Pulping paper-making process with zero discharge of sewage water

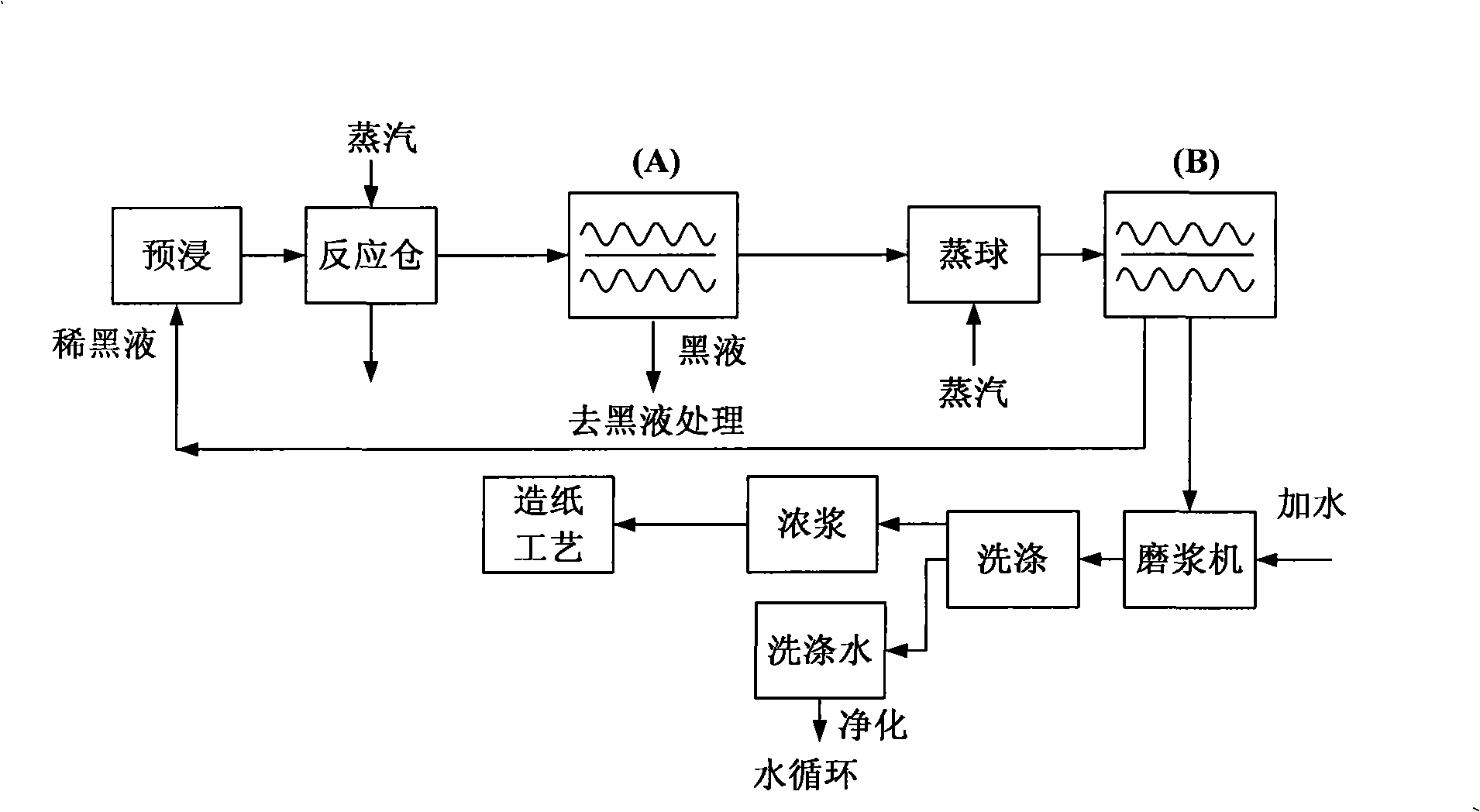

A technology for pulping and papermaking with zero discharge, applied in pulp beating/refining method, papermaking, textiles and papermaking, etc., can solve the problems of high operating cost and large investment, reduce investment, simplify concentration process, and improve water drainage. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

