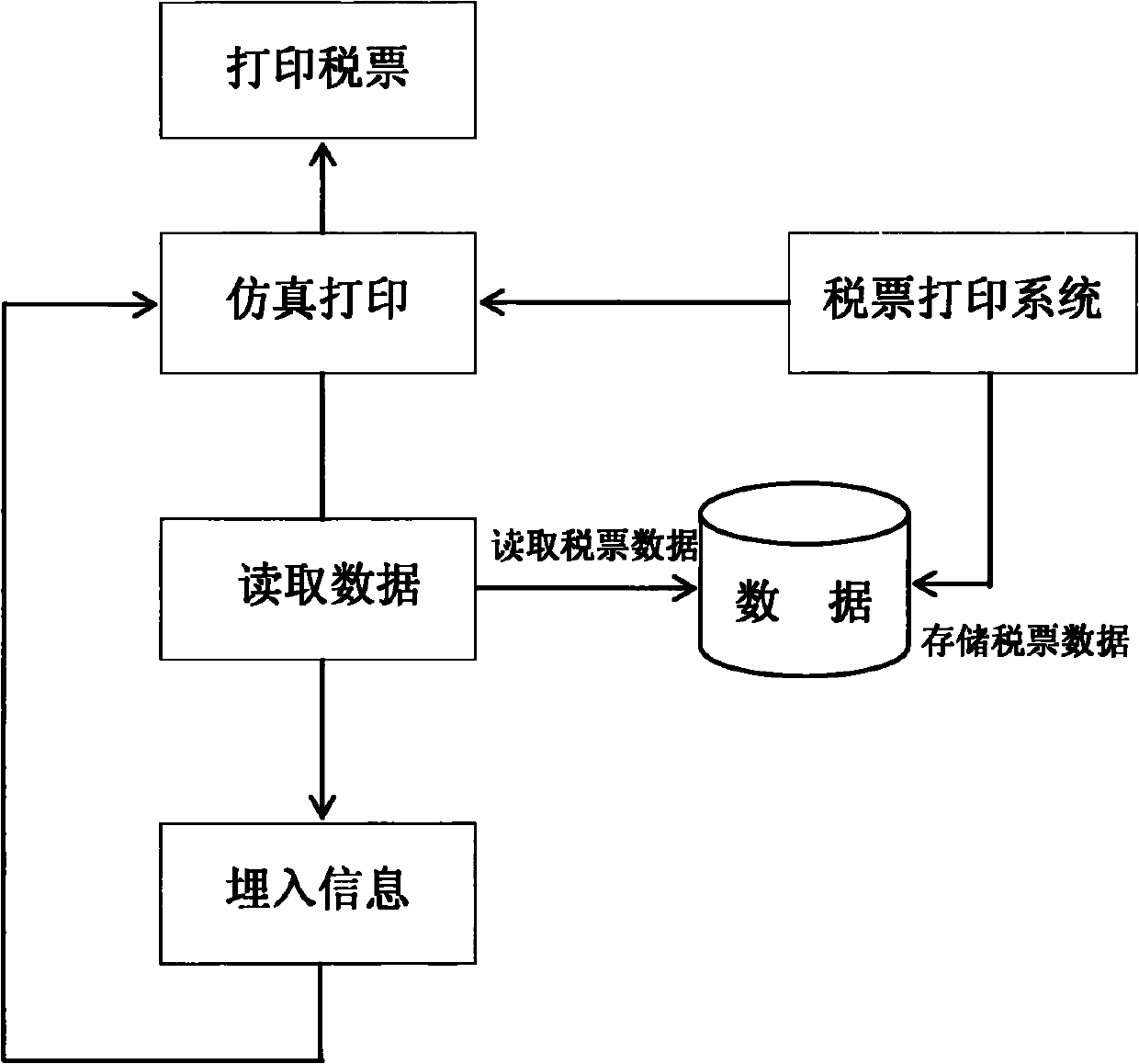

The invention relates to a constituting method of a novel two-dimensional bar code in the field of information processing. The constituting method is characterized in that a two-dimensional bar code can be constituted on a printing medium or a commodity in a printing manner or by a laser marking press by a low-precision printer or an ink-jet printer without damaging the printed images or influencing the appearance of the commodity. Meanwhile, the constituted two-dimensional bar code is anti-counterfeiting. Printed contents of tax receipts can be embedded in the bar code in the manners of characters, patterns and shading by the novel two-dimensional bar code technology for realizing functions of embedding content information and automatically reading tax receipts and restraining tax dodging and evasion without influencing appearances of tax receipts. Meanwhile, anti-copy performance and the identification of the tax receipts can be realized. Therefore, problems of counterfeiting and falsifying tax receipts and counterfeiting commodities are prevented from spreading in the society, and the harmonious development of society is promoted.

Owner:顾泽苍

Communication method and device for automatic driving vehicle control, equipment and storage medium

PendingCN110782705ASolve the problem of maliciously creating obstaclesAchieve anti-counterfeiting effectParticular environment based servicesAnti-collision systemsInformation controlEngineering

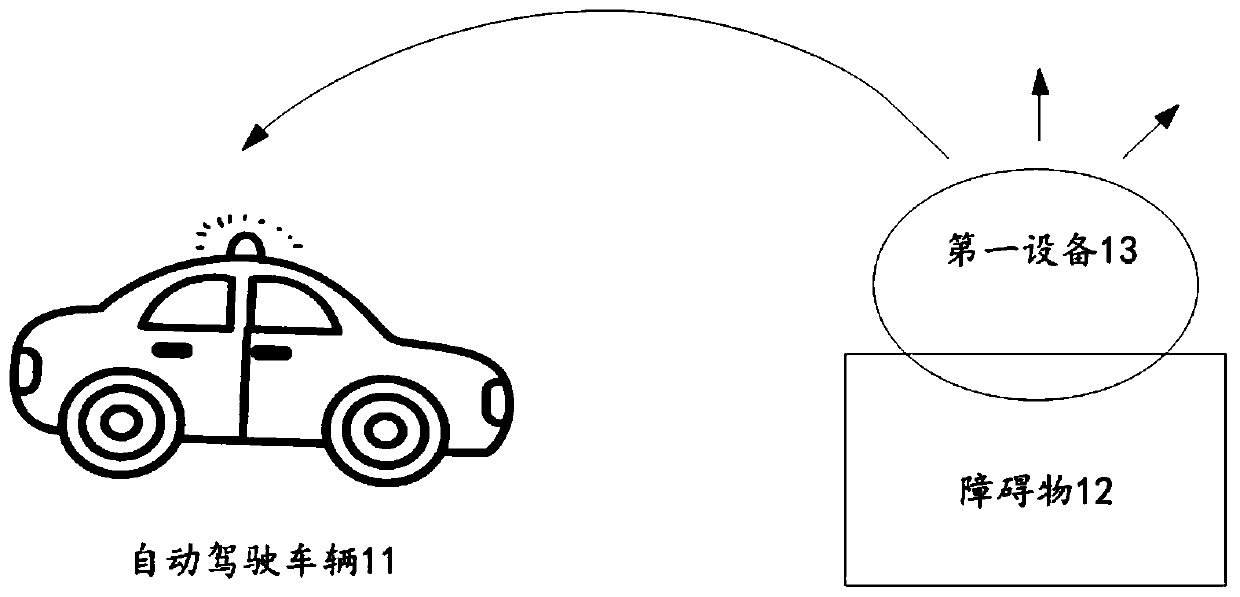

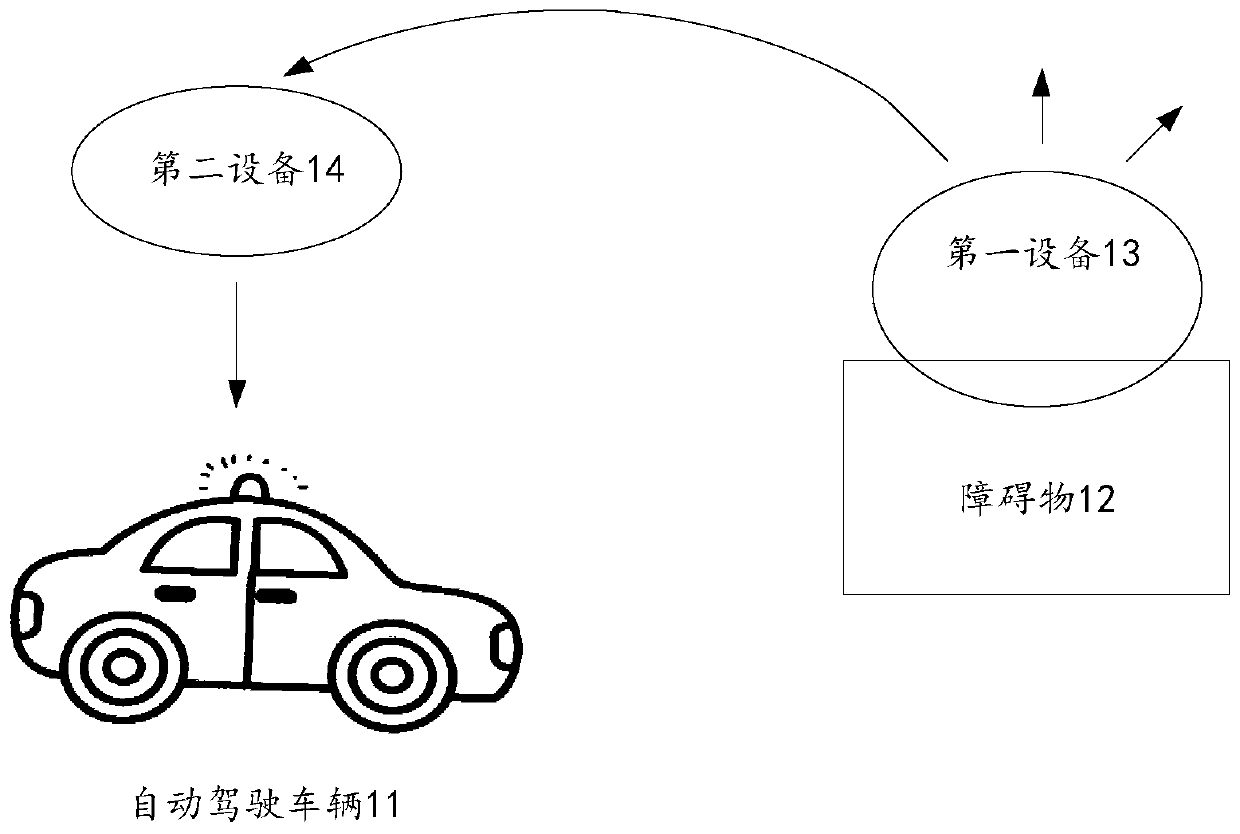

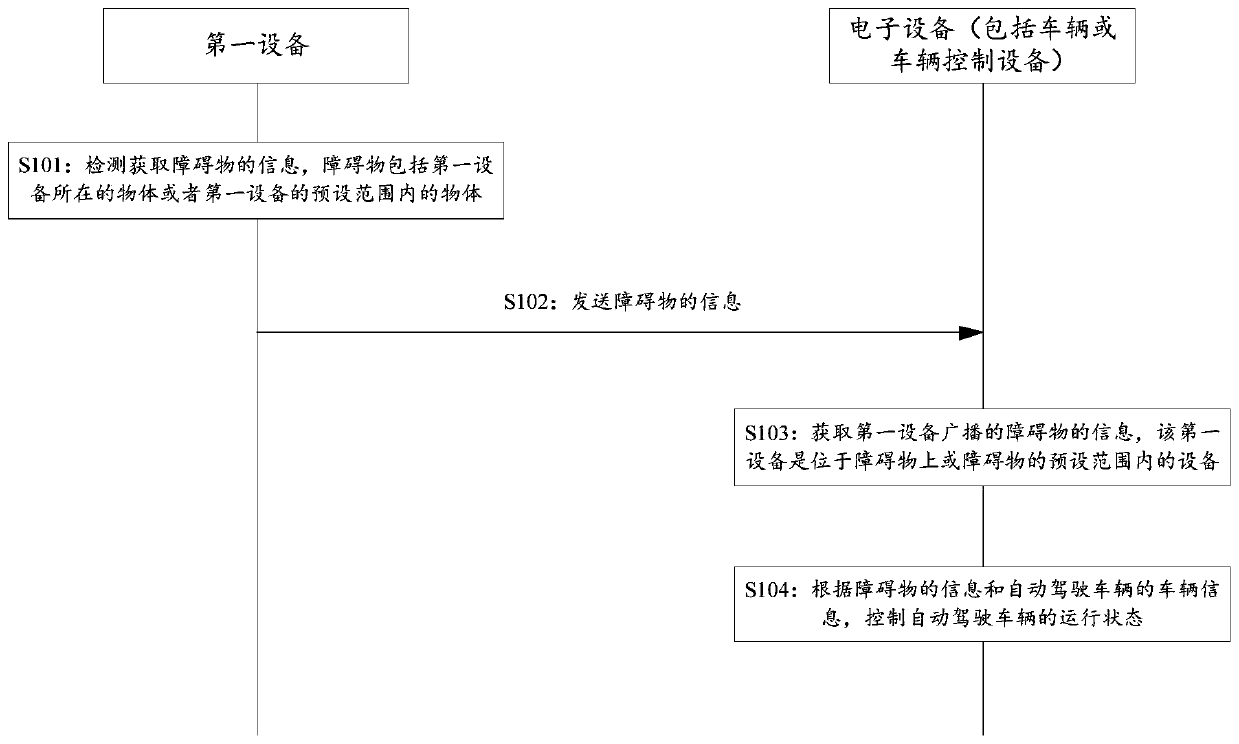

The application, which relates to the technical field of automatic driving, discloses a communication method and device for automatic driving vehicle control, equipment and a storage medium. The method comprises the following steps: acquiring obstacle information by a first device arranged on an obstacle or within the range of the obstacle and carrying out broadcasting; and controlling the runningstate of an automatic driving vehicle by a device receiving the obstacle information according to information of the obstacle and the vehicle information of the automatic driving vehicle. Since the first device arranged on the obstacle or within the influence range of the obstacle can automatically broadcast the information of the obstacle, the automatic driving vehicle can obtain the obstacle intime, so that a problem that the obstacle cannot be avoided due to the time delay of obstacle detection by a sensing device is solved and thus the driving safety of the automatic driving vehicle is improved.

Owner:APOLLO INTELLIGENT DRIVING (BEIJING) TECHNOLOGY CO LTD

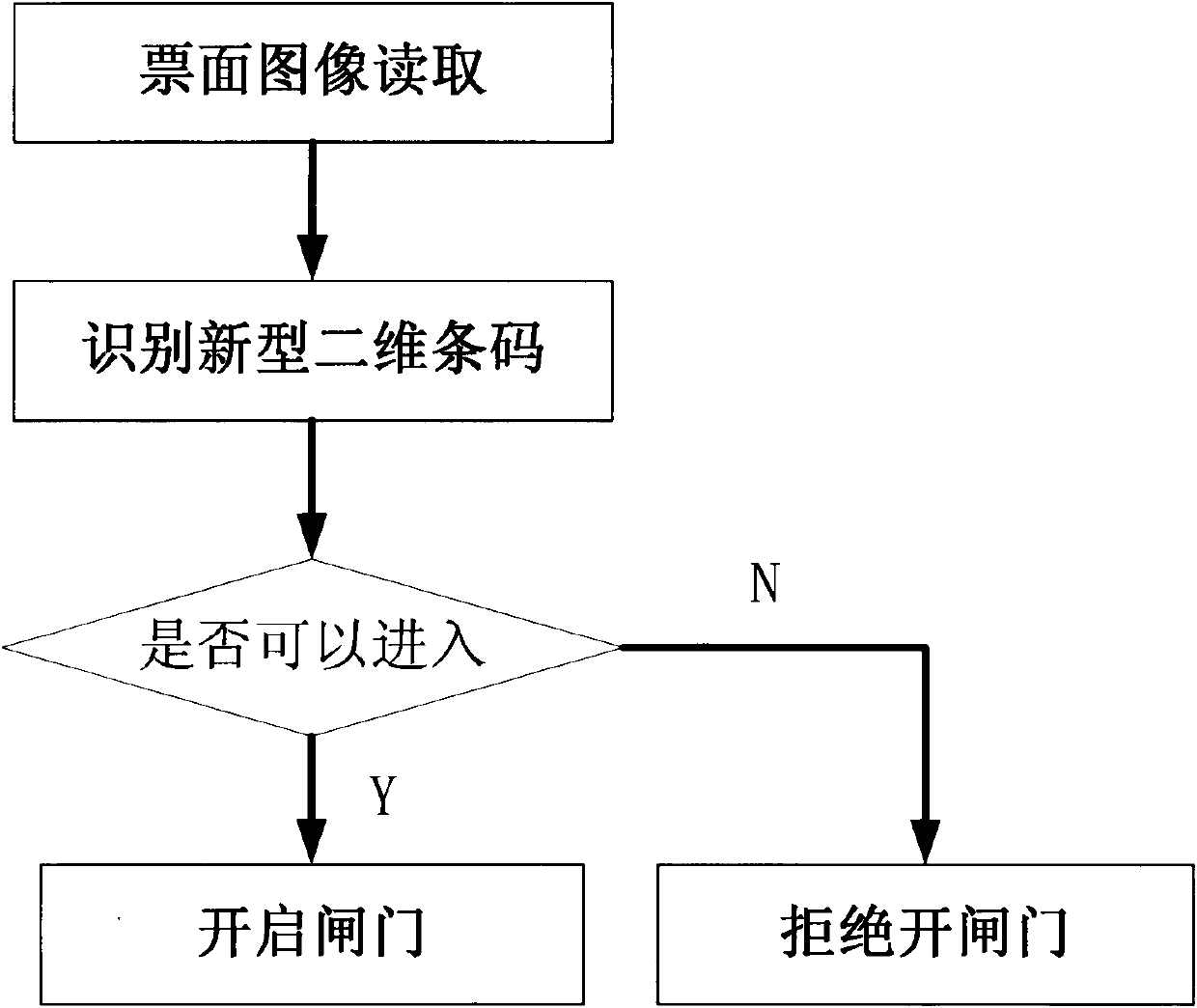

Constituting method for access control system with novel two-dimensional bar code

ActiveCN102890788ABeautiful faceAchieve anti-counterfeiting effectIndividual entry/exit registersRecord carriers used with machinesInformation processingPublic place

The invention relates to a constituting method for an access control system with a novel two-dimensional bar code, and an access control method in the field of information processing. The constituting method is characterized in that an access control system is provided, for the access control system, an admission ticket can be printed by a low-precision printer; ticket information can be embedded on the paper admission ticket without influencing the appearance of the ticket; meanwhile, the access control system is anti-counterfeiting; the access control system can be used for an access control system of an automatic gate; and the access control system can be in common use with an RFID (radio frequency identification devices) card. Problems of high cost of currently used magnetic medium admission ticket, complicated configuration of the automatic gate and frequent maintenance of the current admission tickets can be solved by the introduction of the technology. Meanwhile, the conformity of real-name ticket-buying and automatic real-name ticket-checking is realized, and the automatic checking of travelling content and the anti-counterfeiting information of admission ticket are realized. Therefore, the technological development of access control management of large public places and modern traffics is improved by the constituting method for the access control system with the novel two-dimensional bar code.

