Patents

Literature

112results about "Chemical and mechanical pulp mixture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of manufacturing authenticatable paper products

InactiveUS6054021AConvenient verificationEasy to manufactureSpecial paperPaper after-treatmentFiberWhitening Agents

An authenticatable paper product is prepared by adding to a papermaking furnish fibers treated with from about 50-200 lb / ton of a fluorescent whitening agent (FWA). The paper made from the papermaking furnish will include fluorescent cellulosic fibers in an amount ranging from between 0.1-4.0 lb / ton to achieve FWA concentrations within the range of 1-20 ppm.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC

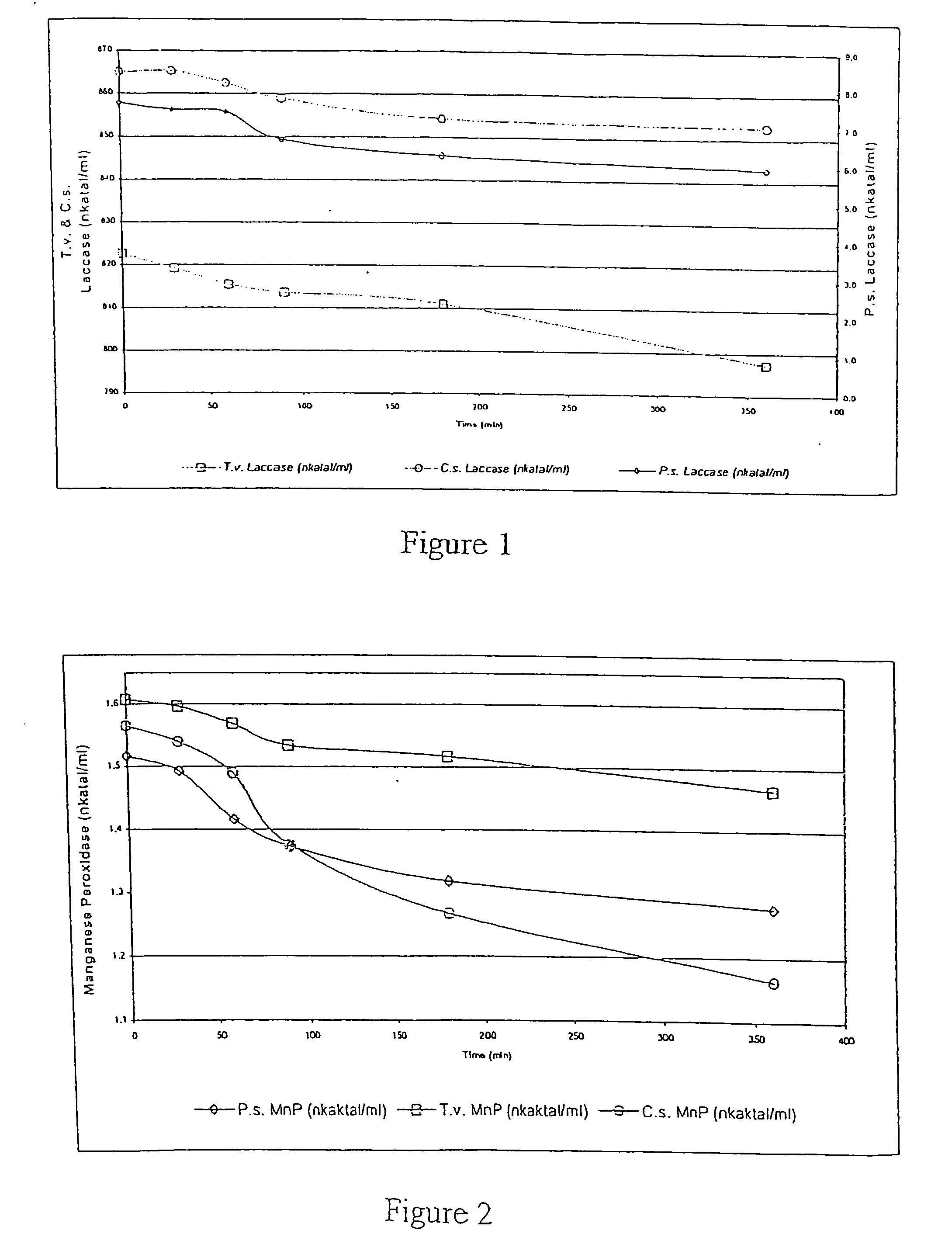

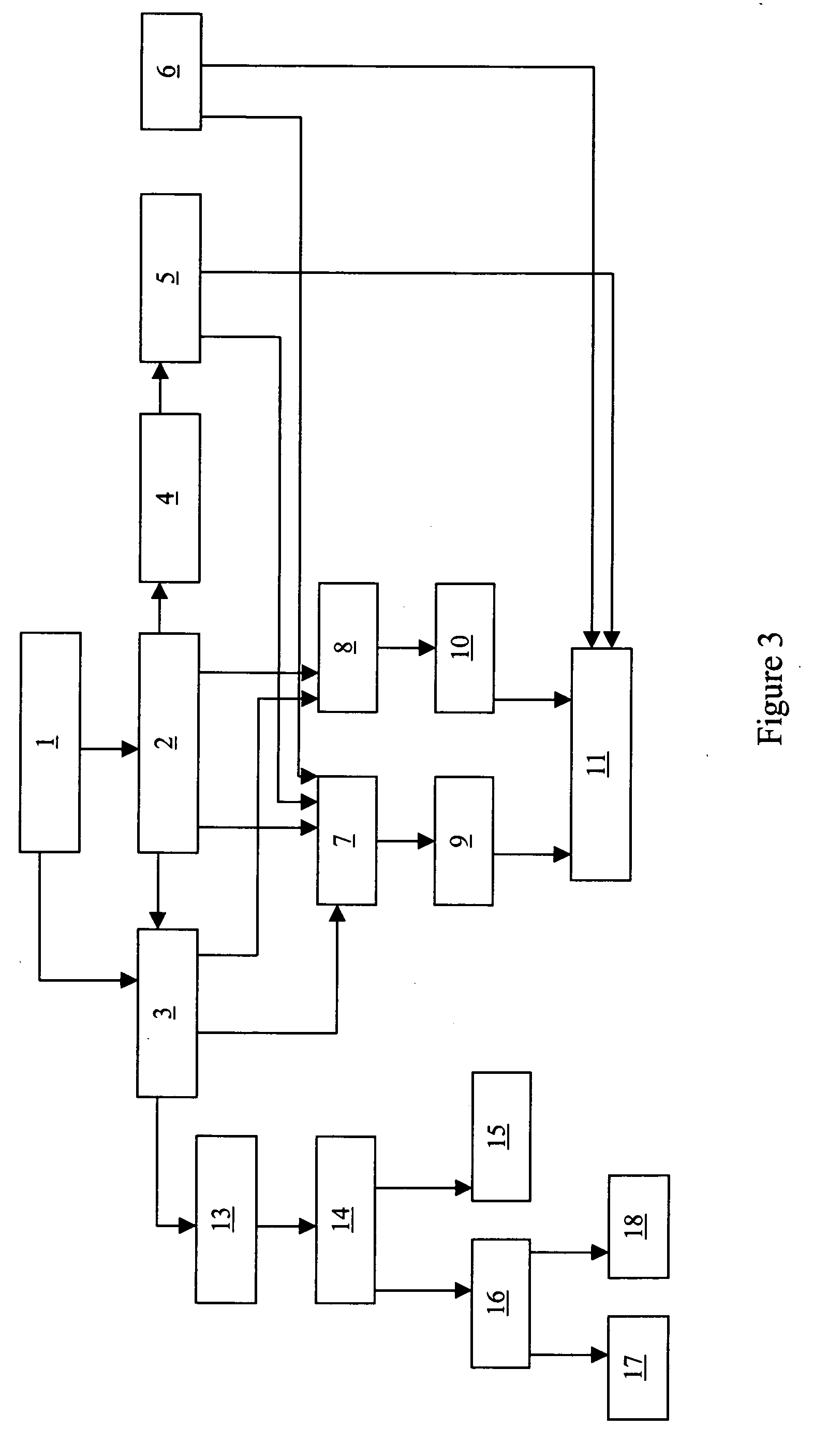

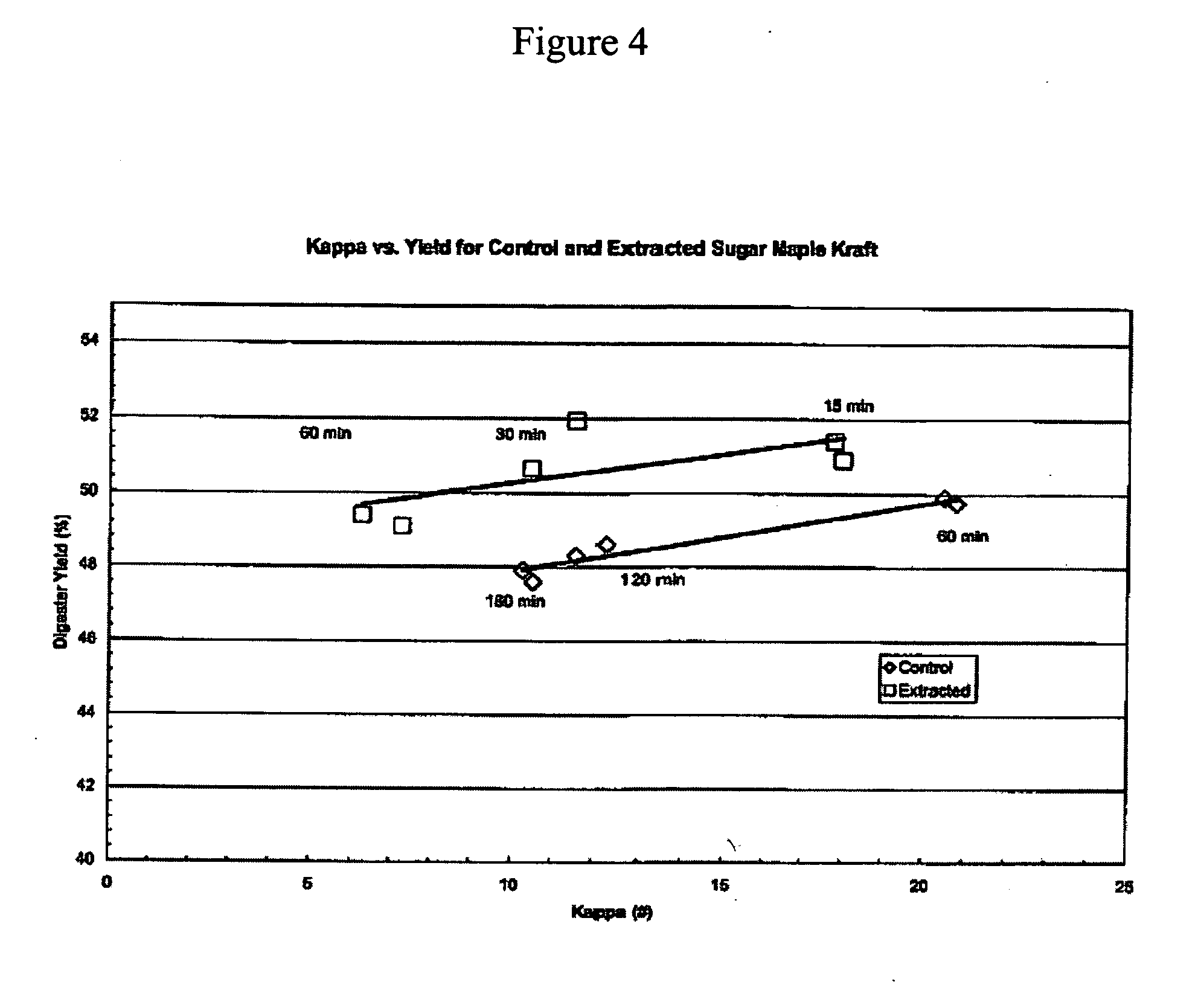

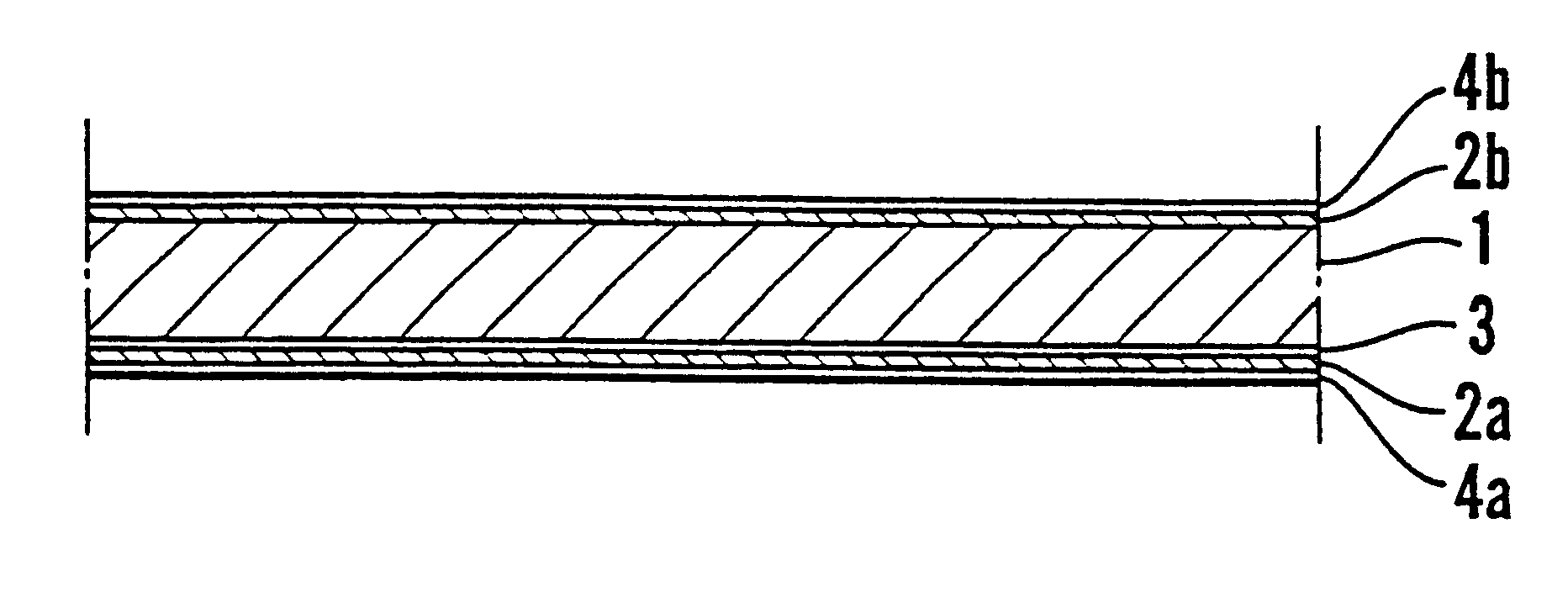

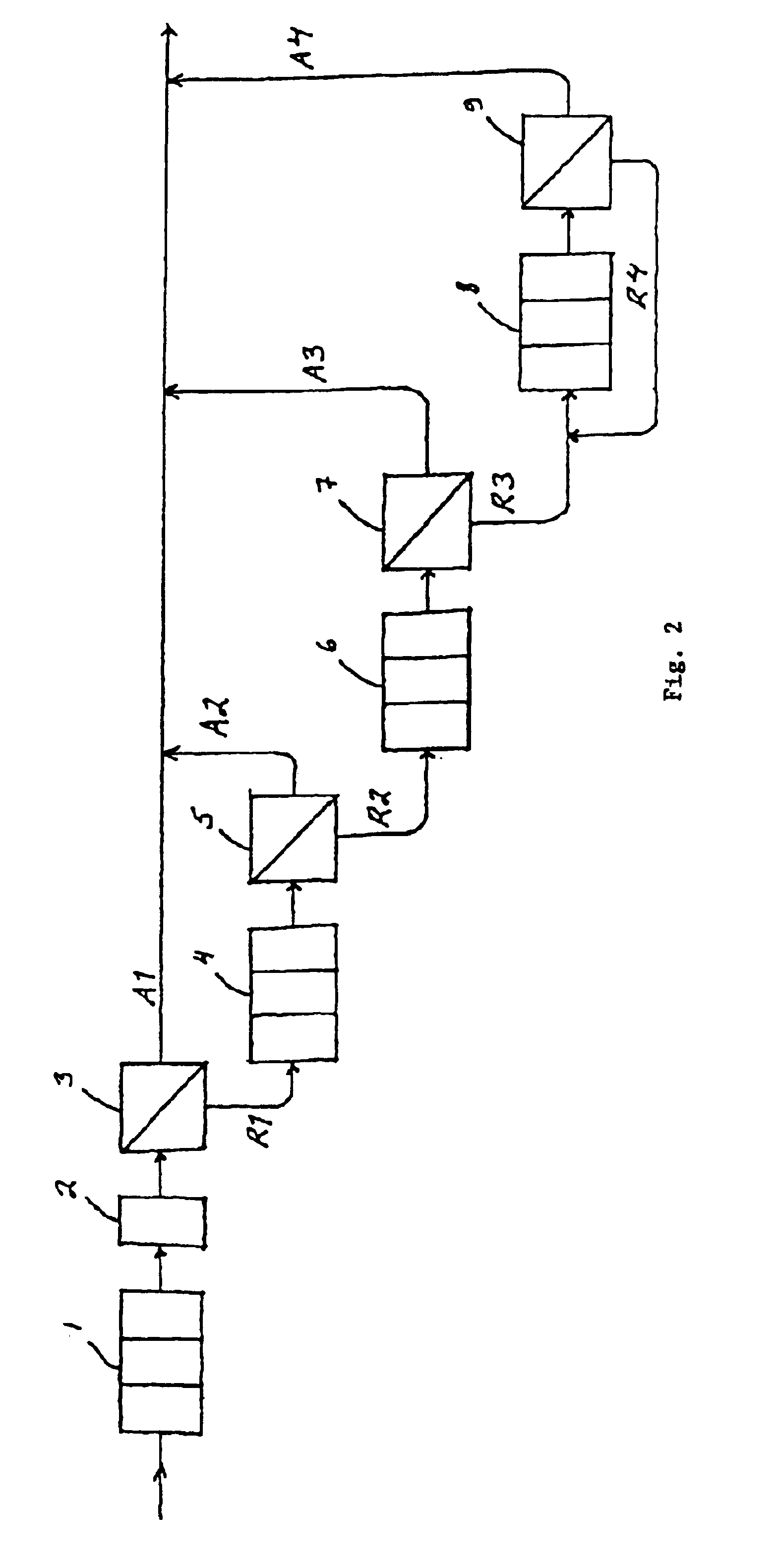

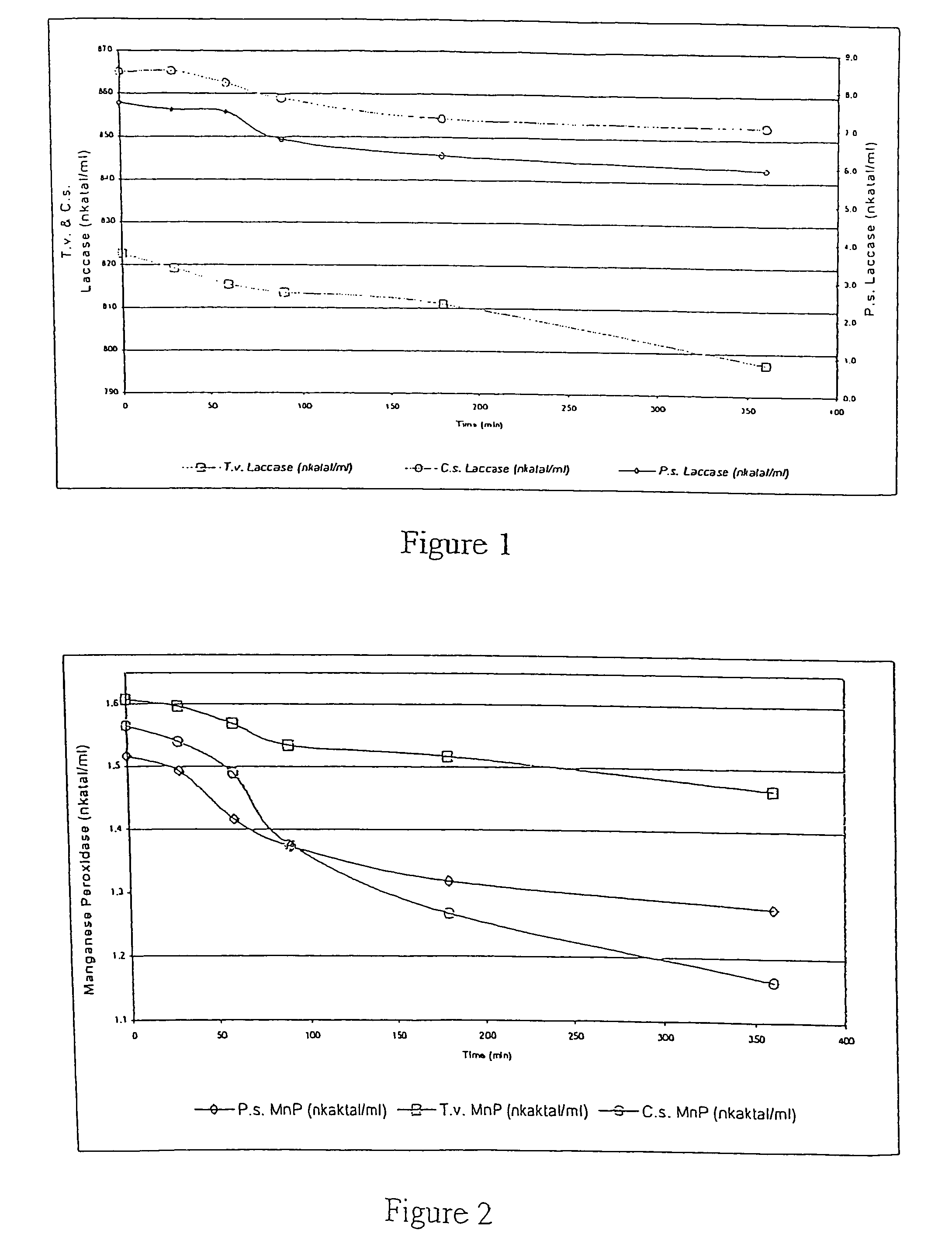

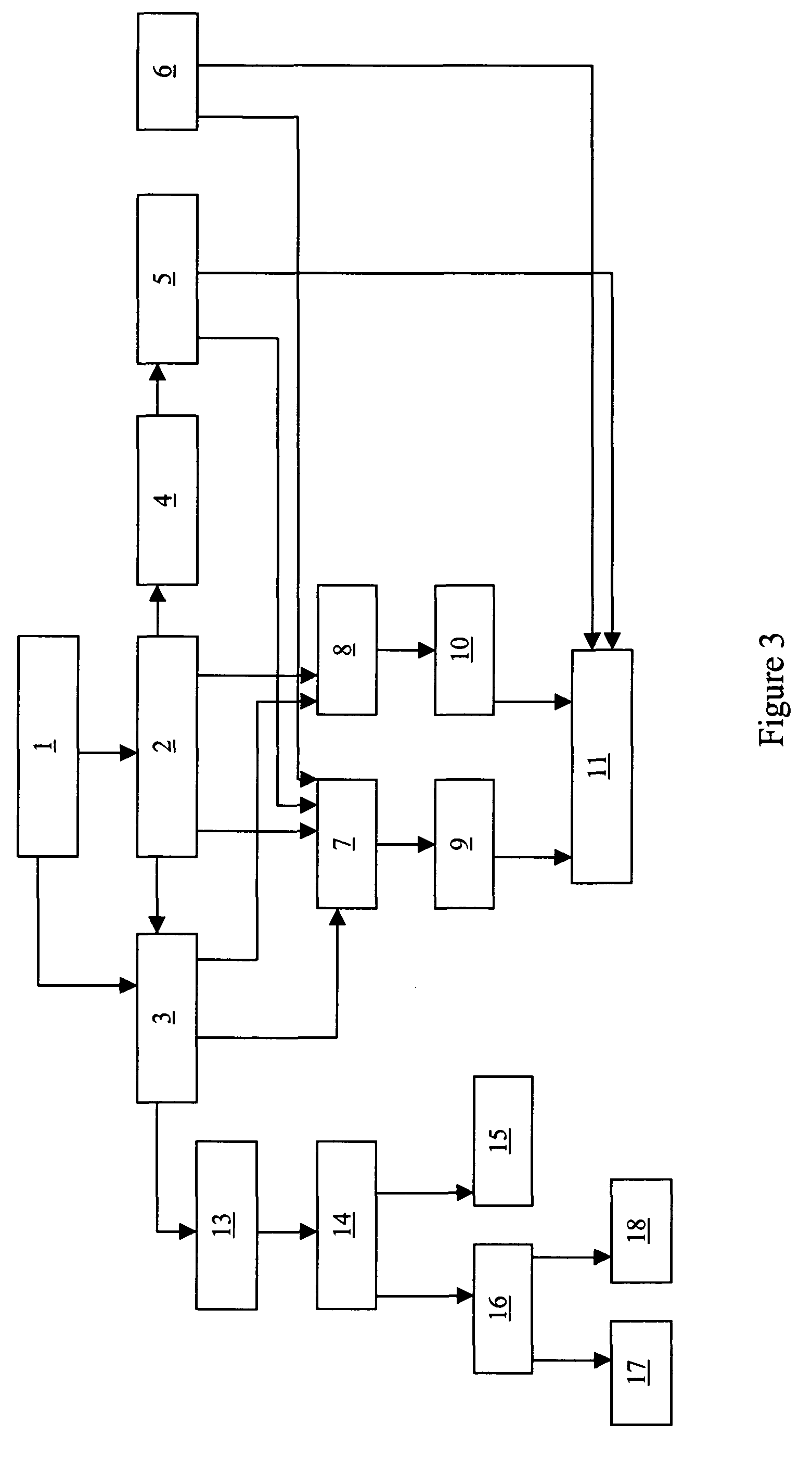

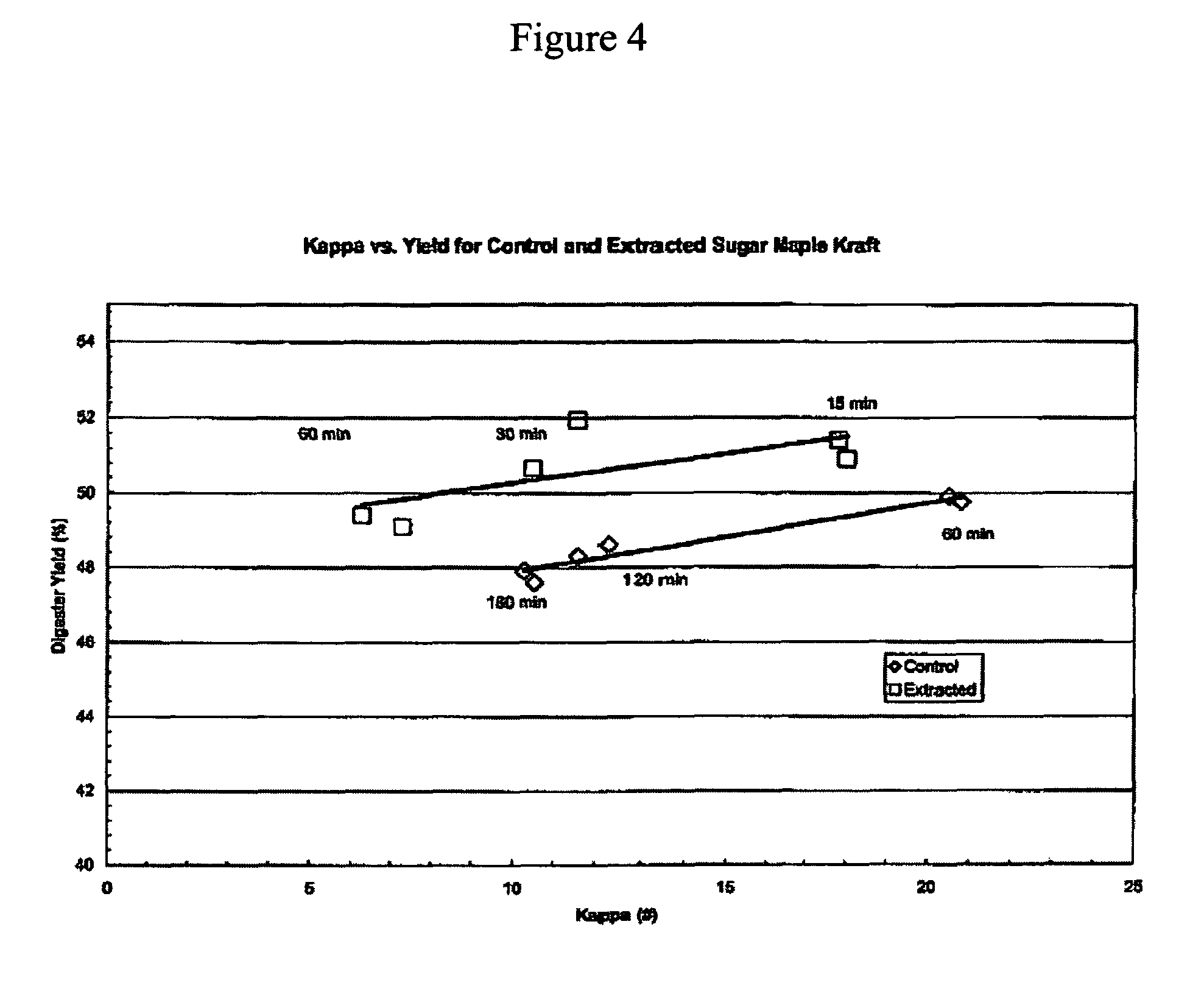

Product and processes from an integrated forest biorefinery

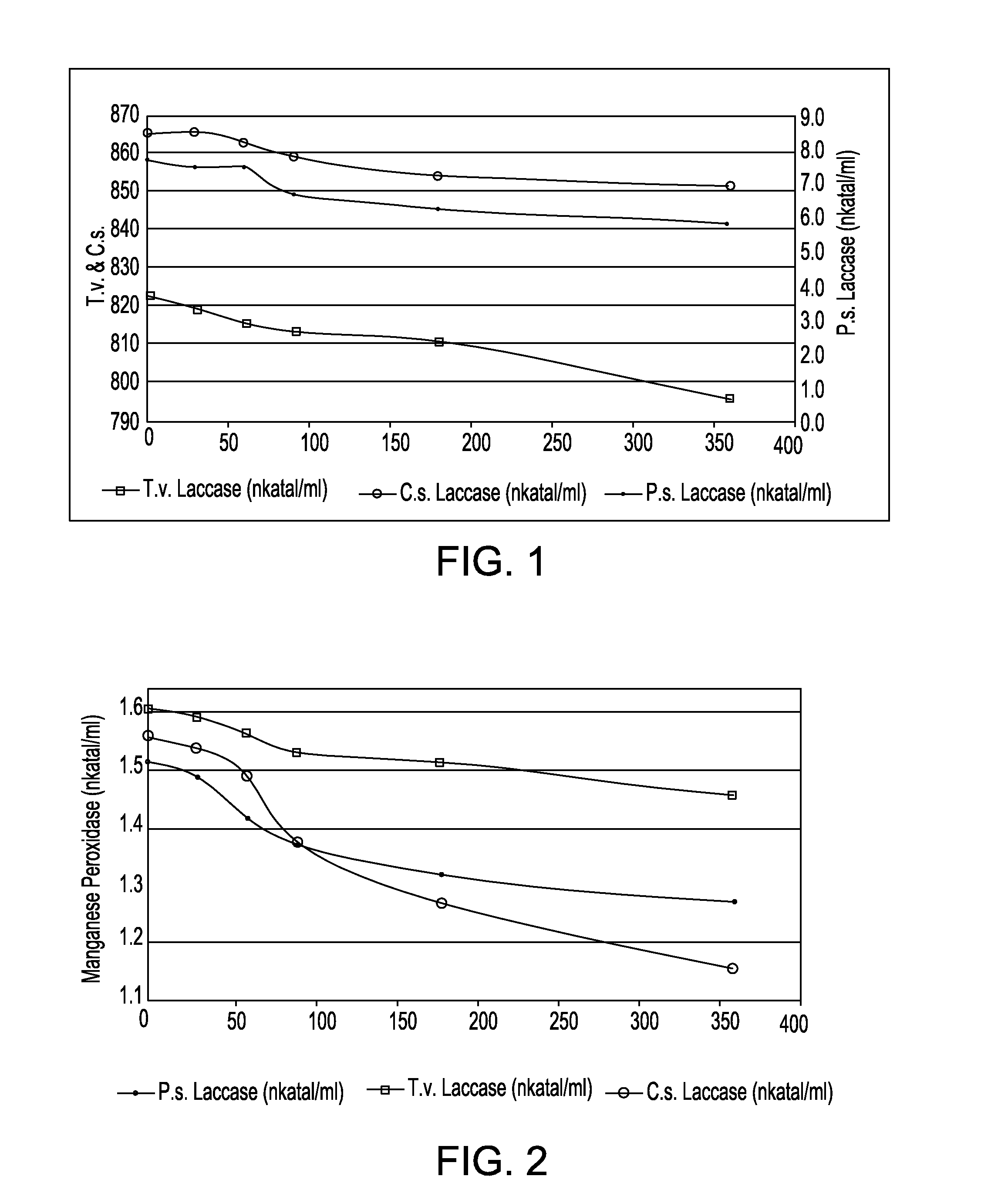

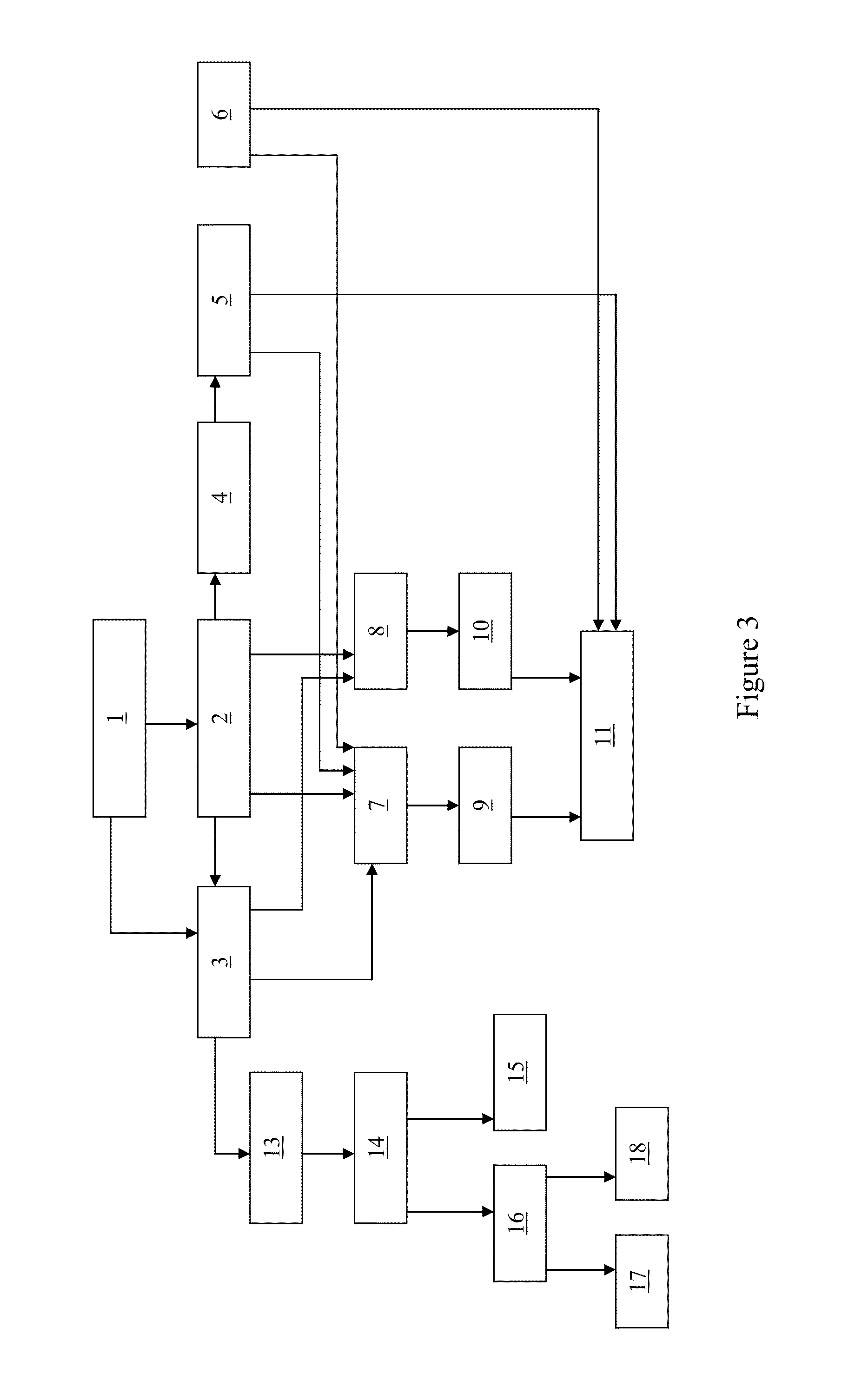

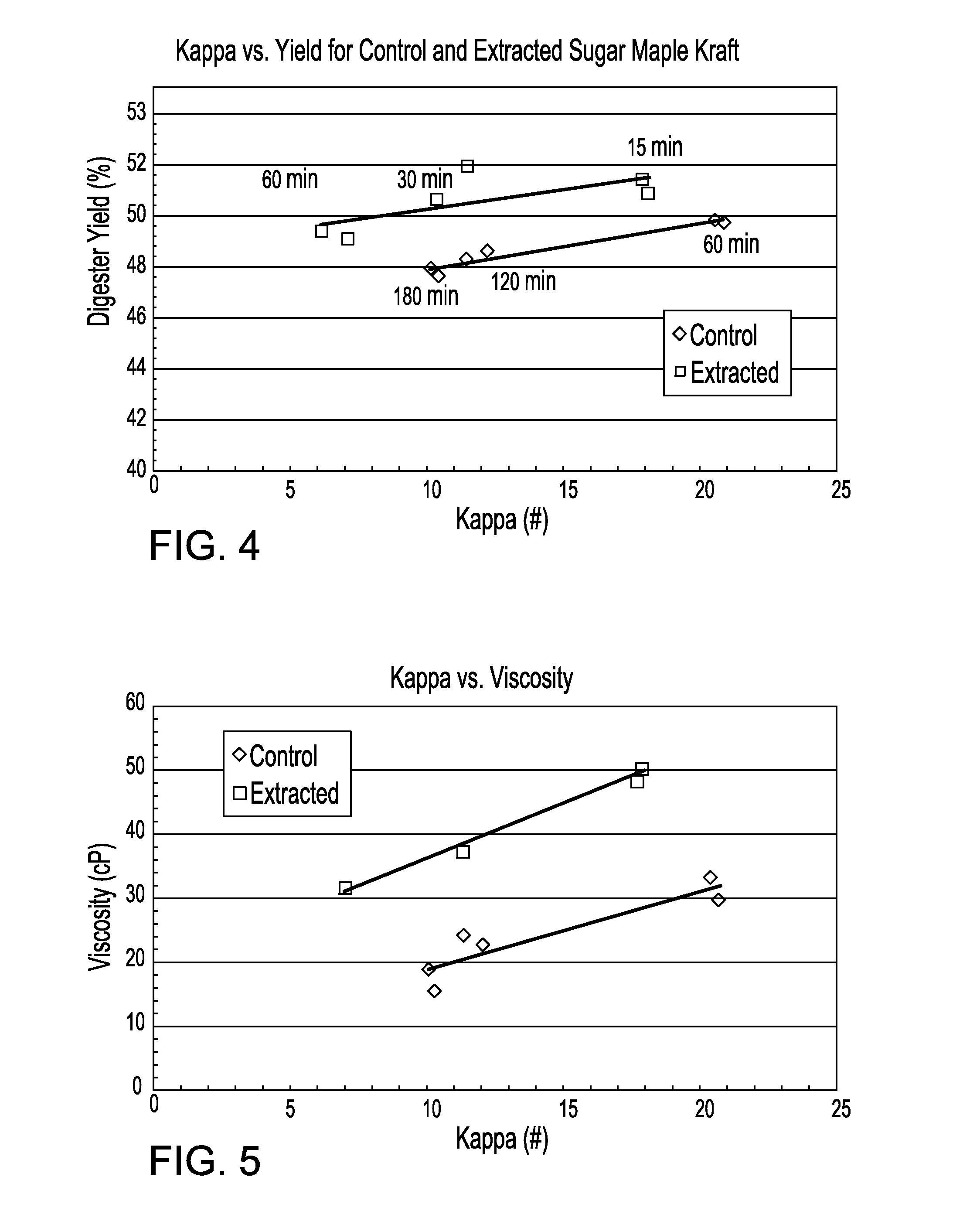

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Paper or paperboard laminate and method to produce such a laminate

InactiveUS6537680B1Increase stiffnessFacilitate folding and subsequent creasingNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed the bulk layer, and on at least one side at the bulk layer at least one secondary layer, secondary layer and bulk layer being joined to one another directly or indirectly over basically the whole of their surfaces facing one another, 40-95% of the bulk layer consists of cellulose fibers with a freeness of 550-950 ml CSF, the secondary layer / layers has / have a greater density than the bulk layer, and the laminate has a bending stiffness index higher than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine and transverse direction.

Owner:STORA ENSO AB

Printing paper

InactiveUS6923889B2Increase coverageGood printabilityNon-fibrous pulp additionSpecial paperFiberSurface roughness

