Patents

Literature

109results about How to "Slow down the feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

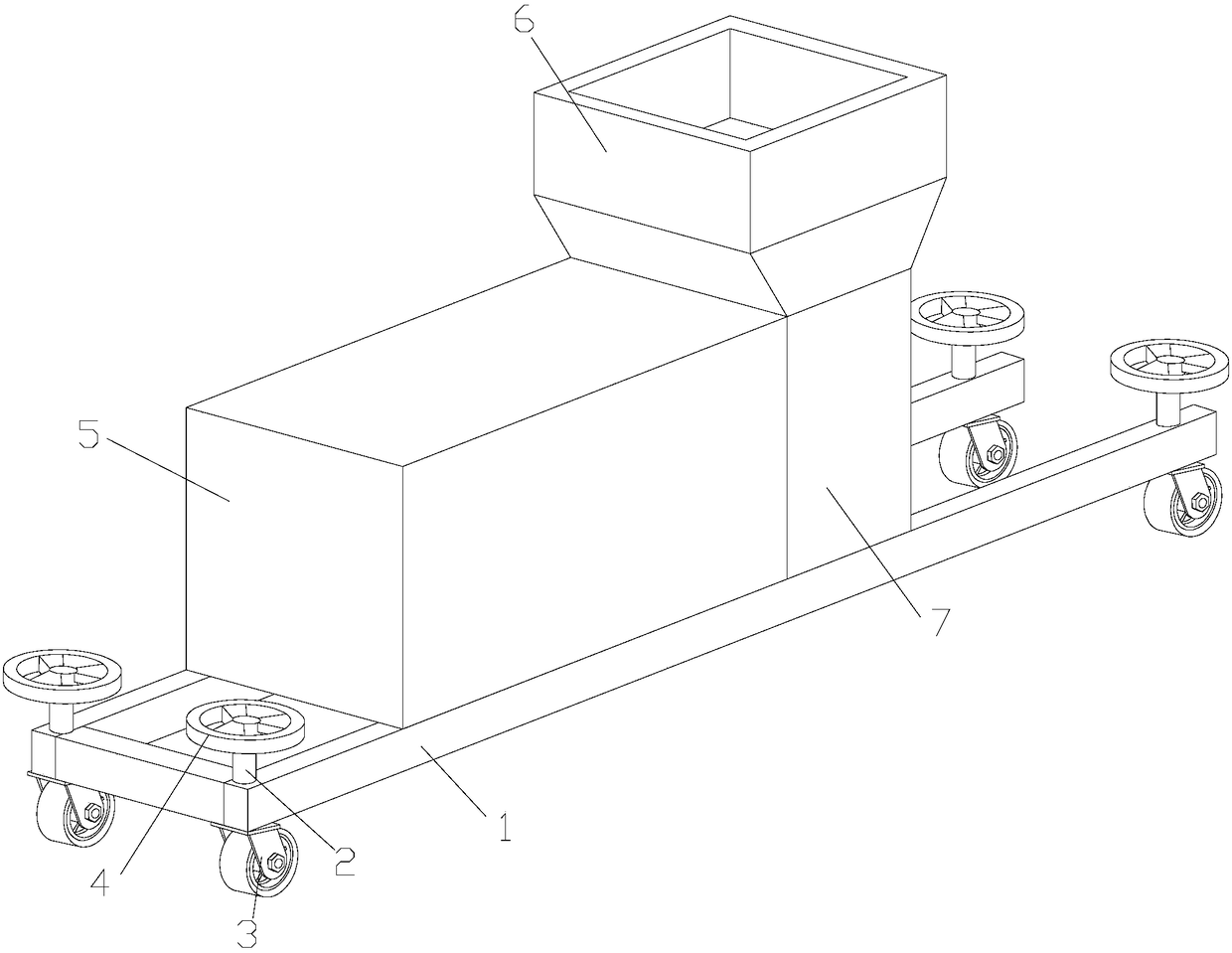

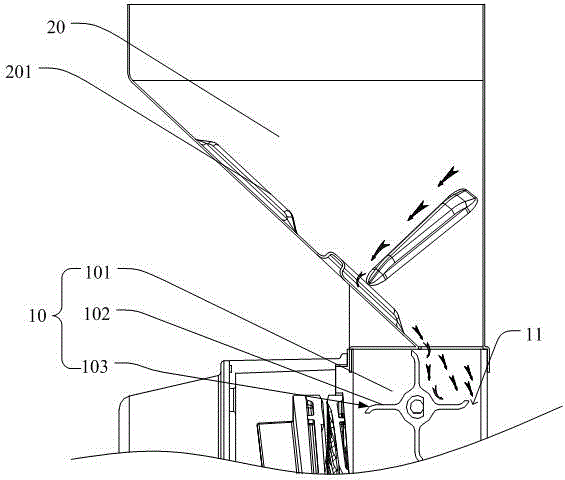

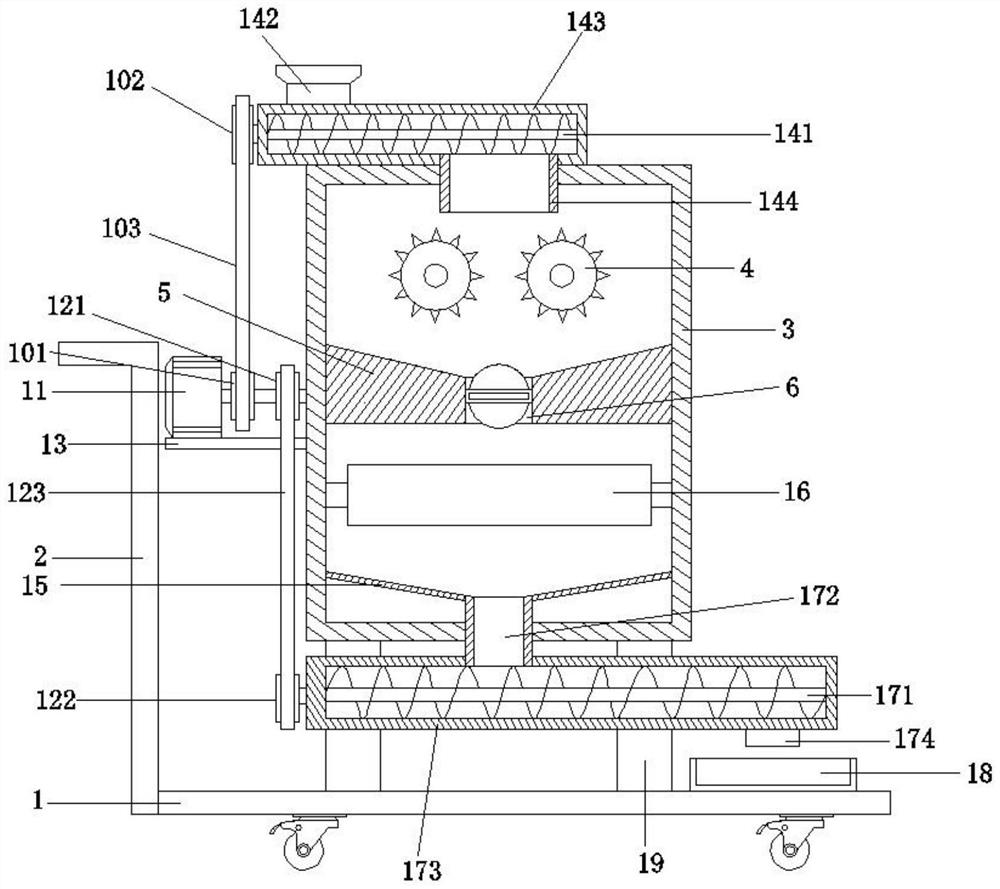

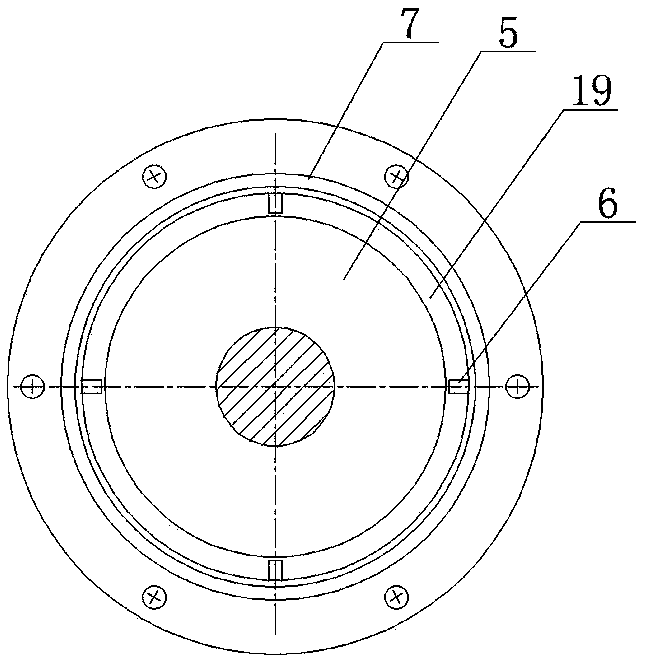

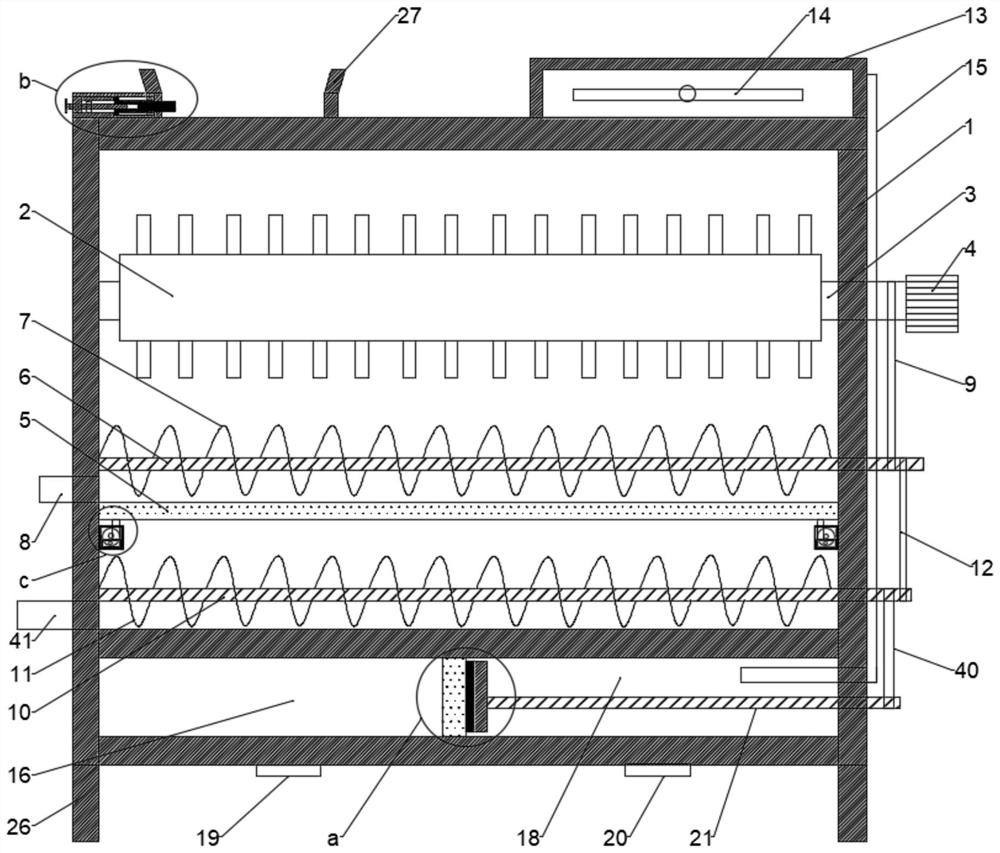

Novel building mortar finishing machine

ActiveCN108149907AIncrease the feeding speedSlow down the feeding speedBuilding constructionsArchitectural engineeringMachining

The invention discloses a novel building mortar finishing machine. The novel building mortar finishing machine structurally includes a base, screws, moving wheels, a rocking wheel, a machining box, amortar hopper, a discharge tube, square holes, rectangular openings, division plates and a finishing mechanism; one ends of the screws are vertically welded with the top of the moving wheels, the other ends of the screws are vertically installed at the middle of the bottom of the rocking wheel in a welding connecting mode, and four corners of the base are provided with threaded holes; and the screws penetrate through the threaded holes and are connected with the threaded holes in a thread mode, and the bottom of the base is provided with four moving wheels. According to the novel building mortar finishing machine, a vibration device is structurally installed in the machining box, when mortar falls on the to-be-tiled ground from a hopper, and the exciting force generated by a vibration motor passes through a vibration plate to carry out vibrating compacting to paved mortar; and gaps exist in the mortar are ejected, the damage of clotted mortar can be reduced, the vibrated mortar is flattened with a plastering roller, and the construction quality is improved.

Owner:无锡恒洋科技有限公司

Method for treating molten steel calcium, composite calcium line and method for manufacturing steel

The invention provides a method for treating molten steel calcium, a composite calcium line and a method for manufacturing steel. The method for treating molten steel calcium comprises the following steps of: performing calcium treatment to molten steel in a mode of feeding a calcium line to the molten steel; and controlling the feeding position of the calcium on the position which is 200 to 350mm from the edge of the exposed region on the molten steel surface. The composite calcium line comprises an inner pure calcium line, an outer steel casing and ferrosilicon powder filled between the inner layer and the outer layer. The method for manufacturing steel comprises the following steps of: primarily melting molten steel, pre-deoxidizing, refining molten steel by LF (ladle furnace) and performing calcium treatment, wherein the step of calcium treatment is to perform calcium treatment on the molten steel by adopting the molten steel calcium treatment method. In the steel making process, calcium can be quickly brought to the deep part of molten steel by using the method, so that the staying time of calcium in molten steel can be prolonged, the effect of calcium treatment can be reinforced, the molten steel splashing strength can be weakened, and steel with better quality can be obtained finally.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Wear-resistant corrosion-resistant powder paint for aluminum alloy template and preparation process thereof

PendingCN111471358AReduce performanceImprove light resistanceSievingOrganic chemistryStearic acidSilicon dioxide

The invention discloses wear-resistant corrosion-resistant powder paint for an aluminum alloy template and a preparation process thereof. The powder paint is prepared from the following raw materialsin parts by weight: 20-25 parts of polyvinylidene chloride, 1.5-4 parts of titanium dioxide powder, 1.5-4 parts of silicon dioxide powder, 3-5 parts of stearic acid, 4-8 parts of a reinforcing agent,1.6-2 parts of silicone oil and 2-4.5 parts of polyethylene wax. The powder paint contains the stearic acid. When the powder paint is smeared on the aluminum alloy template, a layer of hydrophobic film is formed on the surface of the aluminum alloy template, and water is prevented from penetrating through the coating film to be in contact with the aluminum alloy template, so that the corrosion resistance of the aluminum alloy template is improved. The reinforcing agent is prepared on the preparation process of the powder paint and contains a benzoquinone structure, the benzoquinone structure has good light shielding property, and the reinforcing agent contains a hindered phenol structure, so that light resistance of the powder paint is improved.