Owner:天津市阿波罗信息技术有限公司

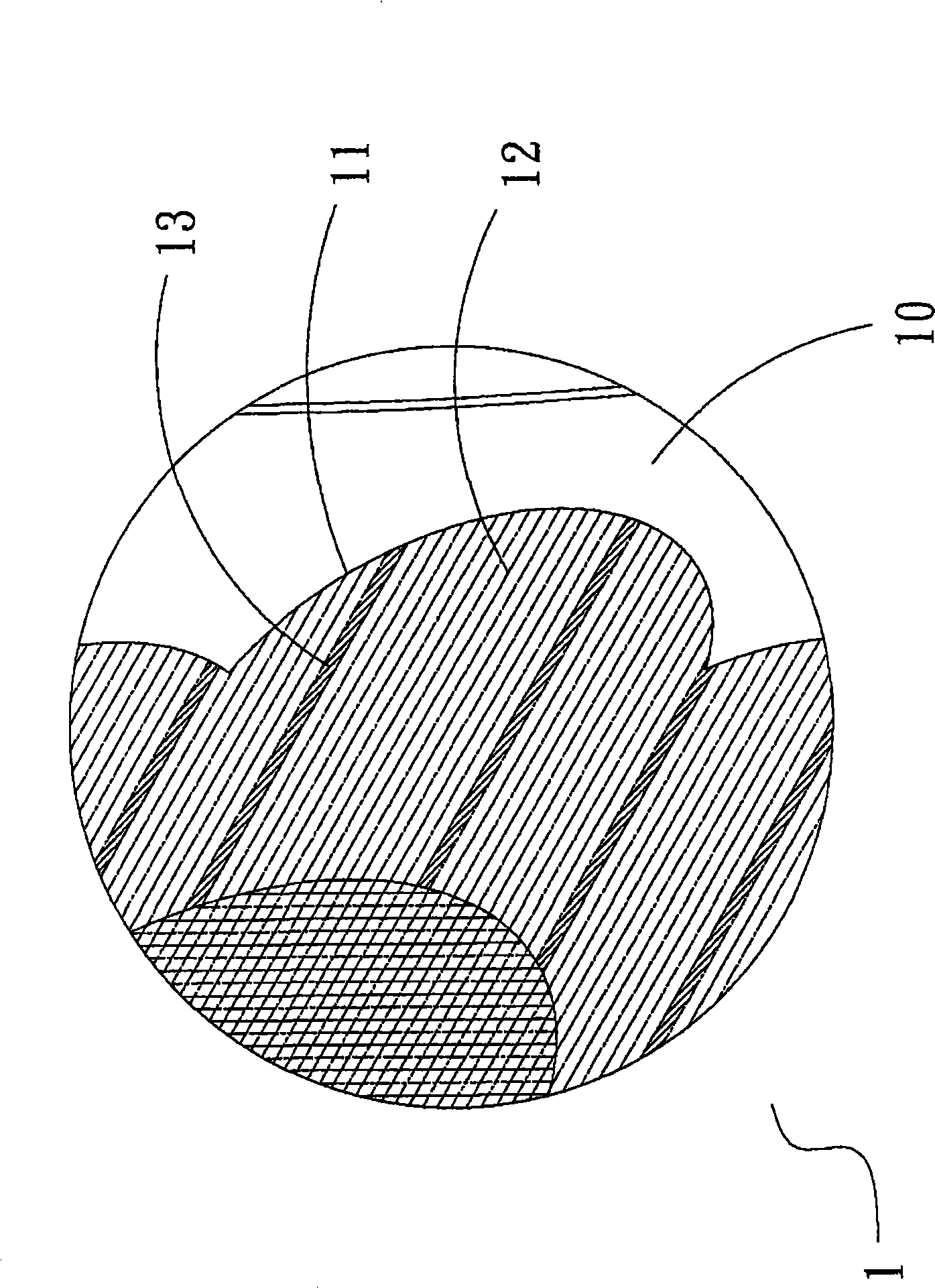

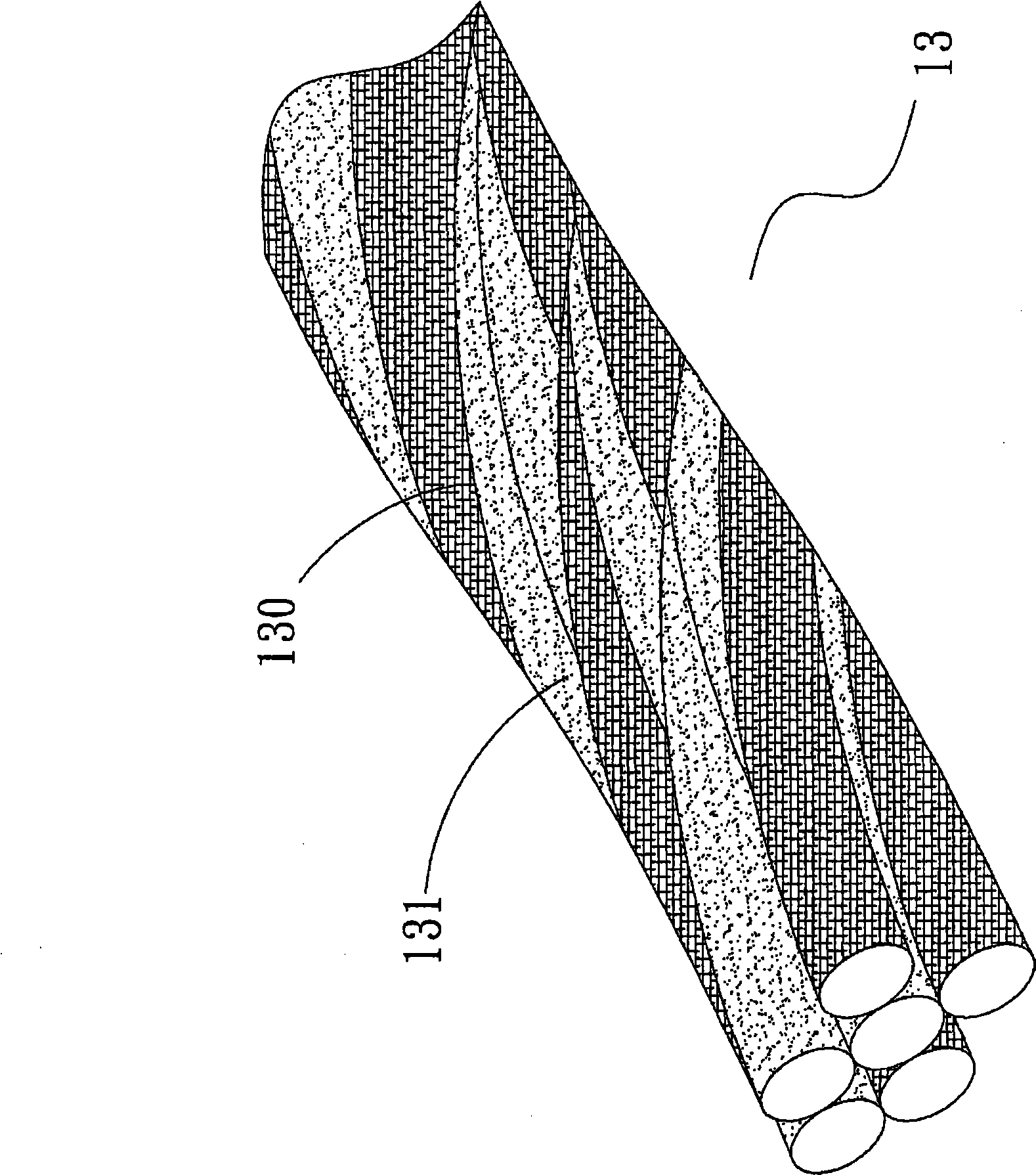

Anti-counterfeiting identification mark formed by composite fibers

The invention relates to an anti-counterfeiting identification mark, in particular to an anti-counterfeiting identification mark formed by composite fibers. The anti-counterfeiting identification mark is twisted by the composite fibers in a form of one or more fiber yarns, and the fibers forming the anti-counterfeiting mark have special characteristics through the characteristics of ultraviolet ray, infrared ray, night light, fluorescence, temperature-sensitive color change, light-sensitive color change and the like. Therefore, the anti-counterfeiting mark manufactured by the fibers with various special characteristics can generate corresponding anti-counterfeiting identification effect according to the characteristics of the composite fibers, achieve easy anti-counterfeiting identification to reduce the problems of counterfeiting and the like, and generate practical progress.

Owner:NEW PRISMATIC ENTERPRISE

Anti-counterfeiting method through combination of two-dimension code, serial number and special paper

InactiveCN105654309AHigh anti-counterfeiting levelProtect intellectual propertyCommerceThe InternetSerial code

The invention relates to an anti-counterfeiting method through combination of a two-dimension code, a serial number and special paper. Each tag is enabled to have random anti-counterfeit paper texture characteristics after completion of printing by utilizing the two-dimension code, the random serial number and special paper and is associated with a unique two-dimensional code image and a unique verification code serial number so that the objective of uniqueness can be achieved. The tag pattern is saved in a database, and the tag pattern is scheduled for comparison through the internet in product authenticity verification so as to achieve the product anti-counterfeiting effect.

Owner:李化宾

Environment-friendly laser anti-counterfeiting printing process

The invention relates to an environment-friendly and anti-counterfeiting laser printing technique, which pertains to the field of laser printing. The main point of the invention is that a plain paper is adopted by the technique, when in use, firstly an information layer of pictures and words is directly and continuously printed on the plain paper by a flexographic plate; then a bright layer is printed on the information layer of pictures and words by the flexographic plate, at the same time a laser layer of pictures and words is pressed on the bright layer by a film; the bright layer and the laser layer of pictures and words are solidified; finally with the continuous solidification of the bright layer and the laser layer of pictures and words, pressed films are continuously and immediately peeled off from the paper by a peeling device. The environment-friendly and anti-counterfeiting laser printing technique of the invention has an optimization and improvement on the existing technical process and has the advantages that by adopting the laser printing technique of the invention, printing can be directly processed on the plain paper, industrialized and continuous printing can be realized, and the product printed by the invention can present the effect of node laser. Furthermore, the laser printing technique of the invention is far superior to the products of the prior art in the aspects of practicability, environmental friendliness and economical efficiency.

Owner:ZIBO TAIBAO FP PROD CO LTD

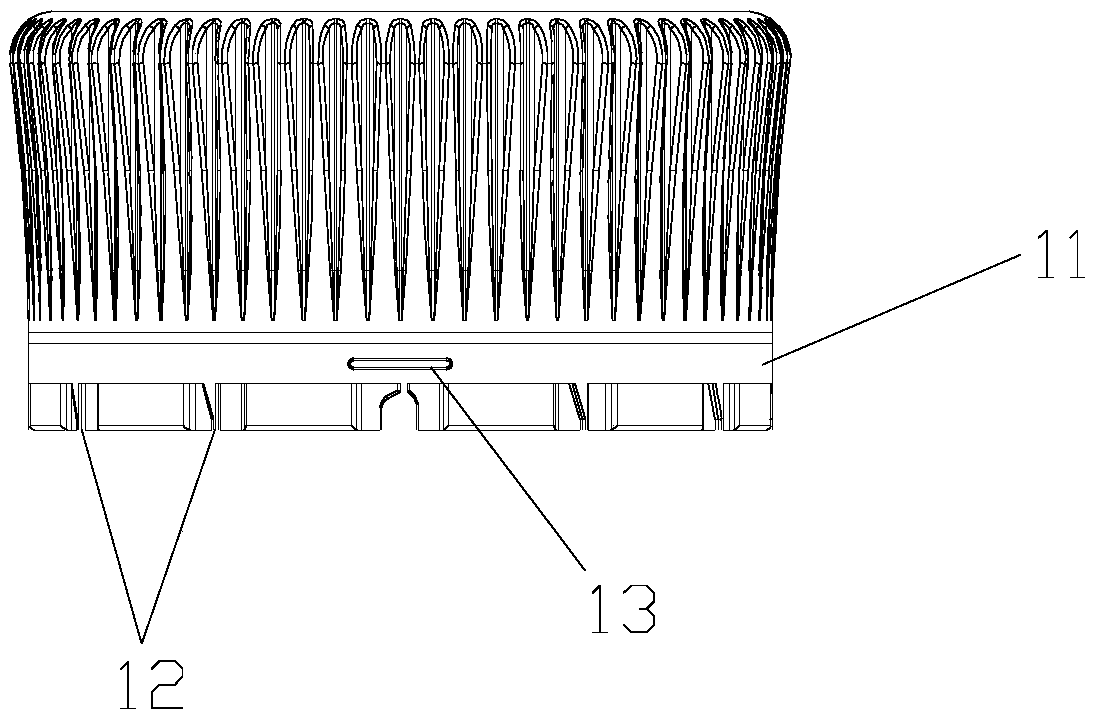

Disposal false proof buckle for fish products

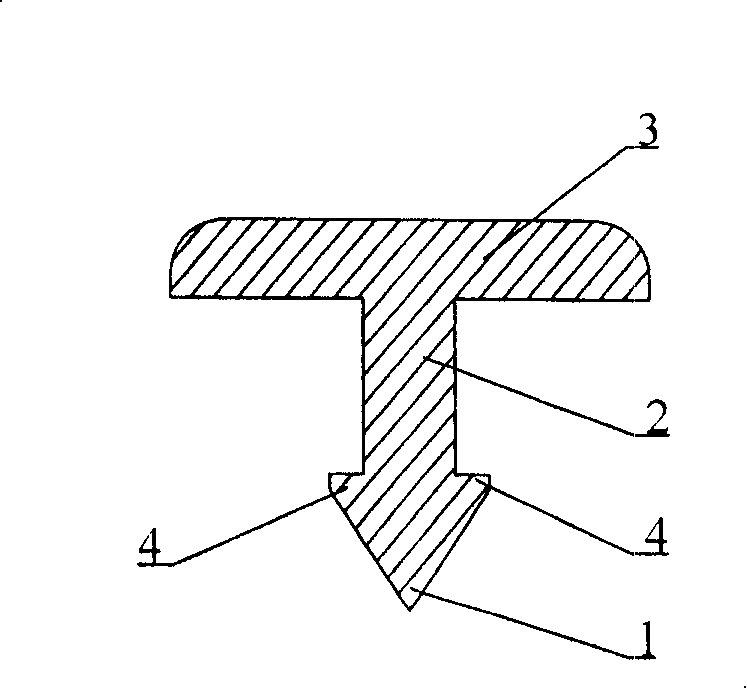

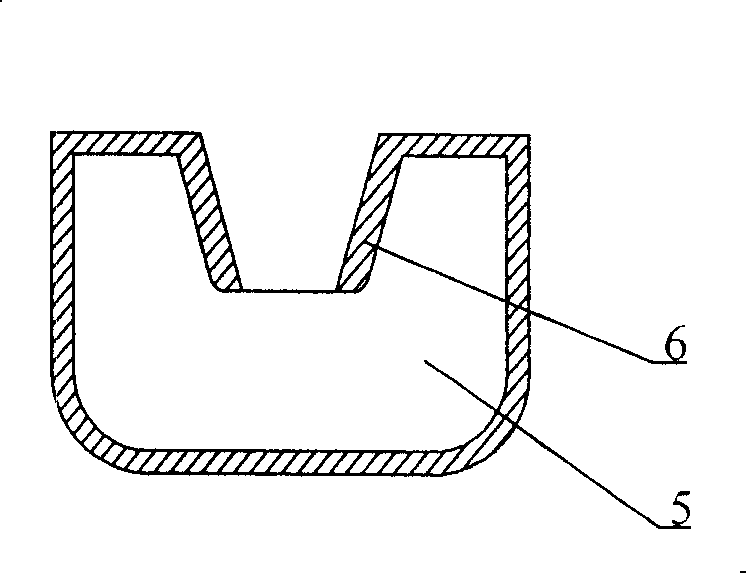

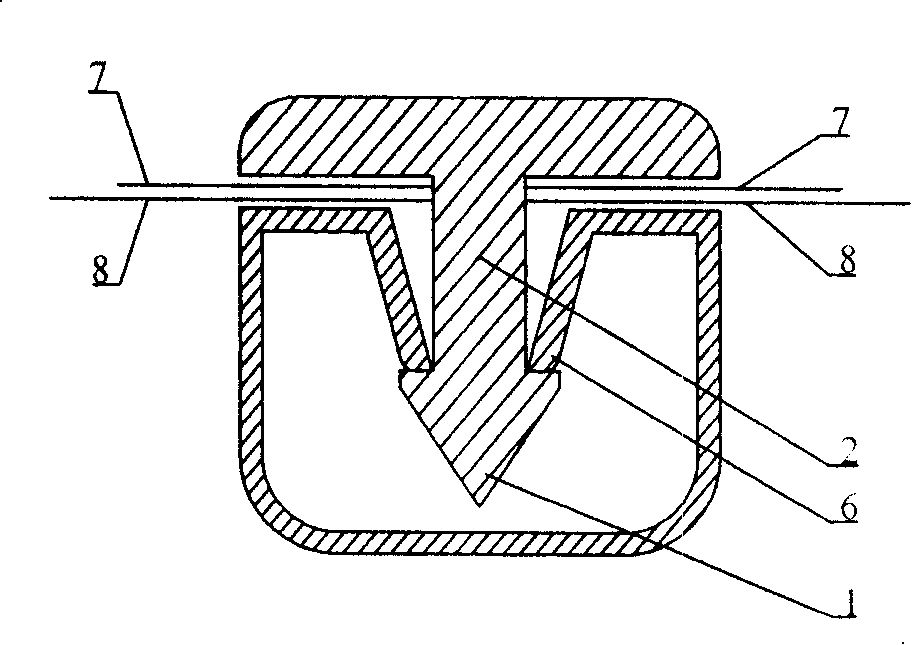

InactiveCN101226707ASimple and efficient operationLow manufacturing costStampsIdentification meansFish finFastener