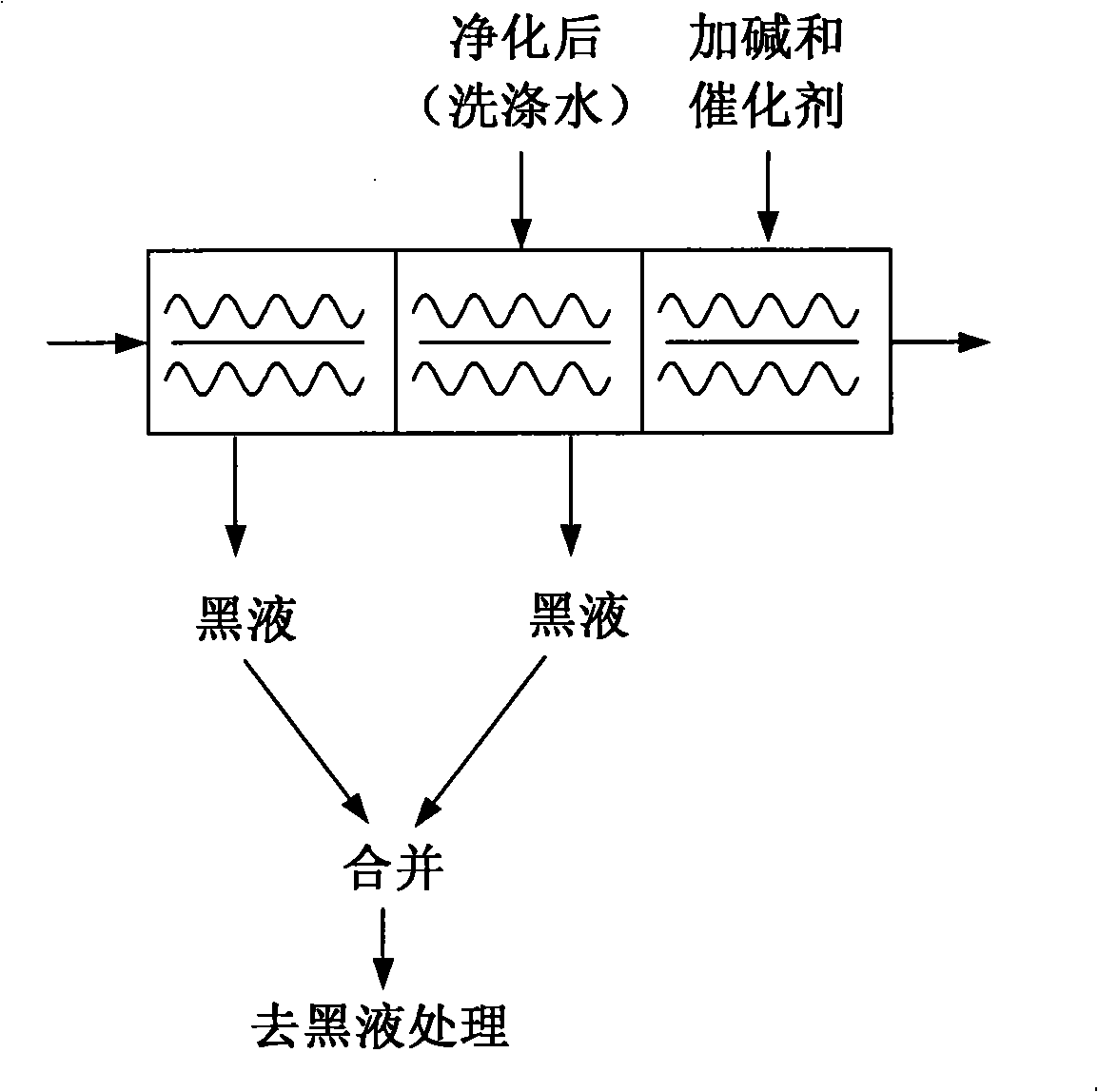

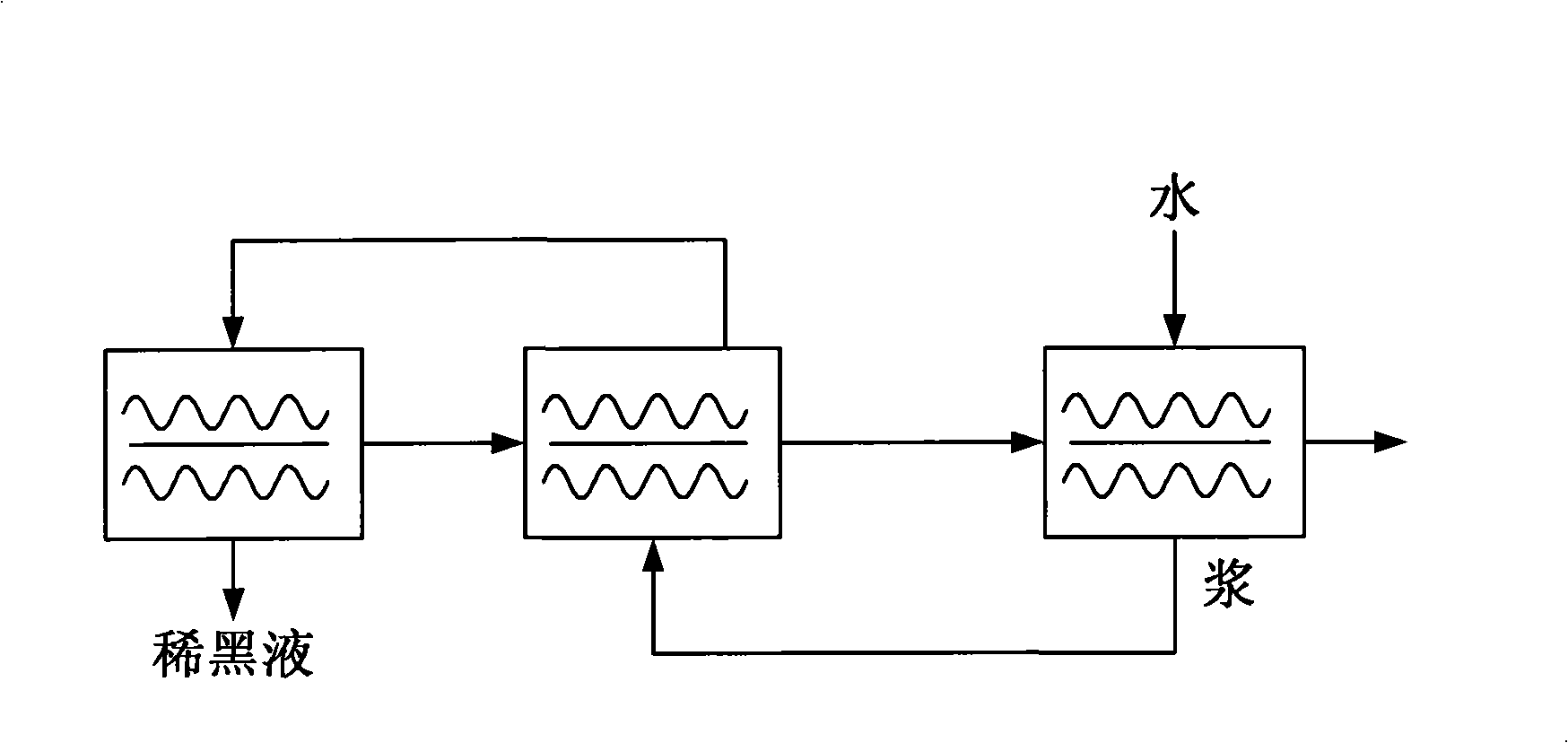

[0035] Using reed as raw material for pulping, add 10m of black liquor with 8mg / l residual alkali at room temperature to 2000kg of crushed and dedusted reed 3 Carry out presoaking, and drain after presoaking for 2 hours. When the moisture content of the raw material is 65% to 75%, put the raw material into the reaction pot and heat it with steam for low-temperature cooking. The temperature is controlled at 100°C to 120°C. When the pH value of the inner liquid is about 7, stop the reaction, use a twin-screw rubbing pulper to separate the material, extract black liquor, add alkali and catalyst, the concentration is 20% sodium hydroxide and 600L of catalyst solution, of which the catalyst The mass dosage is 3%, of which urea is 0.2%, and ammonium sulfite is 2.8%. The treated raw materials for pulping are added into the cooking pot for cooking. The cooking pressure is 0.3-0.4Mpa, the cooking time is 3 hours, and the slurry concentration is controlled at 20-25%. After cooking, the...

Embodiment 2

[0037] Using cotton stalks as raw material for pulping, add 10m of black liquor with 12mg / l residual alkali at room temperature to 2000kg of broken and dedusted cotton stalks 3 Carry out presoaking, and drain after presoaking for 2 hours. When the moisture content of the raw materials is 65% to 75%, put the raw materials into the reaction pot and heat them with steam for normal pressure cooking. The temperature is controlled at 100°C to 120°C. When the pH value of the liquid