The invention relates to coated printing paper which contains mechanical pulp and whose opacity is at least 89%, brightness at least 65% and surface roughness not more than 4.5 μm. The printing paper contains mechanical pulp at least 90 weight-% of the total fiber content of the paper.

Owner:UPM-KYMMENE OYJ

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

Authenticatable bleached chemical paper products

InactiveUS6019872AConvenient verificationEasy to manufactureNon-fibrous pulp additionSpecial paperFiberPapermaking

An authenticable paper product is prepared from a bleached chemical papermaking furnish containing a minor but detectable amount of lignin containing fibers selected from the group consisting of mechanical, thermomechanical, chemi-thermomechanical and bleached-chemi-thermomechanical.

Owner:P H GLATFELTER CO

Soft tissue comprising non-wood fibers

ActiveUS10145069B2Satisfactory softness and strength and bulkOvercome the small stiffnessPaper/cardboardChemical/chemomechanical pulpFiberMedicine

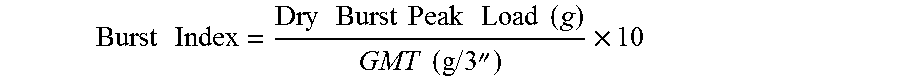

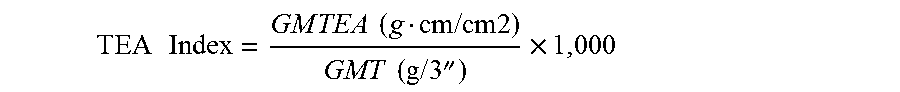

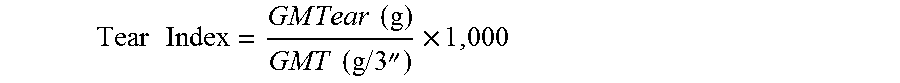

The present invention provides soft, durable and bulky tissue products comprising non-wood fibers and more particularly hesperaloe fiber. The inventors have discovered that high yield hesperaloe pulp fiber, when incorporated in amounts of at least about 5 percent by weight of the tissue product, produces products having a GMT less than about 1000 g / 3″ and a GM Slope less than about 7.0 kg. At the foregoing tensile strengths and modulus the tissue products of the present invention are also generally soft, such as having a Stiffness Index less than about 10.0, and more preferably less than about 9.0, such as from about 7.0 to about 9.0.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Product and processes from an integrated forest biorefinery

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Highly durable towel comprising non-wood fibers