The invention relates to a disposable anti-counterfeiting fastener capable of being applied to fish products, which is composed of a barbed nail and a recess. The barbed nail is composed of a nail point, a nail bar and a nail head, wherein the nail point is provided with barbs. The recess contains a concave cavity, the mouth portion of the cavity is in the shape of an inverted cone, and the size of the mouth portion of the cavity matches with that of the barbs. The invention is simple and convenient in operation, when using, a printed brand label penetrates the nail point of the barbed nail and is fixed on the nail bar, then the nail point is used to puncture fins of a fish body, and further the nail body is inserted in the concave cavity of the recess. The invention is low in manufacture cost and small and simple in structure, the combination of the barbed nail and the recess is in the shape of a clasp with light weight, and the invention is applied to live fishes without bringing any troubles to the floating of the fishes. Because the barbed structure is employed, the barbed nail can not be reused after being extracted, which achieves the effect of anti-counterfeiting.

Owner:金泽邦

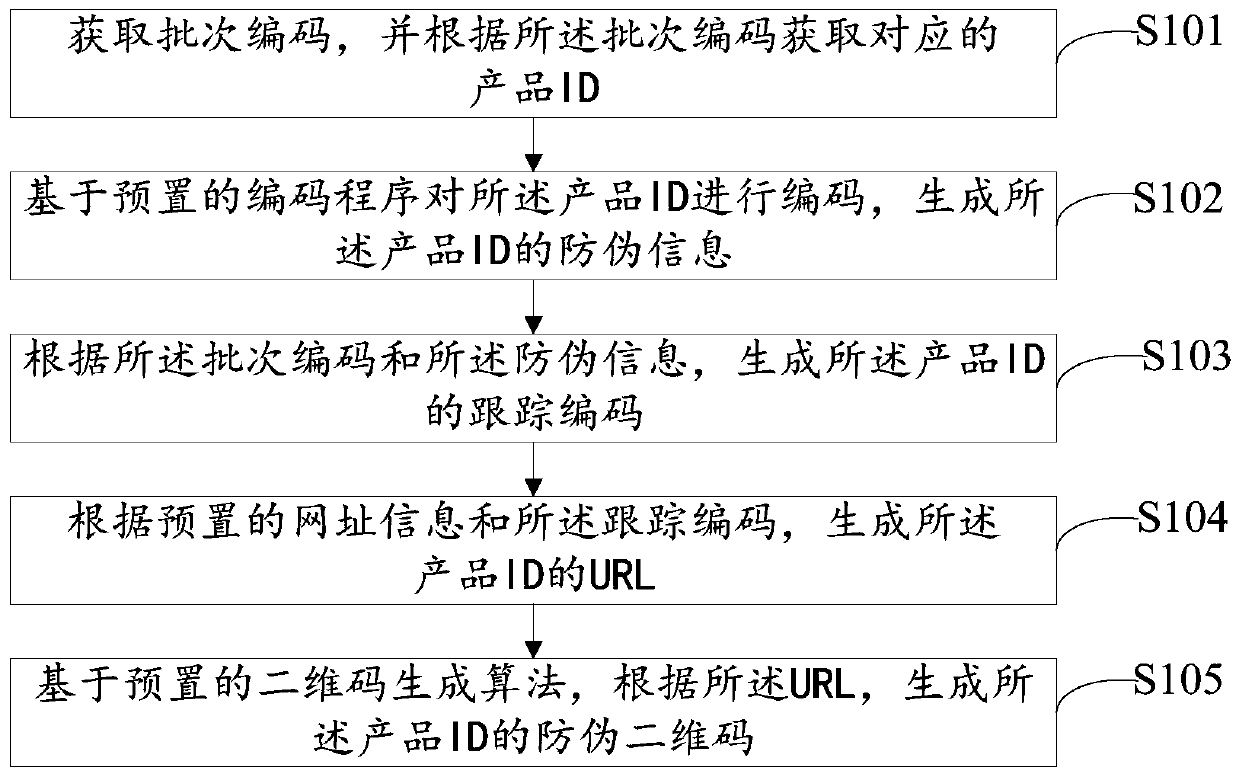

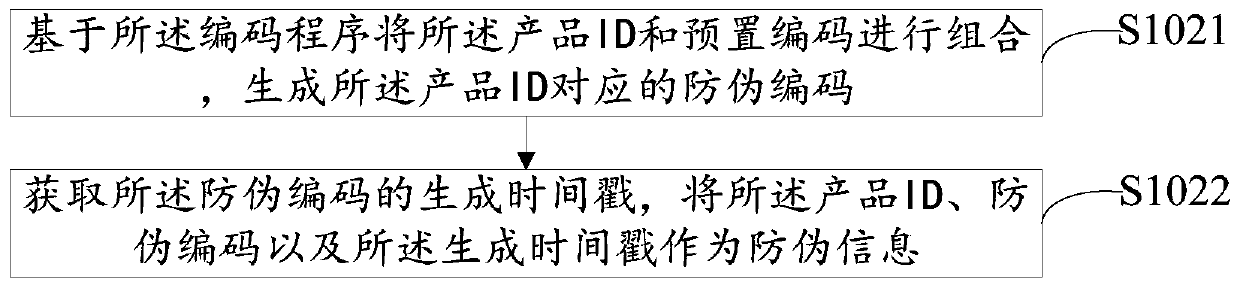

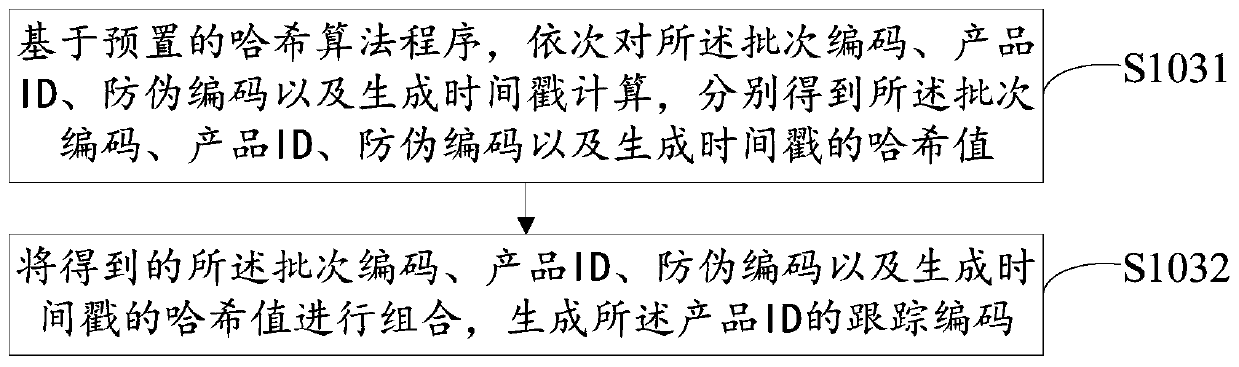

Anti-counterfeiting two-dimensional code generation method and device, server and storage medium

ActiveCN111539502AAchieve anti-counterfeiting effectNatural language data processingCommerceCode generationSoftware engineering

The invention relates to the field of data security, and provides an anti-counterfeiting two-dimensional code generation method and device, a server and a computer readable storage medium. The methodcomprises: obtaining a batch code, and obtaining a corresponding product ID according to the batch code; encoding the product ID based on a preset encoding program to generate anti-counterfeiting information of the product ID; generating a tracking code of the product ID according to the batch code and the anti-counterfeiting information; generating a URL of the product ID according to preset website information and the tracking code; and based on a preset two-dimensional code generation algorithm, generating an anti-counterfeiting two-dimensional code of the product according to the URL, generating the URL from the anti-counterfeiting information of the product ID, and taking the generated URL as the generation information of the two-dimensional code, thereby achieving an anti-counterfeiting effect.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

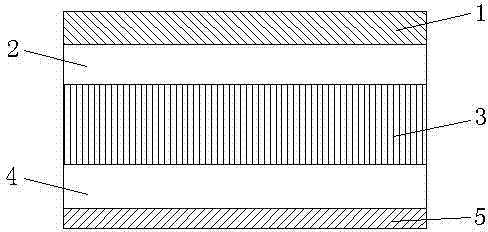

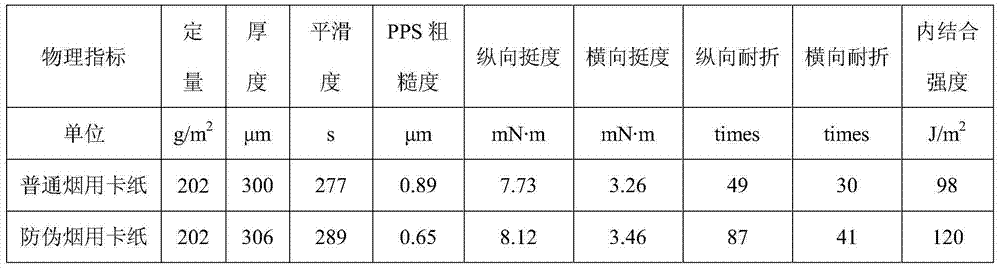

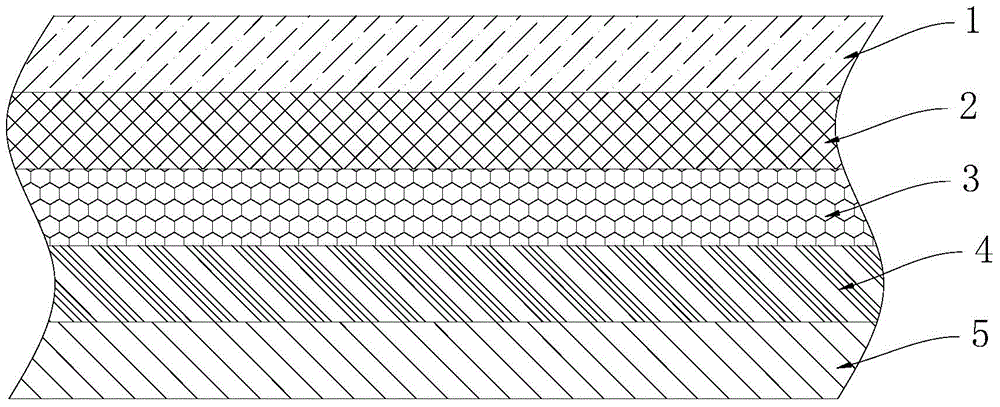

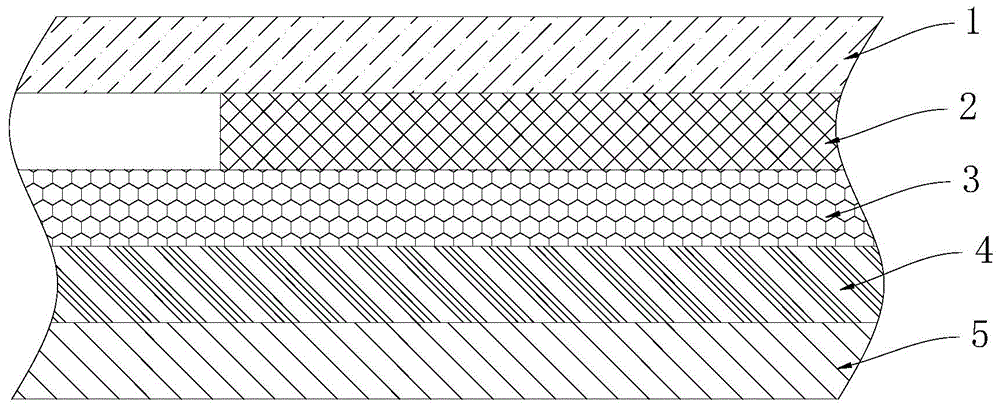

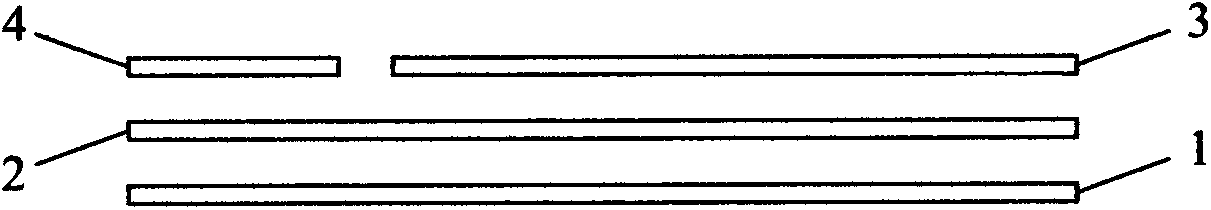

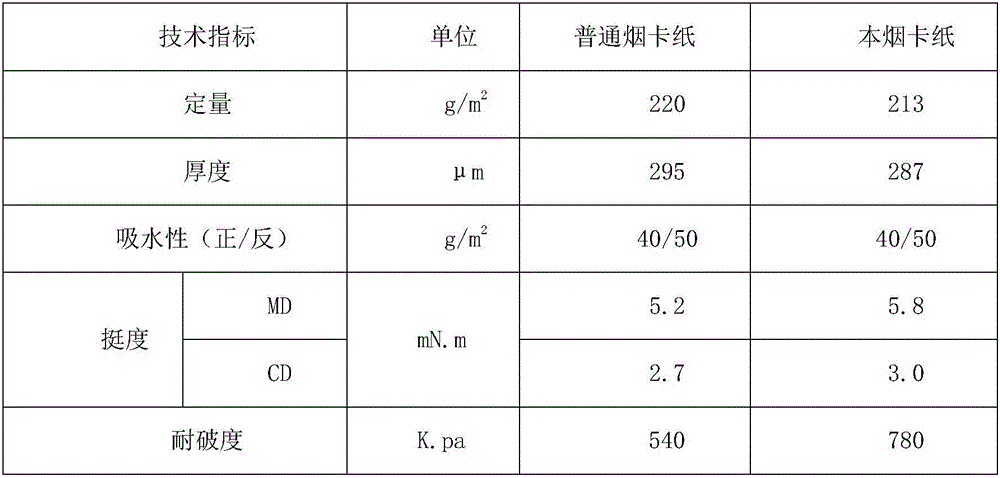

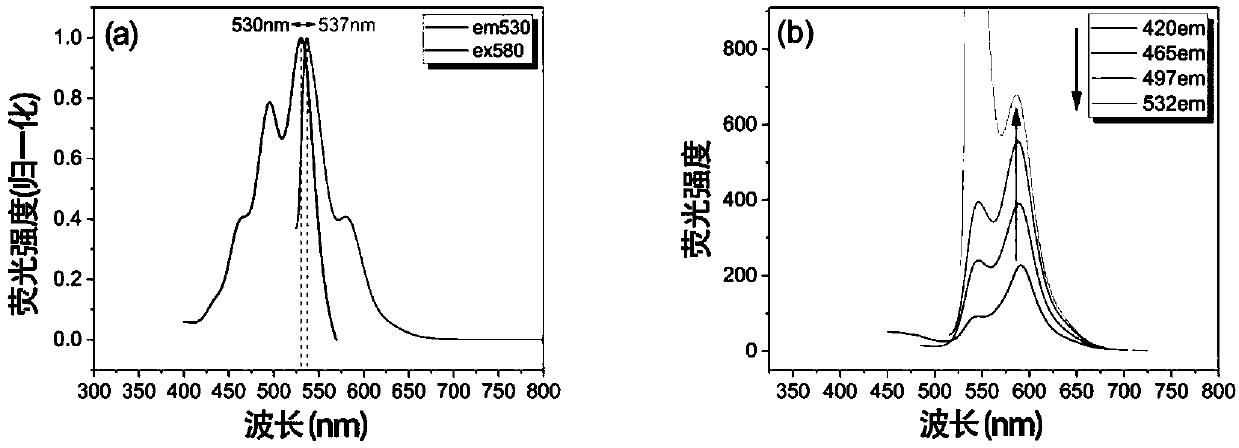

Paperboard for anti-counterfeit cigarette

InactiveCN103790069AIncrease bulkAchieve anti-counterfeiting effectCoatings with pigmentsSpecial paperSurface layerPaperboard

The invention discloses a paperboard for an anti-counterfeit cigarette. The paperboard comprises a surface layer, a core layer and a bottom layer, wherein the surface layer is bleached chemical wood pulp, the core layer is chemi-mechanical pulp and bleached chemical wood pulp, and the bottom layer is bleached chemical wood pulp and unbleached pulp. The bleached chemical wood pulp in the surface layer comprises 30-50% of bleached chemical softwood pulp and 50-70% of bleached chemical hardwood pulp in percentage by weight. The core layer comprises 60-90% of the chemi-mechanical pulp and 10-40% of the bleached chemical wood pulp in percentage by weight. The bottom layer comprises 60-95% of the bleached chemical wood pulp and 5-40% of the unbleached pulp in percentage by weight. According to the paperboard disclosed by the invention, as the bottom layer adopts the unbleached pulp and the bleached chemical pulp, paperboards in different colors can be obtained by adjusting the proportion of the unbleached pulp and the bleached chemical wood pulp so as to realize the anti-counterfeit effect. The paperboard is not easy to simulate. The paperboard disclosed by the invention is small in investment, and the production cost can be greatly lowered.