Owner:丁彪

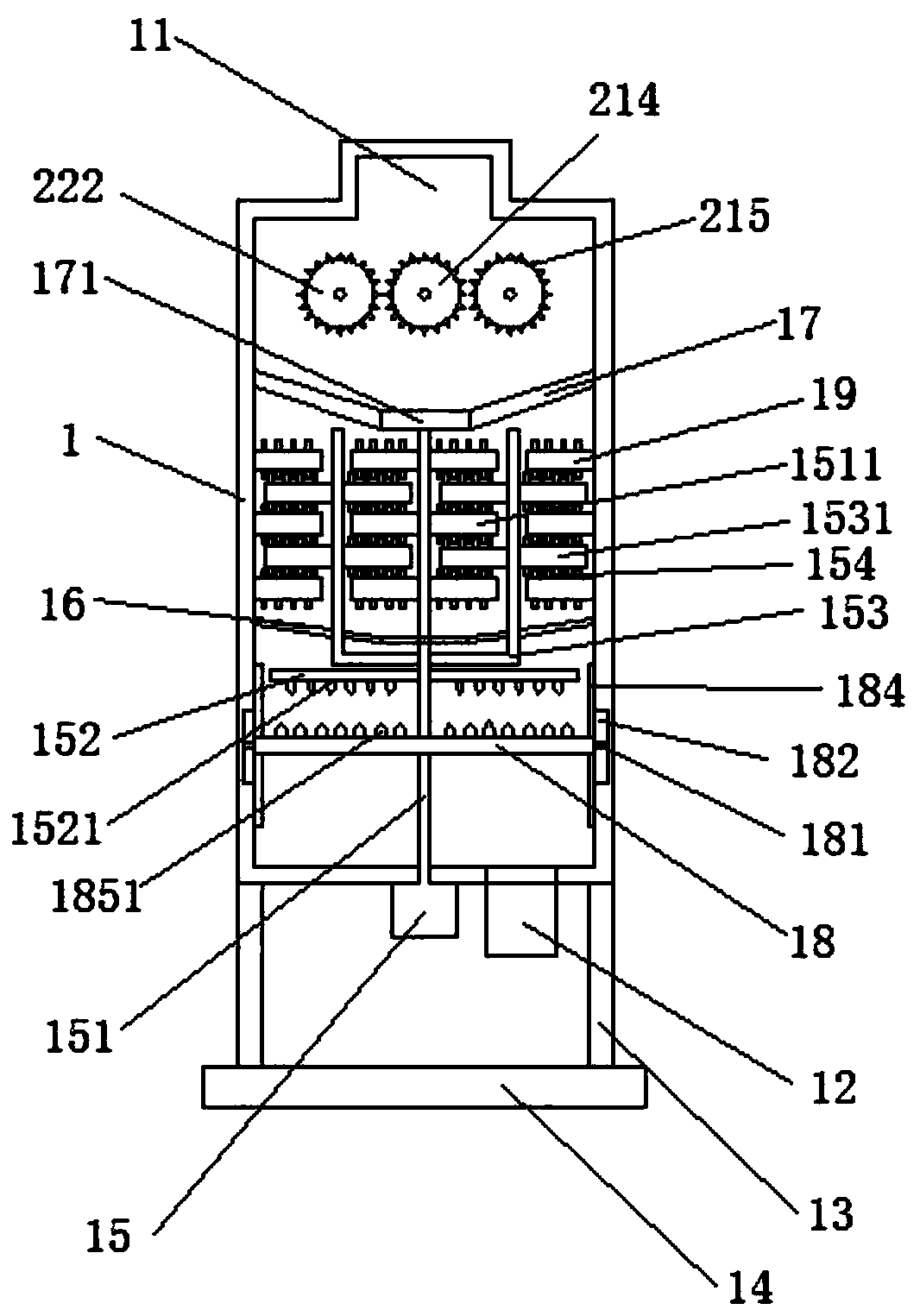

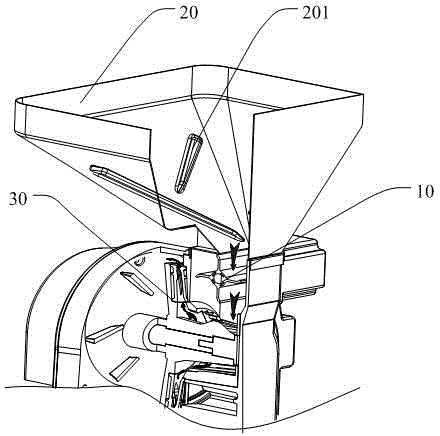

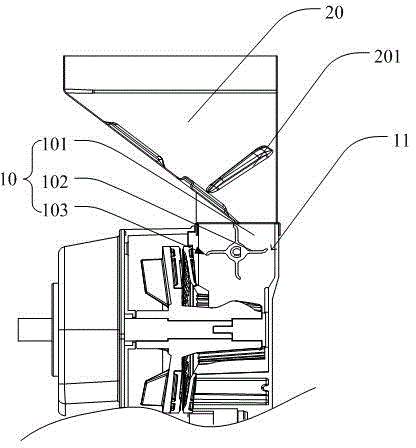

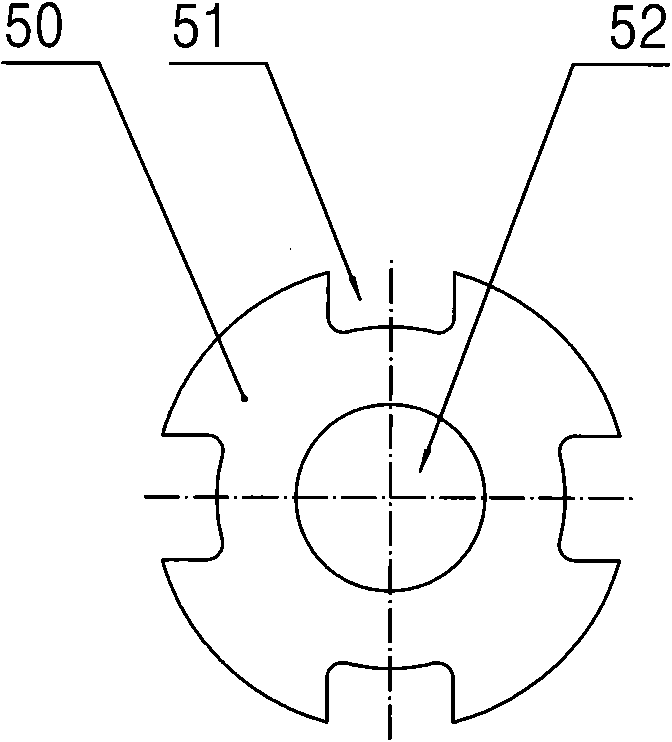

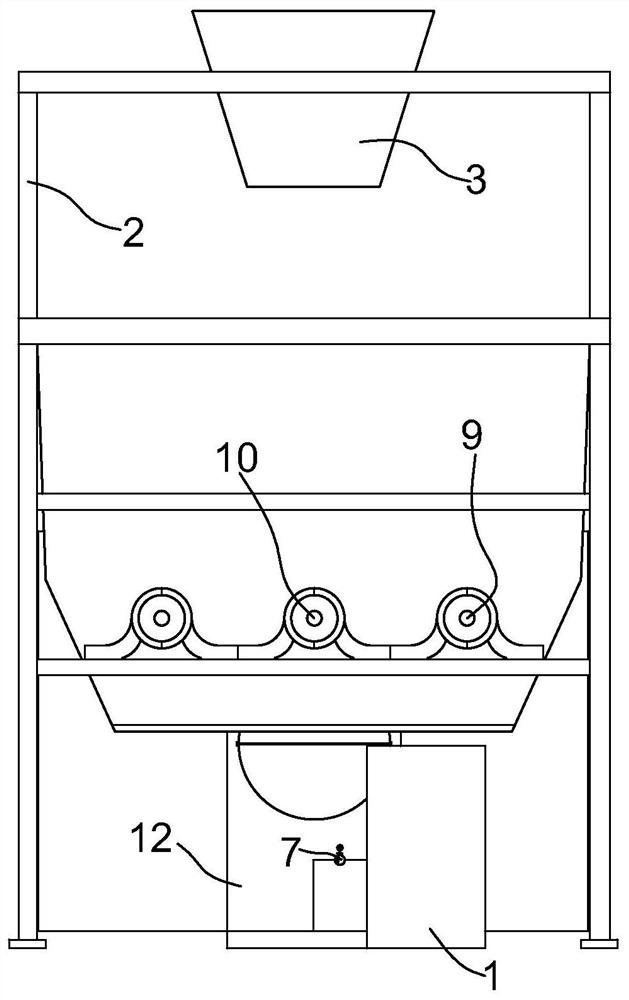

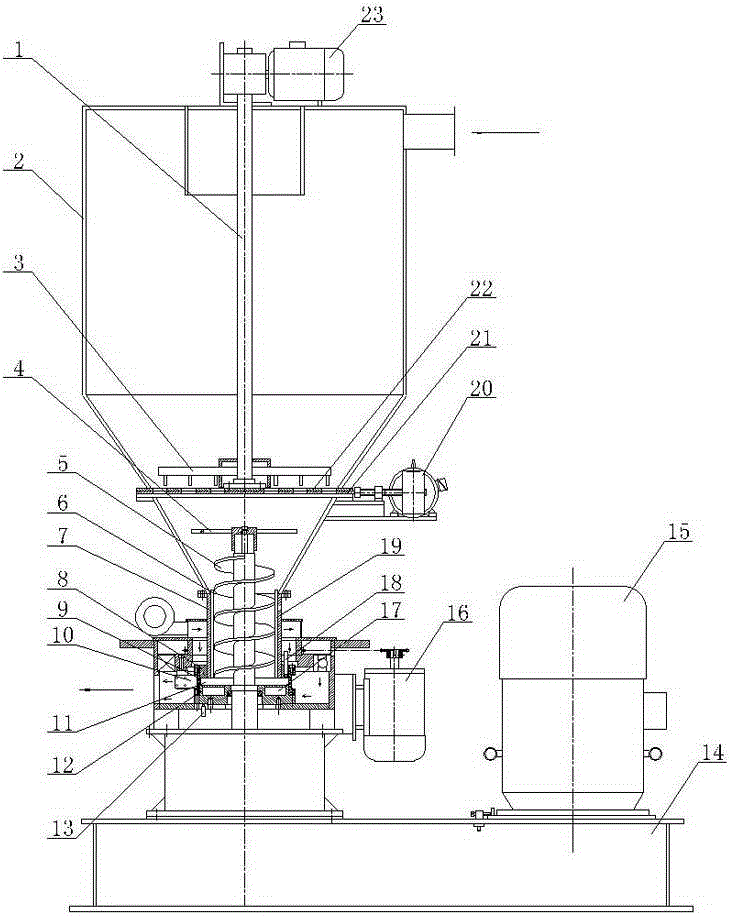

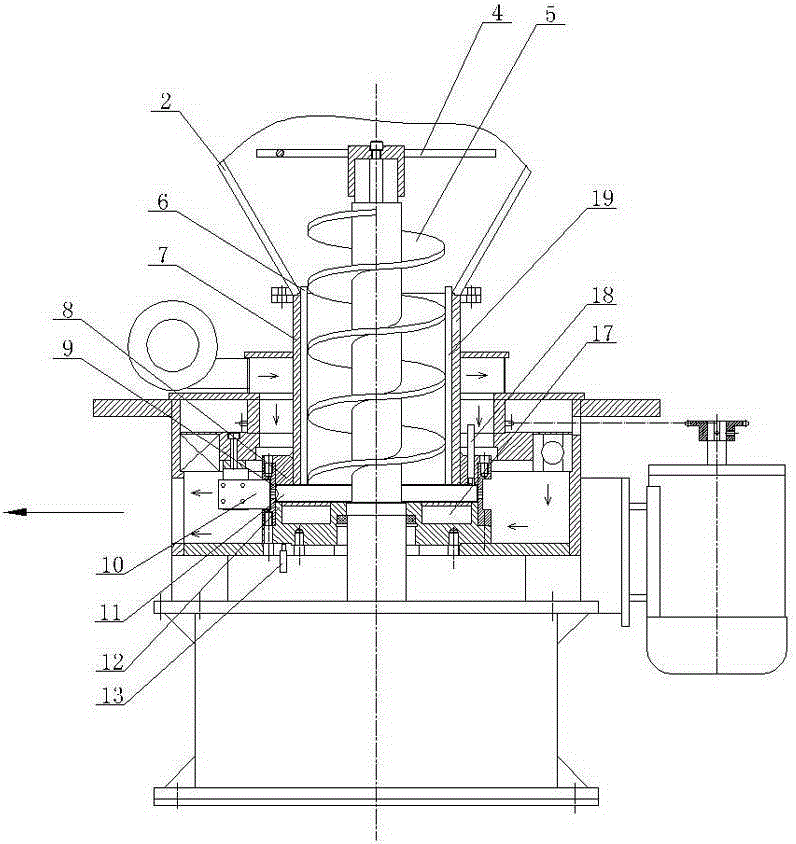

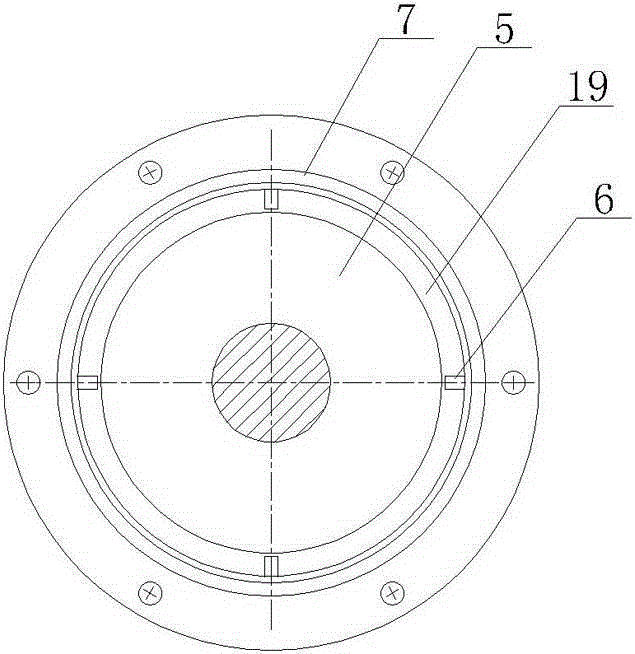

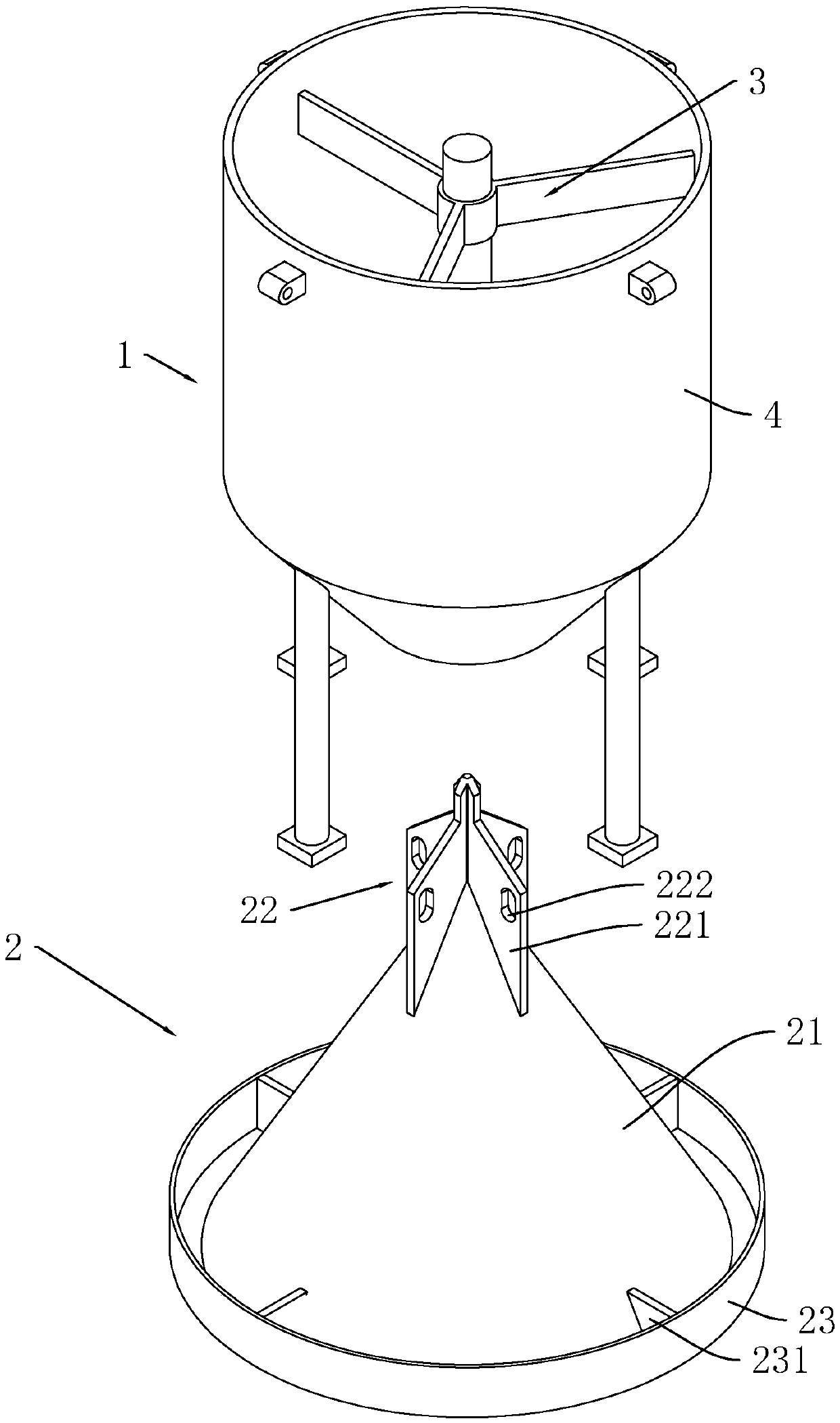

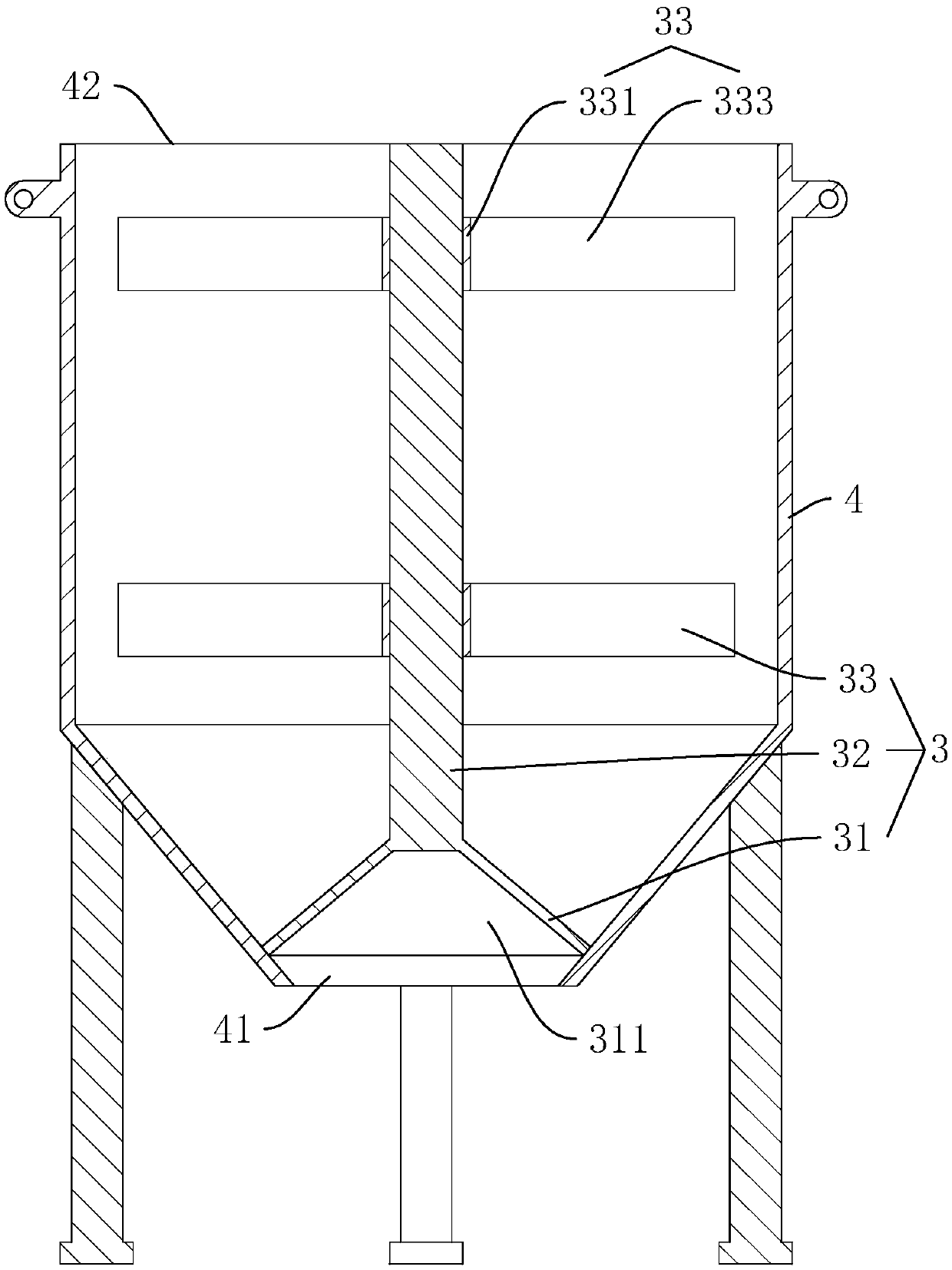

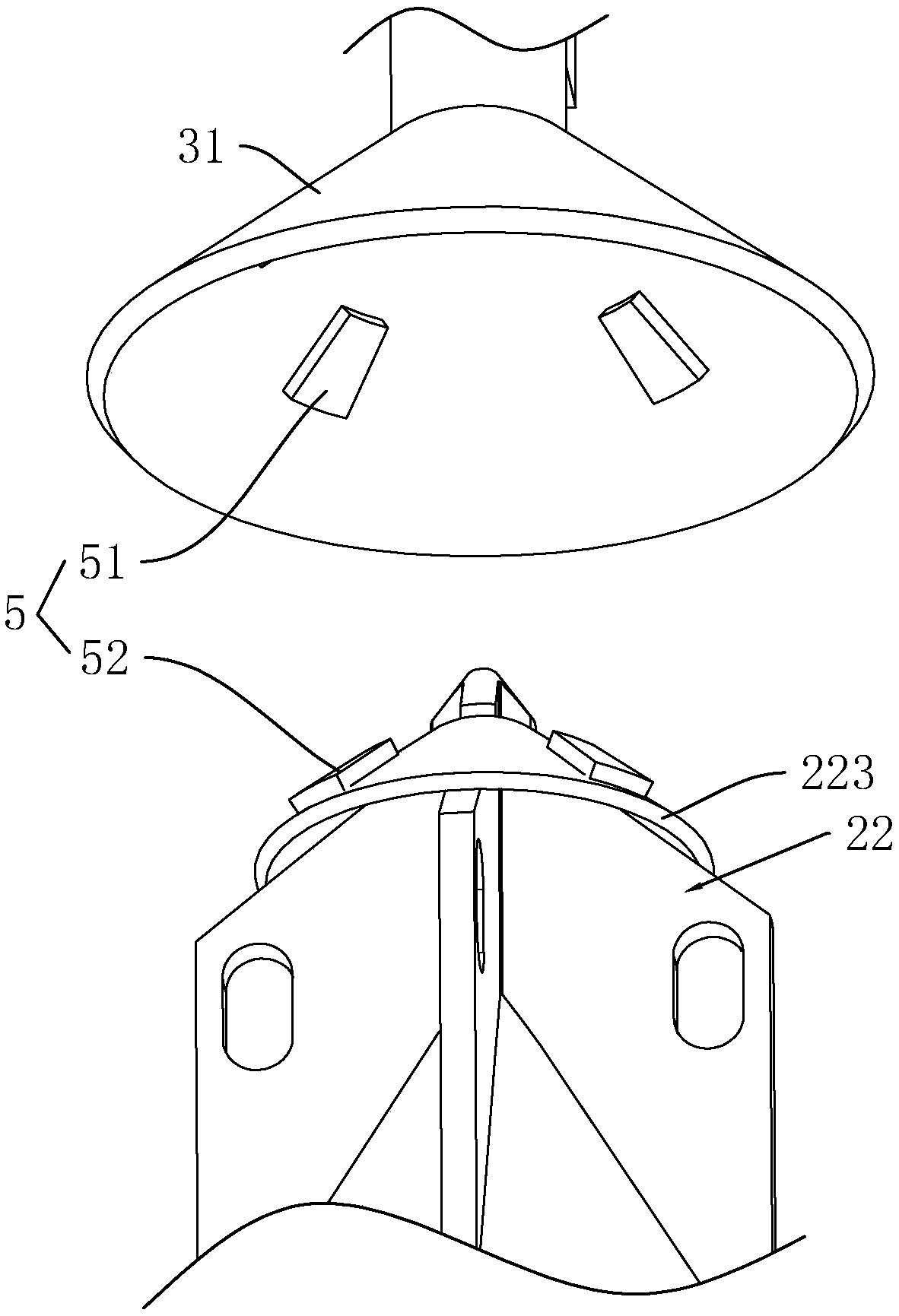

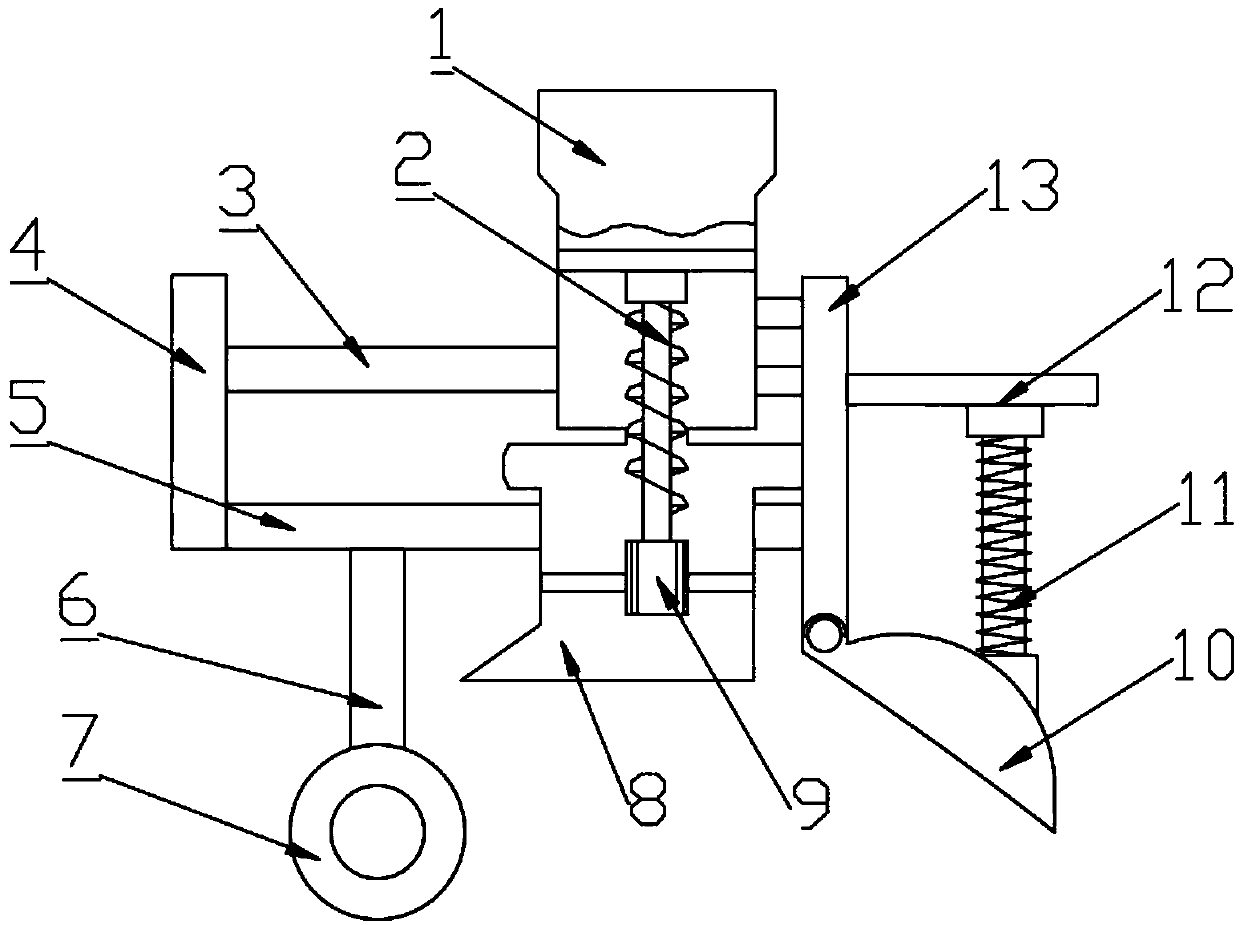

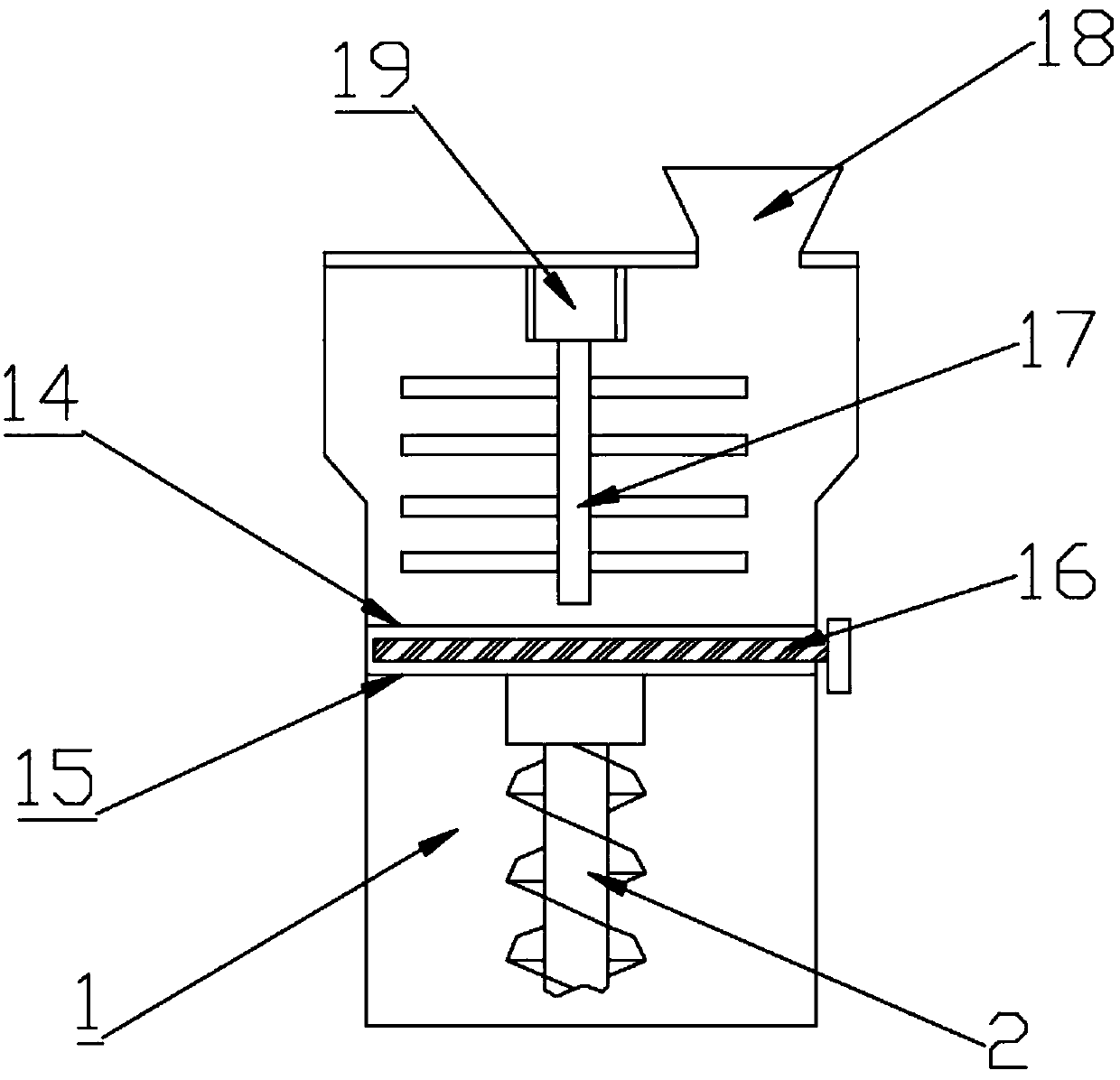

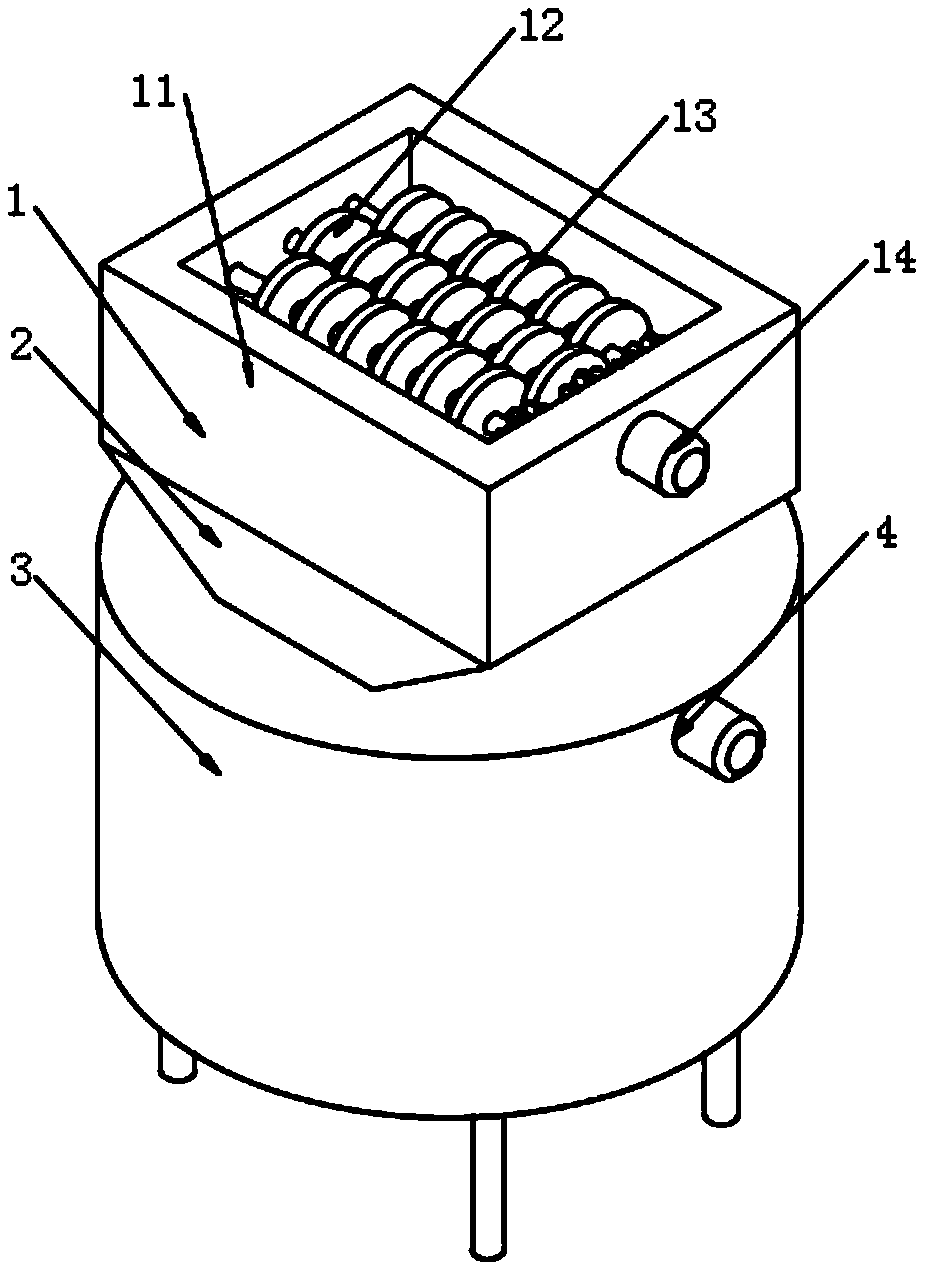

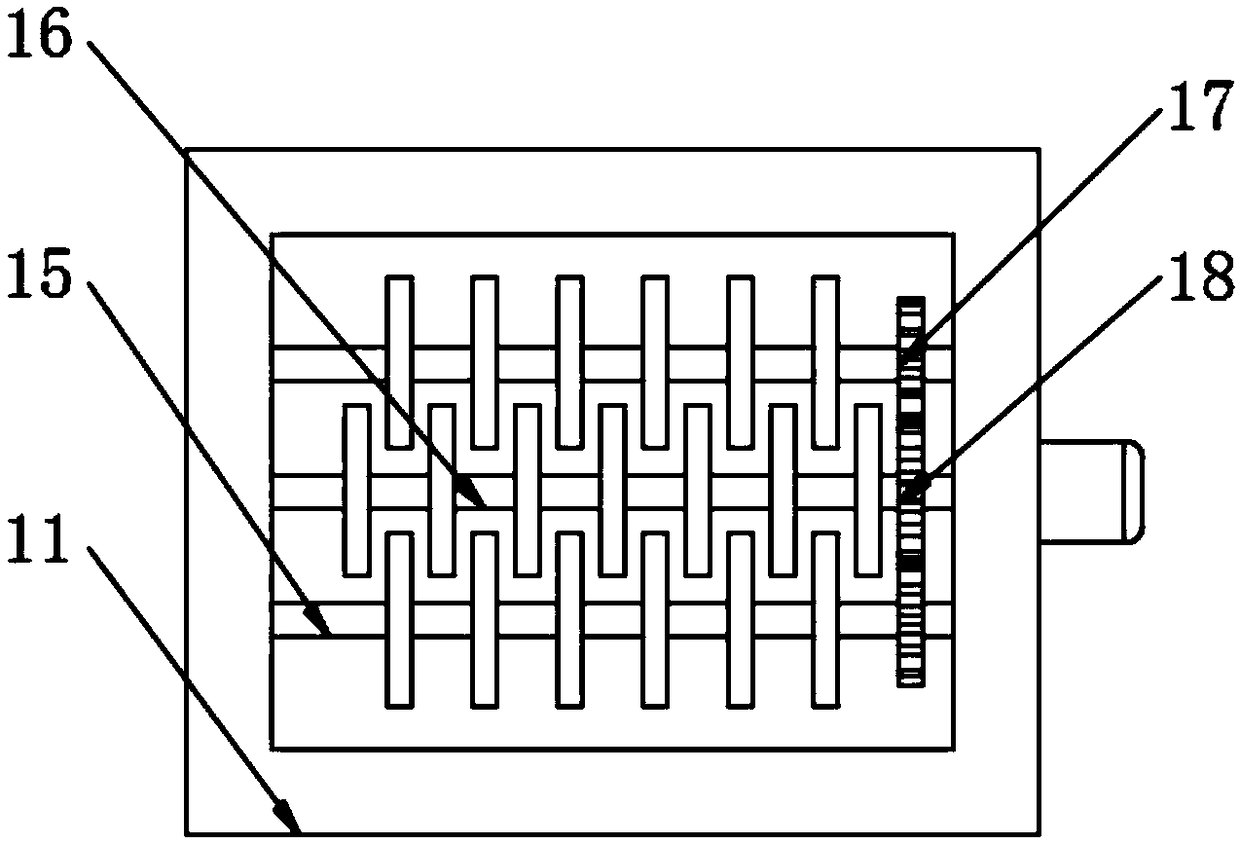

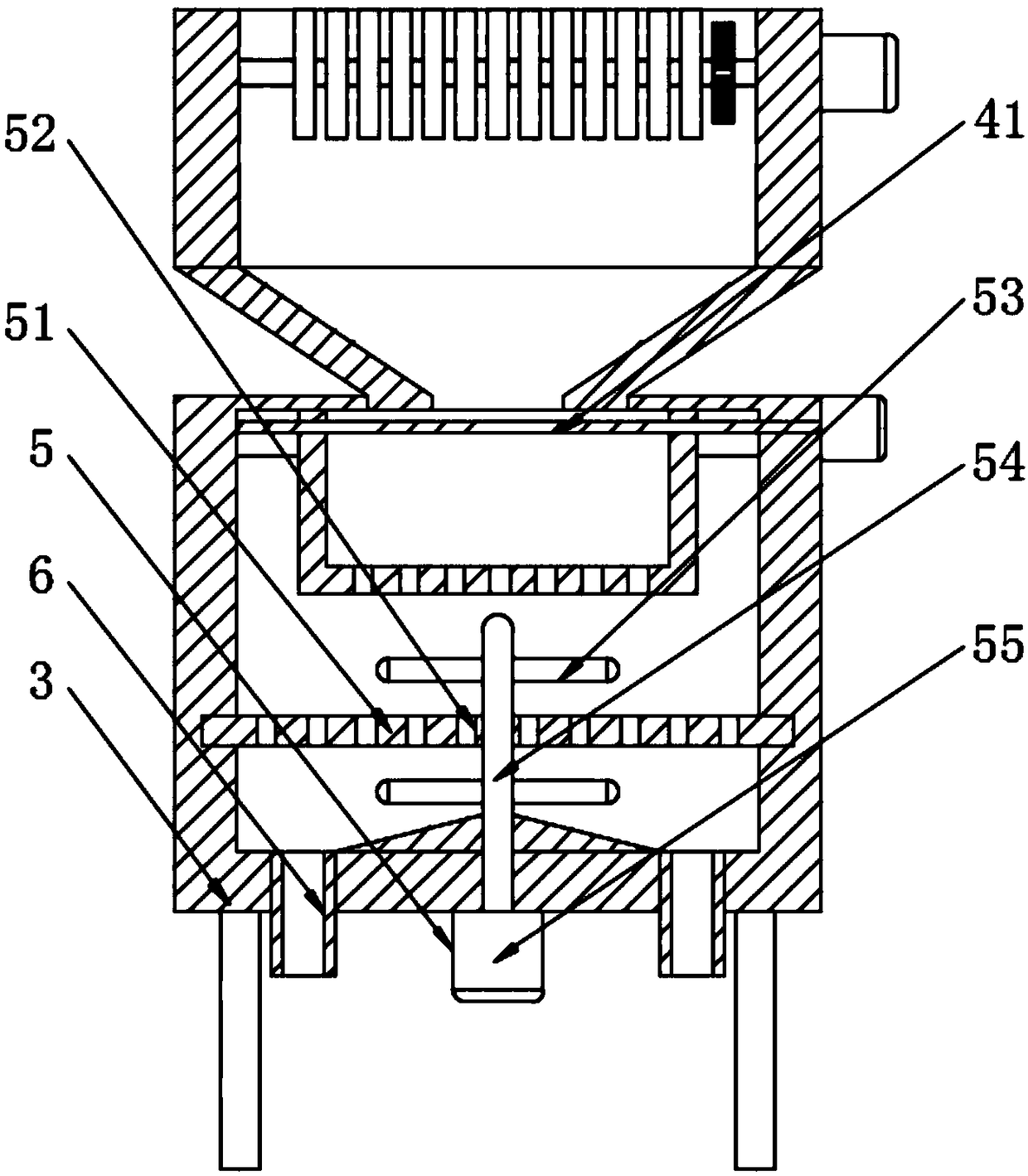

Pulverizer and discharging method thereof

ActiveCN104607302AEven workloadNot easy to heat and high temperatureGrain treatmentsSpecific gravityPulverizer

The invention discloses a pulverizer and a discharging method thereof. The pulverizer comprises an intermittent discharging mechanism and a driving mechanism, wherein the intermittent discharging mechanism is used for controlling the discharging speed; the driving mechanism is used for driving the intermittent discharging mechanism to rotate by a preset angle at a preset interval; the intermittent discharging mechanism is positioned between a hopper outlet and a grinding mechanism of the pulverizer and is connected with the driving mechanism. According to the invention, the intermittent discharging mechanism discharges raw materials intermittently at the preset interval to control the discharging speed of the raw materials with large specific gravity and small particles and to enable all the raw materials to be uniformly mixed in the discharging process and enter the grinding mechanism to be ground, so that nutrition powder is balanced in nutrition and does not layer. In addition, the intermittent discharging manner enables the grinding mechanism to be uniform in workload and not to generate high temperature in the grinding process, so that a sugar material is not burnt and discharged smoothly, and the nutrition of the nutrition powder does not lose.