The present invention relates to tissue products comprising high yield hesperaloe fiber having improved wet performance, such as improved absorbency, CD Wet / Dry Ratio and CD Wet Durability. The addition of high yield hesperaloe pulp fibers surprisingly improves the CD Wet / Dry ratio without negatively affecting the absorbency of the tissue product. For example, tissue products of the present invention generally have an Absorbent Capacity greater than about 6.0 g / g, such as from about 8.0 to 8.0 g / g. As such the tissue products are durable when wet, but are still sufficiently absorbent. This balance of absorbency and wet strength is not found in the prior art without resorting to adding latex binders or the like to the tissue product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

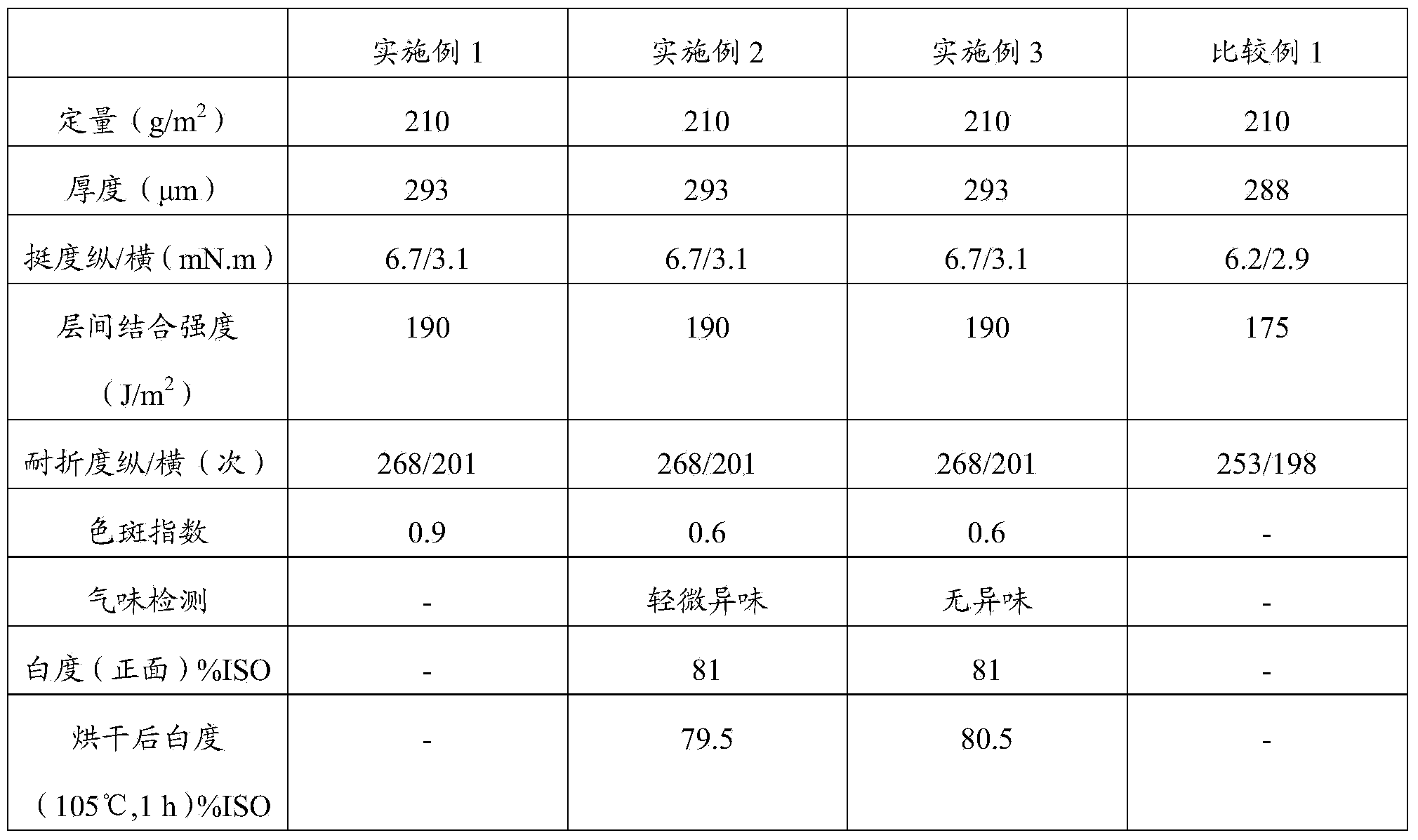

Liquid packaging body paper board and preparation method thereof

The invention provides a liquid packaging body paper board and a preparation method thereof. The liquid packaging body paper board consists of a backing paper layer, a core paper layer, a surface paper layer and a coating layer which are stacked in sequence, wherein the backing paper layer is prepared from the following raw materials in percentage by weight: 80-100 percent of unbleached sulfate pulp and 0-20 percent of non-dried chemical broad-leaf fresh pulp; the core paper layer is prepared from the following raw materials in percentage by weight: 10-20 percent of non-dried chemical broad-leaf fresh pulp, 50-80 percent of unbleached sulfate pulp and 5-30 percent of mechanical pulp; the surface paper layer is prepared from the following raw materials in percentage by weight: 20-80 percent of non-dried chemical broad-leaf fresh pulp and 20-80 percent of chemical needle-leaf pulp. Compared with the prior art, the liquid packaging body paper board has the advantages that the non-dried chemical broad-leaf fresh pulp is added into paper pulp of the backing paper layer, the core paper layer and the surface paper layer, and due to the specific high intensity and high stiffness as well as the high fiber bonding strength of the non-dried fresh pulp, the stiffness and the intensity of the liquid packaging body paper board are improved under a condition that the amount is fixed and is not increased; the liquid packaging body paper board has less-damage performance.