Owner:万国纸业太阳白卡纸有限公司

Heat-sensitive label and preparation method thereof

InactiveCN104900140AServe as information instructionsPlay the role of identificationStampsPaper/cardboard layered productsSurface layerIsolation layer

The invention discloses a heat-sensitive label which comprises heat-sensitive paper, wherein an isolation layer is coated on one side, opposite to a heat-sensitive coating, of the heat-sensitive paper; an ink layer with a preset diagram text is printed on the isolation layer; a glue layer is coated on the ink layer; release paper is bonded onto the glue layer. When the heat-sensitive label is used, the release paper is removed first, and then one side, with the glue layer, of the heat-sensitive label is adhered to a product, wherein the heat-sensitive paper is located on the surface layer, when the heat-sensitive coating is heated, the discoloration occurs so as to play the role of information indication and identification, when the heat-sensitive paper is removed, the ink layer is firmly adhered on the product under the action of the glue layer, and represents the preset diagram text so as to achieve a certain anti-counterfeit effect; the ink layer and the glue layer of the heat-sensitive label are unlikely to remove, so that the heat-sensitive label is more reliable.

Owner:SHENZHEN MOTAI ELECTRONICS MATERIAL CO LTD

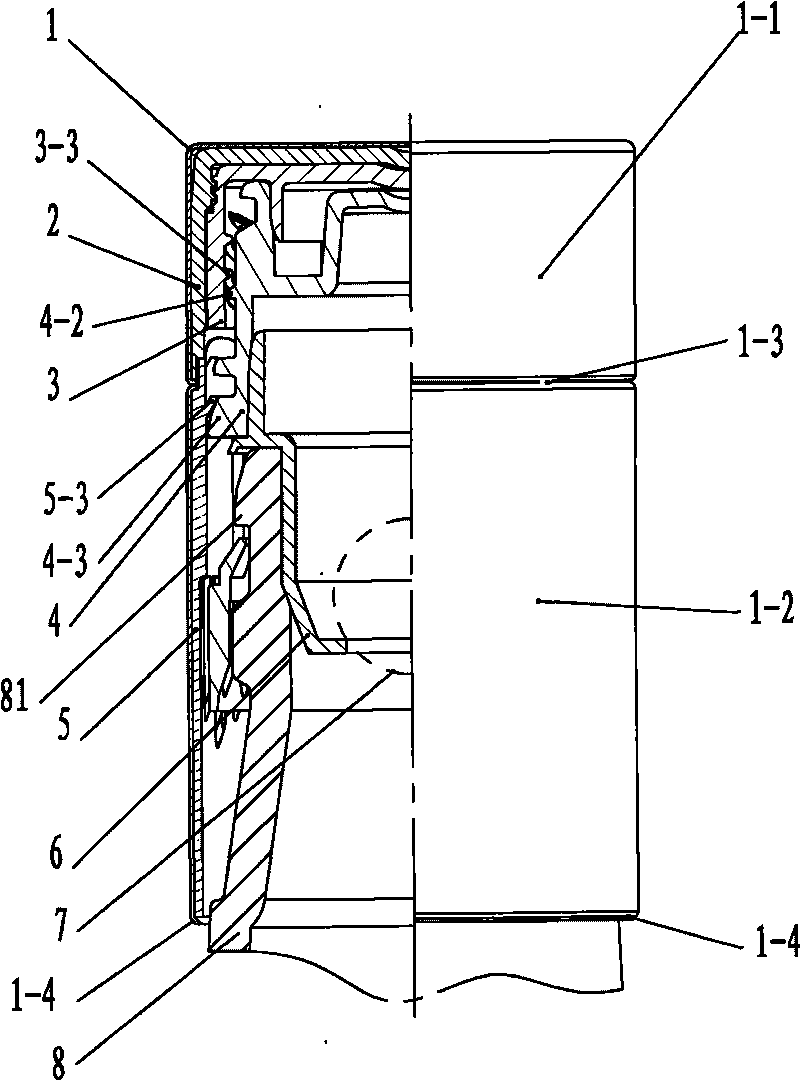

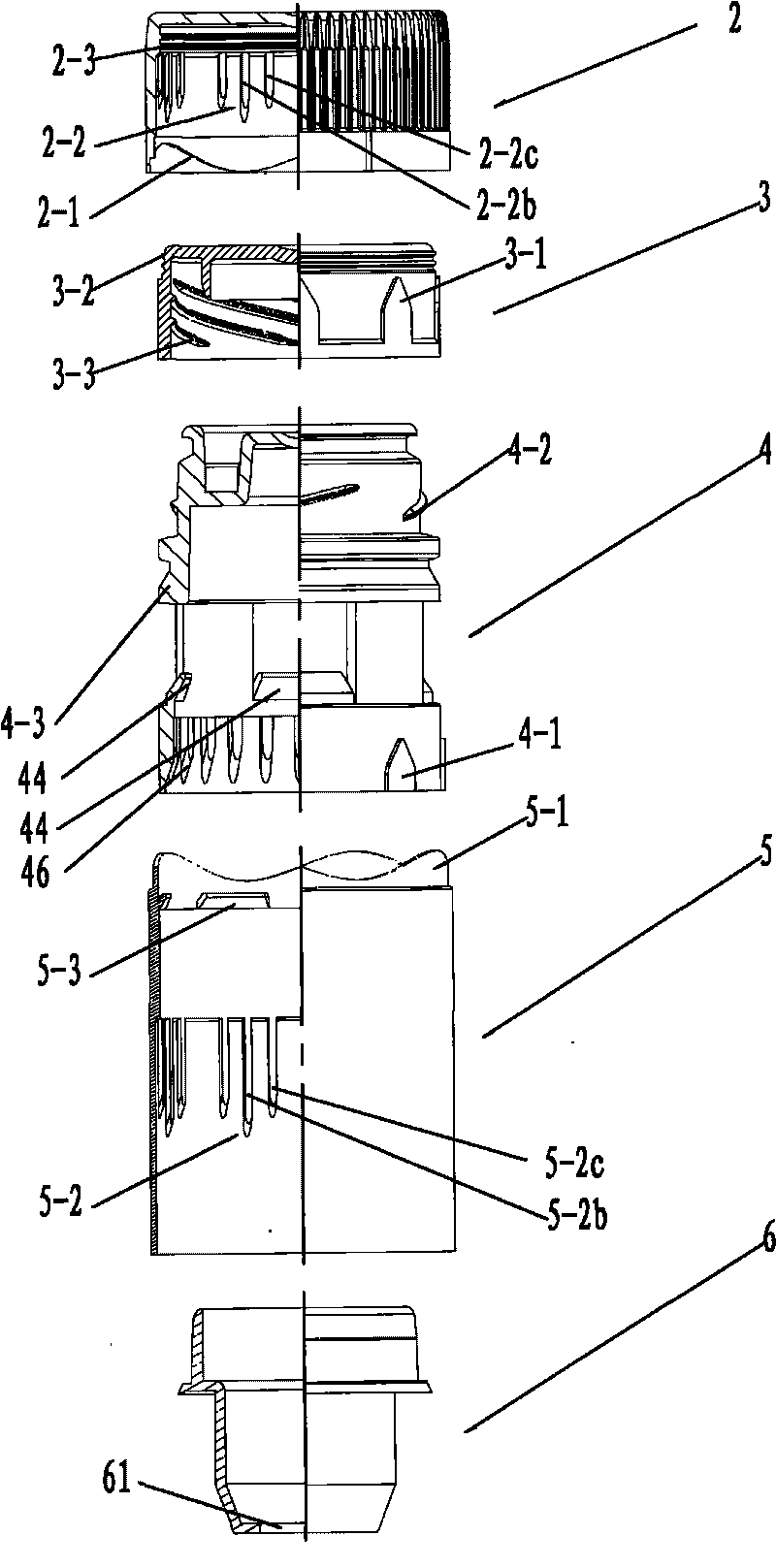

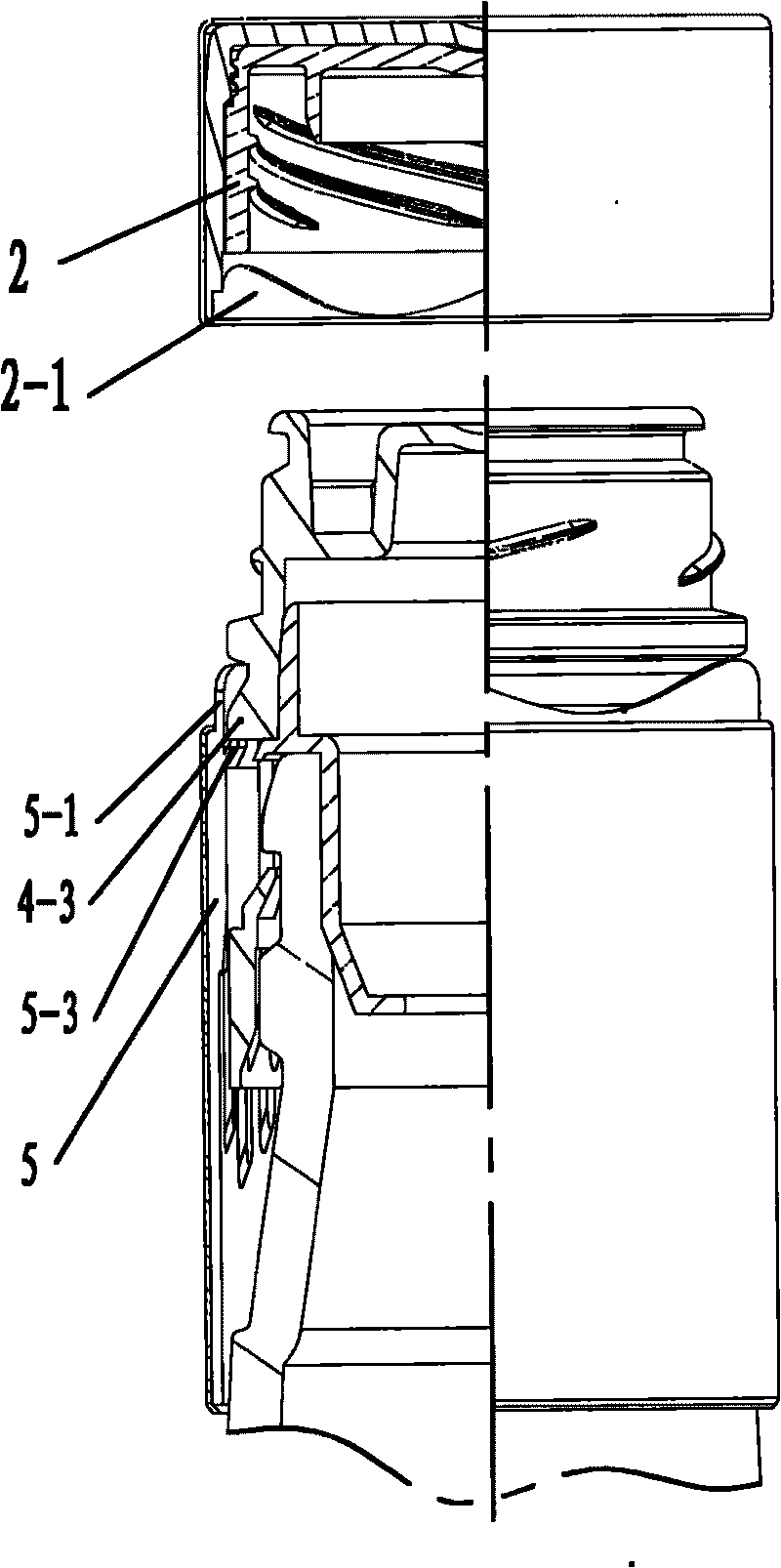

Clamping-type split-combination anti-fake bottle cap

The invention provides a clamping-type split-combination anti-fake bottle cap, which comprises a combination sleeve, an inner cap, an outer cap and a split ring, wherein the lower end of the inner side of the outer cap is provided with a curved concave part of which the upper edge is in a sinusoid shape; the top end of the split ring is provided with a curved convex part of which the upper edge is in a sinusoid shape; the curved convex part and the curved concave part are matched; the upper end of the inner side of the split ring is provided with a plurality of clamping jaws; and the clamping jaws are positioned on the upper edge of a convex part of the combination sleeve. The clamping-type split-combination anti-fake bottle cap indicates that the bottle cap is in an opened state through the downward movement of the split ring, and related components are unnecessary to be made of aluminum, so the bottle cap is low in cost. The convex part on the combination sleeve can prevent the clamping jaws from returning to original positions again under the action of external force after moving downwards, so the opened and unopened states of the bottle cap can be obviously differentiated. The bottle cap can be used for bottles with no boss on bottlenecks and can still achieve anti-fake effects.

Owner:HICAP CLOSURES CO LTD

Anti-counterfeiting hot-stamping method for two-dimensional codes

InactiveCN106608123AAchieve anti-counterfeiting effectIncrease metallicPattern printingOther printing apparatusInformation layerHot stamping

The invention discloses an anti-counterfeiting hot-stamping method for two-dimensional codes. The anti-counterfeiting hot-stamping method comprises the following steps: step 1, designing bottom-layer anti-counterfeiting patterns and two-dimensional anti-counterfeiting patterns; step 2, electroplating the bottom-layer anti-counterfeiting patterns onto a nickel plate; step 3, selecting a base film; step 4, coating release coating on the base film; step 5, coating information-layer coating on the base film; step 6, stamping bottom-layer anti-counterfeiting patterns on the nickel plate onto the base film; step 7, coating a medium containing zinc sulfide on the base film; step 8, printing the two-dimensional anti-counterfeiting patterns onto the base film, wherein centers of the two-dimensional anti-counterfeiting patterns are superposed with those of the bottom-layer anti-counterfeiting patterns; step 9, plating aluminum on the base film; and step 10, coating an adhesive layer on the base film. According to the anti-counterfeiting hot-stamping method disclosed by the invention, the two-dimensional anti-counterfeiting patterns are stamped onto original package of products, so that beautiful and anti-counterfeiting effects of product appearances can be achieved, and the original package of the products is not changed.