Owner:常熟东南高新技术创业服务有限公司

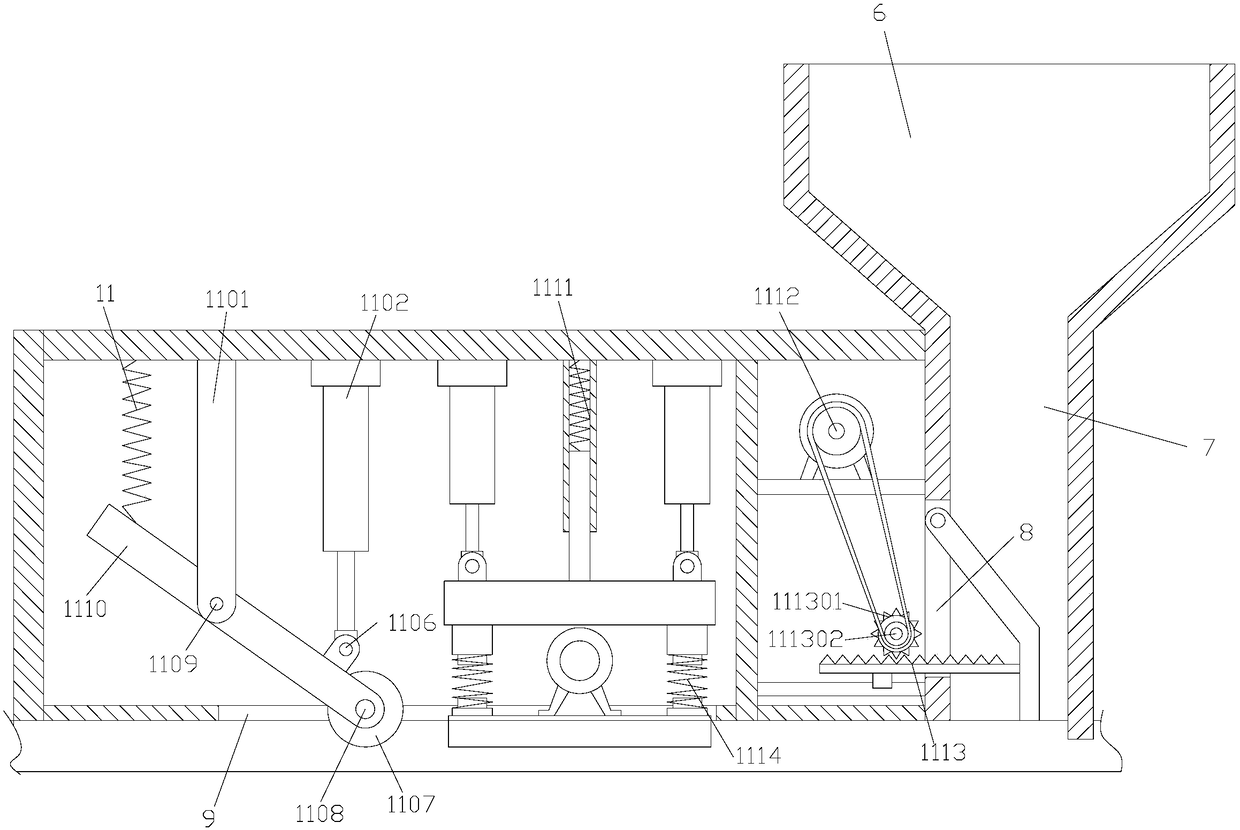

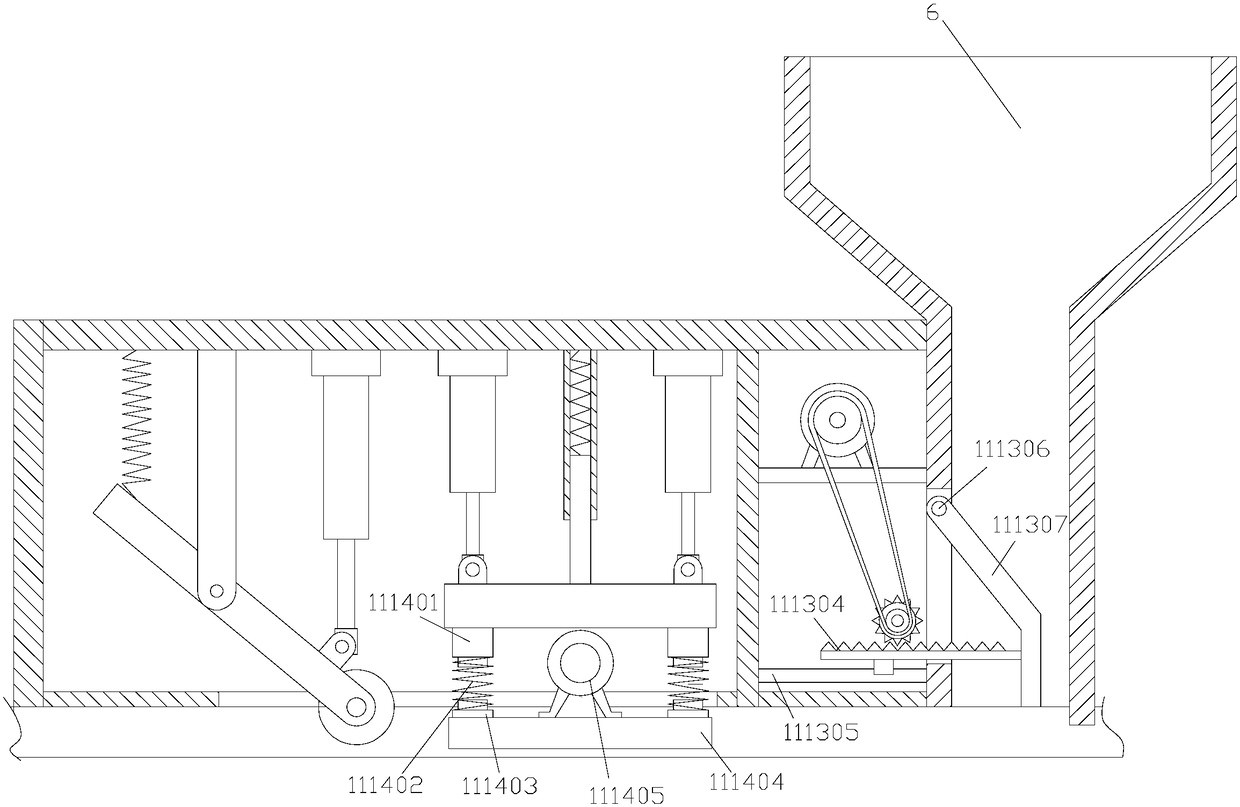

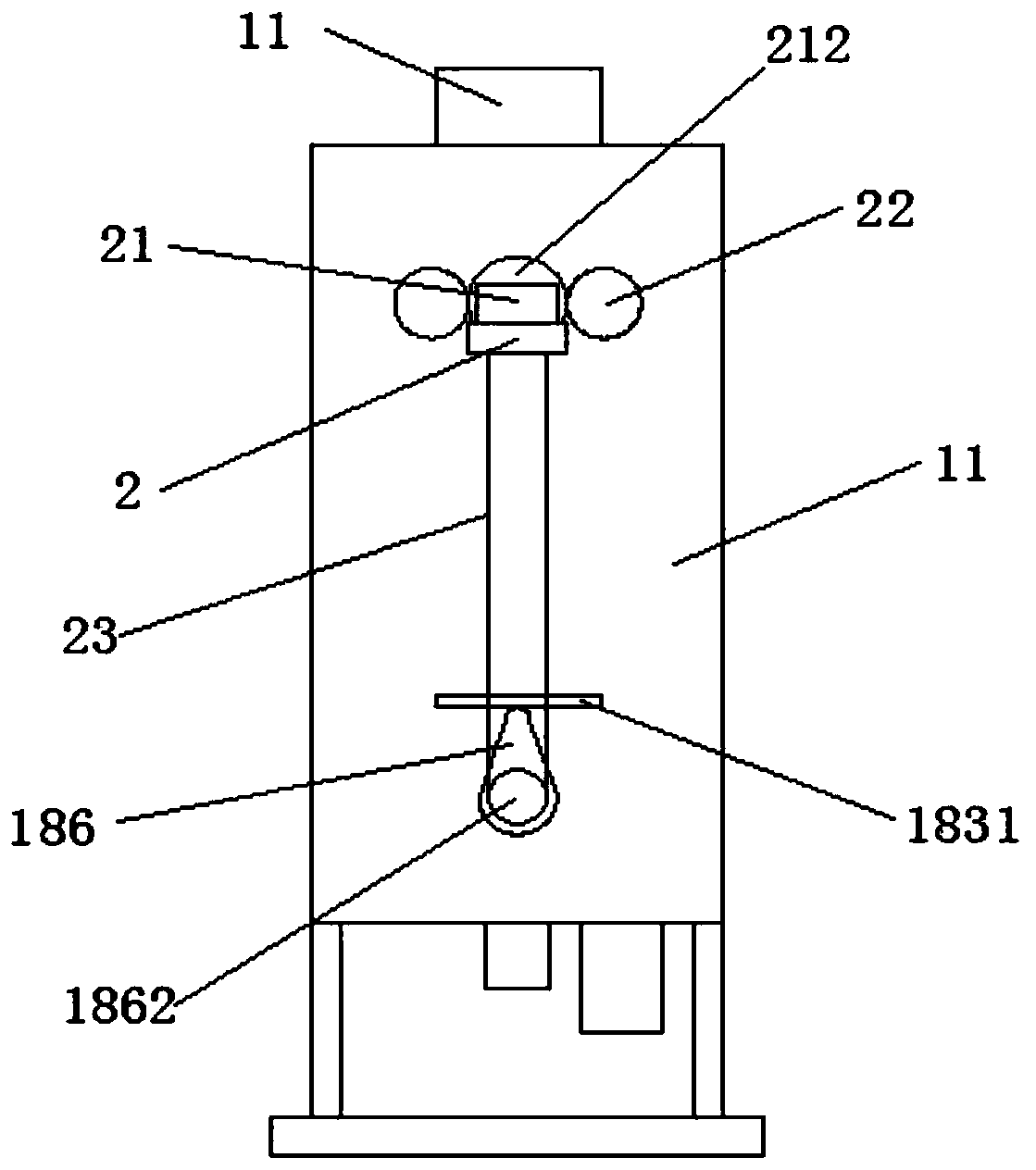

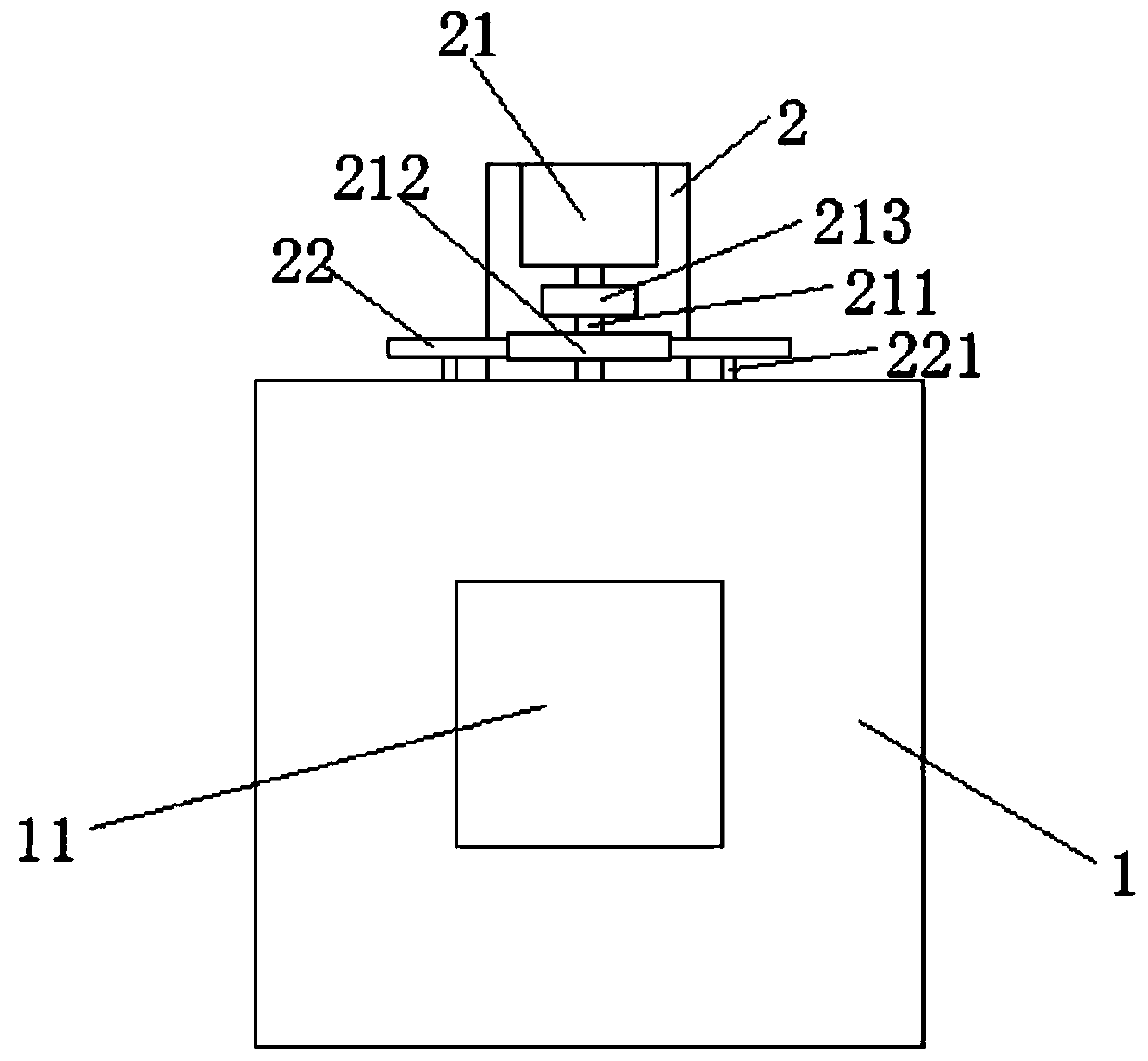

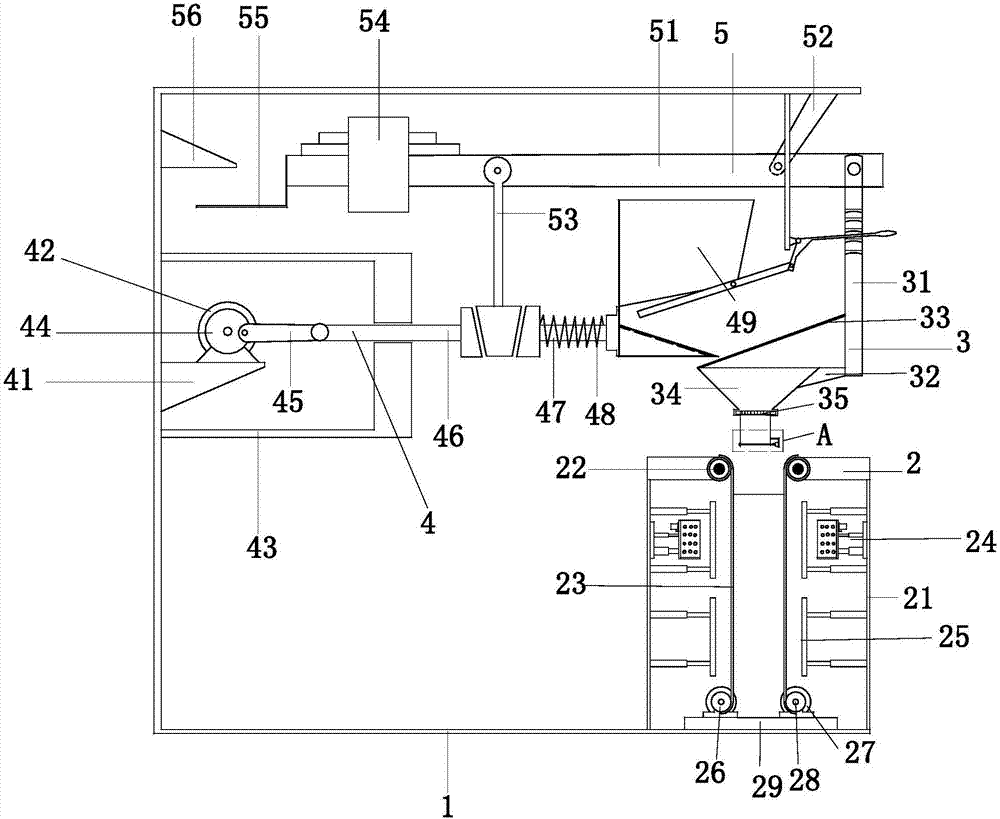

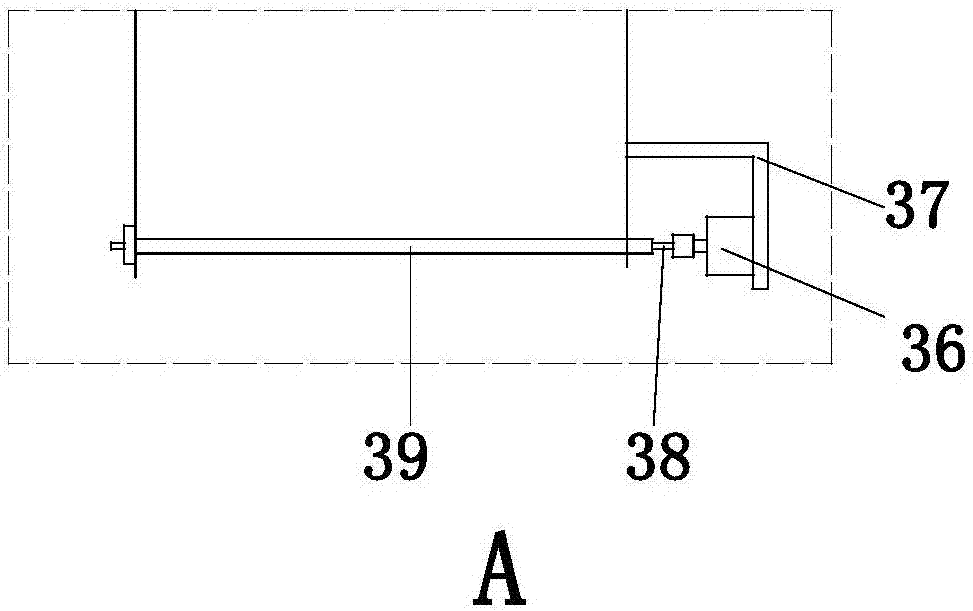

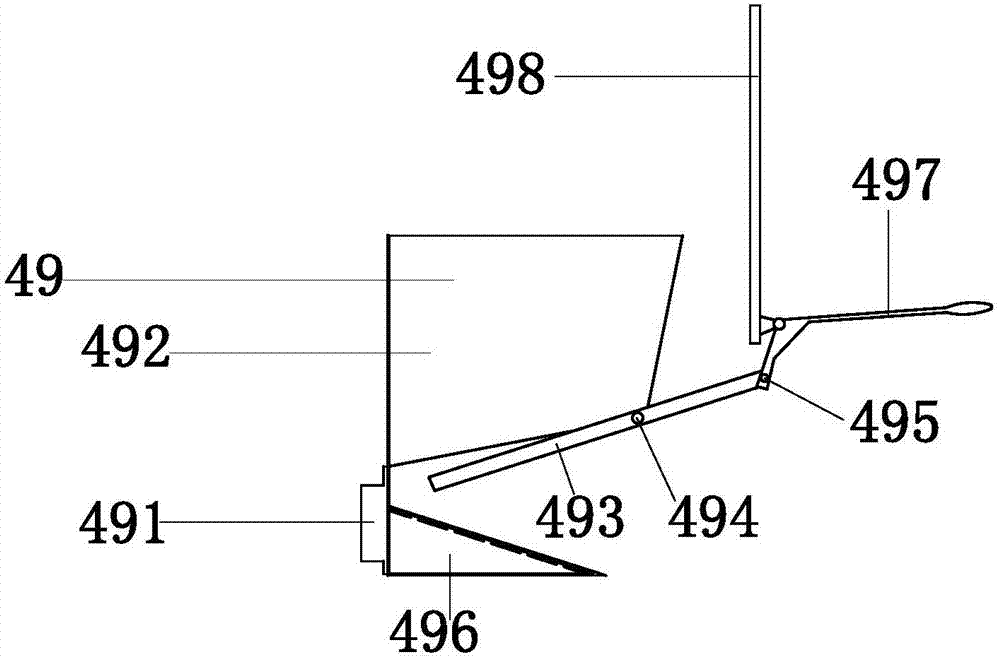

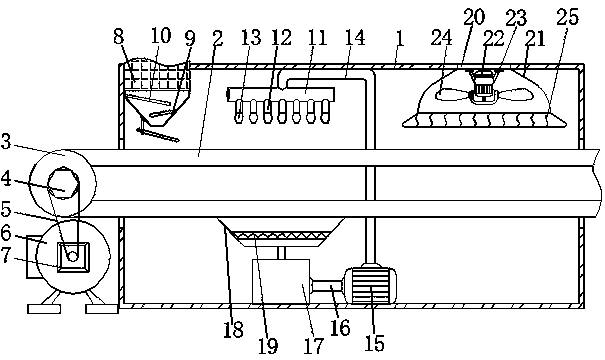

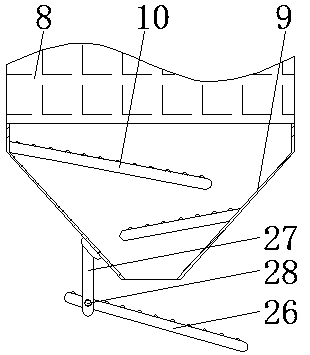

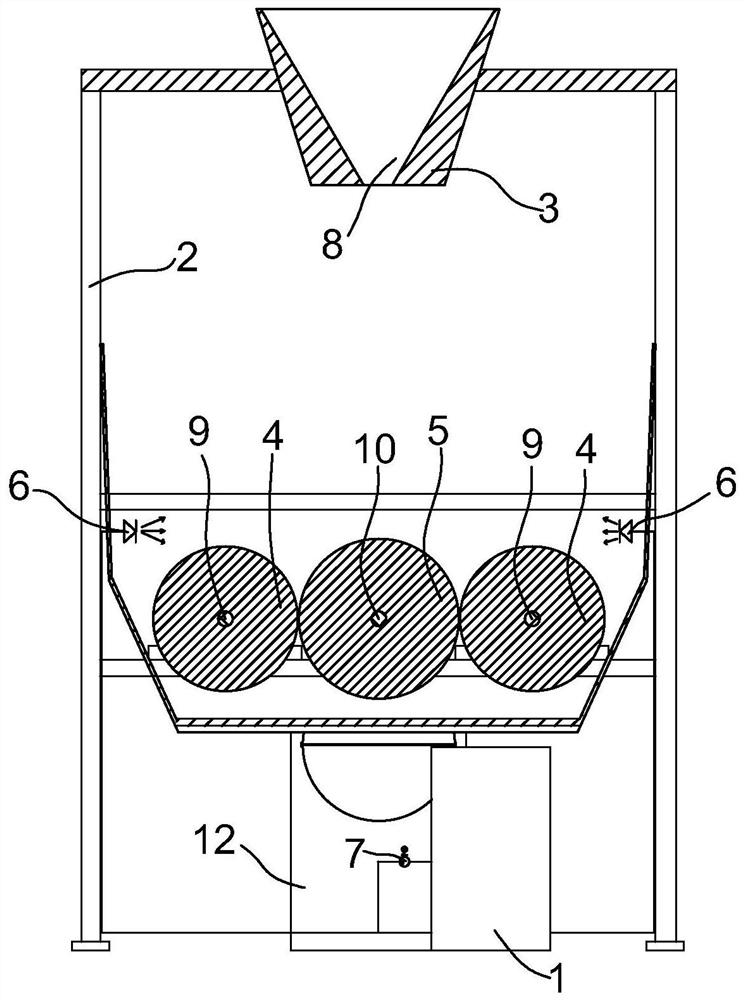

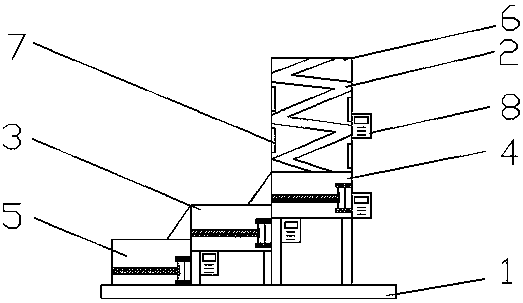

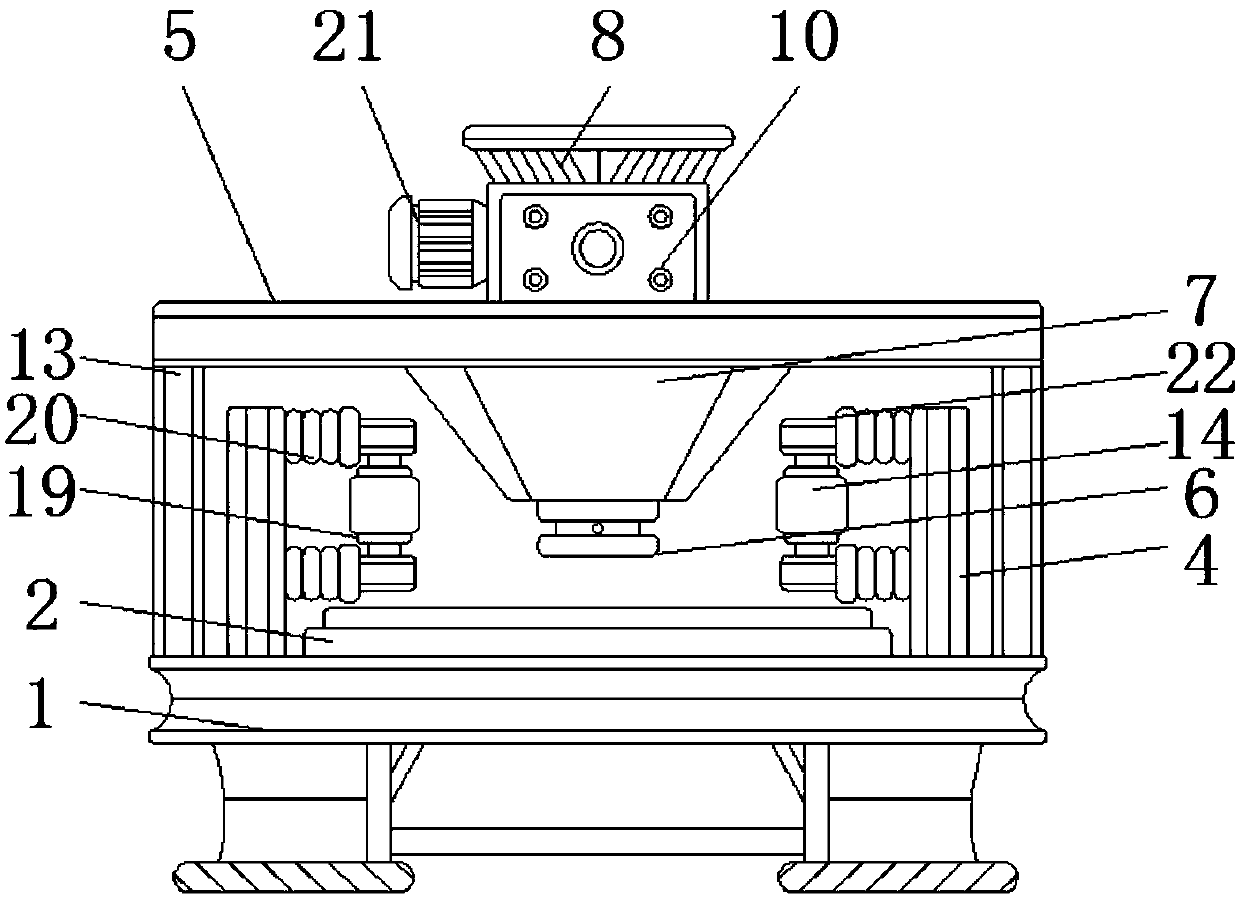

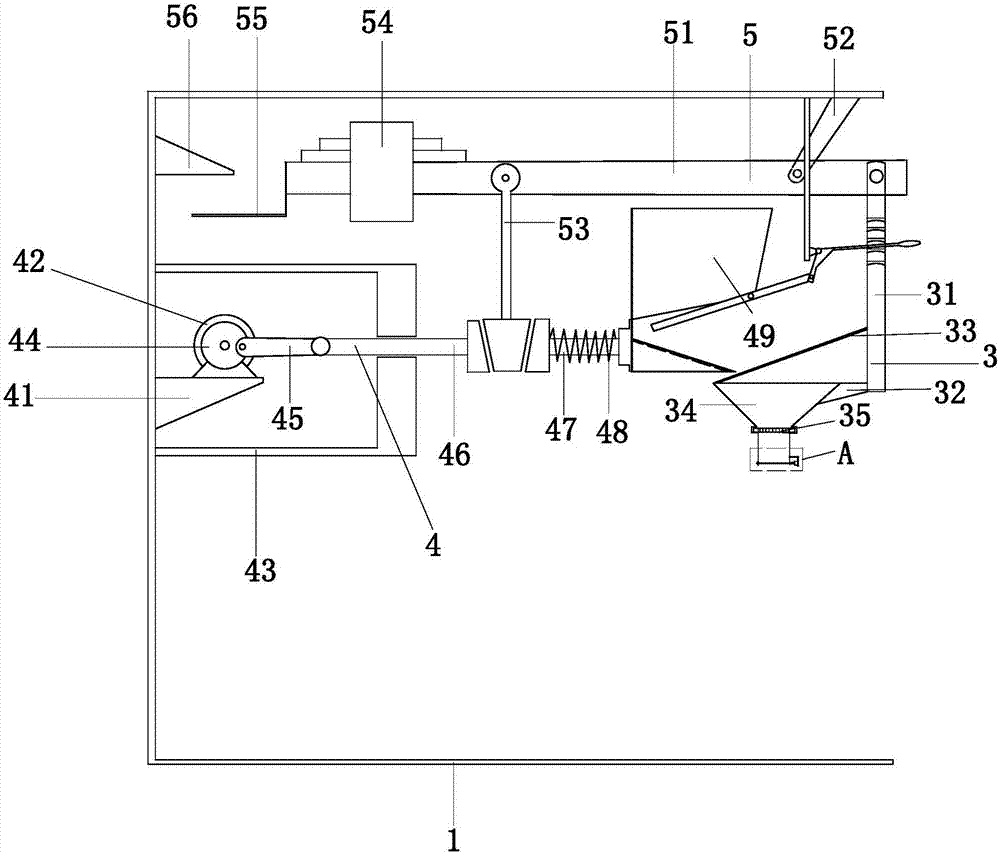

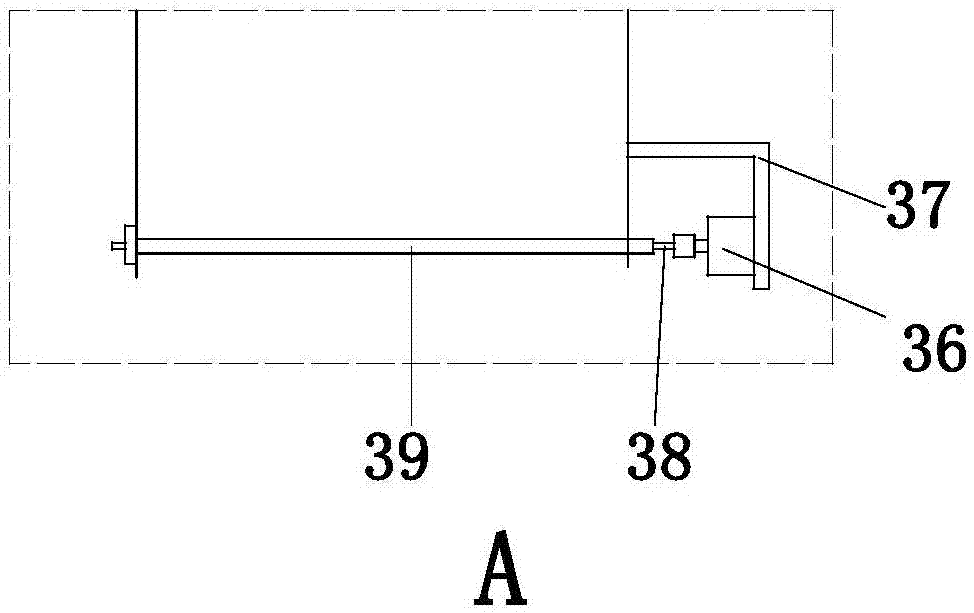

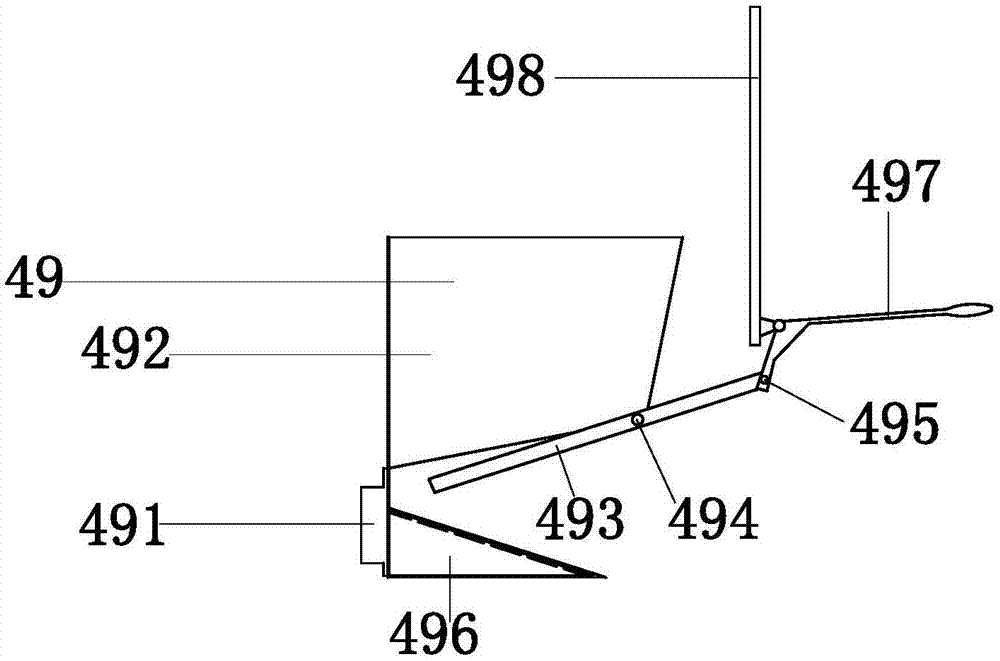

Drying agent packaging machine capable of automatically controlling discharge amount

ActiveCN107161406AReduce labor intensityAvoid dangerWrapper twisting/gatheringSolid materialAutomatic controlEngineering

The invention relates to a drying agent packaging machine capable of automatically controlling a discharge amount. The drying agent packaging machine comprises a rack, a packaging-cutting device, a sieving-discharge device, a vibration device and a press rod device, wherein the rack is of a U-shaped structure; the packaging-cutting device is installed at the bottom of the rack; the sieving-discharge device is located between the packaging-cutting device and the press rod device; the upper end of the sieving-discharge device is connected with the press rod device; the vibration device is located at the left side of the sieving-discharge device; the left end of the vibration device is installed on the left side surface of the rack; and the press rod device is connected with the top of the rack. The drying agent packaging machine disclosed by the invention is capable of solving the problems of low working efficiency, high labour intensity, manual control on the discharge amount of the drying agents, a certain risk in manual packaging, and the like, in existing manual