Owner:ASIA SYMBOL SHANDONG PULP & PAPER

Eucalyptus biomechanical pulping process

InactiveUS7008505B2Used more practically on a large scaleCellulosic pulp after-treatmentPretreatment with water/steamCellulose fiberWhite rot

In a new process for preparing pulped wood chips for paper making, chips from a hardwood such as eucalyptus are inoculated with aliving culture of one or more white rot fungi. The fungi propagate throughout the body of the wood chip, selectively attacking the lignin of the wood without harming the cellulosic fibers. Subsequent mechanical pulpting results in reduced utilization of energy, improved strength, and reduced cooking time.

Owner:BIOPULPING INT

Bovine base solution packaging raw paper

The invention relates to a bovine base solution packaging raw paper used in production of liquid packaging boxes. The base solution packaging raw paper comprises a surface layer, a core layer, a base layer and a coating layer and is characterized in that the surface layer comprises chemical hardwood pulp and softwood pulp; the core layer comprises mechanical pulp, chemical hardwood pulp and unbleached pulp; the base layer comprises unbleached pulp; and the coating layer comprises calcium carbonate, porcelain clay, adhesive, a water-retaining agent and a water repellent agent. The base solution packaging raw paper disclosed by the invention has the advantages of environment protection, low cost, high physical strength as well as good decoration property and printing performance of products, accordance with the food requirement and no harm to human bodies, wherein the using amount of chemicals is reduced so that the environment pollution is reduced, and the using amount of chemicals is reduced so that the cost is reduced.

Owner:万国纸业太阳白卡纸有限公司

High bulk hesperaloe tissue

ActiveUS10132036B2Satisfactory softness and strength and bulkOvercome the small stiffnessPaper/cardboardTissue/absorbent paperFiberPaper towel

The invention relates to tissue products comprising hesperaloe fibers and methods of producing the same. Preferably the hesperaloe fibers are high yield hesperaloe pulp fibers, which have demonstrated the ability to replace substantially all of the long fiber fraction of the papermaking furnish without negatively effecting important tissue product properties such as CD Stretch, CD Durability and bulk. Thus, the tissue product may comprise greater than about 90 weight percent hesperaloe fiber and more preferably greater than about 95 weight percent.

Owner:KIMBERLY-CLARK WORLDWIDE INC

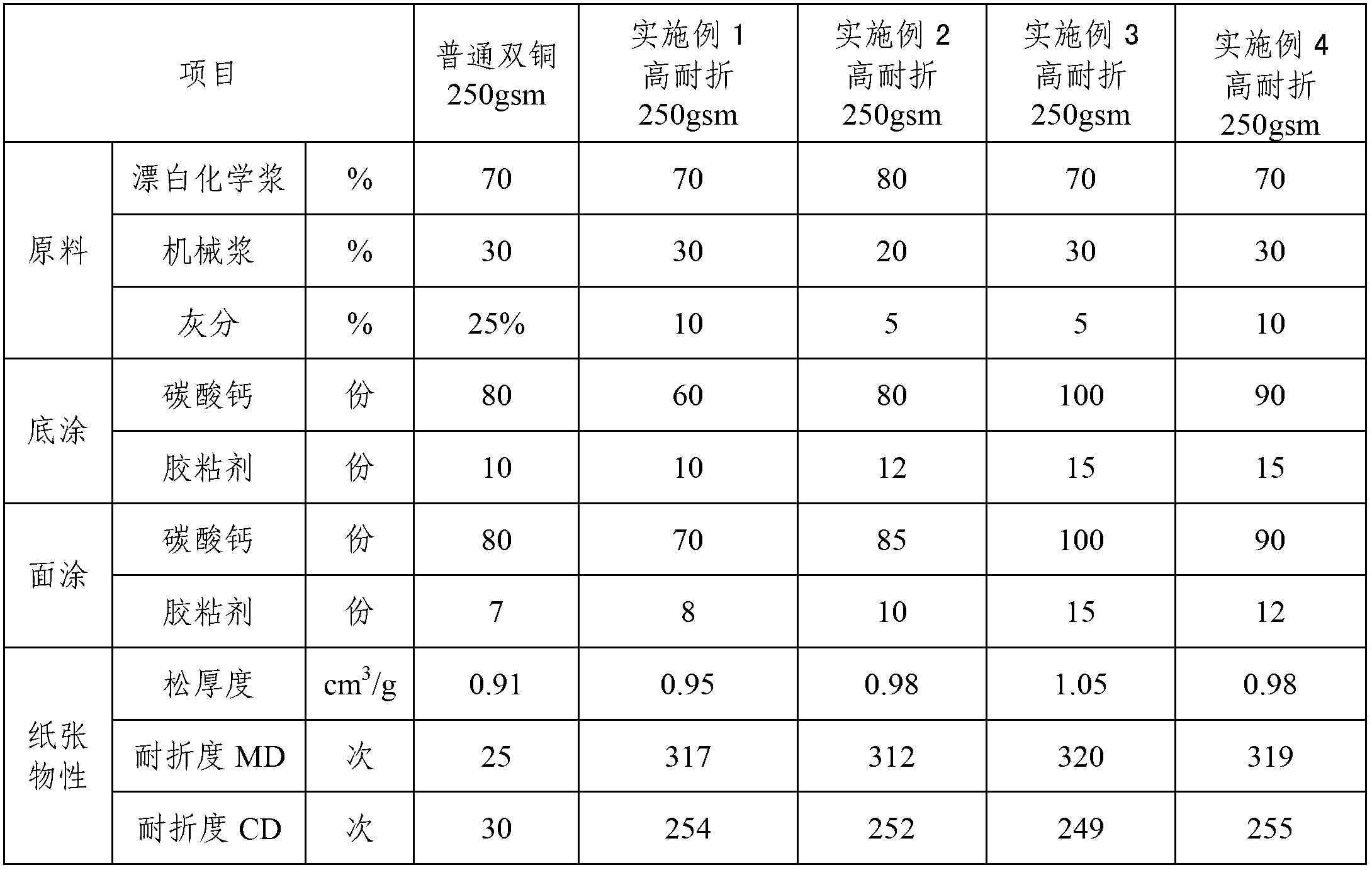

Copper plate card and preparation method thereof

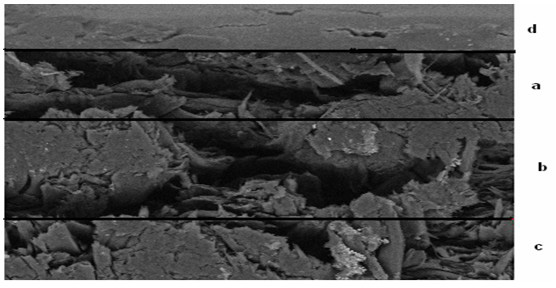

ActiveCN102704321AQuality assuranceWith textureCoatings with pigmentsWater-repelling agents additionNatural resourceFolding endurance

The invention provides a copper plate card, which comprises base paper, a ground coating and a surface coating, wherein the ground coating and the surface coating are coated on both sides of base paper in sequence; the preparation raw material for base paper comprises chemical pulp, mechanical pulp, wet-end chemicals, an inner sizing agent and a surface sizing agent, and the chemical pulp accounts for 20 to 80 parts by weight, and the mechanical pulp accounts for 10 to 30 parts by weight; the ground coating comprises pigment accounting for 60 to 100 parts by weight and an adhesive accounting for 10 to 17 parts by weight; and the surface coating comprises pigment accounting for 70 to 100 parts by weight and an adhesive accounting for 8 to 15 parts by weight. The invention also provides a preparation method of the copper plate card. The copper plate card and the preparation method select and use the mechanical pulp in a suitable proportion, reduce the utilization of the chemical pulp, save natural resources such as forest, water and the like, are beneficial to environmental protection, and ensure the quality; in addition, the bulk of the energy-saving environment-friendly copper plate card with high hard fold quality is controlled within 0.95 to 1.05cm<3> / g, the folding endurance of obtained paper is good, the coating quantity on the both sides are concordant approximately, the remaining effect of printing ink on the paper surface is excellent, and the color of ink is bright.

Owner:HAINAN JINHAI PULP & PAPER

Novel wall paper's crude paper and its mfg. method

InactiveCN1834345ASimple preparation processReduce manufacturing costMachine wet endChemical and mechanical pulp mixturePulp and paper industrySizing

A process for preparing body paper of wallpaper includes preparing mixed size with beating degree as 20-30 degree SR of needle leaf full bleaching chemical wood pulp, 20-30 degree SR of broadleaf full bleaching chemical wood pulp, 40-50 degree SR of self-made bivis cotton pulp and 40-50 degree SR of broadleaf BCTMP pulp; applying AKD neutral sizing in pulp; dewatering by long screen; pressing, drying; press polishing; winding and finishing to obtain said body paper. In the process, screening concentration is 0.5-0.8 %, screening size pH of 7-8 and press polishing is pressurizing mode.

Owner:天津金证科技造纸有限公司

High-whiteness pure paper and manufacturing technology thereof

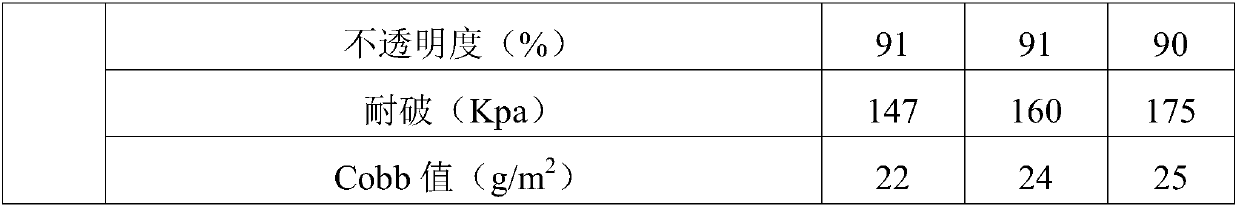

ActiveCN102493259AEnvironmentally friendlySave natural resourcesChemical and mechanical pulp mixtureInorganic compound additionManufacturing technologySulfate

The invention discloses high-whiteness pure paper and a manufacturing technology thereof. In the technology, poplar APMP pulp, needle-leave wood bleached chemical thermomechanical pulp, bleached sulfate needle-leave wood pulp and bleached sulfate broad-leave wood pulp are used for preparing pulp; CMS is added into a pulp preparation pond, wherein due to the water retaining property of the CMS, the dehydration of the high-yield pulp in a net part is slowed down, and the paper uniformity and smoothness are improved; a chelating agent DTPA is added into a white water tank so as to suppress resinaggregation and prevent drop of the pulp whiteness; and before adding the traditional retention aids CPAM and APAM, PAC is added so as to reduce the negative charges of a pulp suspension mainly containing the high-yield pulp, improve the one-pass retention of the manufacturing and increase the paper uniformity and smoothness. The quality indexes of the manufactured high-whiteness pure water are as follows: quantification is 70-80 g / m<2>, the ISO whiteness is 82-86%, the smoothness (front side / back side) is greater than 25 S, the strength of the printing surface is greater than 1.5 m / s, and the bulk is 1.5-1.6 cm<3> / g.

Owner:MCC PAPER YINHE

Soft tissue comprising non-wood fibers

ActiveUS20180135253A1Satisfactory softness and strength and bulkOvercome the small stiffnessPaper/cardboardChemical/chemomechanical pulpFiberMedicine

The present invention provides soft, durable and bulky tissue products comprising non-wood fibers and more particularly hesperaloe fiber. The inventors have discovered that high yield hesperaloe pulp fiber, when incorporated in amounts of at least about 5 percent by weight of the tissue product, produces products having a GMT less than about 1000 g / 3″ and a GM Slope less than about 7.0 kg. At the foregoing tensile strengths and modulus the tissue products of the present invention are also generally soft, such as having a Stiffness Index less than about 10.0, and more preferably less than about 9.0, such as from about 7.0 to about 9.0.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Manufacturing process of ultrahigh bulk paper cup raw paper

InactiveCN104911942AGood filterabilityLow tensile strengthChemical and mechanical pulp mixtureInorganic compound additionSurface layerPapermaking

The invention provides a manufacturing process of ultrahigh bulk paper cup raw paper. The manufacturing process comprises the steps of pulping, blending and papermaking. A surface layer is prepared from the following raw materials in percent: 70-75% of LBKP and 25-30% of NBKP; a bottom layer is prepared from the following raw materials in percent: 65-70% of LBKP and 30-35% of NBKP; a core layer is prepared from the following raw materials in percent: 20-30% of LBKP, 10-15% of NBKP and 60-65% of APMP; the bulkiness of the APMP pulp is 3.5-3.7cm<3> / g, and the tensile strength is 14-16N*m / g; the step of papermaking is to feed three layers of blended pulp into a papermaking machine to carry out compound papermaking; the quantity of the surface layer is 25-35g / m<2>, the quantity of the core layer is 110-130g / m<2> and the quantity of the bottom layer is 35-45g / m<2>. The raw paper has high bulkiness and good flexibility and is not easy to turn and explode.