Owner:深圳清松金泽科技开发有限公司

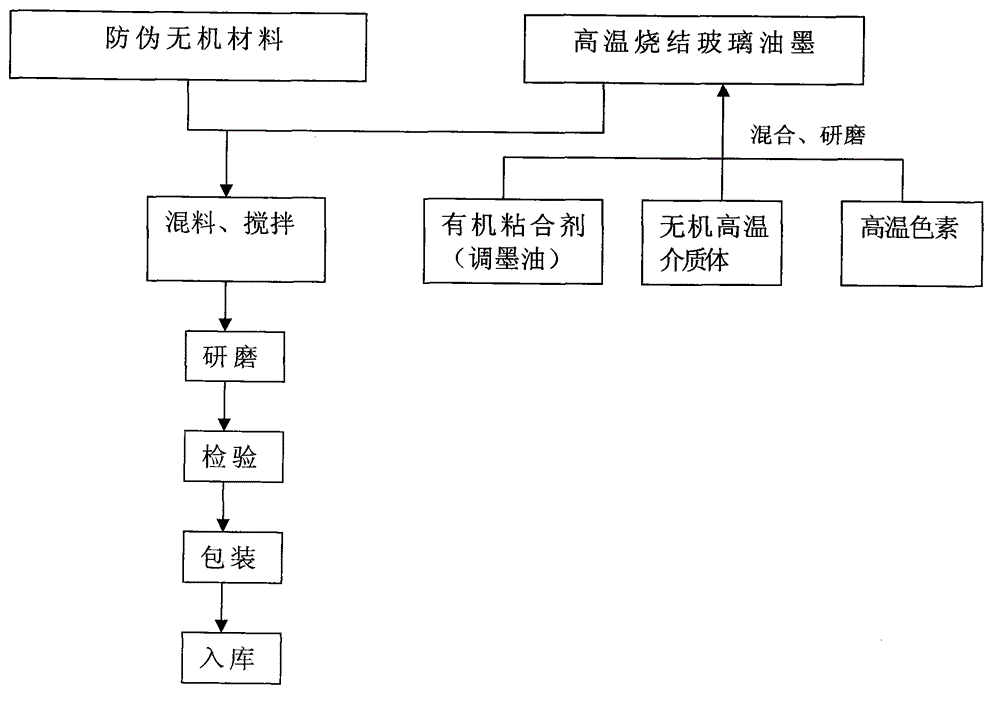

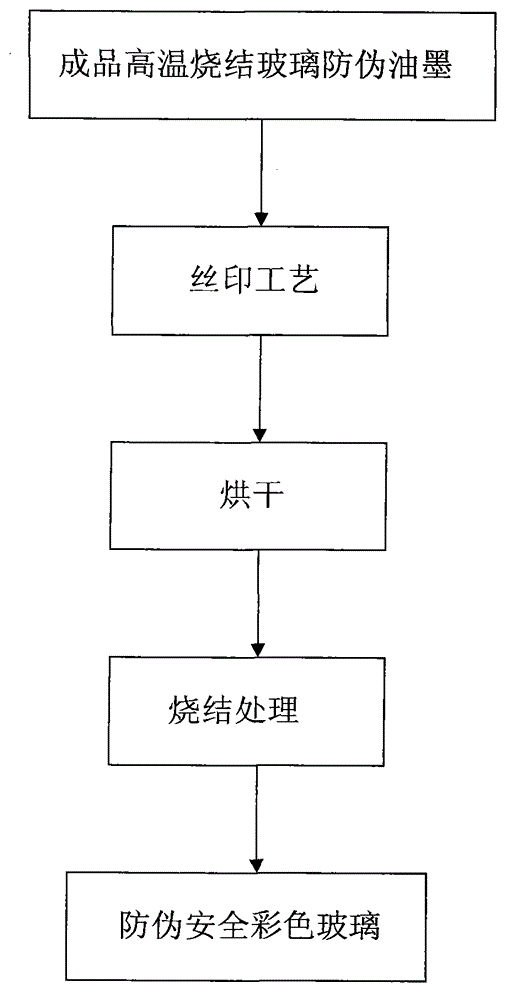

Colorful anti-forgery ink for high temperature sintering toughened glass and microcrystalline glass and use method thereof

InactiveCN103183981AAchieve anti-counterfeiting effectImprove anti-counterfeiting effectInksUltraviolet lightsToughened glass

The invention relates to high temperature sintering glass colorful ink taking inorganic materials as main materials, which serves as a link medium (medium body), contains function materials with a reflection effect to an ultraviolet light source and other light sources, and is printed or sprayed and then subjected to 530-750 DEG C high temperature sintering technology so as to be compounded onto toughened glass or microcrystalline glass and combined permanently and firmly with the glass. Just like a watermark of RMB paper money, an anti-forgery pattern appears under irradiation of ultraviolet light, so that the anti-forgery effect for the glass can be achieved. The anti-forgery glass ink disclosed by the invention is sintered onto the surface of the glass at high temperature, so that the anti-forgery glass ink cannot be erased from the glass and the better anti-forgery effect can be achieved.

Owner:深圳市奥迪博士科技有限公司

Pearlescent pigment anti-fake cigarette paper and manufacturing method thereof

InactiveCN103498386AImprove retentionSolve the low retention rateNon-fibrous pulp additionSpecial visual effect coatingsPapermakingPaper production

The invention discloses pearlescent pigment anti-fake cigarette paper and a manufacturing method thereof. Visually-visible pearlescent pigments are uniformly distributed on the front or on the front and the back of the pearlescent pigment anti-fake cigarette paper, and have scattered twinkling lightspots. The method includes adding the pearlescent pigments after chemical pretreatment into fiber size or filler which is a main raw material for production of the cigarette paper, and executing normal papermaking processes to enable the pearlescent pigments to be added in the cigarette paper; or adding the pearlescent pigments after chemical pretreatment into a surface sizing agent, and forming a pearlescent pigment anti-fake marker on the front of the cigarette paper. By pretreating the pearlescent pigments, the technical quality problem that the pearlescent pigments are low in retention rate, uniform in distribution, poor in binding force and the like is solved; the pearlescent pigments enable the cigarette paper to present pearlescent visual effect in bits and pieces and in various colors, and form the anti-fake marker which is obvious and attractive, so that anti-fake effect of the cigarette paper is realized; the pearlescent pigment anti-fake cigarette paper is manufactured mainly by utilizing existing cigarette paper production processes and equipment, thereby being low in cost.

Owner:HUBEI UNIV OF TECH

Anti-counterfeiting pearlescent pigment coated white cardboard and preparation method thereof

InactiveCN103485236AImprove retentionImprove adhesionCoatings with pigmentsCoatingsCardboardPapermaking

The invention discloses an anti-counterfeiting pearlescent pigment coated white cardboard and a preparation method thereof. Visible pearlescent pigments are uniformly distributed on the bottom surface of the anti-counterfeiting pearlescent pigment coated white cardboard disclosed by the invention. The pearlescent pigments after chemical pretreatment are added into a coating material or a surface sizing agent or a bottom paste, and the bottom surface of the coated white cardboard can form an anti-counterfeiting pearlescent pigment mark by virtue of coating operation or surface sizing operation or papermaking process. Through pretreatment of the pearlescent pigments, the anti-counterfeiting pearlescent pigment coated white cardboard disclosed by the invention can solve the technical quality problems of low retention rate of the pearlescent pigments, non-uniform distribution, poor binding force and the like; the visible pearlescent pigments are uniformly distributed on the bottom surface of the anti-counterfeiting pearlescent pigment coated white cardboard disclosed by the invention, a multi-color tiny spot-like pearlescent visual effect can be achieved according to different series of the pearlescent pigments, and the anti-counterfeiting mark is formed and is obvious and aesthetic, so that the anti-counterfeiting effect of the coated white cardboard can be achieved; the coated white cardboard is prepared mainly based on an existing coating device or a surface sizing device or a papermaking device in a production process flow, and the cost is low.

Owner:HUBEI UNIV OF TECH

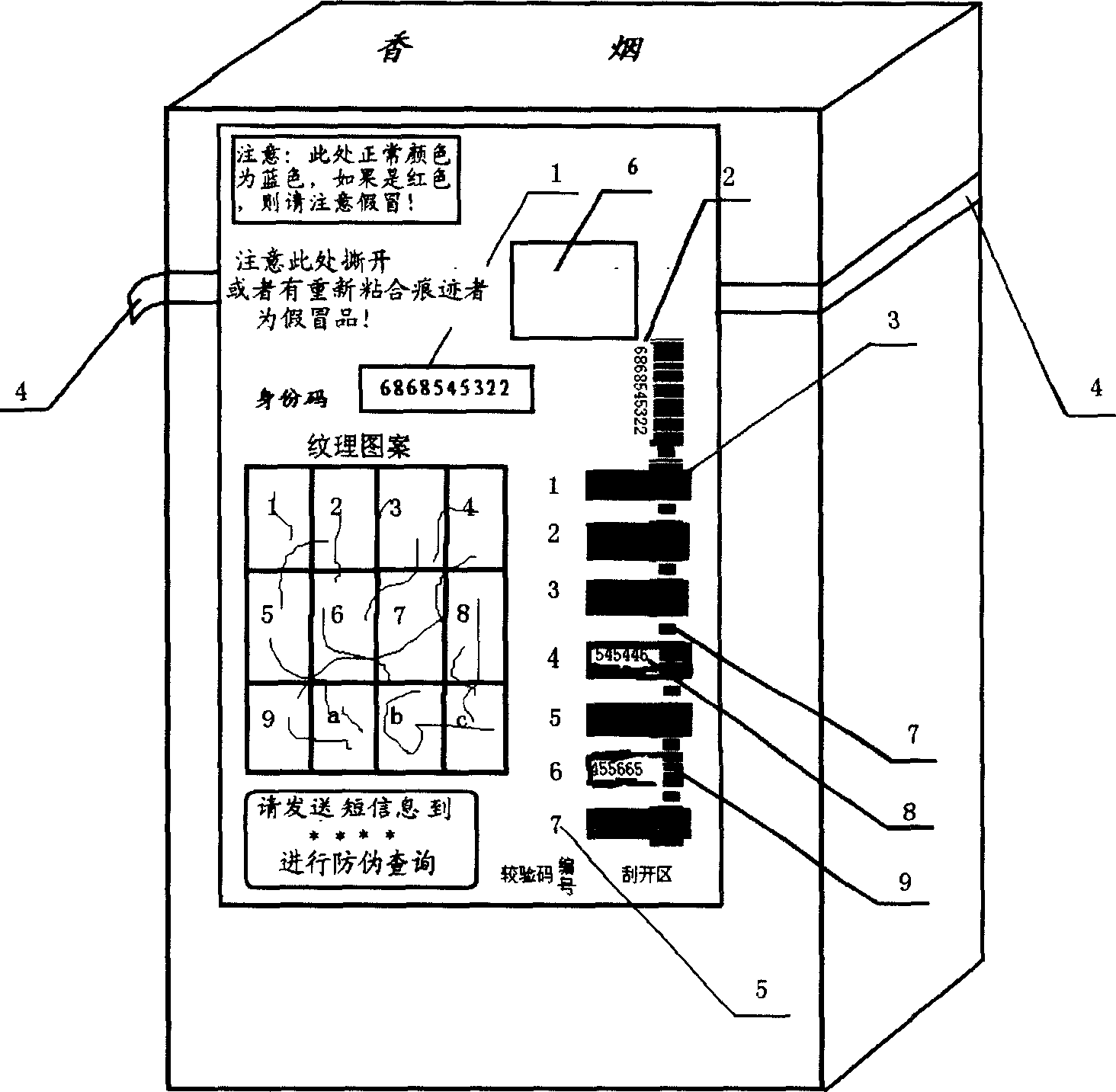

Cigarette information anti-fake mark and its inquiry system

InactiveCN1588394AA large amount of query feedback informationConvenient comparisonTelephonic communicationSpecial data processing applicationsArabic numeralsThird generation

The present invention is cigarette anti-fake mark and the method of establishing the cigarette anti-fake mark inquiring system. The cigarette anti-fake mark has several layers of codes and grains, and includes Arabic number and bar code or 2D bar code. The cigarette anti-fake mark inquiring system includes three parts of: 3G cellphone, PDA or other mobile network equipment, color message cellphone for transmitting and receiving inquiry picture information, and computer for network inquiry in Internet or other network. The three inquiry platforms have united inquiry data base system.

Owner:李红卫

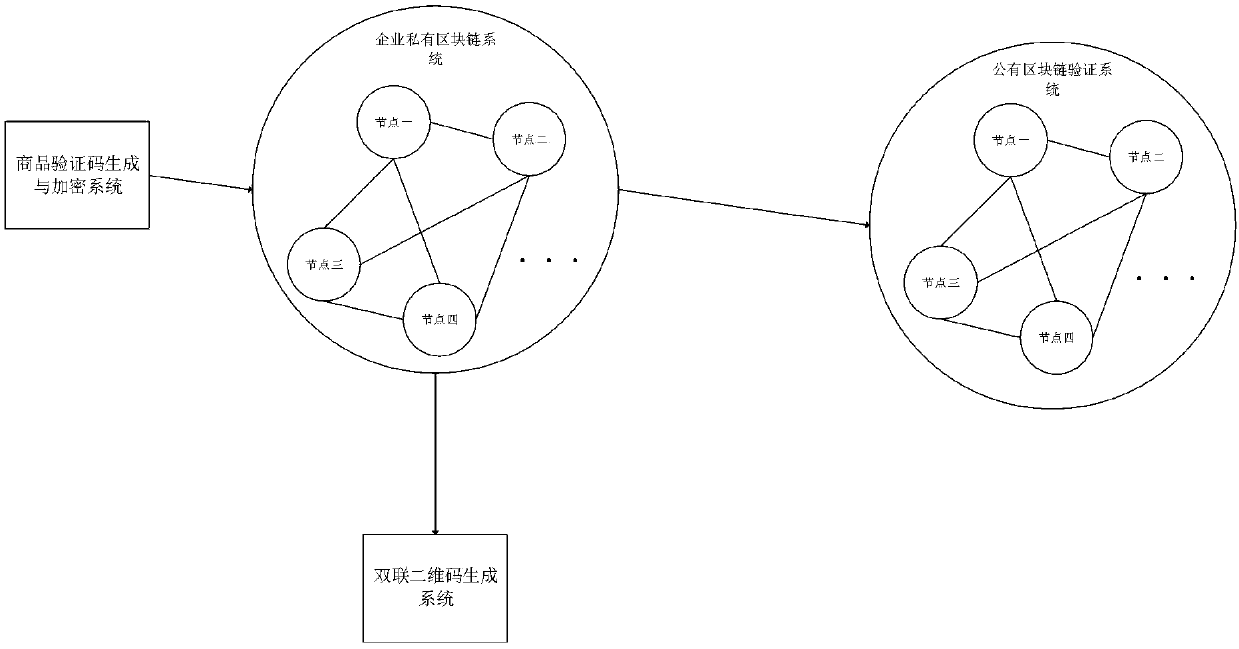

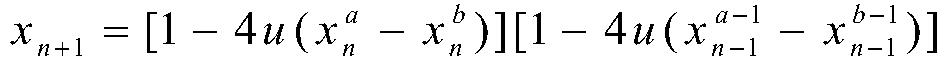

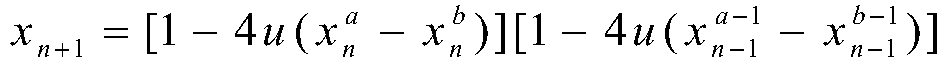

Commodity anti-counterfeiting code generation system based on block chain

InactiveCN110838907AAchieve anti-counterfeiting effectAnti-counterfeiting securityKey distribution for secure communicationSecuring communication by chaotic signalsAlgorithmReliability engineering

The invention provides a commodity anti-counterfeiting code generation system based on a block chain in the field of anti-counterfeiting codes. A layer of public information and a layer of anti-counterfeiting verification information are generated by using duplex anti-counterfeiting technology, and the anti-counterfeiting verification information is invalid after one-time verification, so that anti-counterfeiting cannot be copied, a real anti-counterfeiting effect is achieved, meanwhile, an anti-counterfeiting code cannot be copied, the verification code contains specific information of a commodity, and anti-counterfeiting is safer; verification information is verified through a public block chain, meanwhile, the verification process needs to be photographed and stored for the first time,and photographing information is returned to the public block chain to serve as a return result of subsequent verification, so that an anti-counterfeiting code cannot be copied, and a real anti-counterfeiting effect is achieved. Meanwhile, the true and false verification information is generated by using a chaotic equation, so that repeated true and false verification information is avoided.

Owner:齐爱民

Recessive antifalsification paper and preparation method thereof

InactiveCN103510427AAchieve anti-counterfeiting effectIncrease anti-counterfeiting measuresNon-fibrous pulp additionPaper coatingPulp and paper industry

The invention discloses a recessive antifalsification paper and a preparation method thereof. The recessive antifalsification paper comprises a substrate layer, wherein the substrate layer is provided with a dominant ink layer; and a recessive ink layer is arranged on the dominant ink layer. The recessive antifalsification paper prepared by the preparation method of the invention adopts the specific recessive ink layer, and can be additionally provided with a diacaustic antifalsification layer and a watermark pattern layer, so that the antifalsification measures of the antifalsification paper are effectively increased, and the antifalsification effect is improved. Different materials of the substrate are chosen to adapt to different types of antifalsification papers.

