Manufacturing process of ultrahigh bulk paper cup raw paper

A production process and ultra-high loosening technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of increasing the risk of cracking of the coil opening, reducing the elongation of the base paper, and reducing the performance of the base paper. The effect of bursting, increasing bulk, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

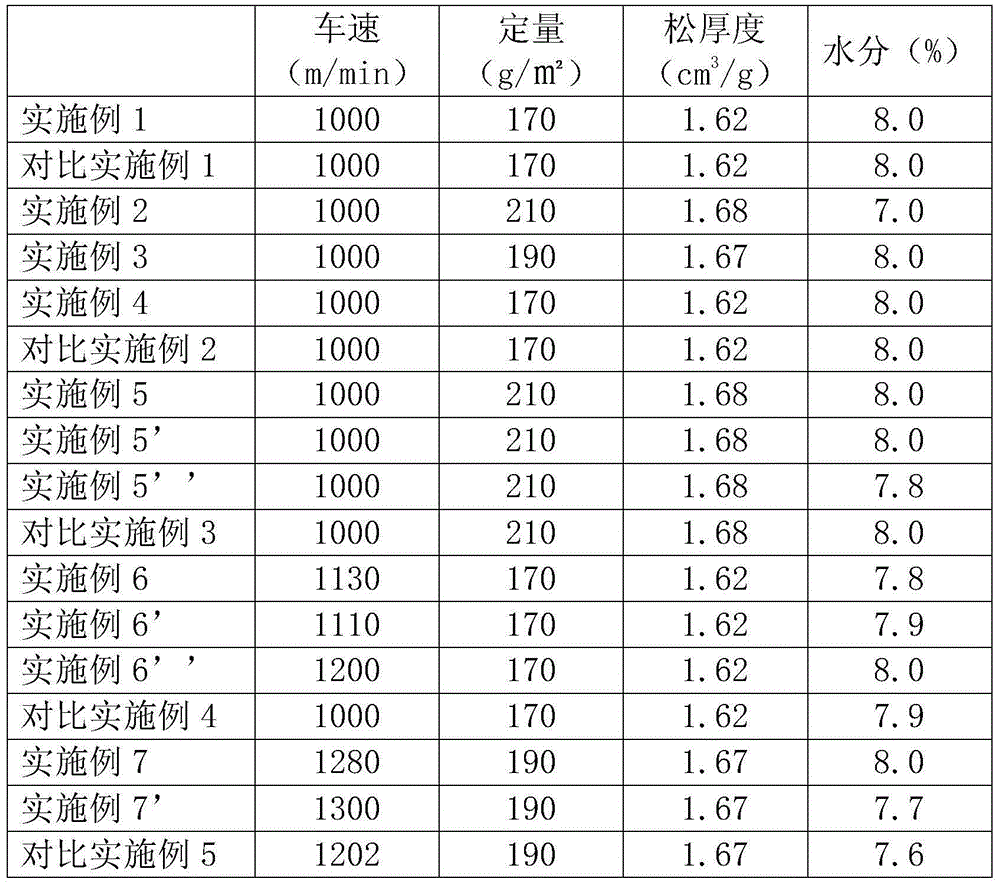

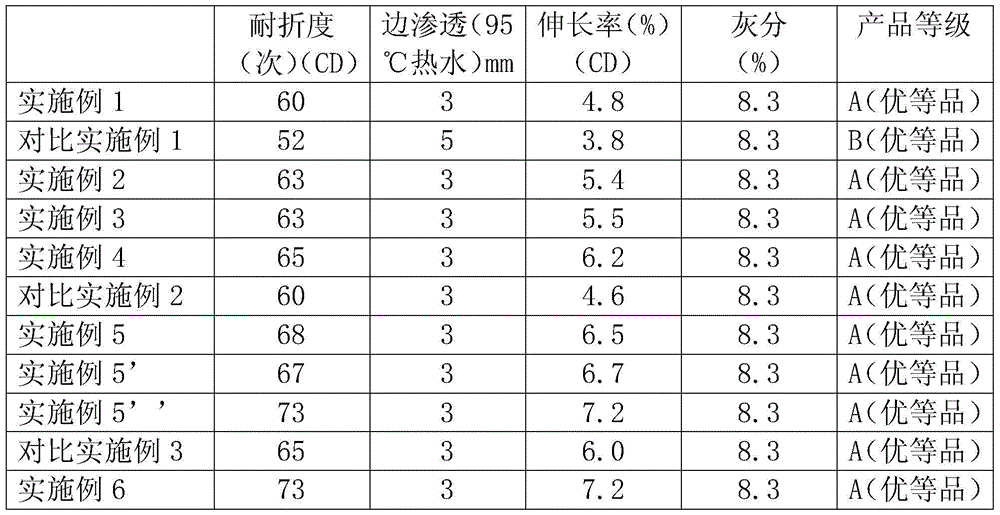

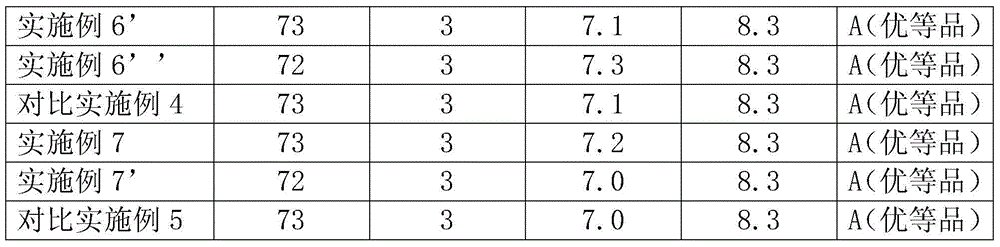

Embodiment 1

[0030]1) pulping: including making three-layer slurry of surface layer, bottom layer and core layer, the surface layer slurry is made of the following raw materials by weight percentage: LBKP 70%, NBKP 30%; the bottom layer slurry is made of the following raw materials by weight percentage Made: LBKP 65%, NBKP 35%; the core layer slurry is made from the following raw materials by weight: LBKP 20%, NBKP 15%, APMP 65%; the bulk thickness of the APMP slurry is 3.5cm 3 / g, tensile strength 14N·m / g.

[0031] 2) seasoning: including sizing, the sizing is to add rosin and aluminum sulfate to three layers of slurries respectively, and the consumption of rosin in each layer is 15kg / t of each layer of slurry, and the amount of aluminum sulfate in each layer is 15kg / t of each layer of slurry.

[0032] 3) Papermaking: The three-layer slurry after the seasoning is sent to a paper machine for composite papermaking, and the surface layer is quantitatively 25g / m2 2 , the core layer quantitat...

Embodiment 2

[0038] 1) Pulping: including the manufacture of three-layer slurry of surface layer, bottom layer and core layer, the surface layer slurry is made of the following raw materials by weight: LBKP 75%, NBKP 25%; The bottom layer slurry is made of the following raw materials by weight Made: LBKP 70%, NBKP 30%; the core layer slurry is made from the following raw materials by weight: LBKP 30%, NBKP 10%, APMP 60%; the bulk thickness of the APMP slurry is 3.7cm 3 / g, tensile strength 16N·m / g.