Owner:GUANGXI JINGUI PULP PAPER

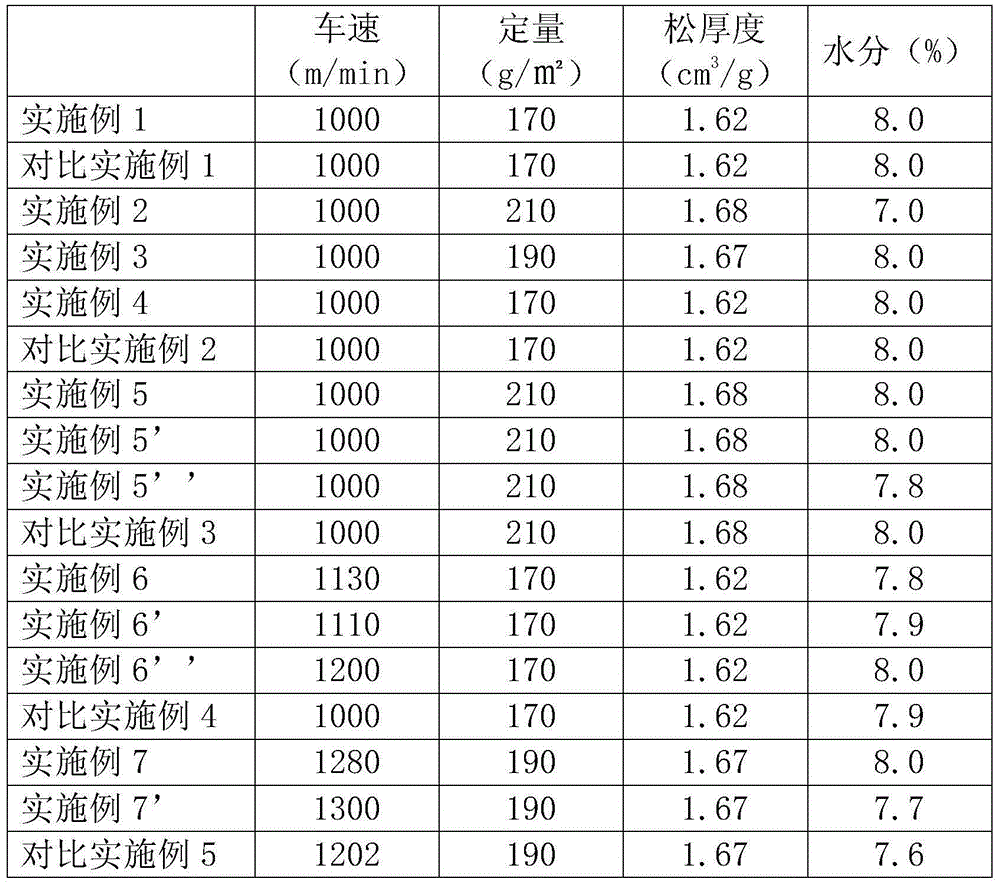

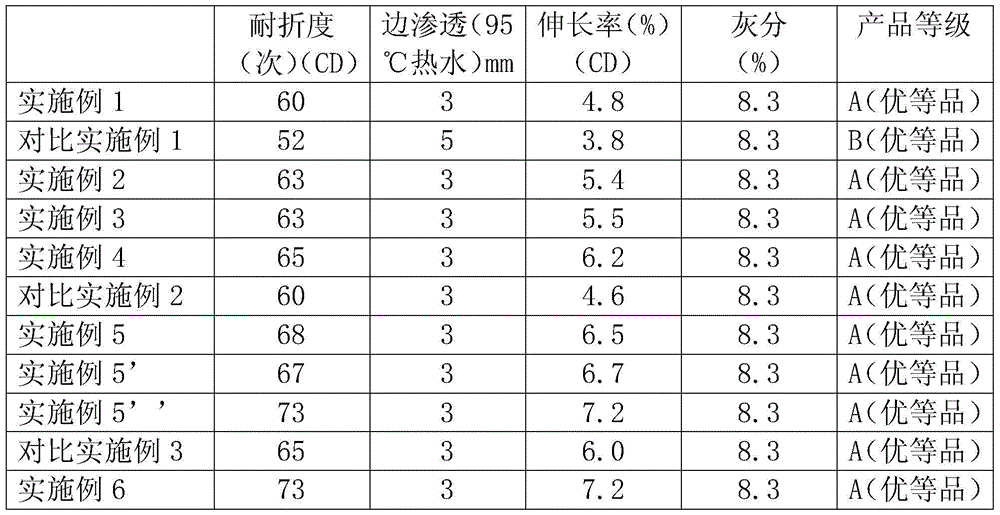

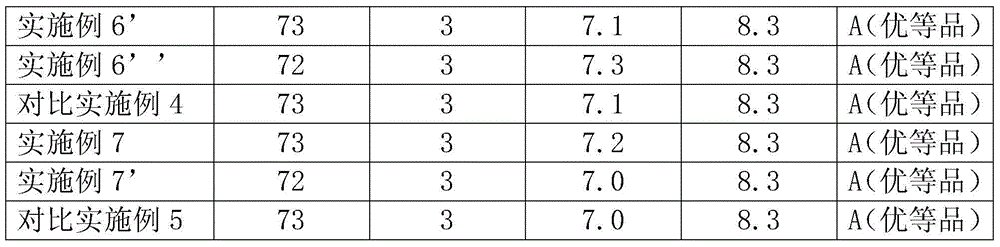

Ultrahigh-loose thickness noodle bowl paper and production process thereof

InactiveCN104562828AReduce usageReduce manufacturing costChemical/chemomechanical pulpChemical and mechanical pulp mixtureMaterials sciencePulp (paper)

The invention discloses ultrahigh-loose thickness noodle bowl paper. The ultrahigh-loose thickness noodle bowl paper comprises a surface layer, a core layer and a bottom layer, wherein both the surface layer and the bottom layer comprise bleached needlebush sulfate pulp, and the content of the bleached needlebush sulfate pulp in the surface layer and the bottom layer is 35 to 50 percent by weight. The invention also provides a production process of the ultrahigh-loose thickness noodle bowl paper. On the premise of improving the loose thickness of the noodle bowl paper, the difficulties of curling cracking, side seepage and oil seepage can be solved.

Owner:ZHUHAI HUAFENG PAPER

Integration of non-woody biorefining at pulp and paper plants

ActiveUS20150275432A1Enhance the imageBiofuelsPulping with acid salts/anhydridesCelluloseProcess integration

In some variations, a process is provided for producing a pulp product at a biorefinery site, comprising: converting a woody cellulosic material to a first pulp stream; converting a non-woody cellulosic material to a second pulp stream; blending the second pulp stream into the first pulp stream; and recovering or further processing the blended pulp stream as a pulp product. Biorefinery site infrastructure may be shared between the woody and non-woody lines. Also, the process may include process integration of mass and / or energy between the woody and non-woody lines. The process may be a retrofit addition to a pulp plant, or a greenfield biorefinery site. The non-woody line also can generate fermentable sugars, for fermentation to ethanol (or other products). Through allocation of carbon credits from the ethanol to the pulp, the final pulp product life-cycle profile can be improved.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

High quality paperboard and products made thereof

ActiveUS7897011B2Increased bending stiffnessMaintain good propertiesNon-fibrous pulp additionPaper after-treatmentCardboardEngineering

The invention relates to a high quality paperboard comprising at least two plies, a first ply having good surface properties and strength, and a second ply for providing the paperboard with bulk wherein the second ply comprises hardwood CTMP. This paperboard has an internal strength and a bending resistance that is comparable with conventional high quality paperboard based on softwood CTMP. The invention also relates to products manufactured of the paperboard.

Owner:STORA ENSO AB

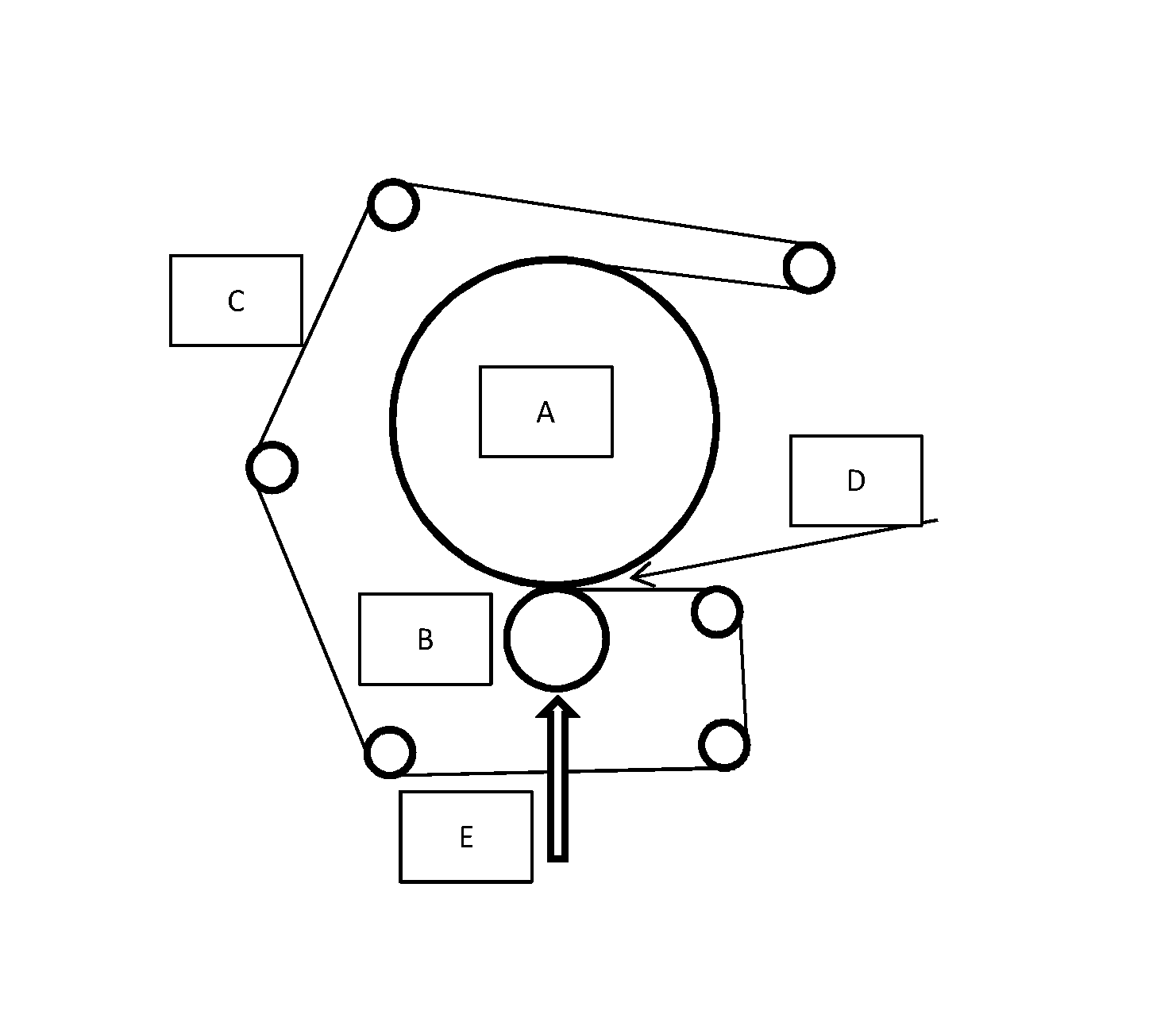

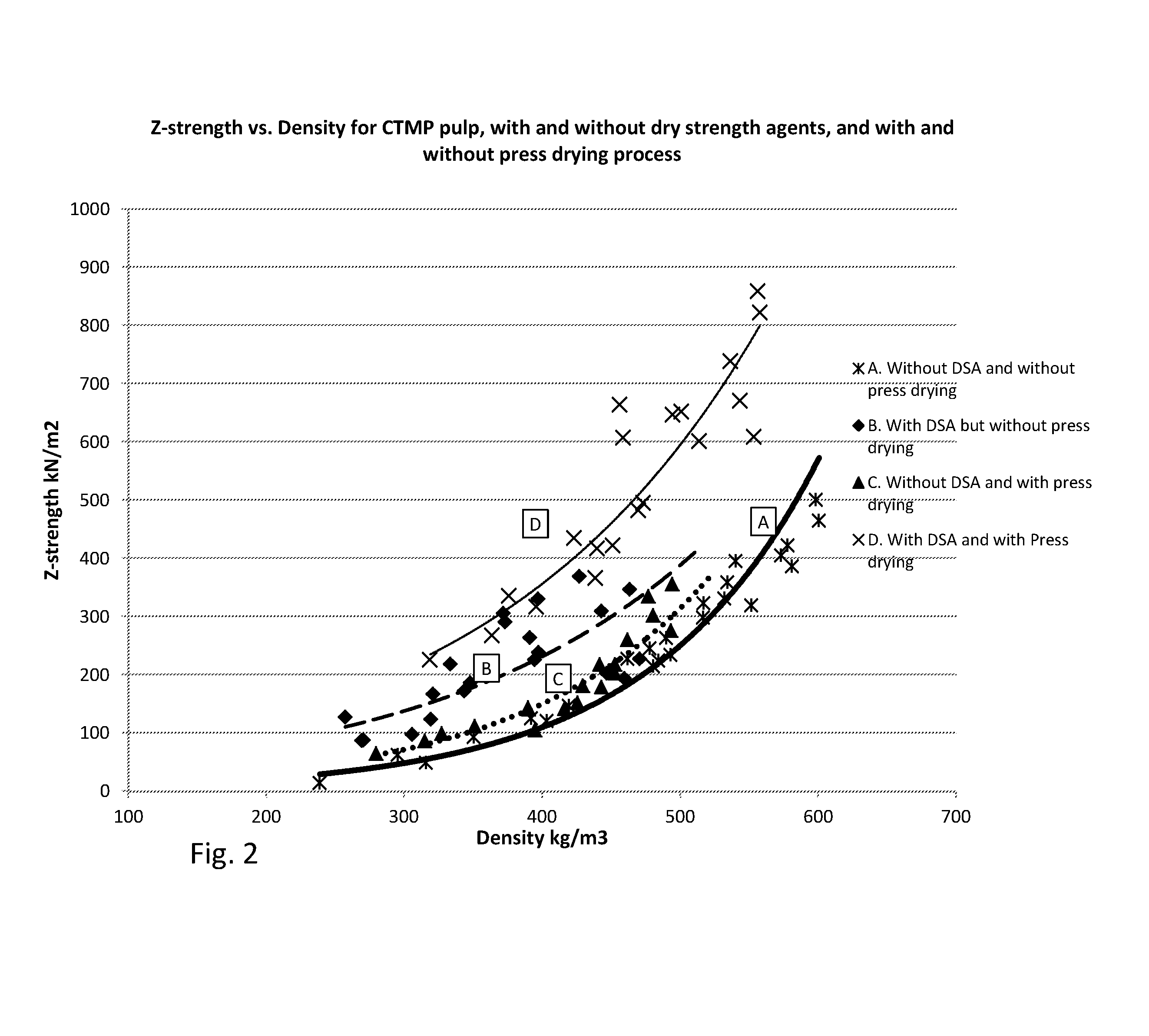

A paper or paperboard product comprising at least one ply containing high yield pulp and its production method