Owner:深圳市华德防伪技术开发有限公司

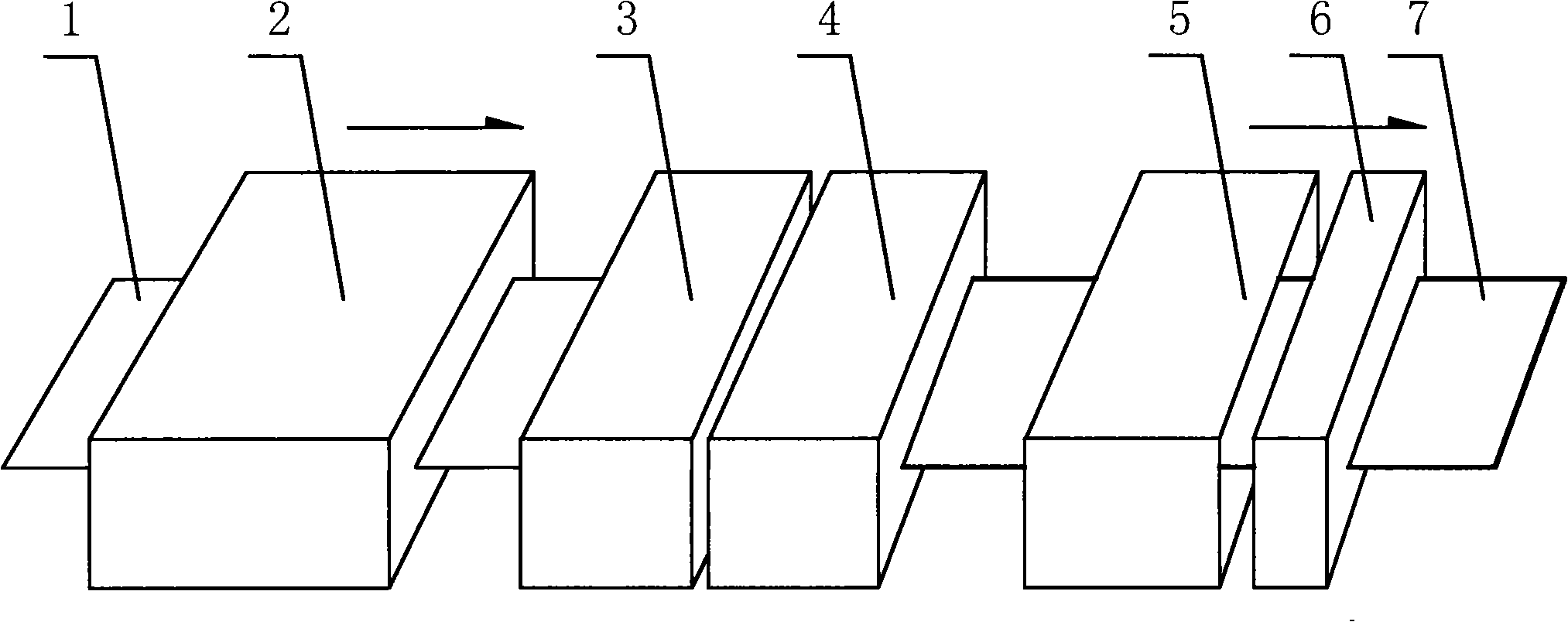

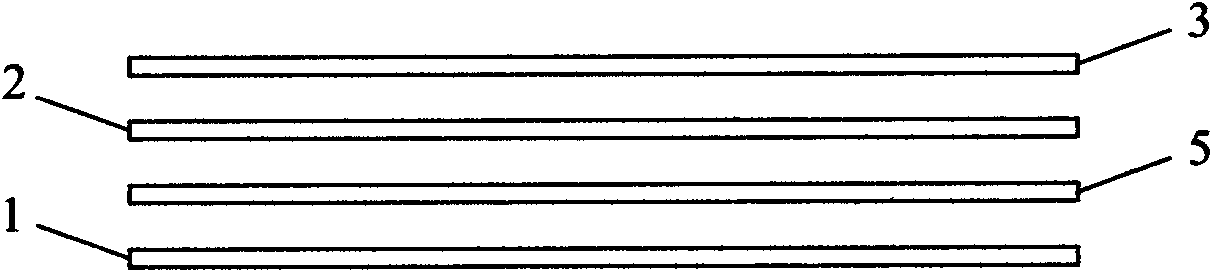

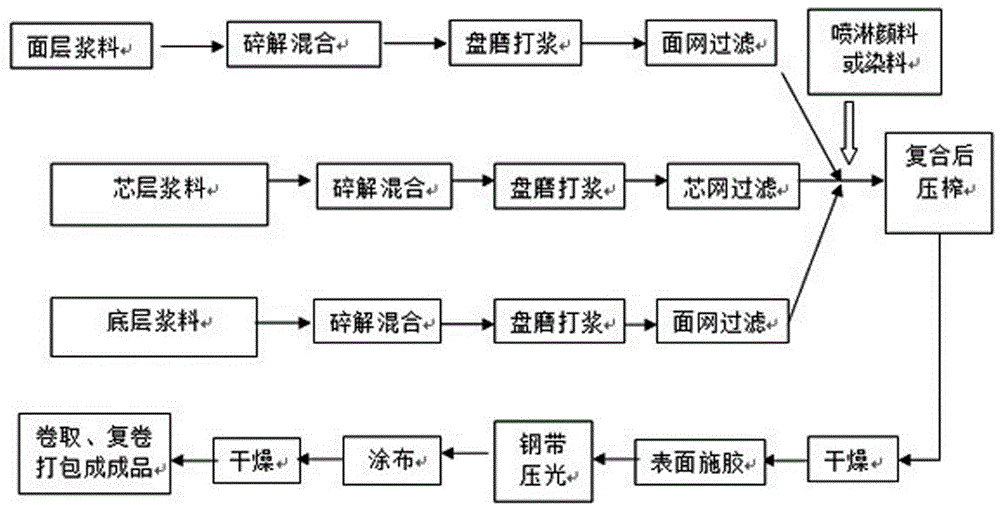

Interlayer color sprayed anti-counterfeit coating white cardboard and production process thereof

InactiveCN104631192AEasy post-processingHuge investmentNon-fibrous pulp additionCoatings with pigmentsCardboardPaper sheet

The invention discloses an interlayer color sprayed anti-counterfeit coating white cardboard. The cardboard comprises a surface layer, a core layer and a bottom layer which are overlapped sequentially, wherein colored pigment or dye is contained between the surface layer and the core layer and / or between the core layer and the bottom layer. The invention further discloses a process for producing the anti-counterfeit coating white cardboard. Compared with a surface printed anti-counterfeit technology, the anti-counterfeit coating white cardboard cannot be simply or easily counterfeited by copying or printing, and the anti-counterfeiting effect is good; compared with other embedded anti-counterfeit technology in the prior art, the anti-counterfeit coating white cardboard is subjected to interlayer color spraying in the composite layer of paper, consumers can find different colors among layers by cutting or tearing the paper, so that the anti-counterfeit effect can be achieved, the identification mode is simple and feasible, and the counterfeiting difficulty is high.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

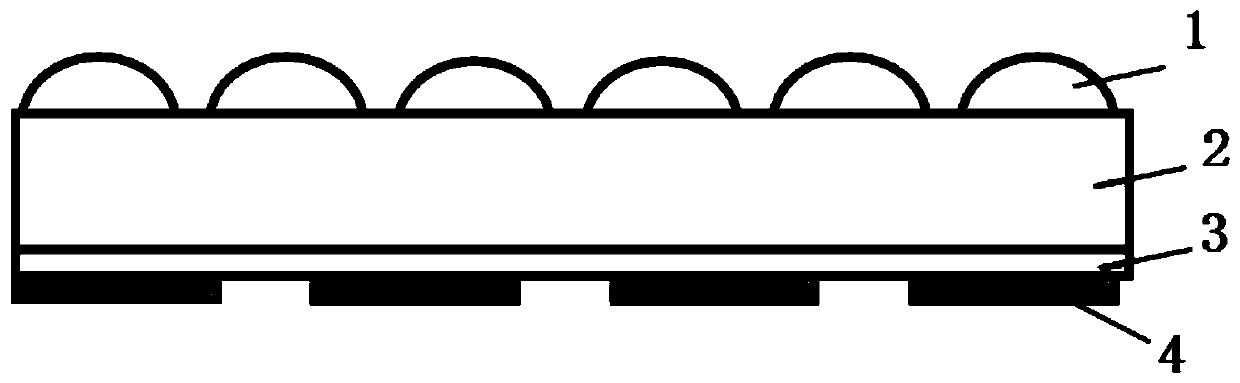

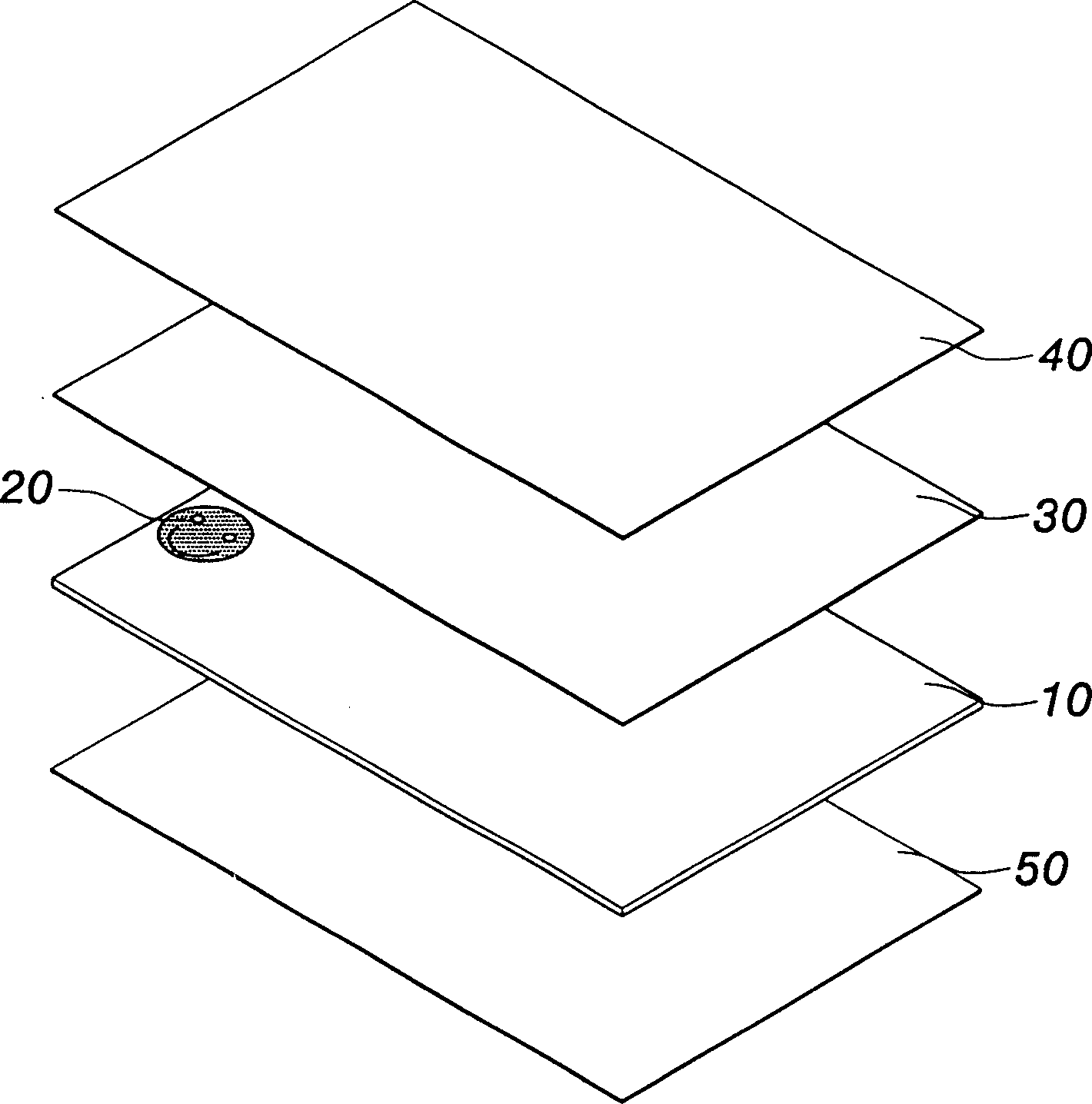

Multilayer color dynamic display anti-counterfeiting film and preparation method thereof

The invention provides a multilayer color dynamic display anti-counterfeiting film, which belongs to the technical field of anti-counterfeiting. The anti-counterfeiting film sequentially comprises a micro-lens array layer, a transparent dielectric layer I, a transparent dielectric layer II and a micro-pattern array metal layer from top to bottom, wherein the micro-pattern array metal layer comprises a light-transmitting pattern part and a light-proof metal part. The invention further provides a preparation method of the multilayer color dynamic display anti-counterfeiting film. The invention provides the multilayer color dynamic display anti-counterfeiting film based on a micro-lens array moire pattern display theory and an interference fringe theory. According to the invention, a dynamicgraph can achieve the dynamic effects of rotation, translation, floating, sinking and the like along with the change of an observation visual angle; in addition, the displayed dynamic graph is a colorgraph; the graph resolution is better; the display is more obvious; and the dynamic graph is expected to be applied to a new generation of anti-counterfeiting technology.

