Cathode load self-generated dynamic membrane bioreactor

A bioreactor, cathode loading technology, applied in the field of water treatment, can solve the problems of short operation period, complex operation, increase system energy consumption, etc., to increase the particle size of floc particles, prolong the cleaning period, and improve the filterability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

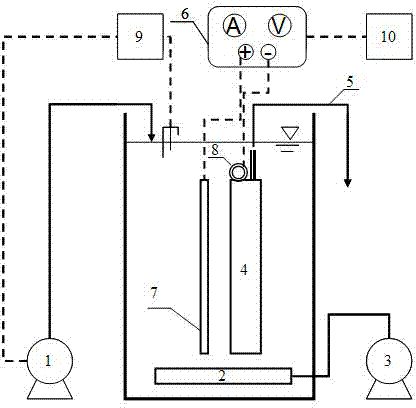

[0022] From figure 1 It can be seen that a cathode-loaded autogenous dynamic membrane bioreactor consists of three parts: a biological treatment system, a cathode-loaded system, and an automatic control system. The biological treatment system consists of water inlet pump 1, perforated aeration pipe 2, aeration pump 3, dynamic membrane module 4, and outlet pipe 5. Aeration pump 3 is connected to perforated aeration pipe 2, and perforated aeration pipe 2 is located in the dynamic membrane module. Directly below 4, the water collection port at the upper end of the dynamic membrane module 4 is connected to the water outlet pipe 5, and the water outlet adopts the form of gravity self-flowing water; the cathode load system is composed of a DC stabilized power supply 6, an electrode plate 7, and a cathode load interface 8, and the DC stabilized power supply 6. The positive pole of the output is connected to the electrode plate 7, and the negative pole of the output is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com