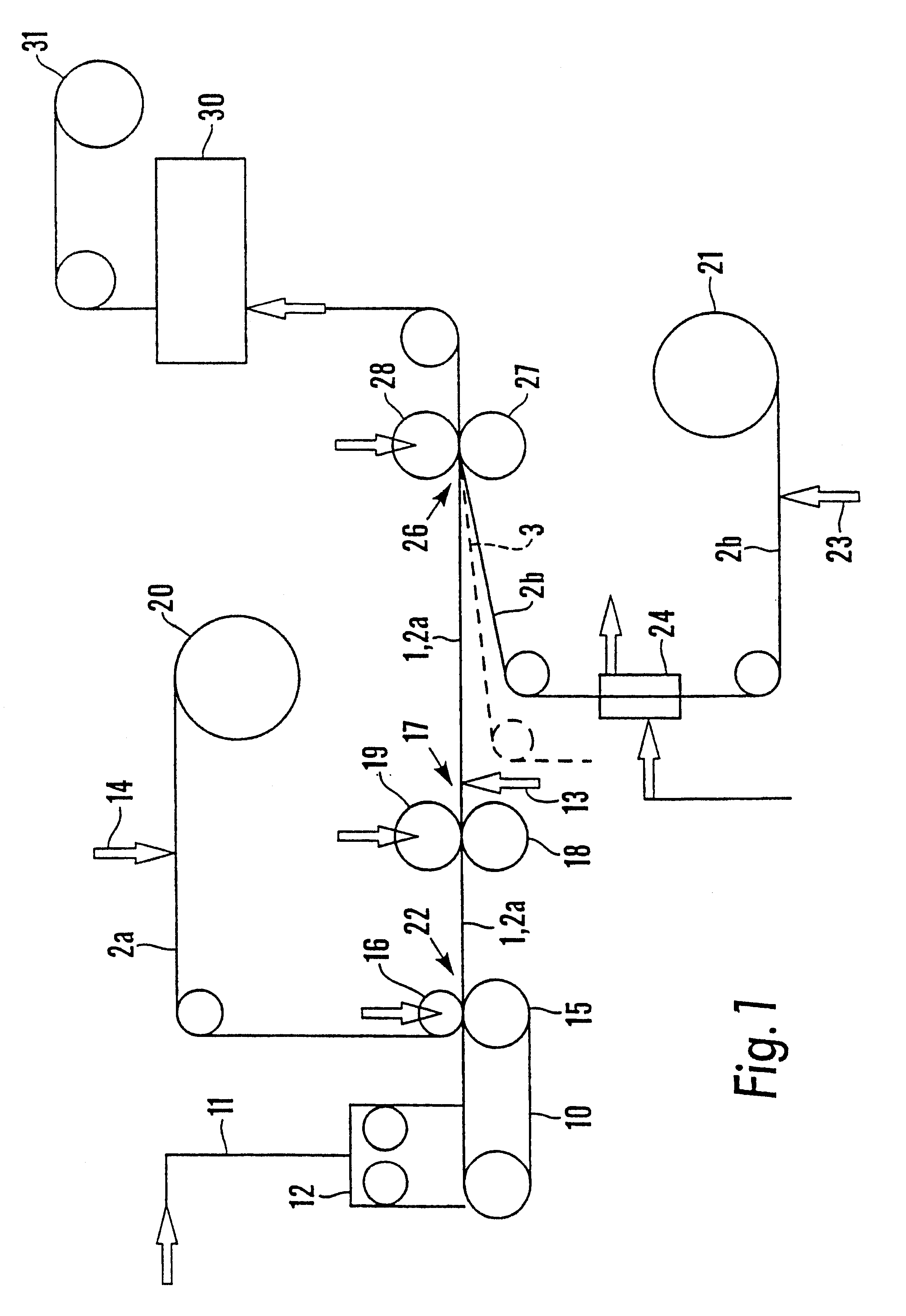

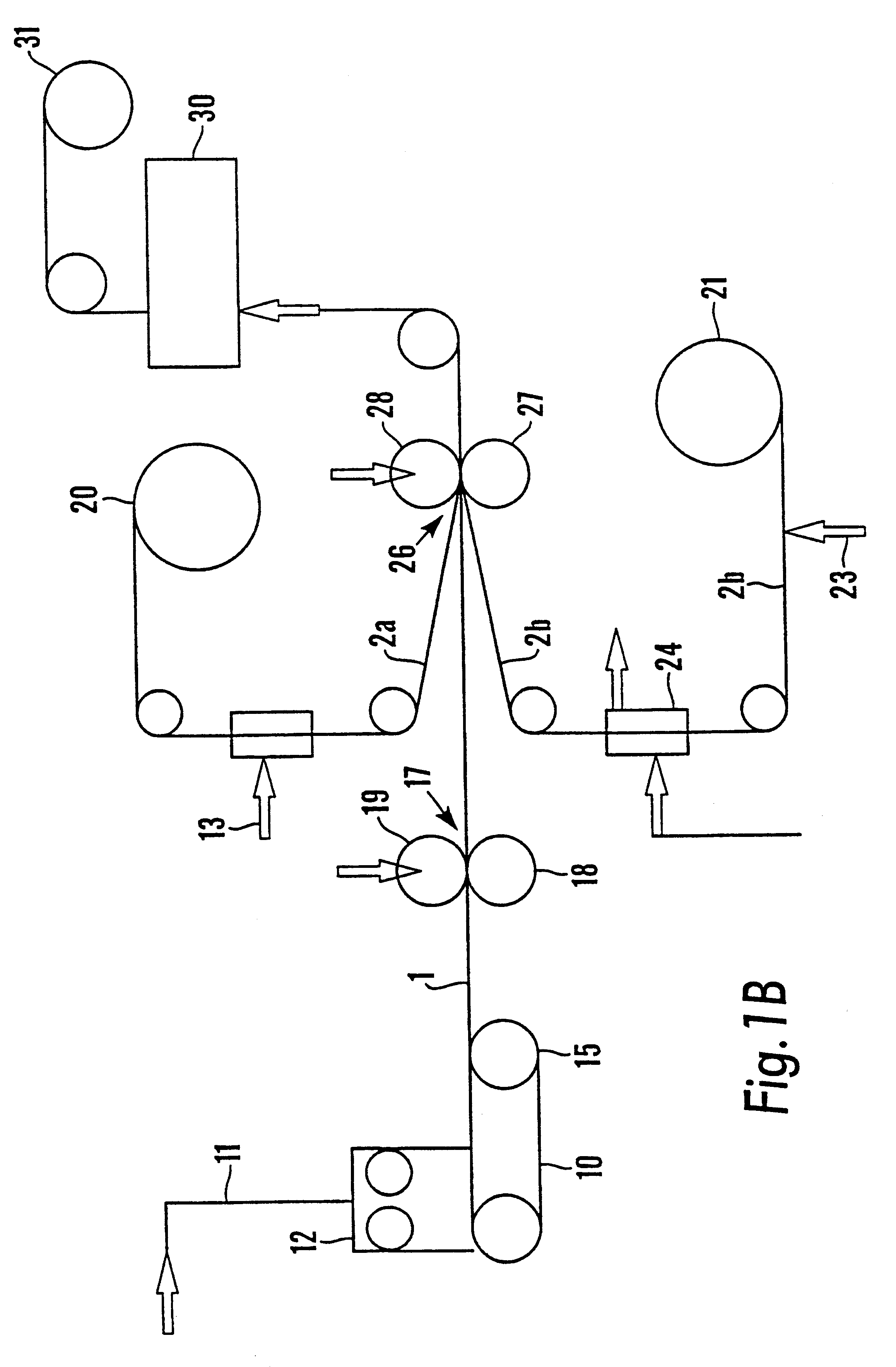

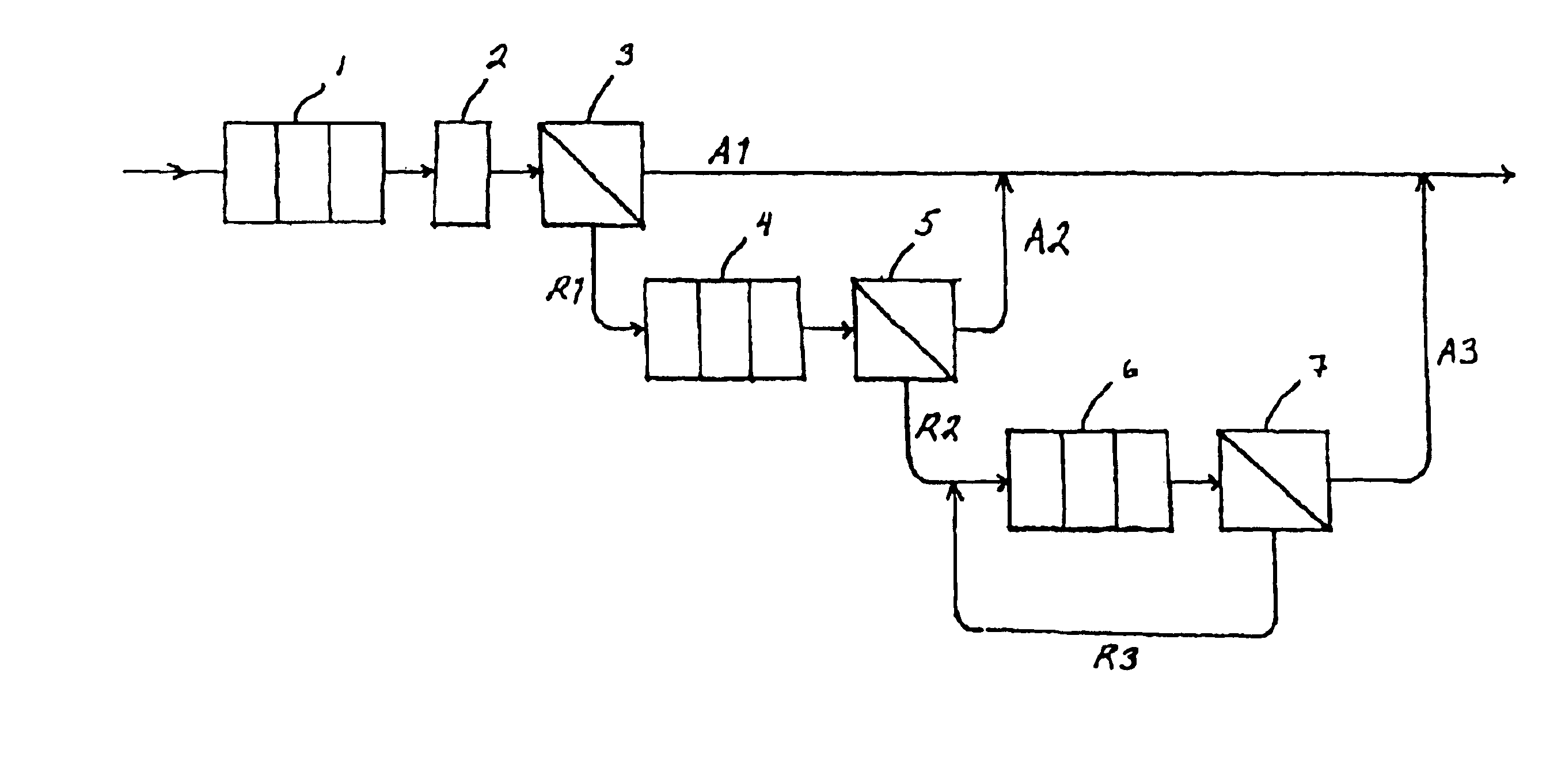

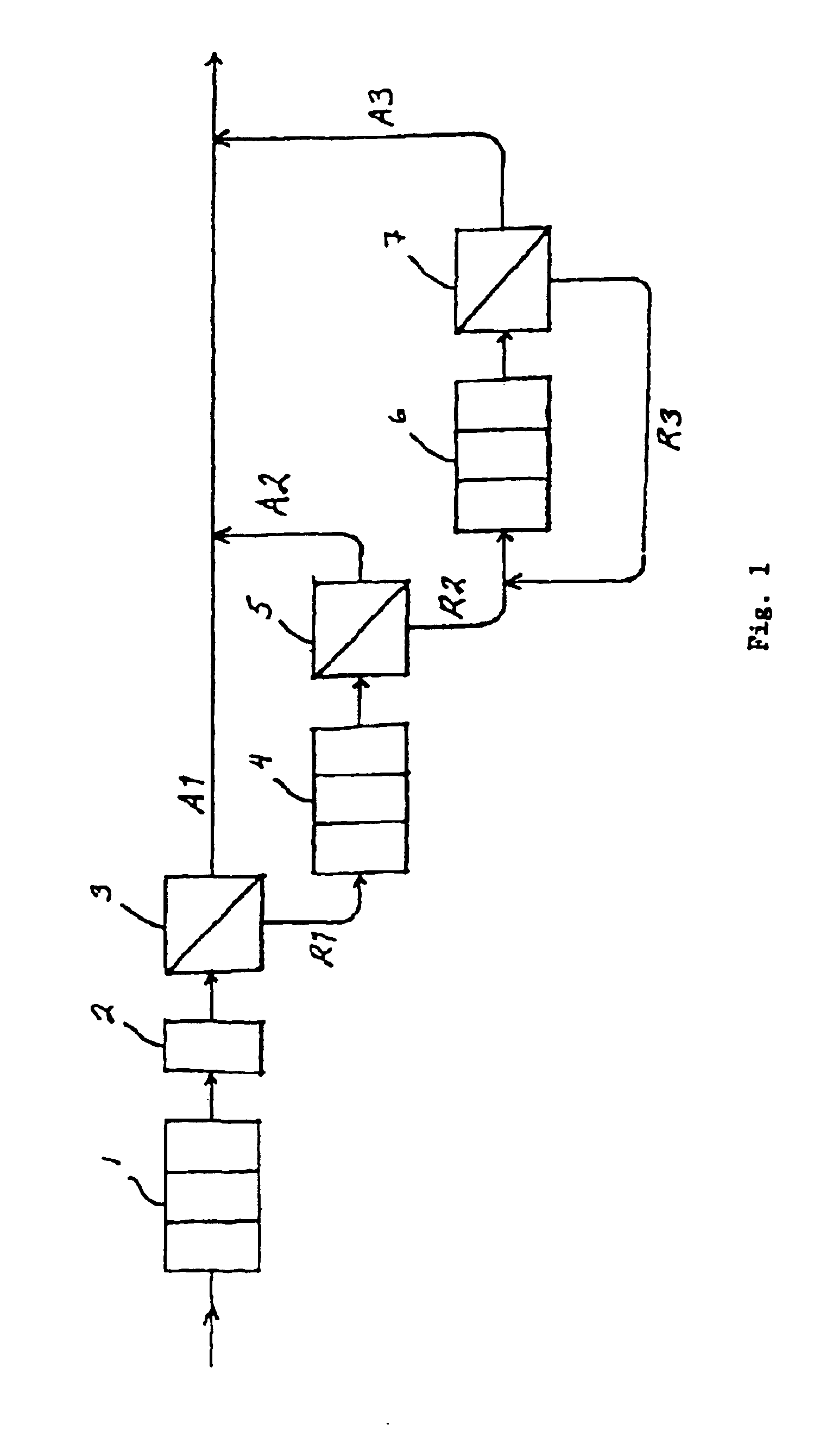

ActiveUS20190218716A1Reduce energy consumptionHigh strengthDryer sectionPress sectionPaperboardSolid content