Owner:四川芯辰光微纳科技有限公司

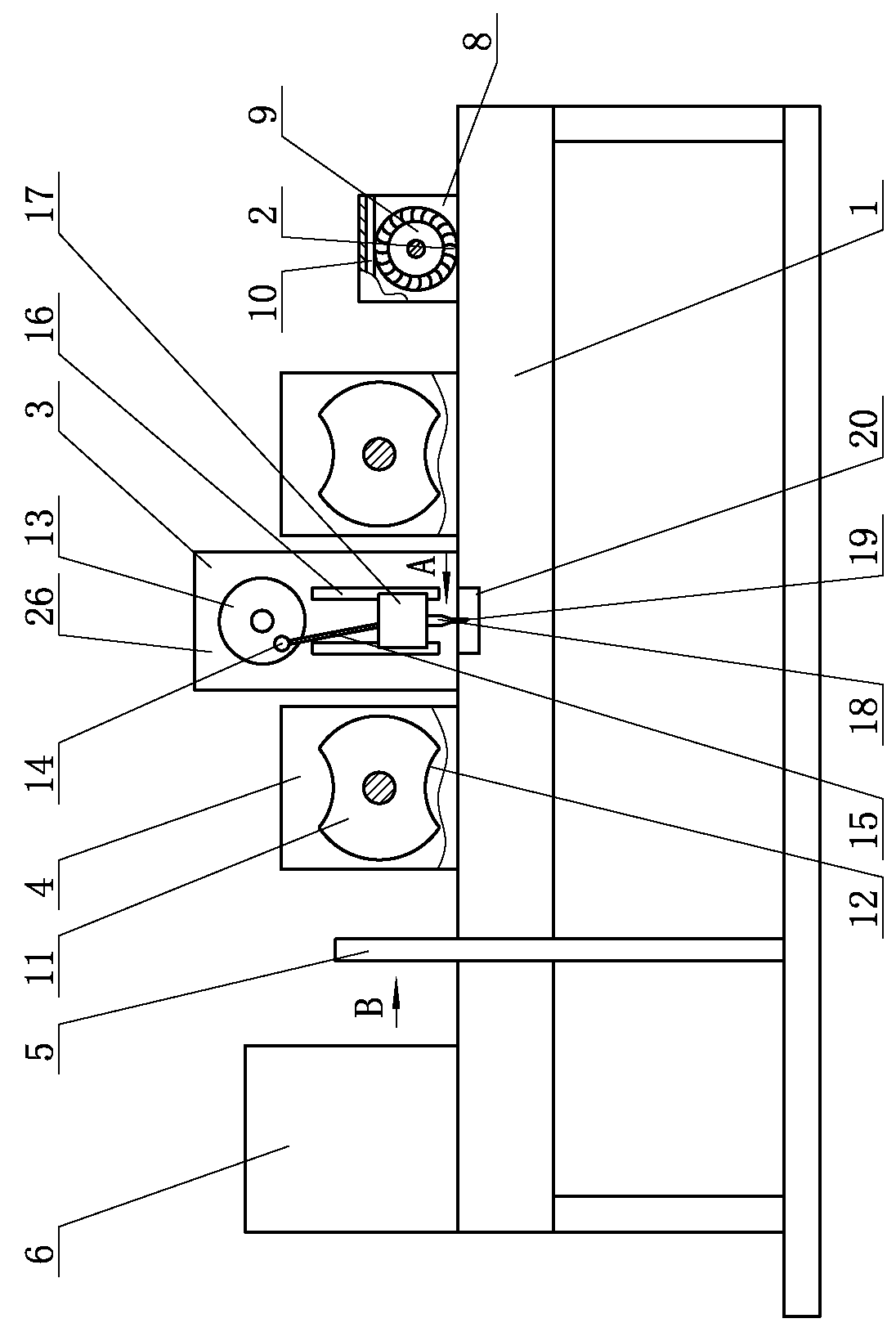

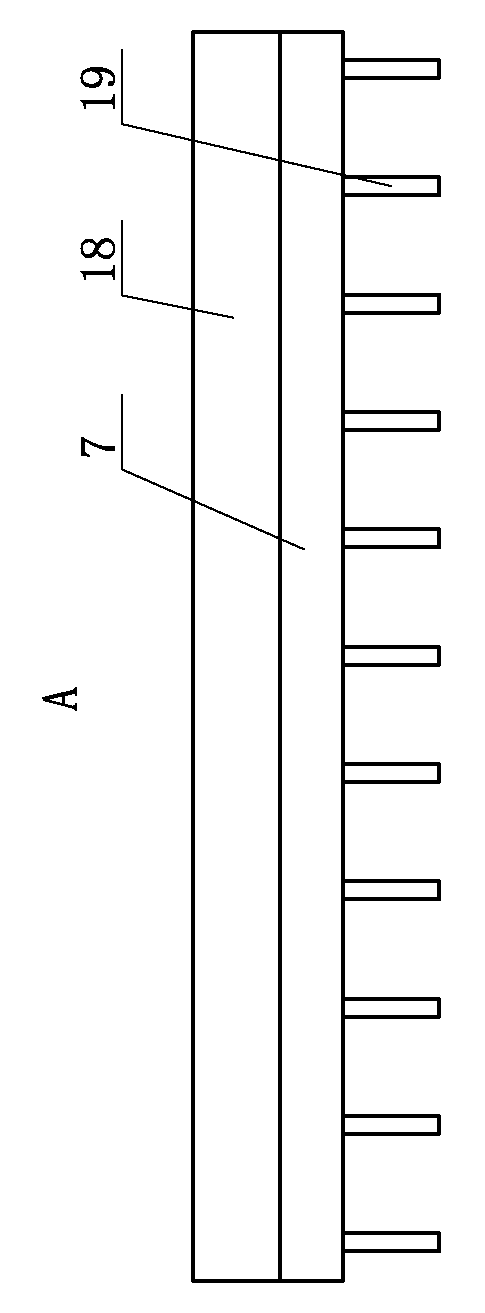

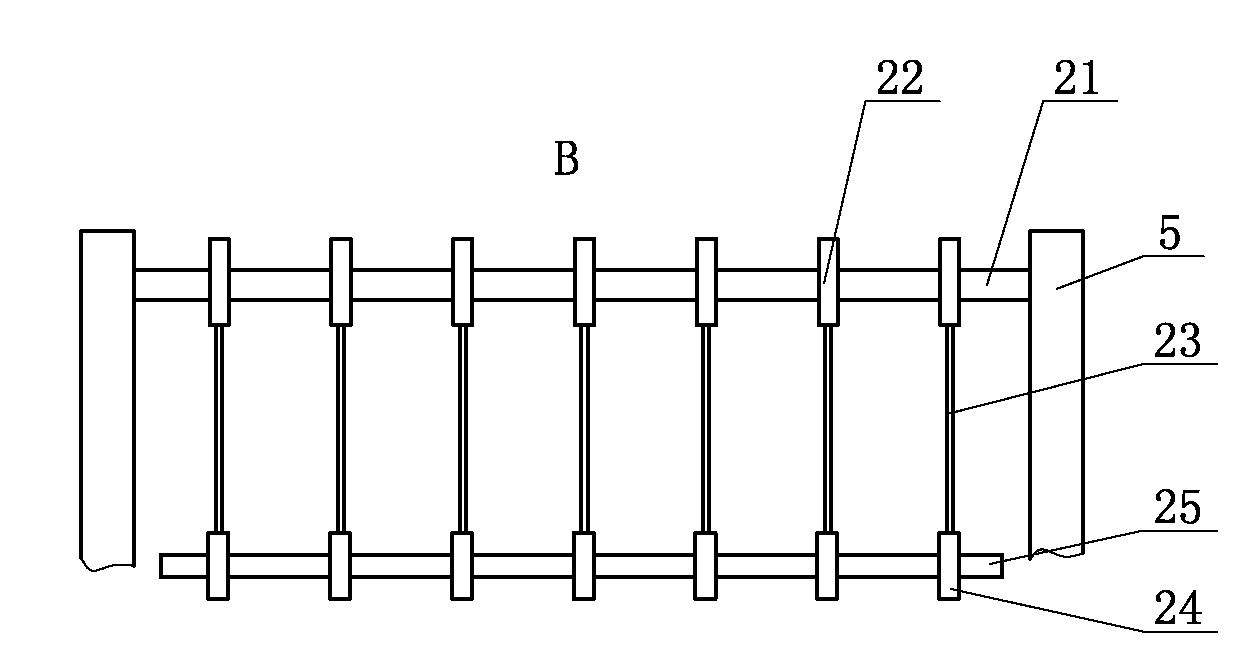

Code punching device for anti-fake printing

A code punching device for anti-fake printing comprises a workbench. The workbench is provided with a code punching machine, a pressing device and a transmission device. The transmission device is composed of a supporting frame and a conveying roller with a motor. An arc-shaped groove is formed in the roller face of the conveying roller. The motor is arranged on the supporting frame. A rotary disc is installed on an output shaft of the motor. The edge of the rotary disc is hinged to one end of a connecting rod and the other end of the connecting rod is hinged to the upper portion of a sliding block. The sliding block is matched with a sliding rail. The sliding rail is vertically installed on the supporting frame. A connecting board is arranged on the lower portion of the sliding block. A pressing sheet is arranged on the lower portion of the connecting board. A groove is formed in the workbench and located on the lower portion of a punching nail. According to the code punching device for anti-fake printing, marking and code punching can be completed at one time, work steps are reduced, and work time is saved; ticket paper is fed at intervals, the feeding distance of each time is fixed, so that the code punching positions of tickets of the same batch are unified, and the anti-fake effect is achieved; each time of code punching can be completed in a static state, so that the deflection of patterns or characters printed on the tickets is avoided, and the definition of code punching is guaranteed.

Owner:广州东港安全印刷有限公司

Reversible thermochromic ink as well as preparation method and application thereof

InactiveCN111196903AImprove thermochromic effectAchieve anti-counterfeiting effectAuxillary controllers with auxillary heating devicesInksThermochromismColor changes

The invention discloses reversible thermochromic ink as well as a preparation method and application thereof. Crystal violet lactone is used as a color former; boric acid is used as a color developingagent to prepare a thermochromic material; the thermochromic material is added into the ink, so that the ink is endowed with a thermochromic effect, is light blue at normal temperature, is grey whiteunder heat sources such as a lighter and the like, the anti-counterfeiting function of the ink is realized, printed images and texts can be subjected to color change through a certain heat source, and the color can be recovered after the heat source is removed for a period of time; the identification method is convenient and rapid, and thermochromism has reversibility.

Owner:HUNAN UNIV OF TECH

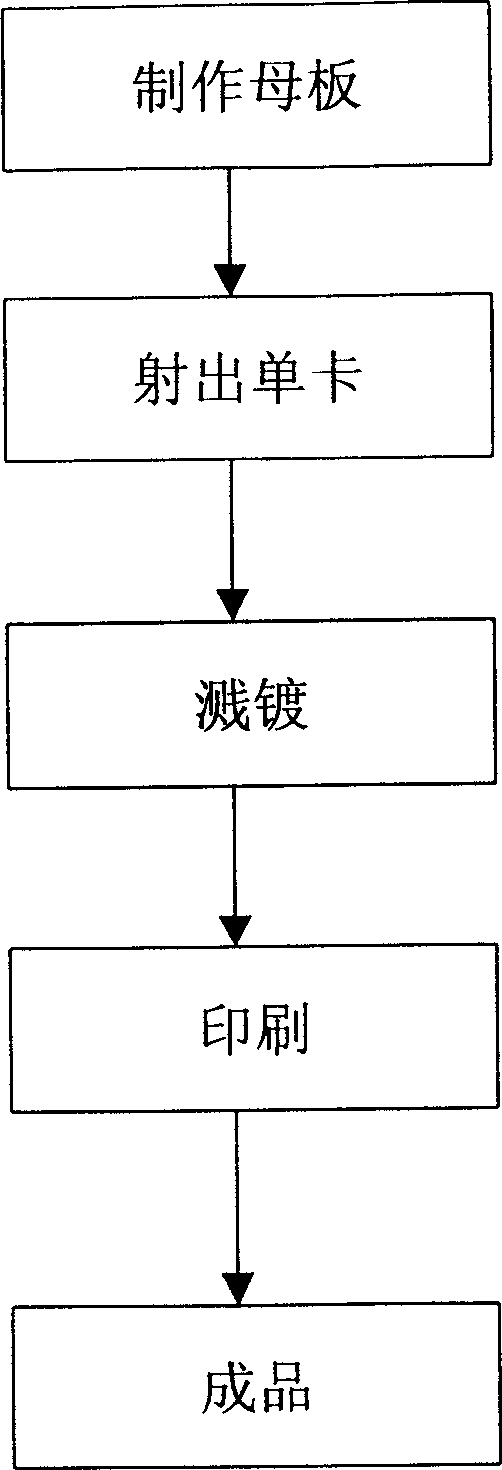

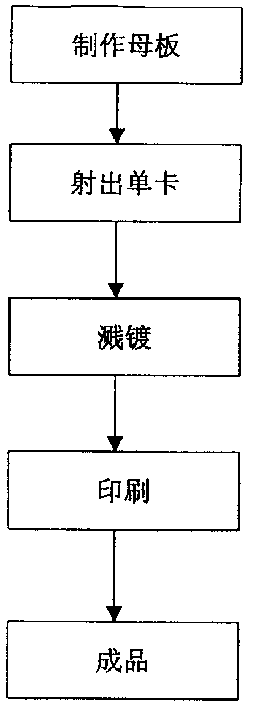

Card forming method capable of producing anti-fake mark

InactiveCN1432977AAchieve anti-counterfeiting effectIncrease the difficultyCoding/ciphering apparatusCredit cardEngineering

The card forming method capable of producing anti-fake mark is used for producing credit card and common bank cards. The card forming method includes making mother board in required pattern, copying the pattern of the mother board to the surface of the card by jetting formation process, sputtering to plate one metal layer on the surface of the card to increase reflection effect, and printing to the surface of the card. The said process can provide writing or pattern with effect similar to that of laser image.

Owner:博铼科技股份有限公司

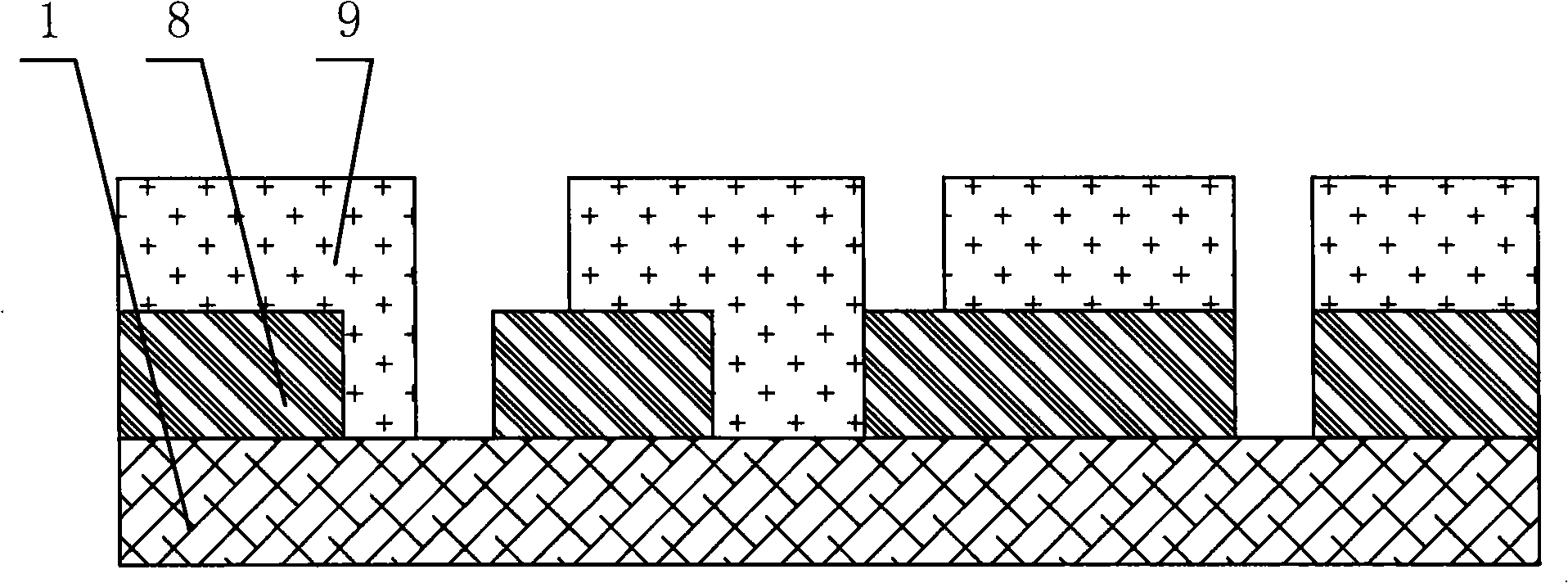

Production method of cigarette paperboards

ActiveCN106245416AAvoid heavy metal residue problemsReduce manufacturing costNon-fibrous pulp additionFlexible coversFiberSurface layer

The invention relates to a production method of cigarette paperboards. The method sequentially comprises the steps of proportioning of raw materials of a surface layer and a bottom layer, repulping, defibrination, proportioning of raw materials of a core layer, repulping, defibrination, dehydration molding, spray compounding, squeezing, drying, calendering and reeling cutting. The cigarette paperboards are produced through the above steps of the production method without a coating process, so the heavy metal residual problem brought by use of a coating is avoided, and the production cost is reduced; colorless fluorescent false-proof fibers are added to the repulping process in step 2, so light or fluorescence with different colors is reflected under the irradiation of natural light or an ultraviolet lamp in order to reach the false-proof effect; and setting of a spraying technology improves the interlayer combination force of paper and prevent layering of paper pages.

Owner:ZHEJIANG JINGXING PAPER

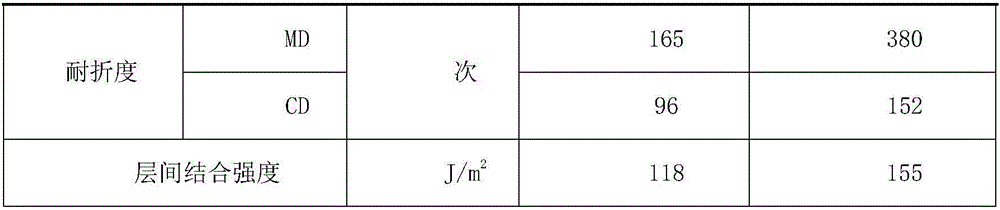

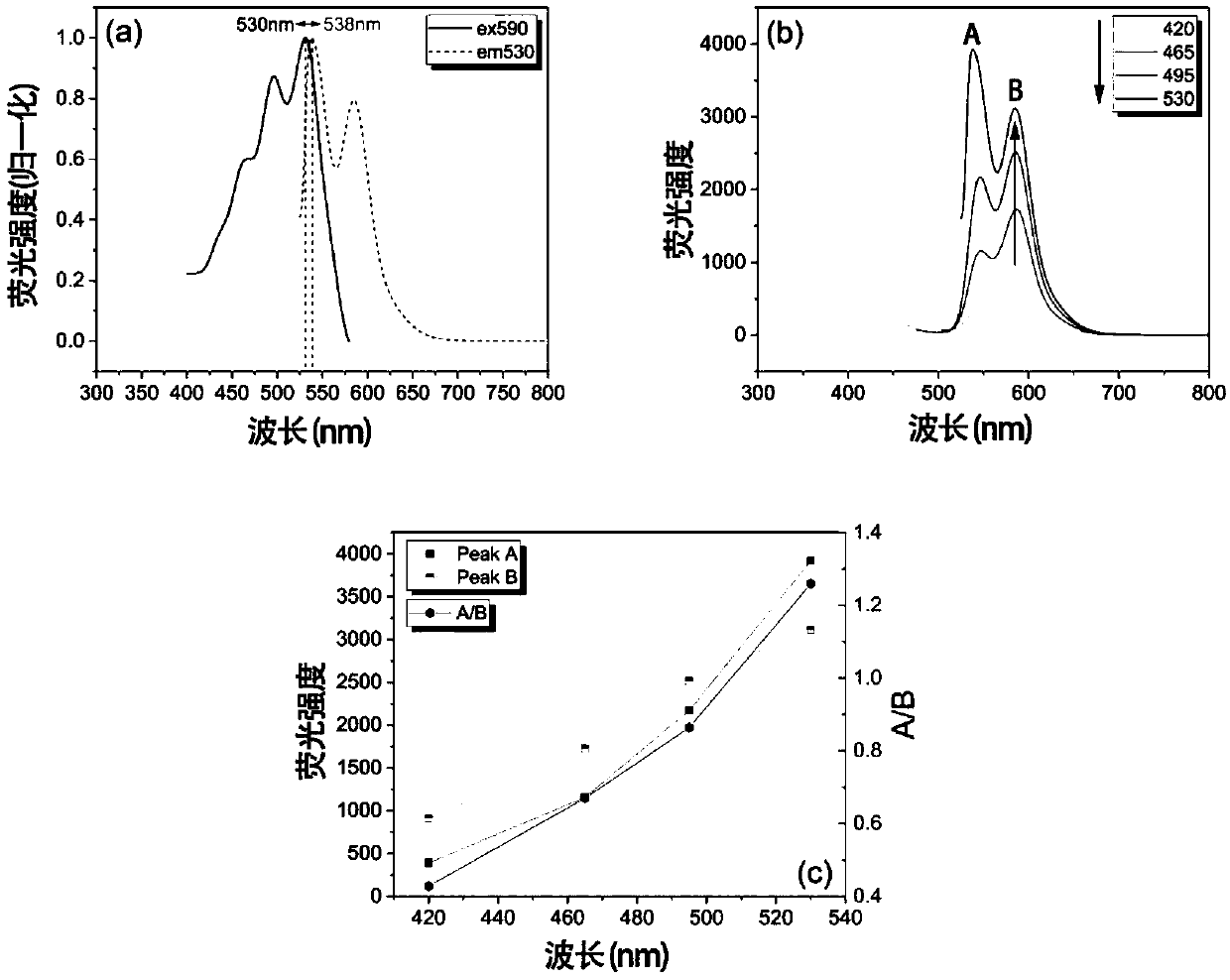

Special fluorescent anti-counterfeit material and preparing method and application thereof

ActiveCN109652064AStable in natureOptical properties are complexInksLuminescent compositionsFluorescencePrinting ink

The invention provides a special fluorescent anti-counterfeit material and a preparing method and application thereof. The fluorescent anti-counterfeit material comprises a compound shown in the formula (I), a stabilizer and / or macromolecule resin. The raw materials involved in the preparing process of the fluorescent anti-counterfeit material are wide in source; the special fluorescent anti-counterfeit material is high in synthesis yield and stable in fluorescence performance, and can be directly printed after being mixed with commercial printing ink, large-scale application and popularization of anti-counterfeit labels are facilitated, and the application prospect is wide. The structure of the formula (I) is shown in the following description.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