sieving-packaging for the drying agents; the functions of automatic control on discharge and packaging-cutting for the drying agents are realized; and the drying agent packaging machine has the advantages of being high in working efficiency, low in labour intensity, capable of automatically controlling the discharge amount of the drying agents, capable of purely mechanically carrying out the packaging-cutting operation, and the like.

Owner:南通北外滩建设工程有限公司

Soil screening device for soil remediation

The invention relates to the field of soil remediation, in particular to a soil screening device for soil remediation. The device comprises a crushing cylinder, a motor, a stirring block, an elastic grinding piece, a screening and filtering assembly and a transmission shaft. The transmission shaft is vertically arranged in the crushing cylinder and is driven by the motor to rotate; the elastic grinding assembly comprises a fixed outer ring, a fixed inner ring and a plurality of elastic strips, the fixed outer ring is fixed to the crushing cylinder, and the fixed inner ring is located below the fixed outer ring and smaller than the fixed outer ring; the upper end of each elastic strip is connected with the fixed outer ring, the lower end of each elastic strip is connected with the fixed inner ring, and the projection of each elastic strip in the horizontal plane is spiral; the stirring block is installed on the transmission shaft and located in an annular space defined by the elastic strips, the stirring block interacts with the elastic strips when rotating along with the transmission shaft to crush blocky soil, the elastic strips are made to extend under extrusion of the blocky soil, then the fixed inner ring is made to rotate, and partial or complete contraction is recovered when the pressure is reduced or disappears; and the screening and filtering assembly is used for receiving and filtering the crushed blocky soil.