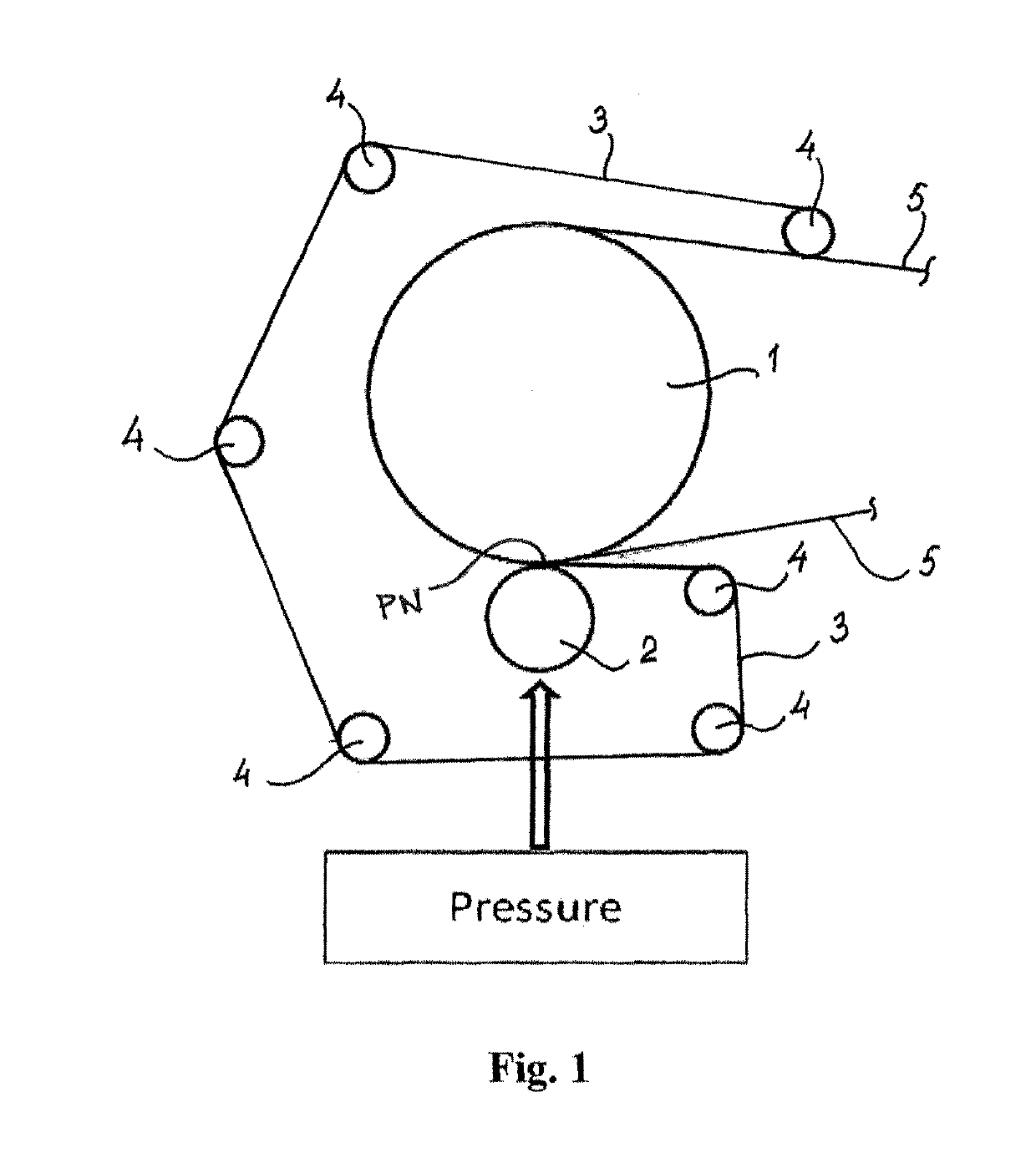

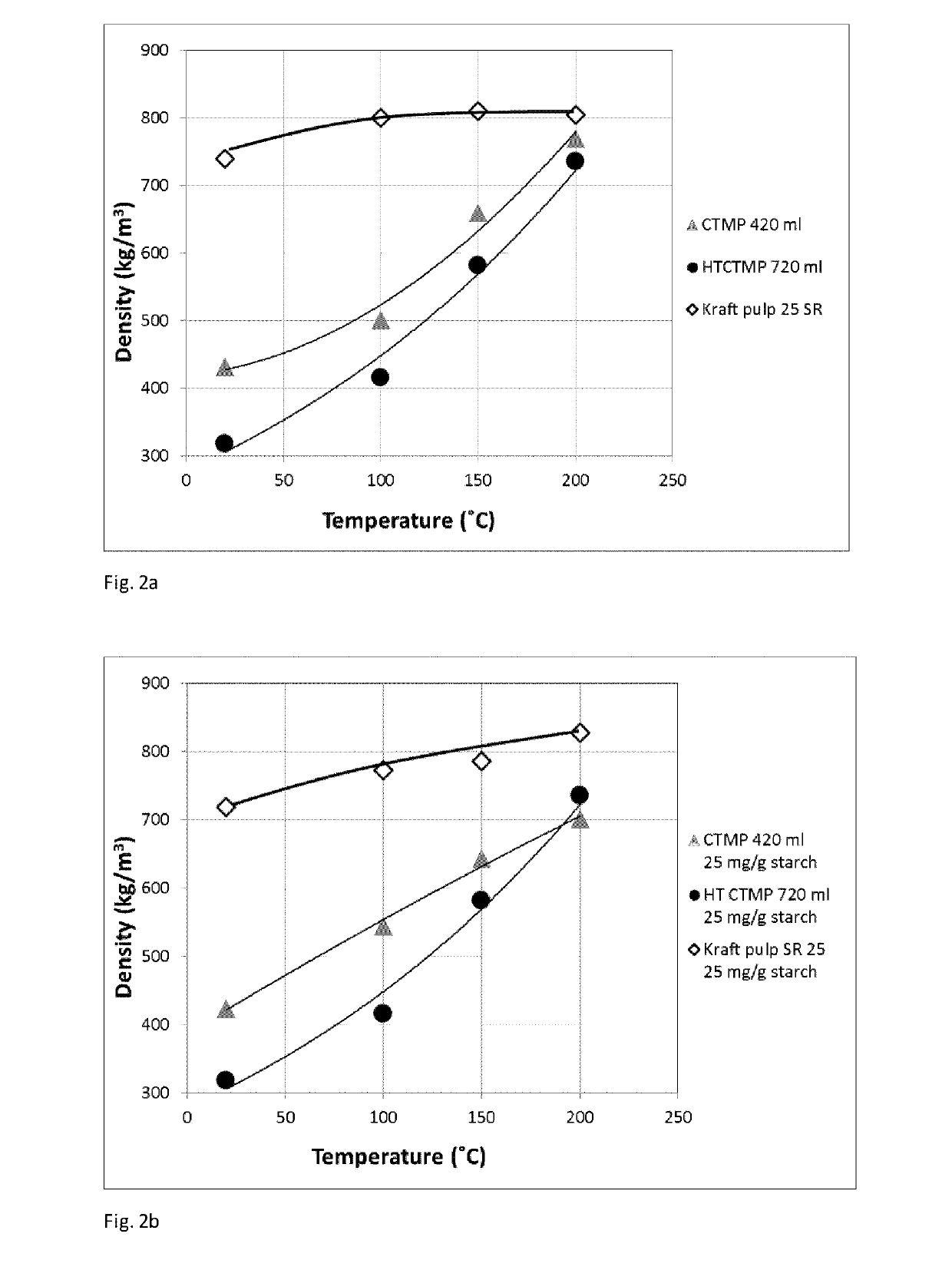

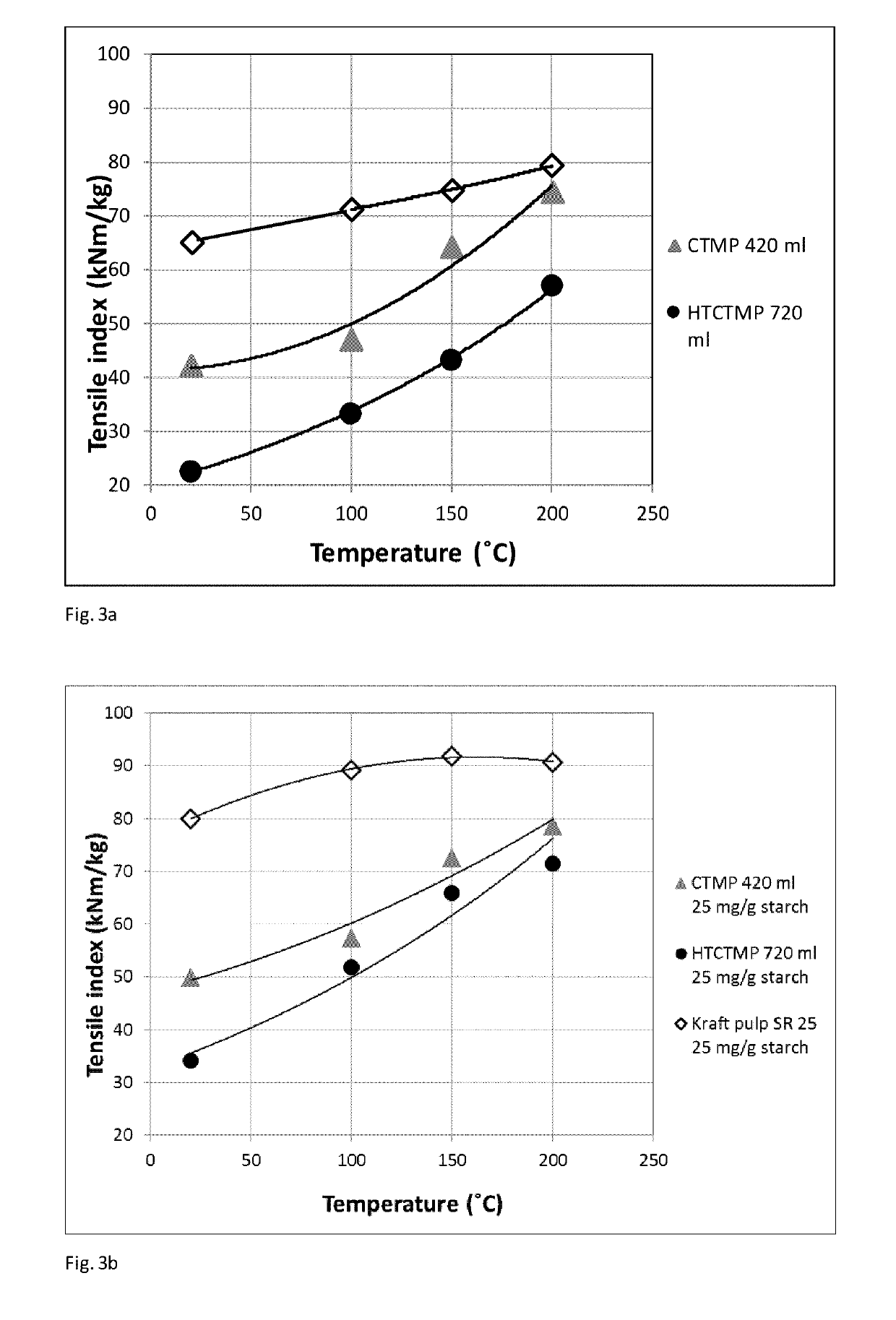

A method of producing a paper or paperboard product having at least one ply comprising high yield pulp (HYP), comprising the steps of: —providing a furnish comprising at least 50% of high yield pulp (HYP) of a total pulp content in said furnish, said high yield pulp being produced with a wood yield above 85%; —dewatering the furnish to form a moist web and pressing said moist web to a dry solids content of at least 40-70%; and —densifying the moist web to a density above 600 kg / m3 in a press nip of a paper machine at a temperature above a softening temperature of water-saturated lignin comprised in said high yield pulp to provide a paper or paperboard product, containing at least 30% high yield pulp (HYP) of a total pulp content of said product.

Owner:IPCO SWEDEN AB CO SANDVIK AB

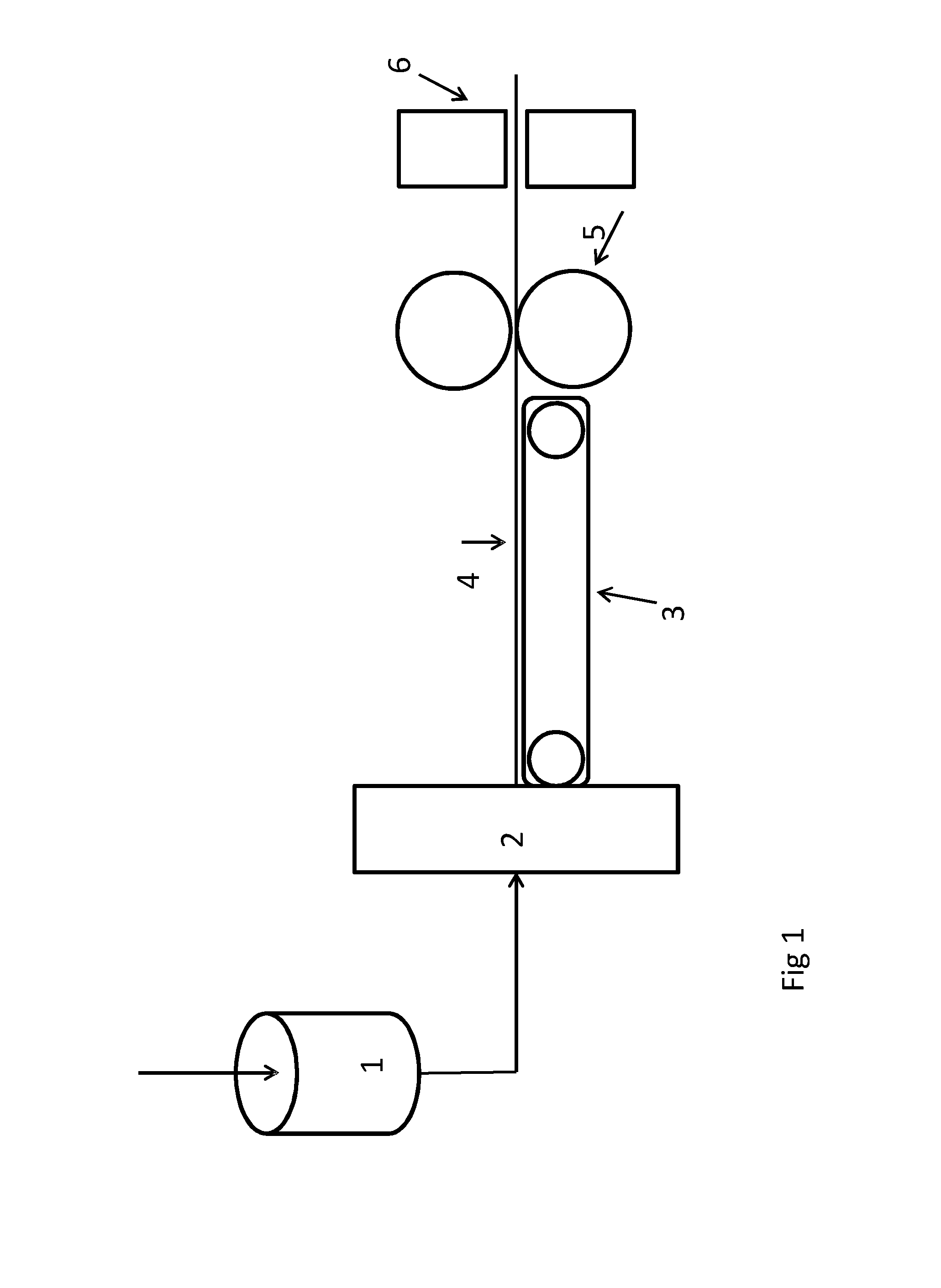

Process for producing at least one ply of a paper or board and a paper or board produced according to the process

ActiveUS20170051456A1High strengthWithout adversely affecting the bulkPulp properties modificationDryer sectionPaperboardPulp and paper industry

The present invention relates to a process for producing at least one ply of a paper or board product wherein a web comprising mechanical and / or chemimechanical pulp and at least one dry strength additive is dried in a press drying process by subjecting the web to heat and an overpressure of above 40 kPa. The present invention also relates to a paper product, a paperboard product and a ply produced according to the process.

Owner:STORA ENSO OYJ

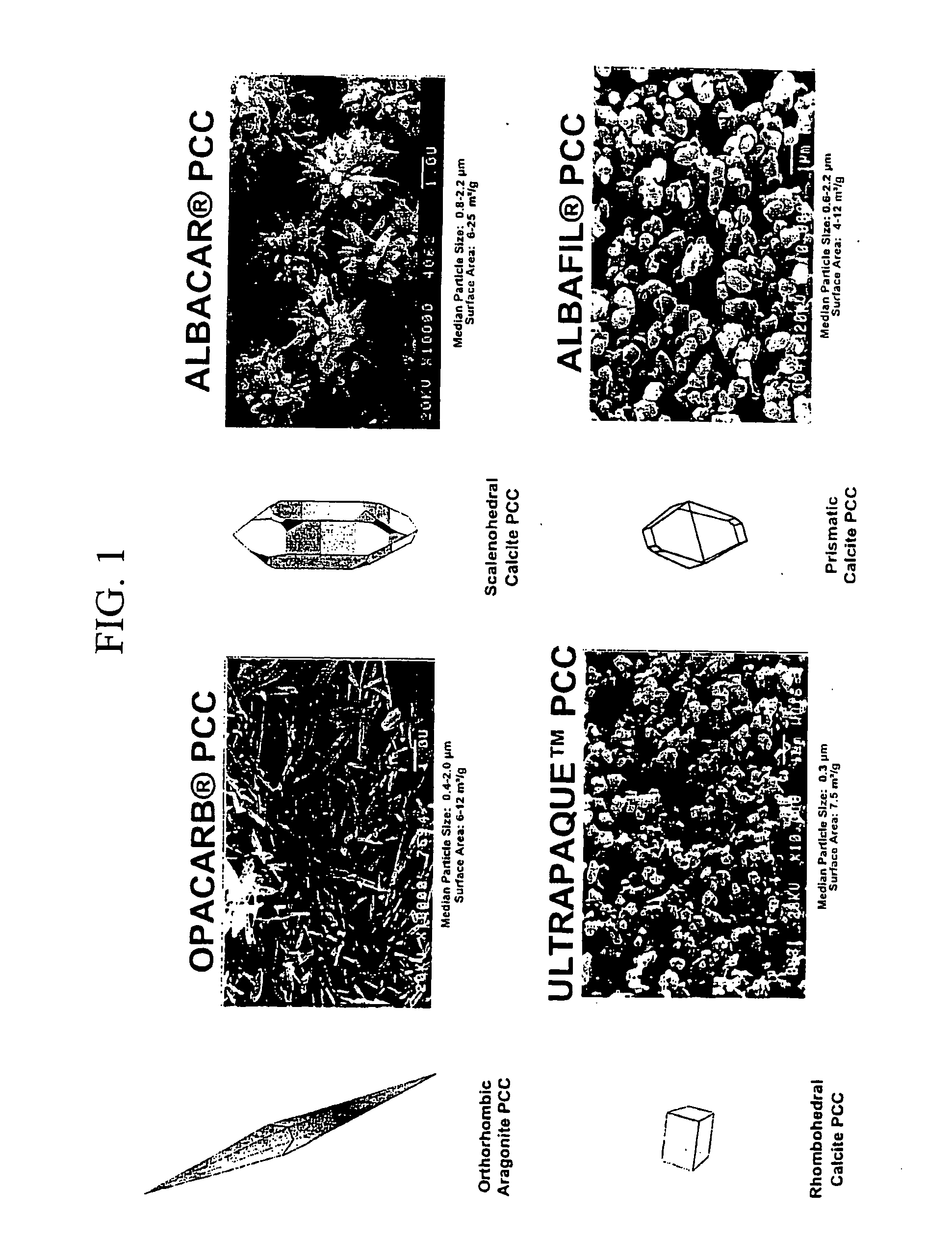

Filler for the manufacture of base paper and method for the manufacture of base paper