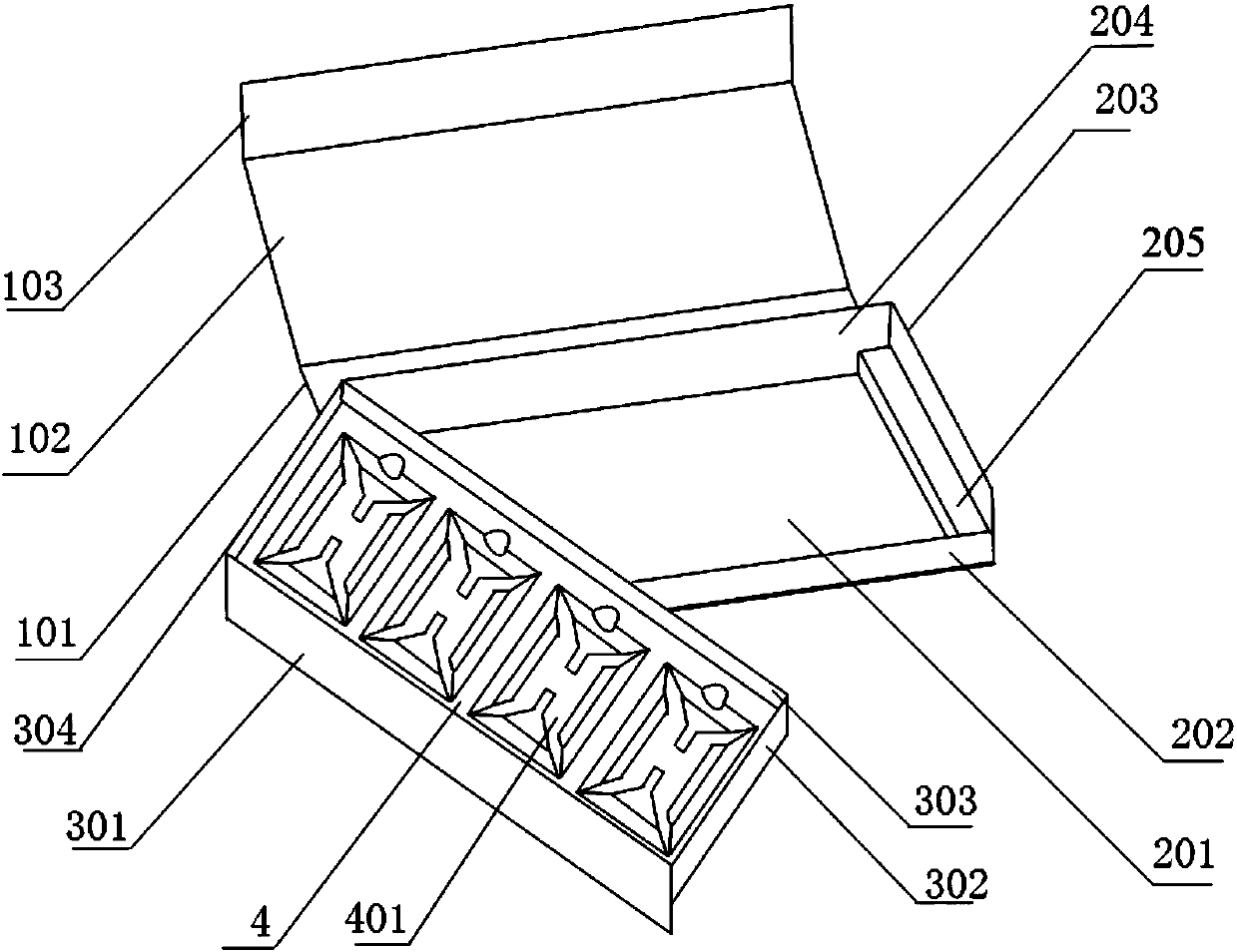

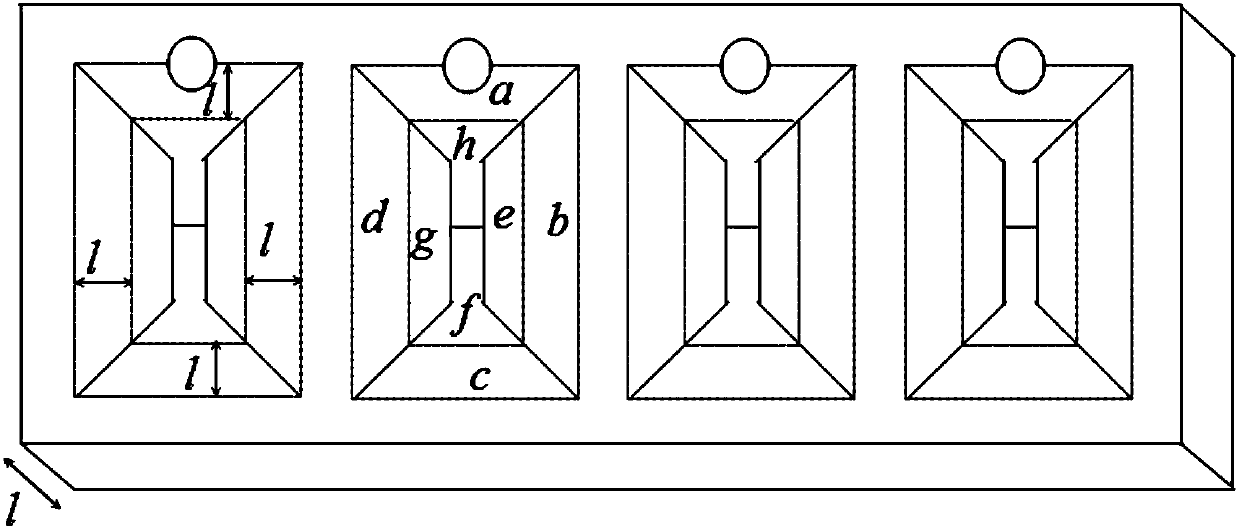

Integrated cut and imprinted sliding double-layer packing box and anti-counterfeit packing method

ActiveCN107934180ANovel structureEasy to openNon-removalbe lids/coversClosures to prevent refillingEngineeringPacking method

The invention provides an integrated cut and imprinted sliding double-layer packing box. The integrated cut and imprinted sliding double-layer packing box comprises a box body and a box cover. The boxbody is internally provided with an inner box. The inner box rotates on the plane determined through an inner box bottom plate with the side edge of a rear plate as an axis. A box frame is placed inthe inner box. The box frame is of a cuboid structure. The upper surface of the box frame is provided with a set of box groove imprints. Meanwhile, the invention provides an anti-counterfeit packing method, and the anti-counterfeit packing method comprises the steps that the box body, the box cover and the box frame are manufactured; the upper surface of the box frame is subjected to cutting and imprinting by using a mold to form the box groove imprints; anti-counterfeit ink is printed on the box groove imprints, an object box is placed on the box frame when the anti-counterfeit ink is not dried and is pressed downwards after the anti-counterfeit ink is dried completely, so that cut marks of the box groove imprints crack, and folding is conducted along impressions to form a box groove, andfinally, the object box sinks into the box groove; and the sliding double-layer packing box is sealed and packed. The integrated cut and imprinted sliding double-layer packing box is novel in structure and simple in process, and anti-counterfeit packing can be achieved.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

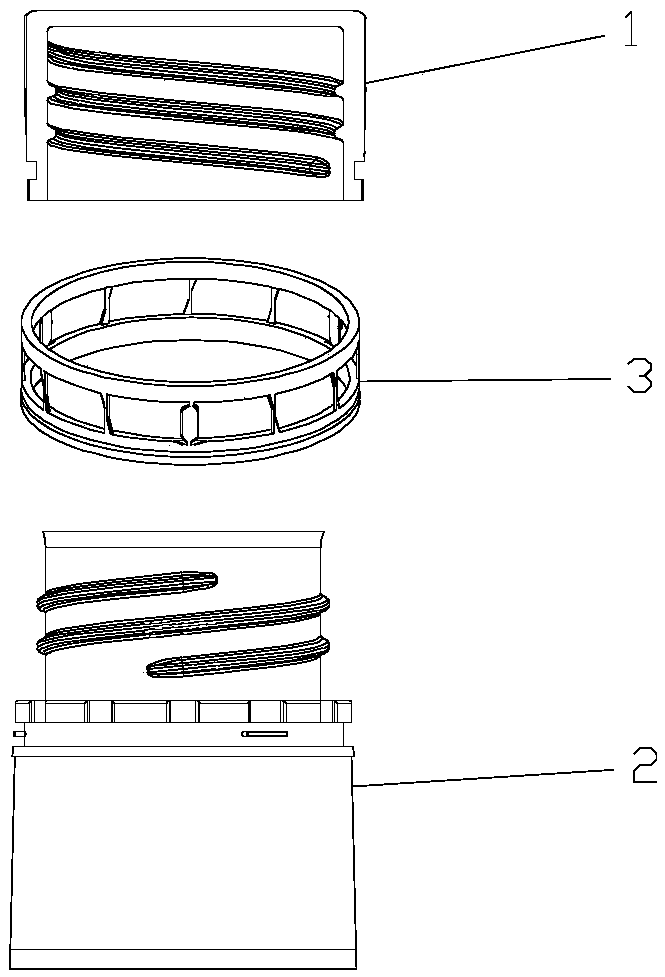

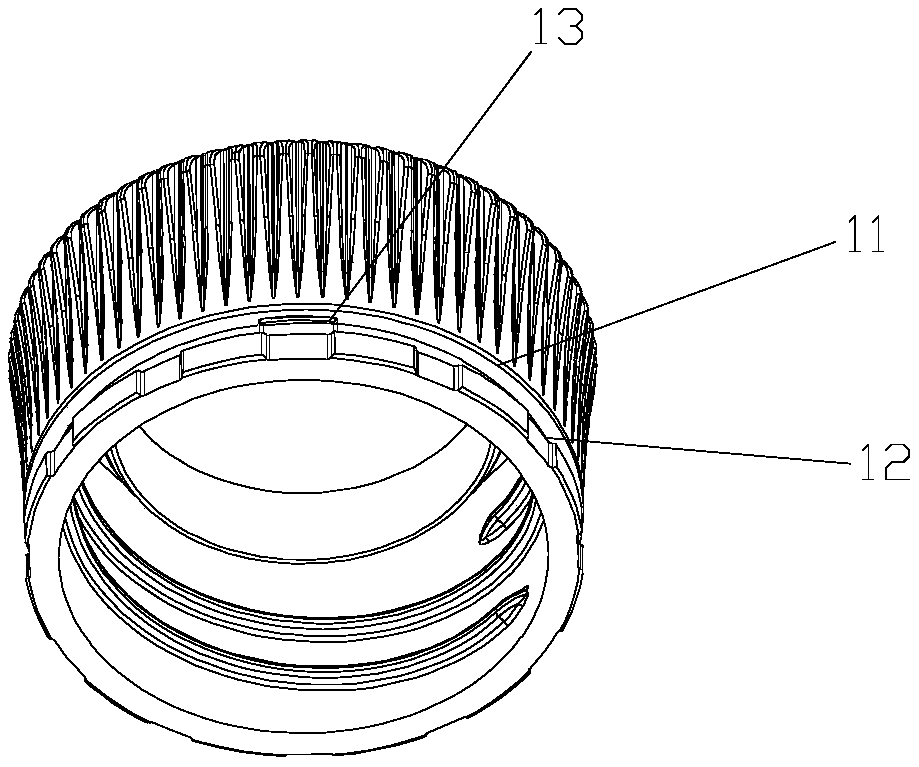

Anti-counterfeiting structure of bottle cap

ActiveCN108688981AEasy to plagiarizeAchieve anti-counterfeiting effectClosure capsLocking devicesEngineeringCapis

The invention relates to an anti-counterfeiting structure of a bottle cap. The anti-counterfeiting structure comprises an upper cap, a base and an anti-counterfeiting ring. The base is mounted on a bottle opening in an embedded mode. The upper cap is mounted above the base in a threaded connection mode. The anti-counterfeiting ring is arranged at the junction of the upper cap and the base and comprises an upper ring, a lower ring and a plurality of connecting bridges for connecting the upper ring with the lower ring. The upper ring and the lower ring are nested on the upper cap and the base correspondingly. The junction of the upper cap and the base is sleeved with the connecting bridges in an embedded mode. According to the anti-counterfeiting structure, the upper cap and a lower cap of the bottle cap are closed, the anti-counterfeiting ring encircles the exteriors of the upper cap and the lower cap, and when the upper cap is rotated anticlockwise, the connecting bridges at the ring part, close to the upper cap and the lower cap, of the encircling-type anti-counterfeiting ring are broken off or burst open due to rotation stress. The anti-counterfeiting structure of the bottle capis difficult to counterfeit after being subjected to one-time damage, the requirements for the technology are high, and compared with an existing anti-counterfeiting bottle cap, the anti-counterfeiting effect is better.

Owner:GUANGZHOU CHENGTIAN PACKAGING DESIGN CO LTD

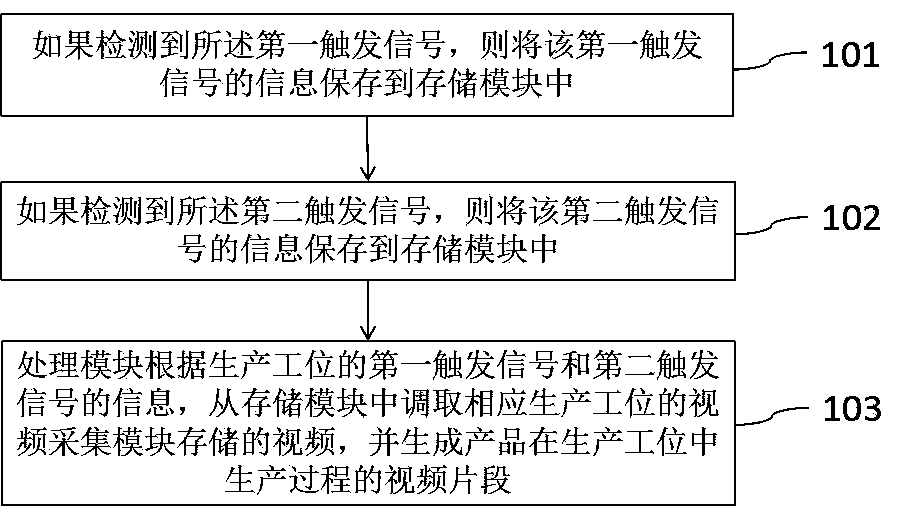

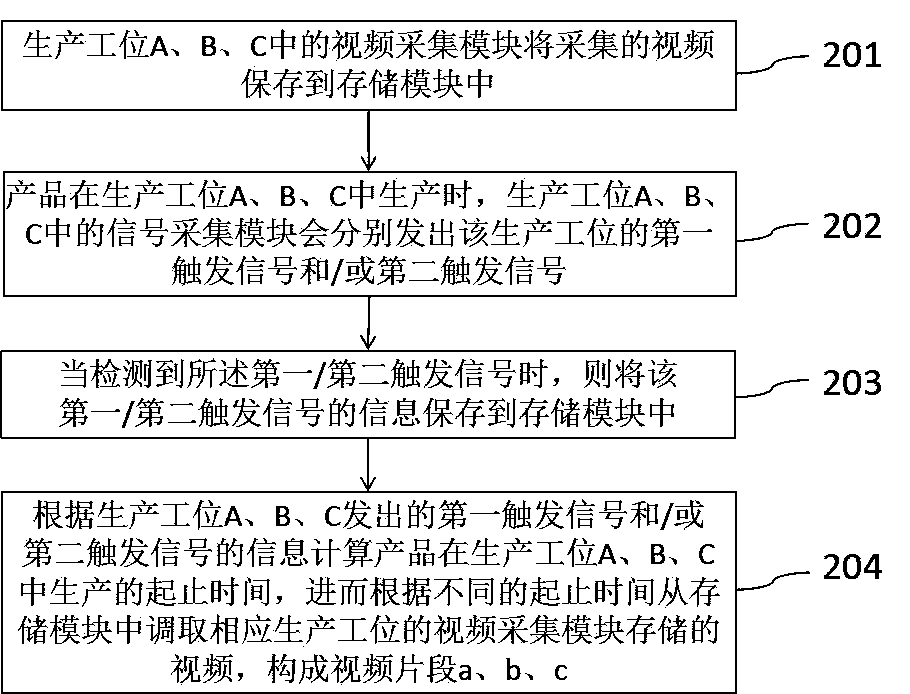

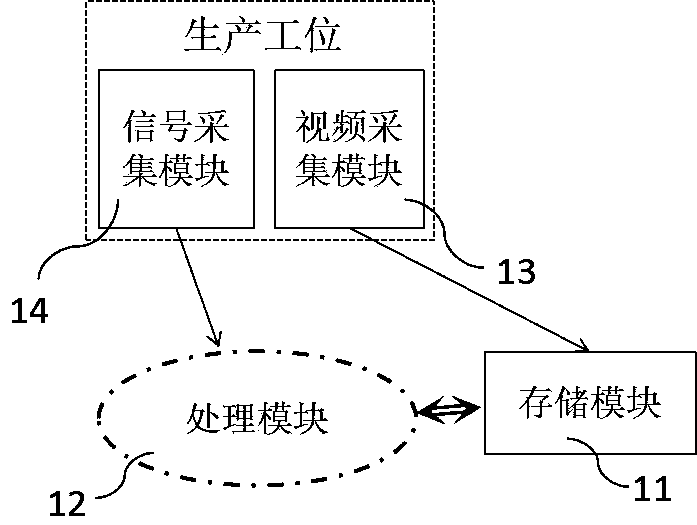

A method and system for producing video clips

InactiveCN109089055AEasy to find out whyImprove development efficiencyTelevision system detailsCo-operative working arrangementsComputer moduleVideo recording

The invention provides a method and a system for obtaining production video fragments. In the invention, the monitoring video of the production station is stored in a storage module (11) without interruption, so that if an abnormal accident or alarm occurs in the production station, the production management personnel can view and trace it through the video recording. According to the informationof the first trigger signal and the second trigger signal in each production station, the processing module (12) calculating the start and end time of production of the product in different productionstations, and according to the different start and end times, calling the video stored in the video acquisition module (13) of the corresponding production station from the storage module (11) to form a video segment of a series of production processes of the product; enterprise managers can quickly retrieve video clips of the production process of the product in each production station accordingto the product number, by viewing and analyzing the video clips of the production process of defective products in various production stations, it is easier to find out the causes of defective products, which can improve the efficiency of new product development and is conducive to the improvement of production processes and product quality.

Owner:李志朋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com