Owner:江苏创新环境工程有限公司

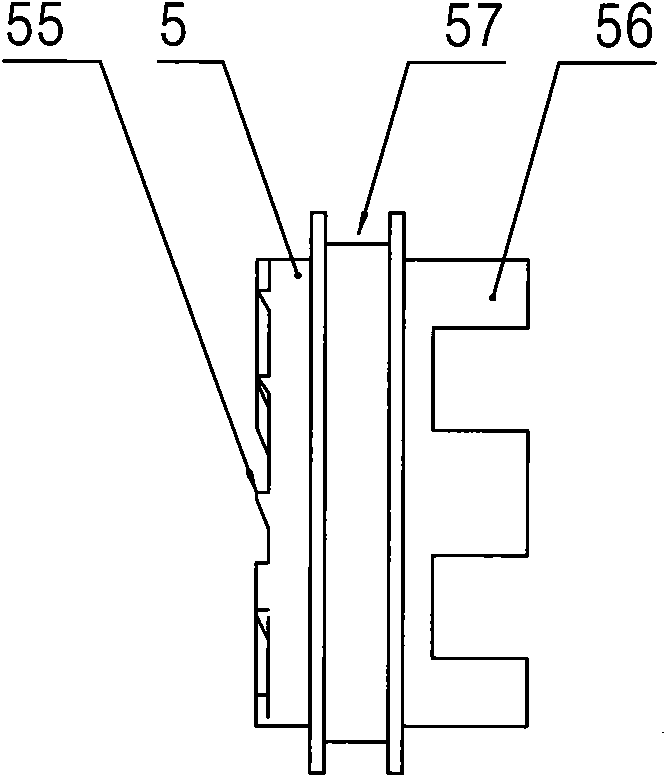

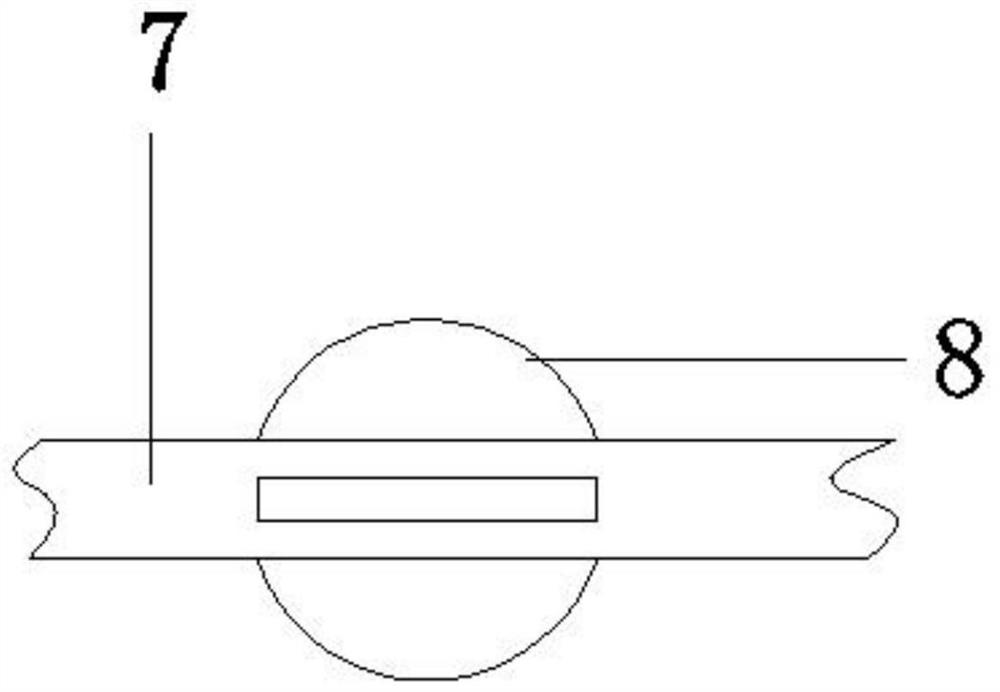

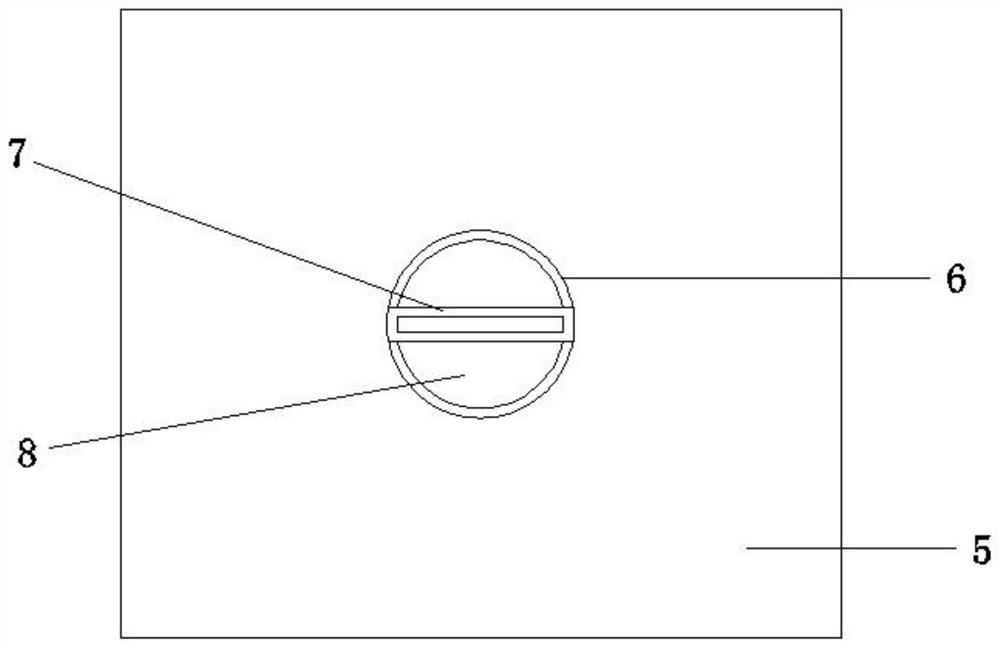

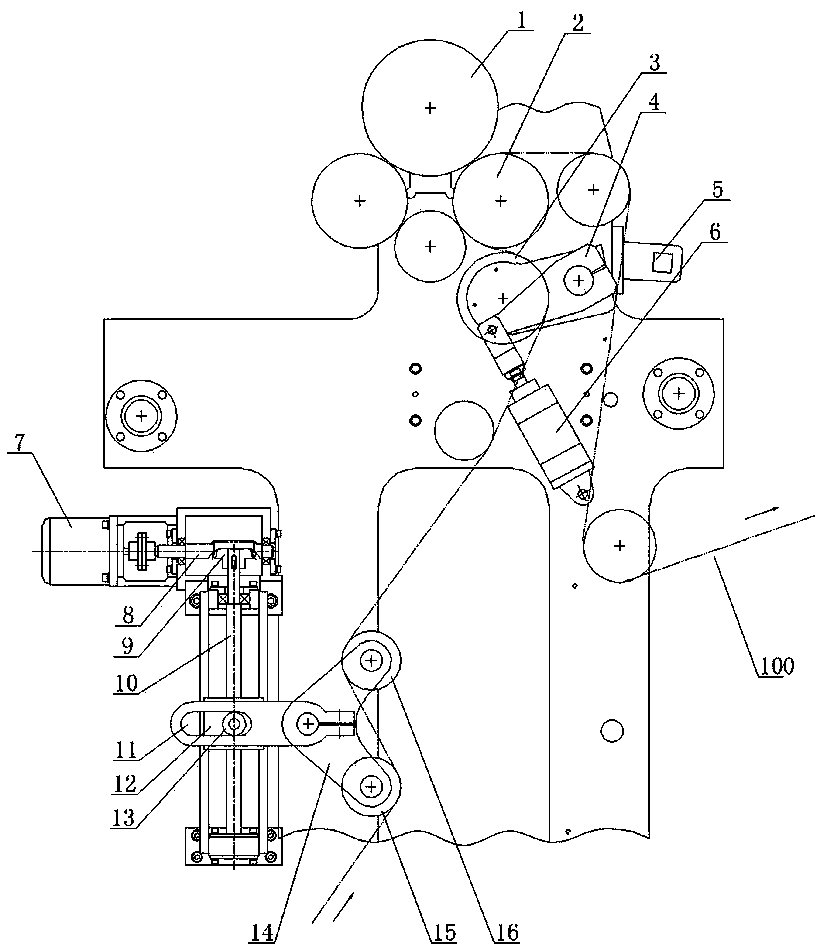

Feeding apparatus

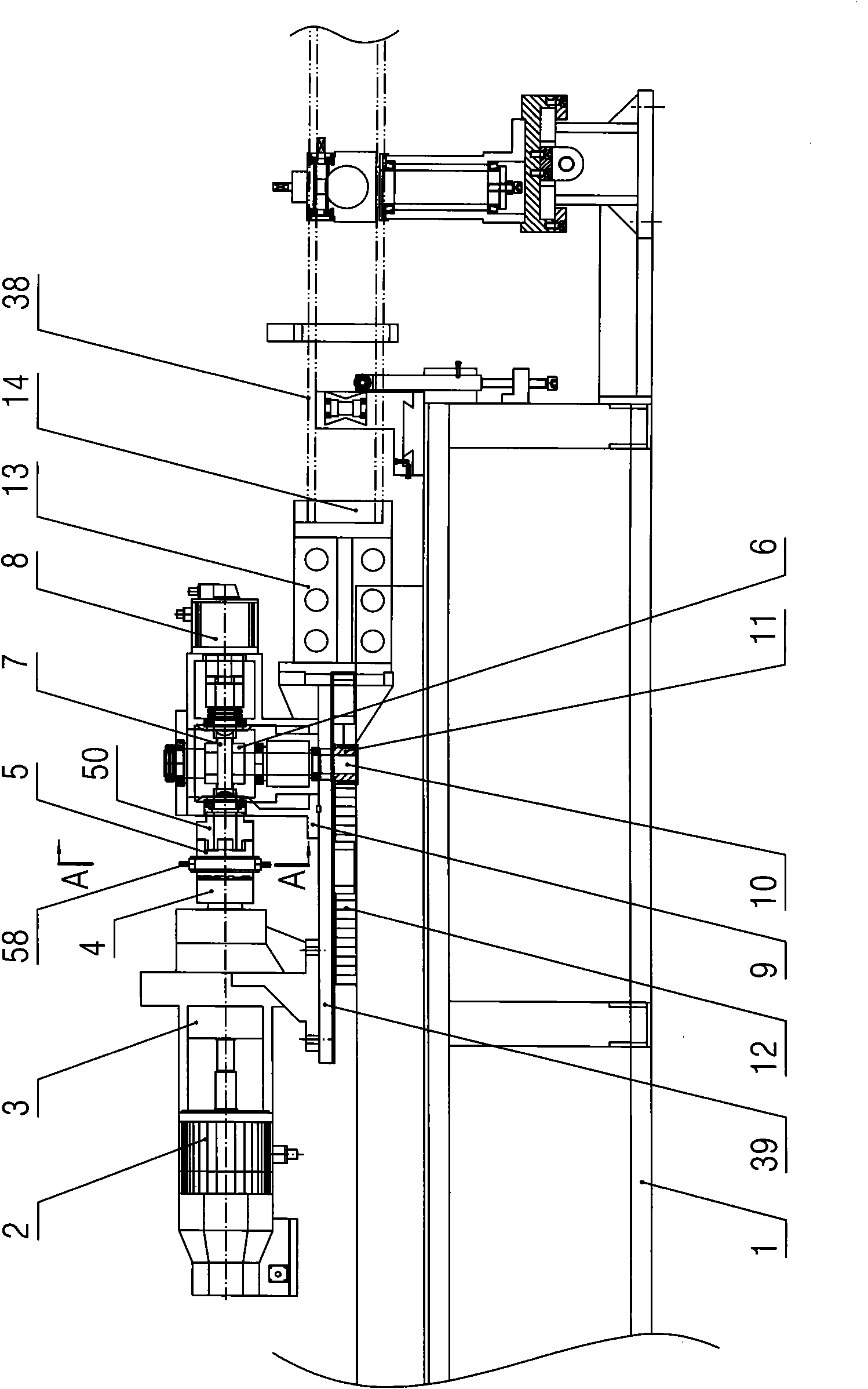

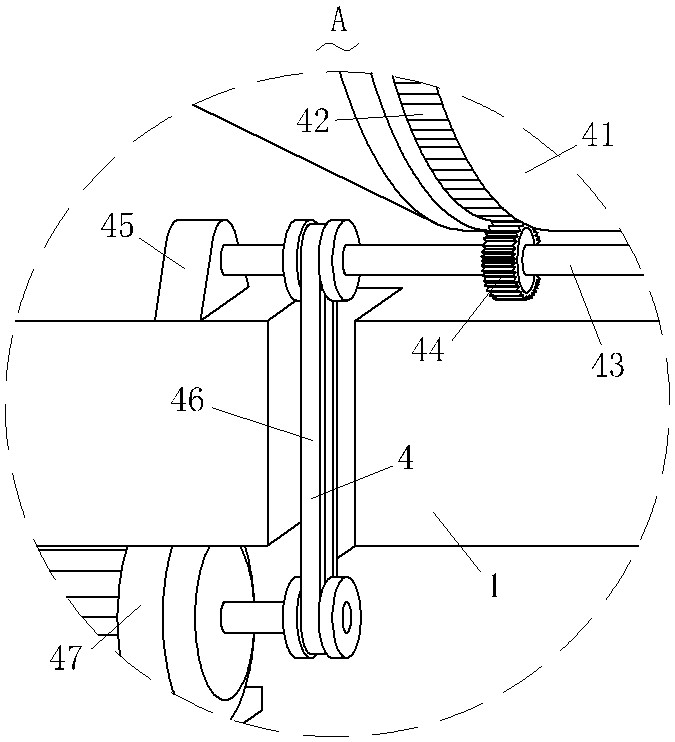

InactiveCN101941033ASlow down the feeding speedMeet the requirements of feeding speedMetal-working feeding devicesPositioning devicesGear wheelDrive shaft

The invention discloses a feeding apparatus capable of greatly reducing feeding speed, which comprises a main body, wherein the main body is movably provided with a feeding bottom plate; the feeding bottom plate is provided with a worm gear box, a feeding motor and a feeding reducer; the feeding motor and the feeding reducer are positioned at one side of the worm gear box; the output shaft of the feeding motor is connected with the input shaft of the feeding reducer; the transmission shaft according to the vertical direction in the worm box is provided with a worm gear; the bottom end of the transmission shaft extends out of the worm gear box and provided with a drive gear; the drive gear is meshed with a rack on the main body; a horizontal worm, which cooperates with the worm gear, penetrates through the worm gear box; one end of the worm is connected with the output shaft of the feeding reducer; and the feeding bottom plate is also provided with a feeding clamping device. The invention is mainly used for a hot bending machine capable of heating and then bending pipes.

Owner:ZHANGJIAGANG MINGHUA MACHINERY MFG

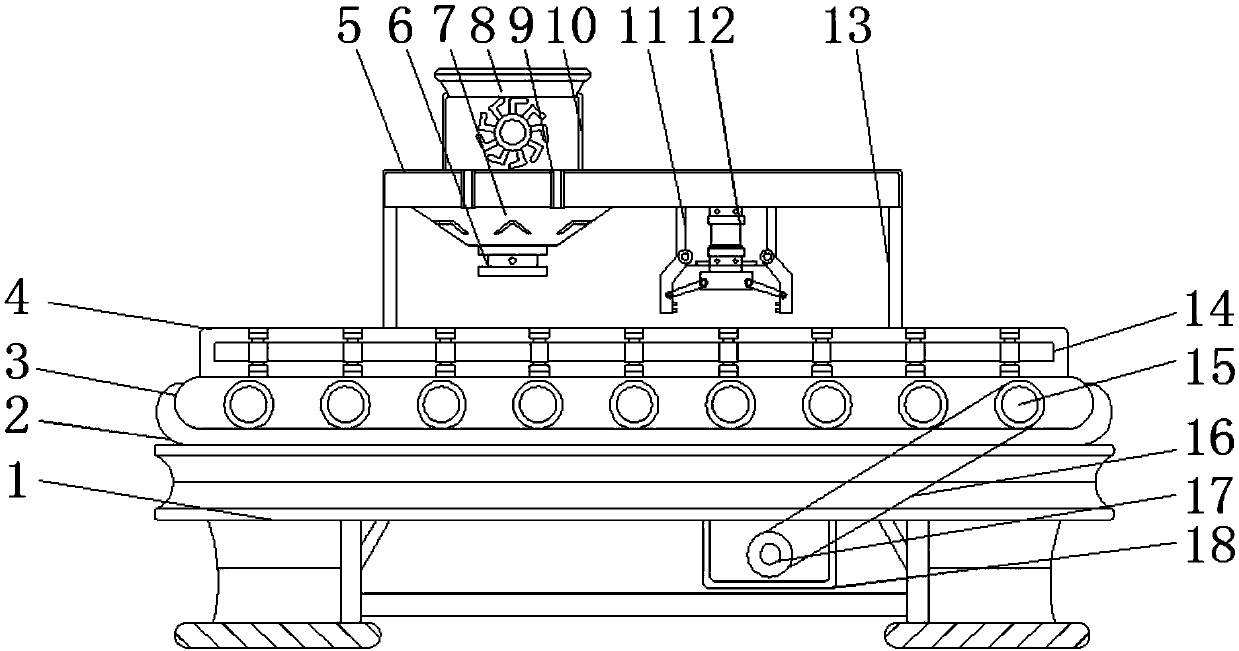

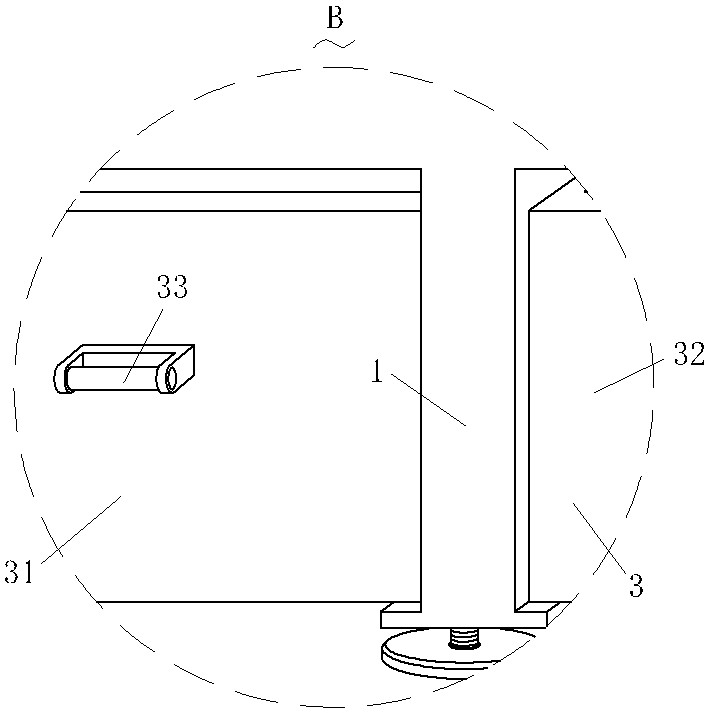

Unloading device for blank processing

InactiveCN111170014AEasy to change the angleConvenient location changeConveyorsStacking articlesPipe fittingStructural engineering

The invention discloses an unloading device for blank processing and relates to the technical field of tubular product blank unloading. The unloading device comprises a base, wherein a first bracket and a second bracket are fixedly connected to the top surface of the base, separately, and two connecting rods are fixedly connected between opposite surfaces of the first bracket and the second bracket. The unloading device also comprises a material moving assembly. The first bracket and one surfaces of the connecting rods are fixedly connected to the material moving assembly. The material movingassembly comprises a material carrying box, wherein a peripheral surface of the material carrying box is fixedly connected to the first bracket and the connecting rods, separately, rotating shafts arerotatably connected among the inner surfaces of the material carrying box, and the peripheral surfaces of the rotating shafts are fixedly connected to material carrying rollers. By designing an electric push rod, it is convenient to change the angle and position of a material receiving platform, so that it is convenient that the material receiving platform is in abut joint to an unloading platform quickly. By designing the material moving assembly, on the one hand, pipefittings can be unloaded orderly and on the other hand, the unloading speed of the pipefittings can be buffered effectively,so that the pipefitting unloading safety is further guaranteed.