[0039] 2) seasoning: including sizing, the sizing is to add rosin and aluminum sulfate to the three layers of slurries respectively, and the consumption of rosin in each layer is 20kg / t of each layer of slurry, and the amount of aluminum sulfate in each layer is 25kg / t of each layer of slurry.

[0040] 3) Papermaking: send the seasoned three-layer slurry into a paper machine for composite papermaking, adjust the pulp-to-web speed ratio in the process of papermaking to 0.94, and the surface lay...

Embodiment 3

[0042] 1) Pulp making: including making three layers of slurry: surface layer, bottom layer and core layer, the surface layer is made of the following weight percentage of the slurry: LBKP 72%, NBKP 28%; the bottom layer is made of the following weight percentage of the slurry Manufactured: LBKP68%, NBKP 32%; the core layer is made of the following pulps by weight: LBKP 25%, NBKP10%, APMP 65%; the bulk of the APMP pulp is 3.6cm 3 / g, tensile strength 15N·m / g.

[0043] 2) seasoning: including sizing, the sizing is to add rosin and aluminum sulfate to three layers of slurries respectively, and the consumption of rosin in each layer is 18kg / t of each layer of slurry, and the amount of aluminum sulfate in each layer is 20kg / t of each layer of slurry.

[0044] 3) Papermaking: send the seasoned three-layer slurry into a Fourdrinier paper machine for compound papermaking, adjust the pulp-to-web speed ratio in the papermaking process to 0.96, and the surface layer quantitatively to 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk | aaaaa | aaaaa |

| Bulk | aaaaa | aaaaa |

| Bulk | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com