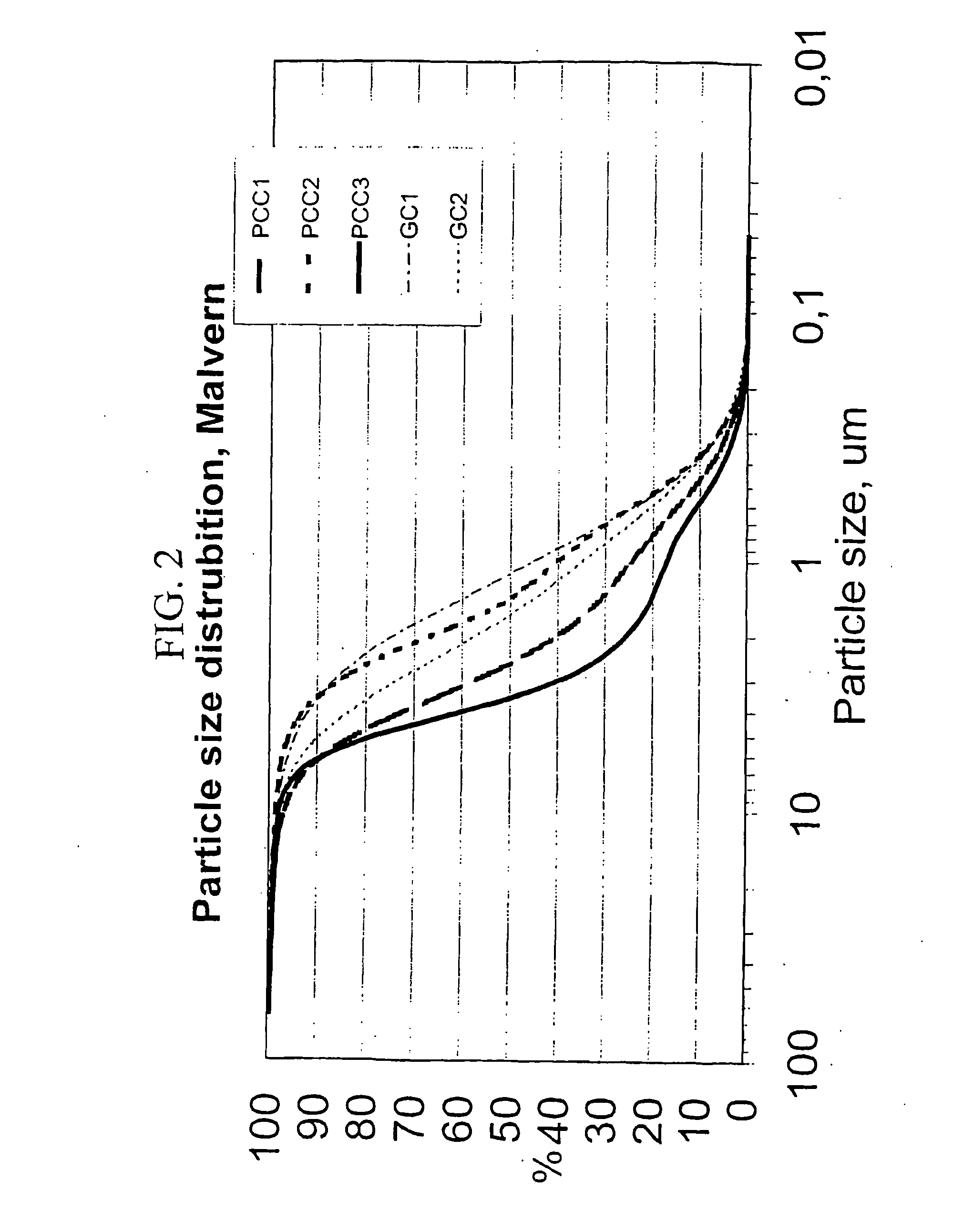

InactiveUS20040256067A1Lose weightHigh densitySpecial paperPaper after-treatmentFiberPrecipitated calcium carbonate

The invention relates to the use of precipitated calcium carbonates (PCC) as fillers for the manufacture of base paper together with mechanical hardwood pulp and chemical softwood pulp, and to a method for the manufacture of base paper, in which method pulp produced from hard woods, in particular from the wood of the genus Populus, and chemical softwood pulp are used together with a PCC filler. The use of precipitated calcium carbonate (PCC) for the manufacture of base paper together with mechanical hardwood pulp and chemical softwood pulp is characterized in that >=20 wt-% of the fibres of the mechanical hardwood pulp is included in the fibre size fraction of <200 mesh and 10-40 wt-% of them is included in the fibre size fraction of {fraction (28 / 48 mesh, the brightness of the mechanical hardwood pulp is >=75, the particle size distribution of the precipitated calcium carbonate is 90%<=9 mum, 50%<=5 mum and 20%<=1.5 mum, and the basis weight of the base paper is 25-150 g / m<2>.

Owner:M REAL OYJ

Paper composition

A paper product may include high energy thermomechanical pulp (TMP), low energy TMP, and microfibrillated cellulose. The paper product may also include inorganic particulate material. A papermaking composition suitable for making the paper product, a process for preparing the paper product, and use of microfibrillated cellulose may include high energy TMP, low energy TMP, and microfibrillated cellulose, and optionally inorganic particulate material. The microfibrillated cellulose may have a fiber steepness of from about 20 to about 50 in the paper product.

Owner:FIBERLEAN TECH LTD

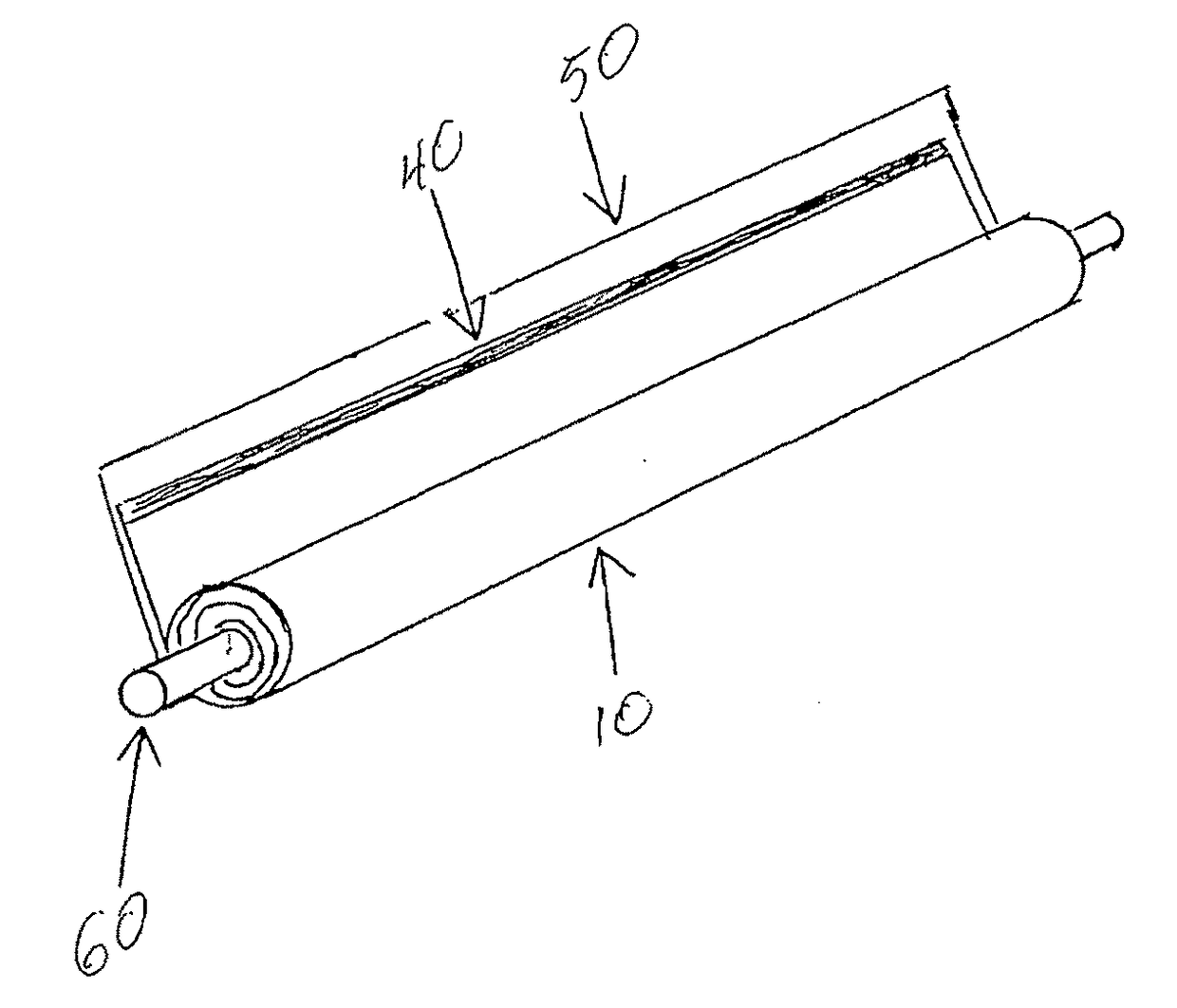

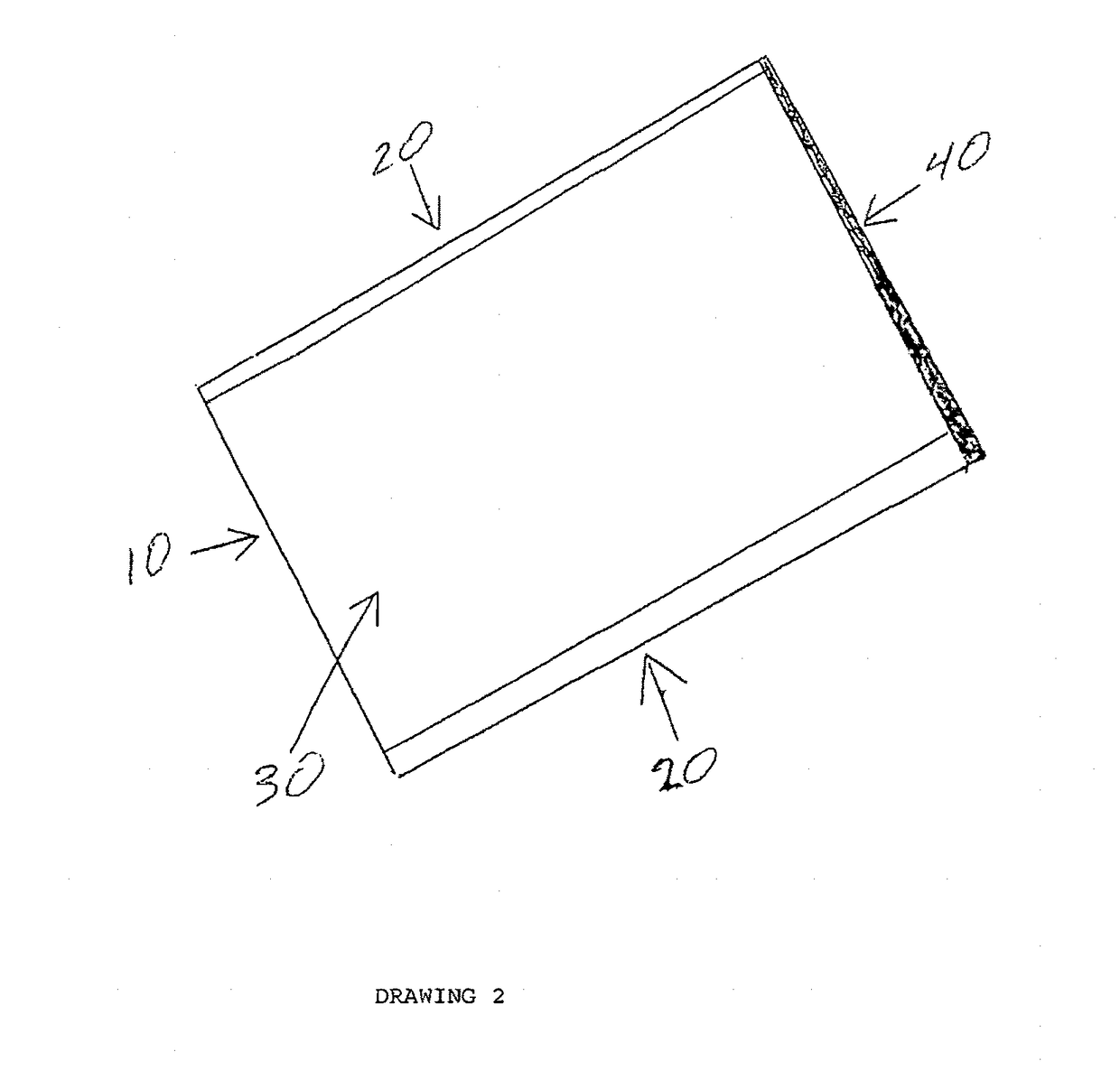

Non-tobacco non-thc industrial hemp fiber smoking article

InactiveUS20180027869A1Cost-effectiveEasy for consumers to rollTobacco treatmentCigar manufactureCannabisCellulose

The present invention is a non-tobacco smoking article for consumers to use to make their own herbal smoking articles. It is a non-THC containing industrial hemp product, made with industrial hemp, cellulose and other ingredients. The product is an herbal, non-nicotine and non-hallucinogenic alternative to tobacco wraps and cigarette rolling papers.

Owner:NEW IMAGE GLOBAL INC

Product and processes from an integrated forest biorefinery

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Glass interleaving paper

ActiveUS20170152633A1Avoid scratchesNon-fibrous pulp additionFlexible coversMohs scale of mineral hardnessHardness

Provided is a glass interleaving paper capable of suppressing scratches on surfaces of glass plates in a manufacturing process or a distribution process for storing and transporting a plurality of stacked glass plates. The glass interleaving paper is characterized in that a main component is cellulose pulp, a basis weight is 10 to 100 g / m2, and content of mineral having a Mohs hardness of at least 5 is 400 ppm or less. When the mineral having a Mohs hardness of at least 5 is a silicate mineral, the glass interleaving paper is more useful.

Owner:OJI HLDG CORP

Production method of lightweight paper

InactiveCN109680536AHigh yieldHigh opacityWater-repelling agents additionChemical and mechanical pulp mixtureSulfatePaper manufacturing

The invention discloses a production method of lightweight paper. The production method comprises a wood pulp proportioning step and a mixing step. Needle BCMTP chemimechanical pulp and needle bleached chemical wood pulp are proportioned and pulped; a neutral sizing agent, cationic starch, cationic polyacrylamide and talcum powder are used; then a paper manufacturing process is performed. Importedneedle wood pulp and broadleaf wood bleached sulfate pulp are respectively pulped and blended, and various additives are added; the blend is conveyed into an approaching system for dehydration forming through a wet part and then is further dehydrated through a squeezing part; after pre-drying, semi-dry calendaring and surface sizing are performed, the product is dried through a drying part; the product is baked at low temperature, subjected to soft calendaring finishing and wound. First of all, high bulkiness is achieved, and the flatness and the tensile strength of paper are not affected, sothe production method is suitable for high-speed printing; secondly, no flourescent brightener is contained; compared with common coated paper, offset paper and lightweight paper, the lightweight paper produced according to the method is relatively dark and has a color close to the primary color of wood pulp, so that visual fatigue cannot be caused by long-time reading.

Owner:SHANDONG TIANYANG PAPER

High-quality environment-friendly recycled paper processing method

InactiveCN108978296AIncrease valueIncreased gelatinizationPulp beating methodsPaper/cardboardHot stampingAdhesive

The invention discloses a high-quality environment-friendly recycled paper processing method, and belongs to the technical field of environment-friendly recycled products, and solves a problem in theprior art that environment-friendly recycled paper through the waste paper recycling production is lower in quality. The method comprises the following steps: (1), smashing sorted and cleaned waste paper, mixing and grinding the smashed paper and water to form paper pulp, and performing filtering and stirring to make recycled pulp; (2), making semi-finished base paper; (3), making semi-finished surface paper; (4), coating the upper surface of the semi-finished base paper with an adhesive, pasting the semi-finished surface paper on the semi-finished base paper, and compressing the paper througha roller press to make semi-finished raw paper; (5), coating the surface of the semi-finished raw paper prepared at the step (4) with surface coating liquid, and performing the drying, surface pressing and polishing, finishing and winding to obtain finished recycled paper; (6), filling a surface gap to make the surface even; (7), preparing composite gloss oil and coating the paper with the glossoil; (8), performing hot-stamping operations, and placing the paper quietly. The environment-friendly recycled paper prepared through the method is clean and flat, is higher in quality, and can be used in various fields.

Owner:河南东贵电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com