Owner:曾俊

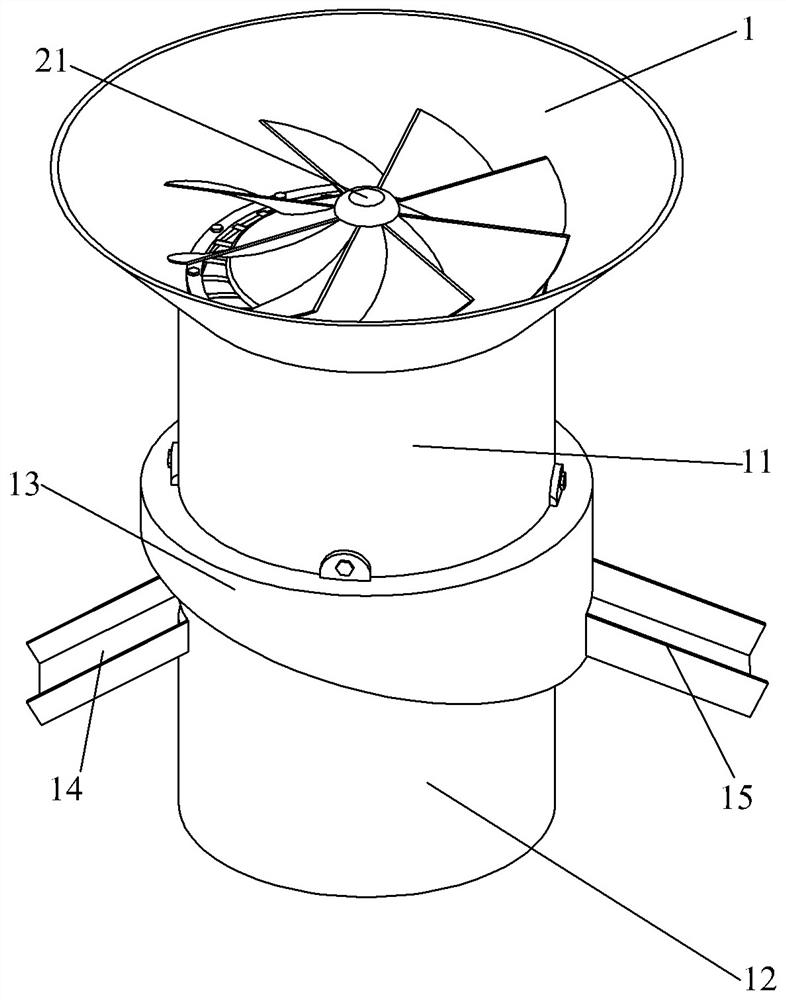

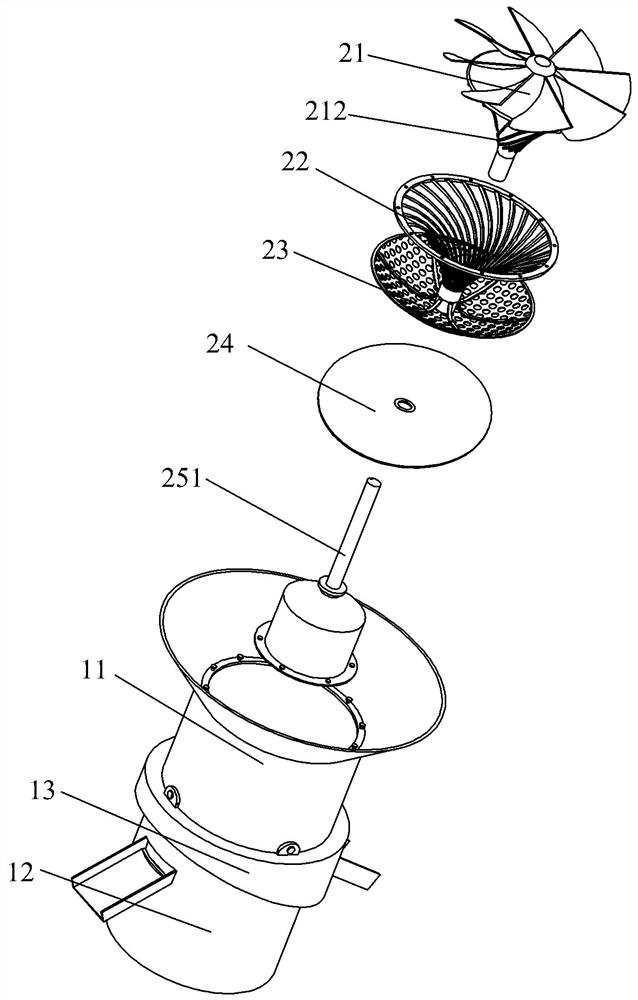

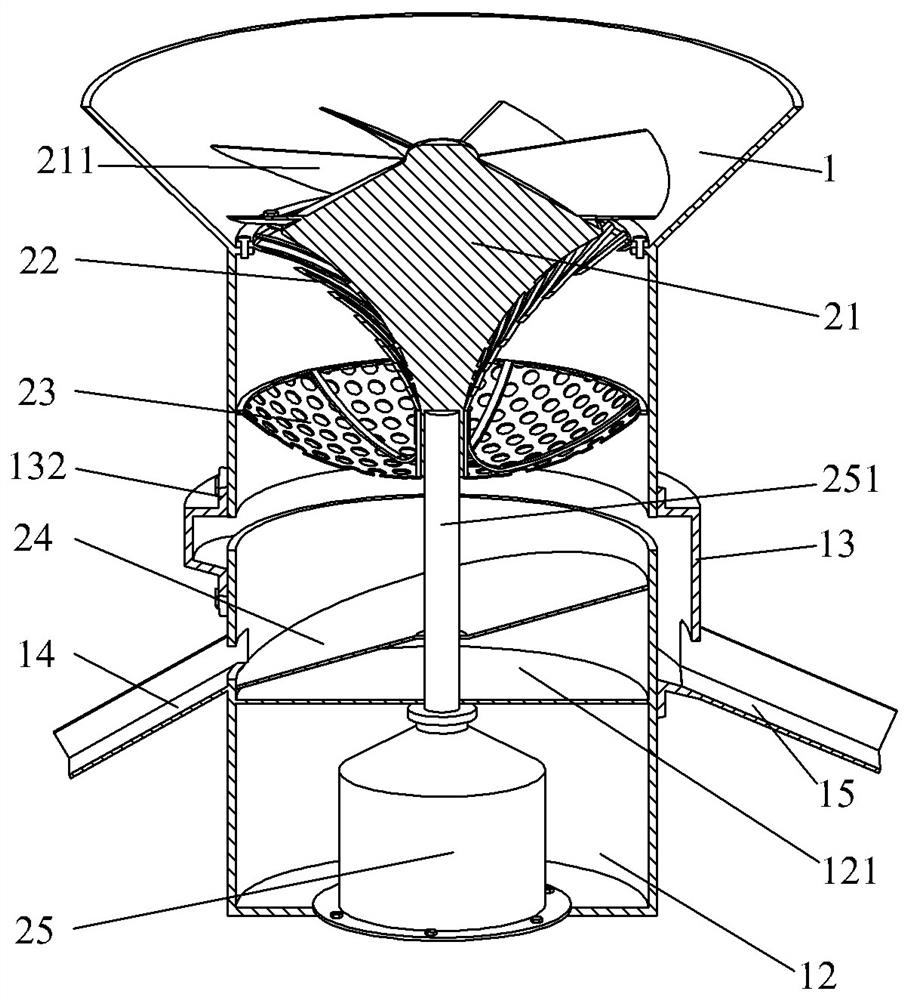

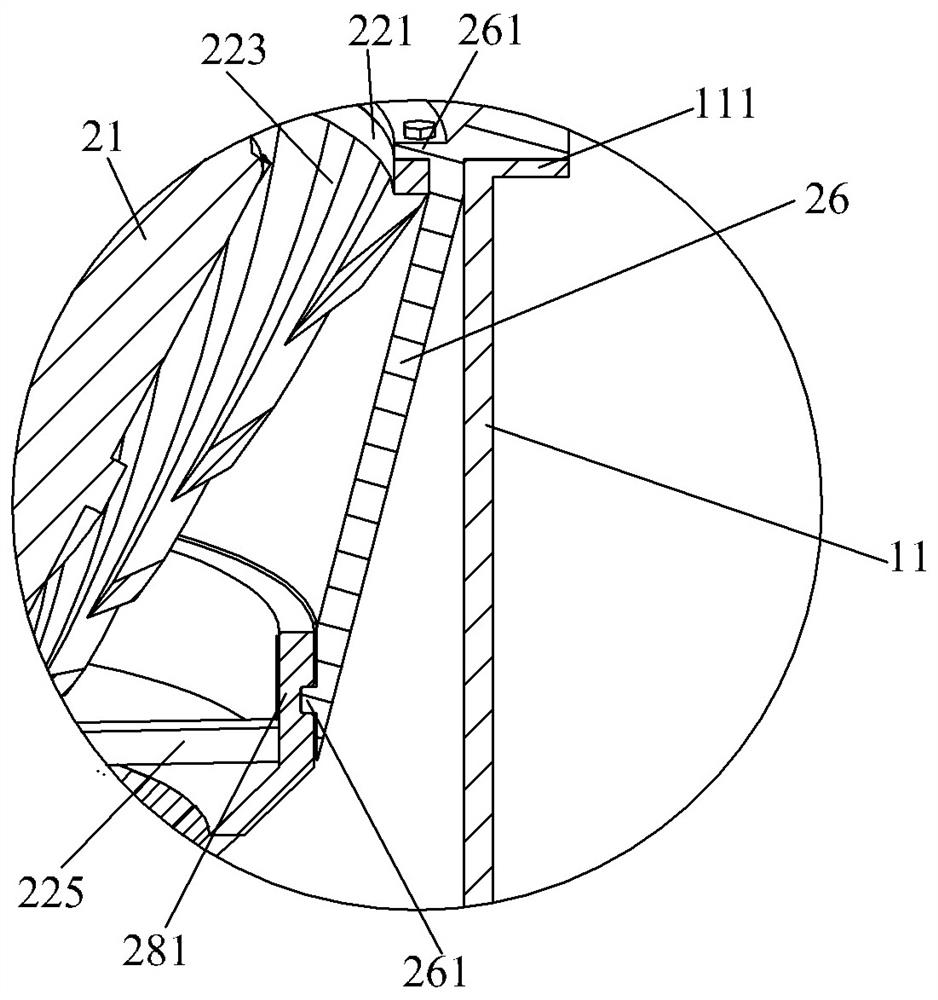

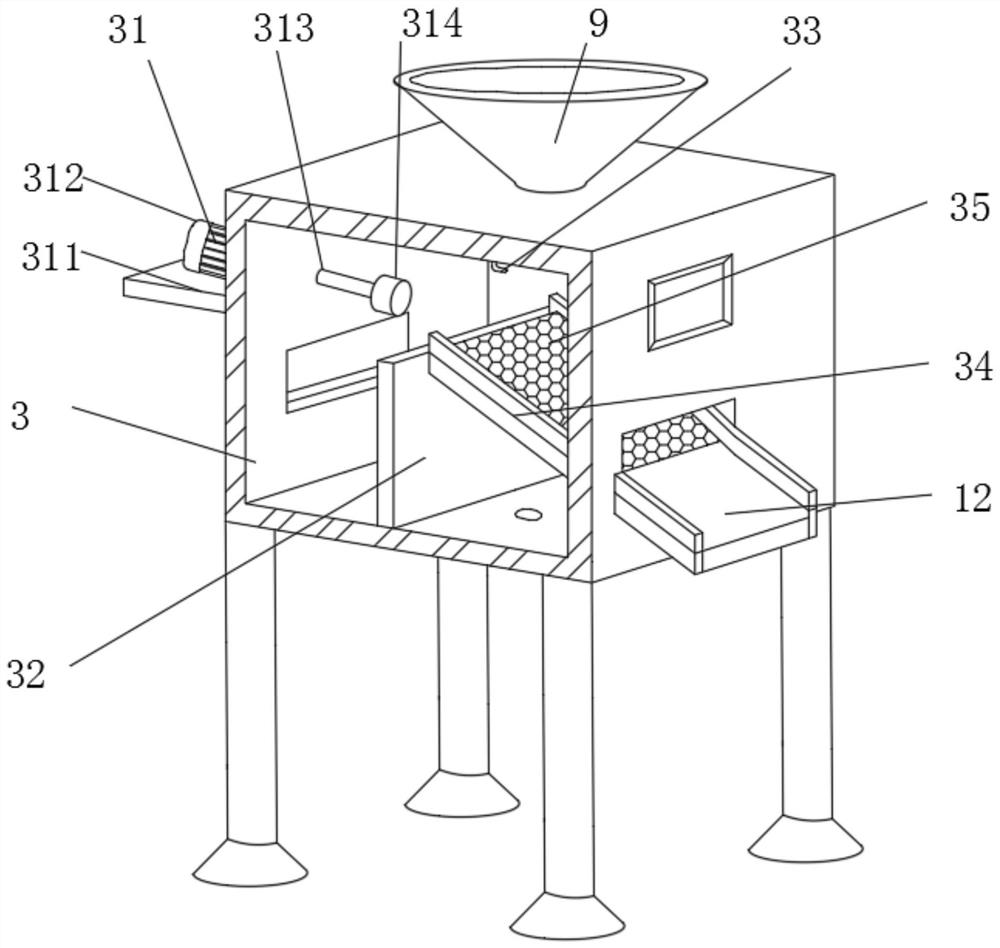

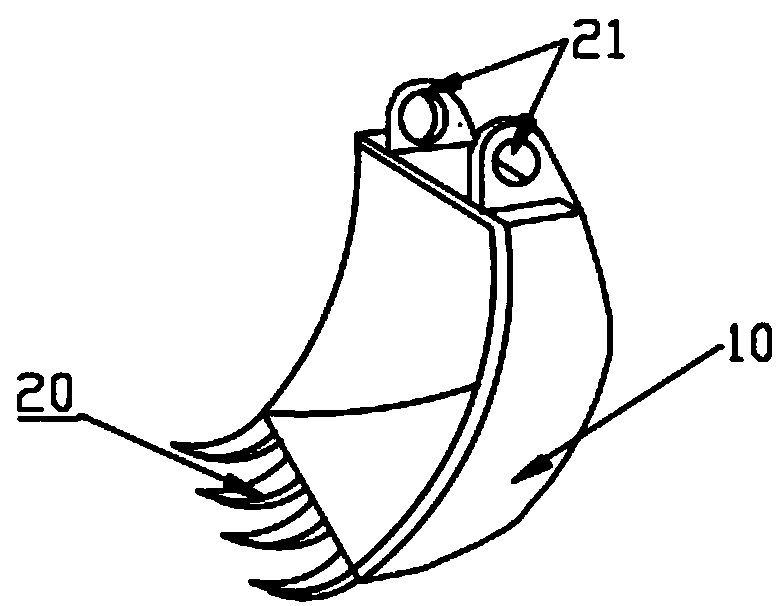

Garbage crushing device for constructional engineering

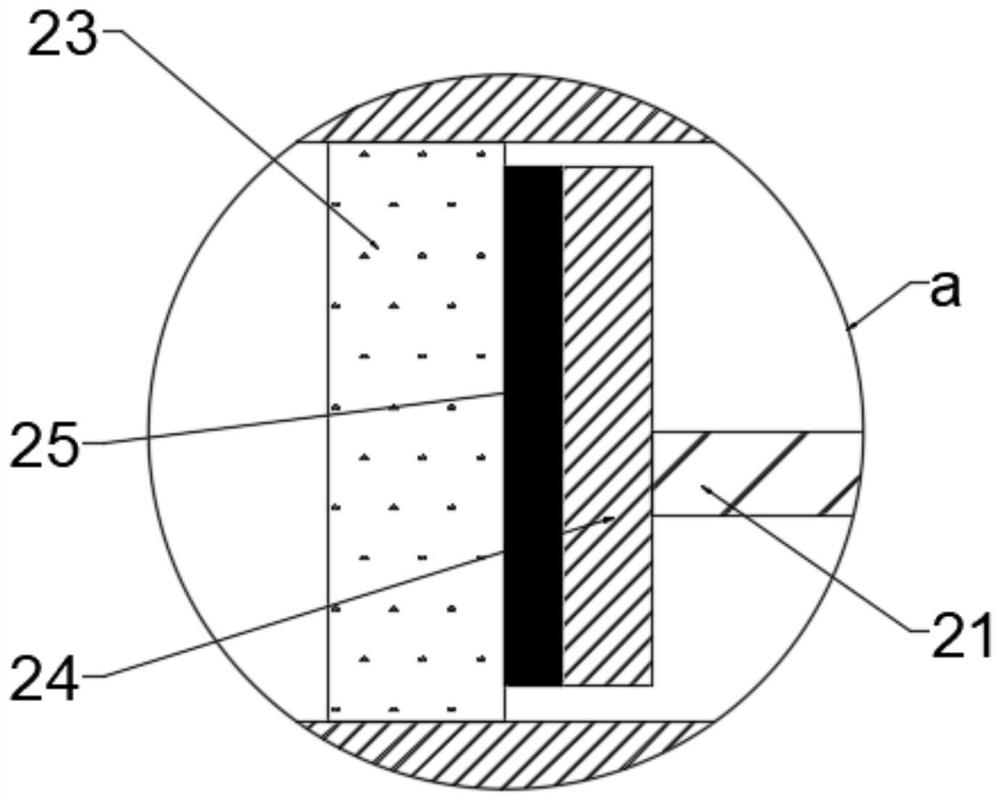

InactiveCN111686914AAvoid cloggingSlow down the feeding speedGrain treatmentsElectric machineryEngineering

The invention discloses a garbage crushing device for constructional engineering in the technical field of constructional engineering. The garbage crushing device comprises a base with rollers, wherein a pushing handle is fixed to the left end of the base; supporting rods are fixed to the periphery of the upper end of the base; a box body is fixed to the upper ends of the supporting rods; a crusher is fixed inside the box body; a discharging seat is fixed to the middle of the box body; the upper end of the discharging seat is arranged to be in a funnel shape; a discharging opening is formed inthe middle of the discharging seat; a rotating shaft is rotationally limited inside the discharging seat; a plurality of rotating blades are uniformly arranged at the position, positioned inside thedischarging opening, of the outer side of the rotating shaft; a rectangular plate is fixed to the outer end of the box body; a transmission motor is fixed to the upper end of the rectangular plate; anoutput shaft of the transmission motor is connected with the rotating shaft; and a first transmission mechanism and a second transmission mechanism are arranged on the upper side and the lower side of the output shaft of the transmission motor correspondingly. According to the garbage crushing device, the transmission motor rotates to drive the rotating blades to rotate, so that a discharging hole is prevented from being blocked, the discharging speed is reduced, the operation is convenient and fast, and dust can be prevented from escaping out of the box body in the crushing process.