in the pot is about 7, stop the reaction, use a twin-screw rubbing squeezer to separate the material, extract black liquor, add alkali and catalyst, the concentration is 20% sodium hydroxide and 700L of catalyst solution, of which The mass dosage of catalyst is 3.5%, wherein urea is 0.2%, ammonium sulfite is 2.8%, and potassium sulfate is 0.5%. The treated raw materials for pulping are added into the cooking pot for cooking. The cooking pressure is 0.3-0.6Mpa, the cooking time is 3 hours, and the slurry c...

Embodiment 3

[0039] Using rice straw as raw material for pulping, add 10m of black liquor with normal temperature residual alkali of 10mg / l to 2000kg of crushed and dedusted rice straw 3 Carry out presoaking, and drain after presoaking for 2 hours. When the moisture content of the raw materials is 65% to 75%, put the raw materials into the reaction pot and heat them with steam for normal pressure cooking. The temperature is controlled at 100°C to 120°C. When the pH value of the liquid in the pot is about 7, stop the reaction, use a twin-screw rubbing squeezer to separate the material, extract black liquor, add alkali and catalyst, the concentration is 20% calcium hydroxide and 1000L of catalyst solution, of which The mass dosage of catalyst is 4.5%, wherein urea is 0.3%, ammonium sulfite is 3.7%, and potassium sulfate is 0.5%. The treated raw materials for pulping are added into the cooking pot for cooking. The cooking pressure is 0.2-0.4Mpa, the cooking time is 2 hours, and the slurry co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com