Production method of cigarette paperboards

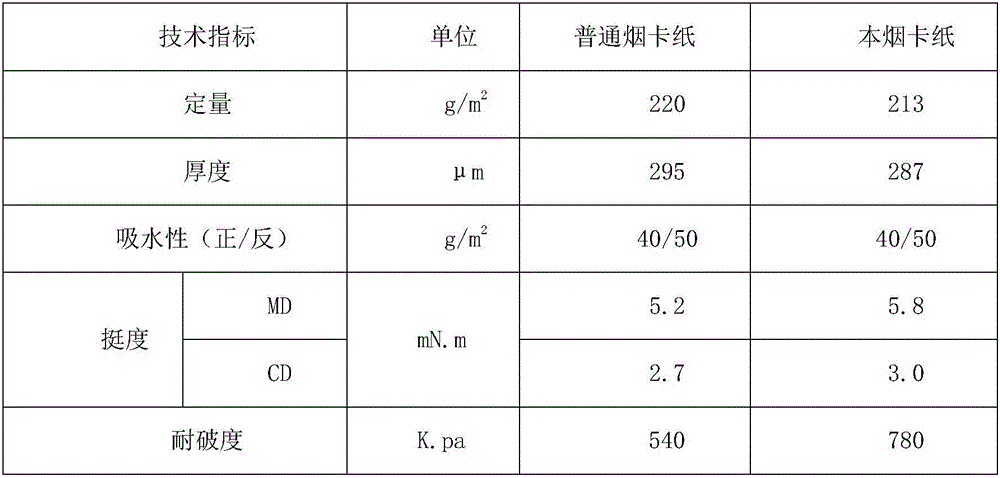

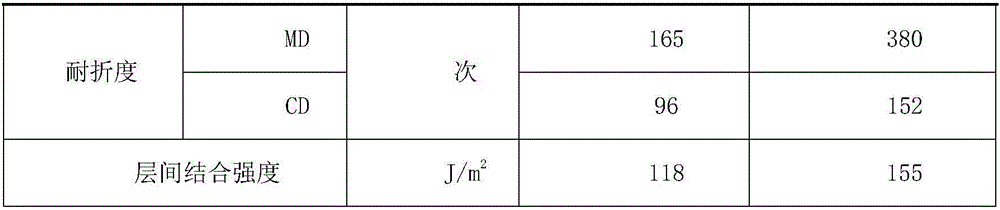

A production method and technology for cigarette card paper, which are applied in pulp beating method, pulp beating/refining method, papermaking, etc., can solve the problems of high cost of cigarette card, poor environmental protection, poor anti-counterfeiting performance, etc., so as to reduce production cost and improve quality. The effect of interlayer adhesion and prevention of sheet delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for producing cigarette cardboard, comprising a surface layer, a core layer and a bottom layer, and the surface layer and the bottom layer both include the following components: 40% natural softwood pulp and 60% bleached hardwood pulp, and the core layer includes the following components Composition: mechanically ground wood pulp 80% and bleached hardwood pulp 20%, including the following steps in turn:

[0033] Step 1: Raw material ratio of surface layer and bottom layer: mix unbleached softwood pulp and bleached hardwood pulp to make 100% unbleached unbleached wood pulp;

[0034] Step 2: Disintegration: Put the unbleached unbleached natural wood pulp raw material in step 1 into the hydraulic pulper through the chain plate machine, and add colorless fluorescent anti-counterfeiting fibers to the hydraulic pulper, and then disintegrate to form pulp , the weight ratio of the colorless fluorescent anti-counterfeiting fiber to the unbleached unbleached wood pulp ra...

Embodiment 2

[0047] A method for producing cigarette cardboard, comprising a surface layer, a core layer and a bottom layer, and the surface layer and the bottom layer both include the following components: 50% natural softwood pulp and 50% bleached hardwood pulp, and the core layer includes the following components Composition: mechanically ground wood pulp 70% and bleached hardwood pulp 30%, including the following steps in turn:

[0048] Step 1: Raw material ratio of surface layer and bottom layer: mix unbleached softwood pulp and bleached hardwood pulp to make 100% unbleached unbleached wood pulp;

[0049] Step 2: Disintegration: Put the unbleached unbleached natural wood pulp raw material in step 1 into the hydraulic pulper through the chain plate machine, and add colorless fluorescent anti-counterfeiting fibers to the hydraulic pulper, and then disintegrate to form pulp , the weight ratio of the colorless fluorescent anti-counterfeiting fiber to the unbleached unbleached wood pulp ra...

Embodiment 3

[0061] A method for producing cigarette cardboard, comprising a surface layer, a core layer and a bottom layer, and the surface layer and the bottom layer both include the following components: 60% natural softwood pulp and 40% bleached hardwood pulp, and the core layer includes the following components Composition: mechanically ground wood pulp 60% and bleached hardwood pulp 40%, including the following steps in turn:

[0062] Step 1: Raw material ratio of surface layer and bottom layer: mix unbleached softwood pulp and bleached hardwood pulp to make 100% unbleached unbleached wood pulp;

[0063] Step 2: Disintegration: Put the unbleached unbleached natural wood pulp raw material in step 1 into the hydraulic pulper through the chain plate machine, and add colorless fluorescent anti-counterfeiting fibers to the hydraulic pulper, and then disintegrate to form pulp , the weight ratio of the colorless fluorescent anti-counterfeiting fiber to the unbleached unbleached wood pulp ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com