Owner:山东水利职业学院

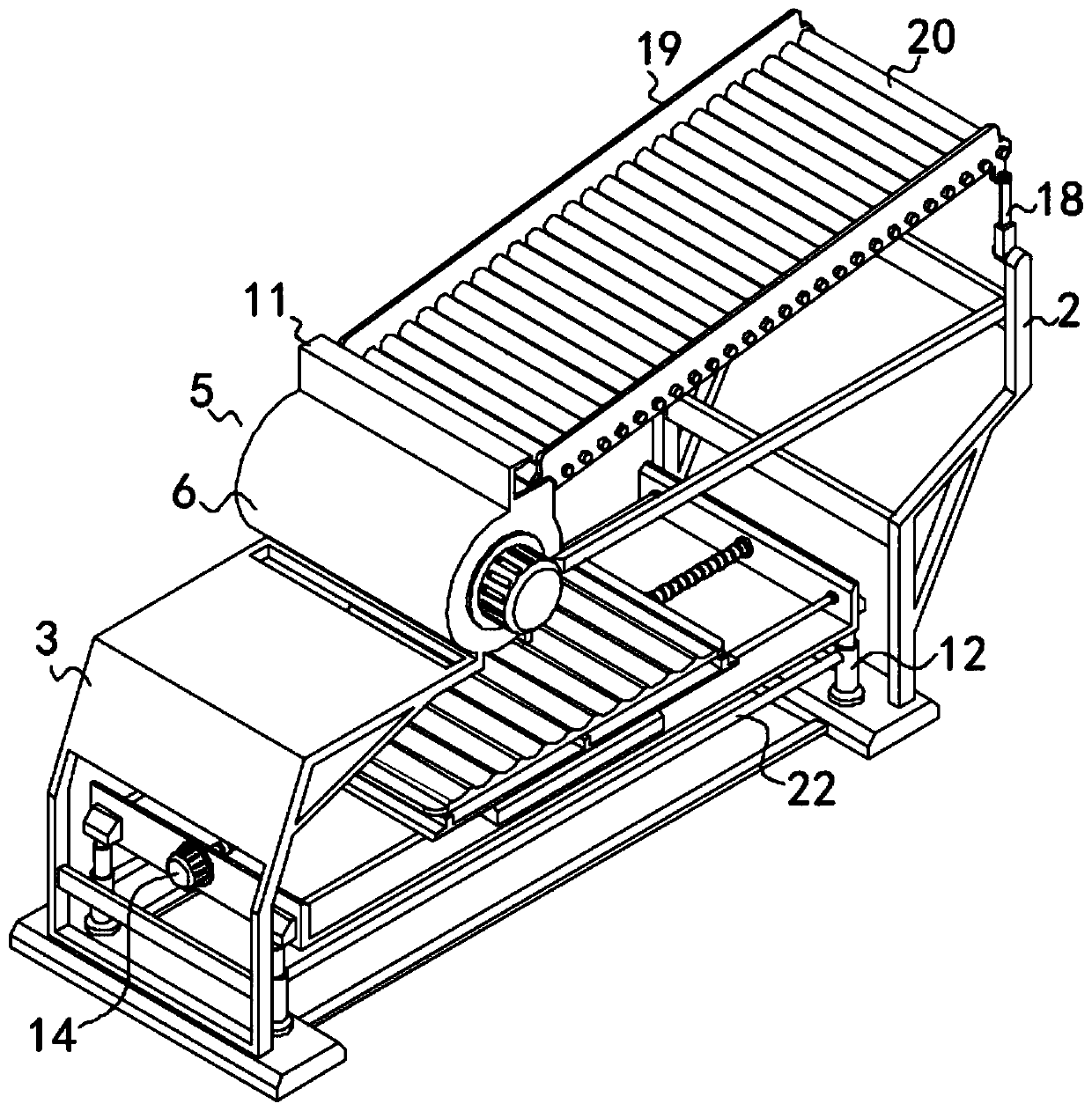

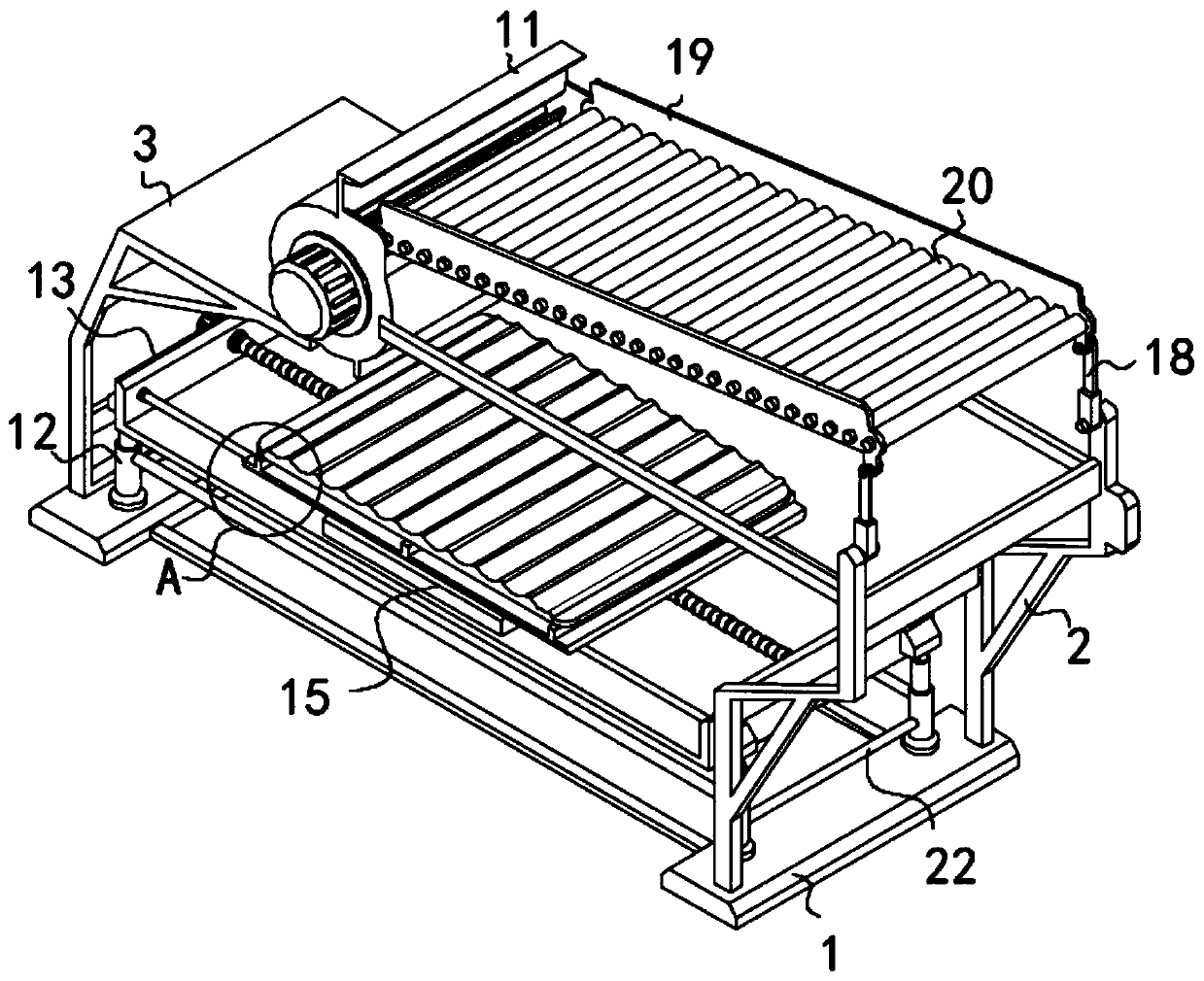

Shot-blasting material particle cleaning device

InactiveCN108393814ASolve the problem of many operating procedures, slow speed and low efficiencySlow down the feeding speedAbrasive machine appurtenancesCleaning using liquidsDrive wheelDrive motor

The invention discloses a shot-blasting material particle cleaning device. The shot-blasting material particle cleaning device comprises a shell, a baffle, spray heads, a collecting tank, an air blower, electric heating wires and a material guide plate. The shell is provided with a conveying belt, and the conveying belt is installed on a drive roller. The drive roller is provided with a drive wheel. A driving motor is installed below the drive roller and is further provided with a driving wheel. The driving wheel and the drive wheel are in drive connection through a drive belt. A shot-blastingmachine discharging outlet is formed in a mounting hole in the upper portion of the left side of the shell, and a discharging groove is formed below the shot-blasting machine discharging outlet. Thebaffle is installed on the inner wall of the discharging groove. According to the shot-blasting device with a particle size screening function, due to arrangement of the shell, the baffle, the spray heads, the collecting tank, the air blower, the electric heating wires and the material guide plate, the problems that the shot recovery speed is low, efficiency is also low, shots can be splashed easily in the recovery process and abrasion to recovery equipment is large are solved.

Owner:JIANGSU YINGDA MACHINERY

Crushing and repairing device for heavy metal soil

The invention relates to the field of soil remediation, in particular to a crushing and repairing device for heavy metal soil. The device comprises a motor, a transmission shaft, an upper elastic grinding assembly, a lower elastic grinding assembly, a screening and filtering assembly and a sliding column. The upper elastic grinding assembly comprises an upper fixing outer ring, a plurality of upper elastic strips and an upper fixing inner ring, and the upper fixing outer ring is fixedly installed; the upper ends of the upper elastic strips are connected with the upper fixing outer ring, the lower ends are connected with the upper fixing inner ring, and the spiral direction of the projection in the horizontal plane from inside to outside is opposite to the rotating direction of the transmission shaft; the lower elastic grinding assembly comprises a lower fixing outer ring, a plurality of lower elastic strips and a lower fixing inner ring, and the lower fixing outer ring is rotatably arranged; the inner end of the sliding column is connected with the upper fixing inner ring, and the outer end is vertically slidably mounted on the lower fixing outer ring; the upper ends of the lower elastic strips are connected with the lower fixing outer ring, the lower ends are connected with the lower fixing inner ring, and the lower elastic strips and the upper elastic strips are opposite in rotation direction; stirring blocks are arranged in spaces defined by the upper elastic strips and the lower elastic strips; and the screening and filtering assembly is used for receiving and filtering the crushed soil.

Owner:YIXING INNOVATION ENVIRONMENTAL PROTECTION

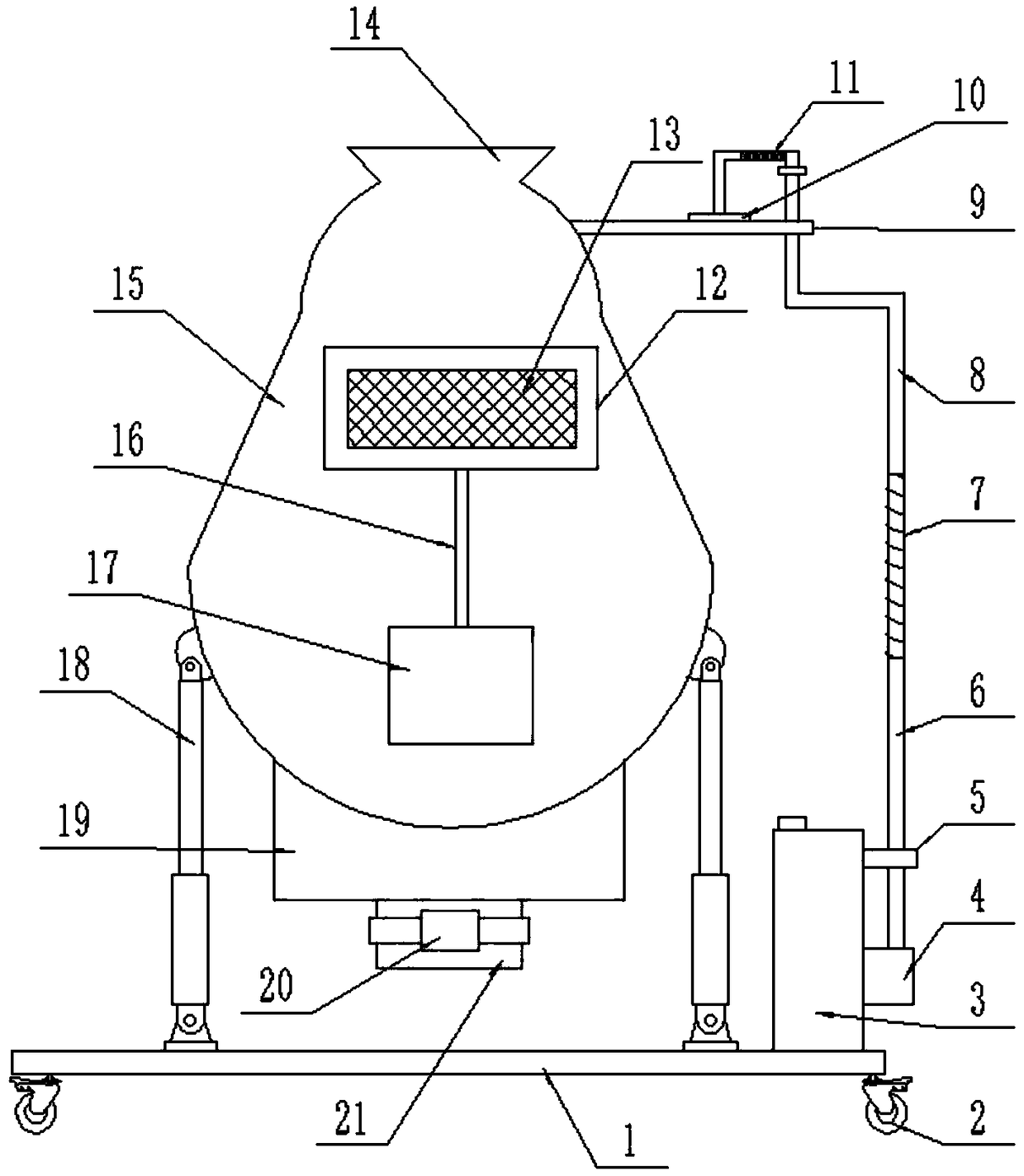

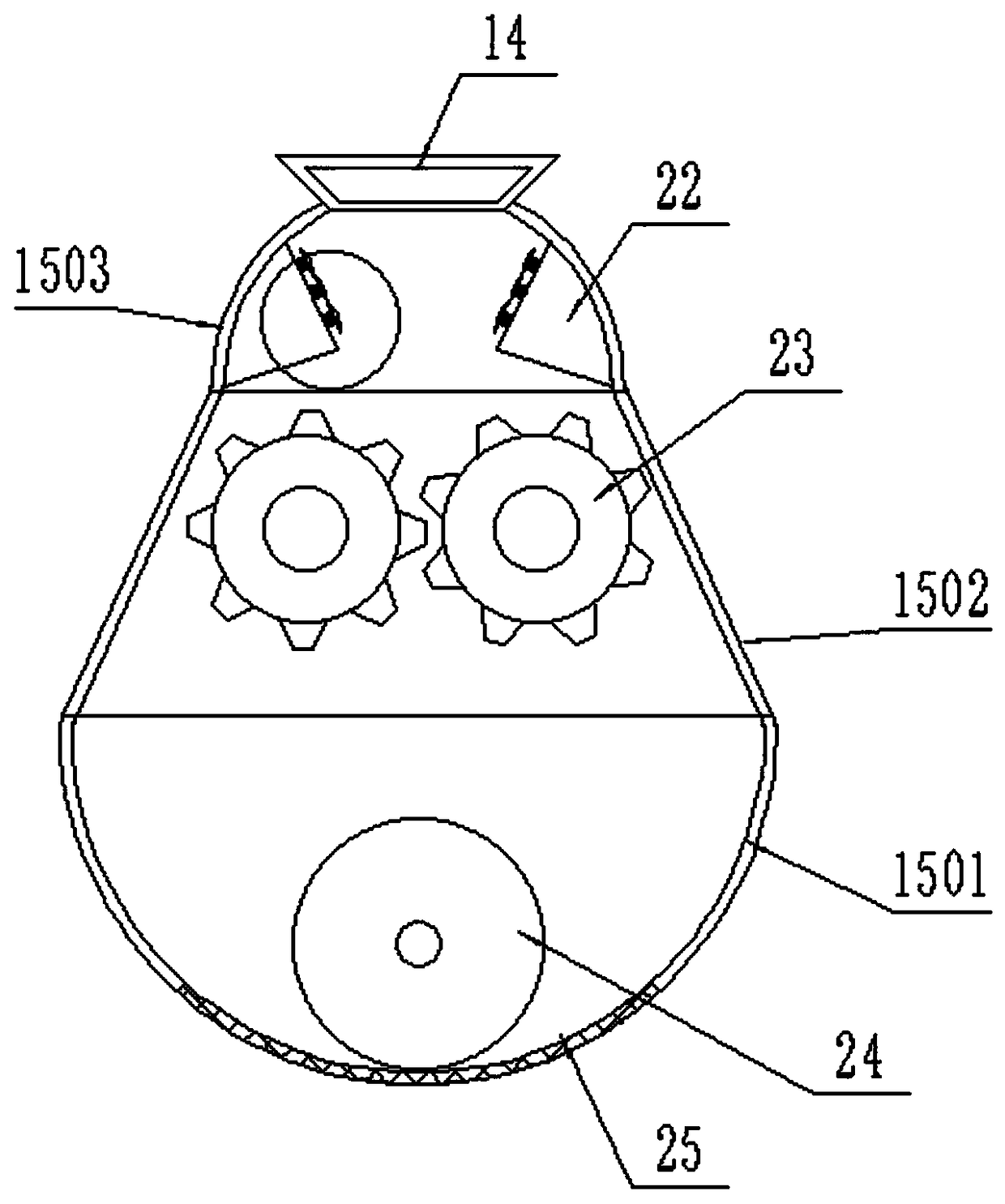

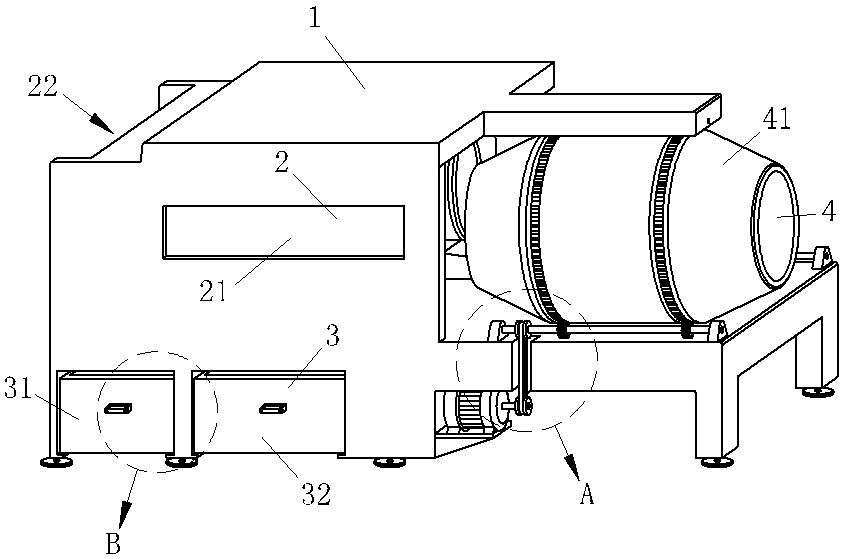

Grinding device convenient to clean for agricultural scientific research experiments

InactiveCN109499666ASlow down the feeding speedReduce shockHollow article cleaningGrain treatmentsAgricultureEngineering

The invention belongs to the technical field of agricultural scientific research, and particularly relates to a grinding device convenient to clean for agricultural scientific research experiments. The problems that the grinding difficulty of a grinding device is large and the efficiency is low are aimed, so that the technical scheme is provided as follows that the grinding device comprises a base, universal wheels are all arranged at four corners of the outer wall at the bottom of the base, four electric control hydraulic rods are arranged on the outer wall of the top of the base, and the topouter walls of the four electric control hydraulic rods are provided with the same tank body; and the tank body comprises an upper tank body, a lower tank body and a middle tank body, a feeding portis formed in the outer wall of the top of the upper tank body, a feeding hopper is arranged on the inner wall of the feeding port, a water tank is arranged on one side of the outer wall of the top ofthe base, and a water pump is arranged on the outer wall of one side of the water tank. According to the grinding device, the feeding speed can be reduced, a buffer table is of an obtuse-angle triangular structure, the buffer contact surface is added, and the impact on equipment during the feeding is greatly reduced; and a water spraying disc is moved to the position above the feeding hopper, namely the tank body can be sprayed and cleared, and the cleaning portability of the tank body is improved.

Owner:湖南全望信息科技有限公司

Efficient recoverer for construction waste

PendingCN112371683ARealize separation operationHigh recovery rateConstruction waste recoveryWaste processingWater resourcesEnvironmental engineering

The invention discloses an efficient recoverer for construction waste. The efficient recoverer comprises a screening box, wherein the right part of the lower end of the screening box is fixedly connected with a filter device; the lower part of the right end of the screening box is fixedly equipped with a discharge part II; the lower end of the discharge part II is fixedly equipped with two supporting rods; the lower ends of the two supporting rods are fixedly connected with a conveying device; the right end of the conveying device is fixedly connected with a recovery box; the left part of thefront end of the recovery box is fixedly connected with a discharge part III; the front end of the discharge part III is fixedly connected with a combustion box; and the upper end of the combustion box and the upper part of the left end of the combustion box are fixedly connected with a heat recovery device. According to the efficient recoverer for construction waste disclosed by the invention, metal waste can be recycled through an adsorption part, the conveying device and the filter device; the recoverer can realize recycling of heat energy and water resources; and besides, a sensor, a control panel and the conveying device can realize automatic sorting and recovery of waste, so that labor burden is relieved.

Owner:占天胜

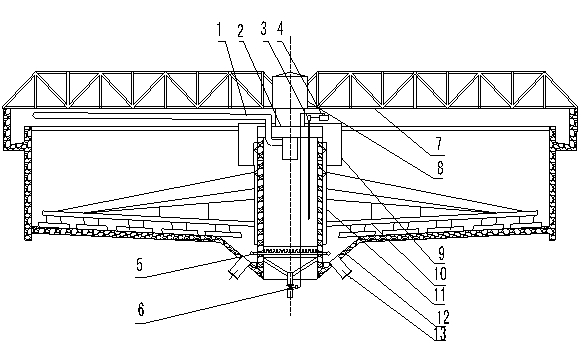

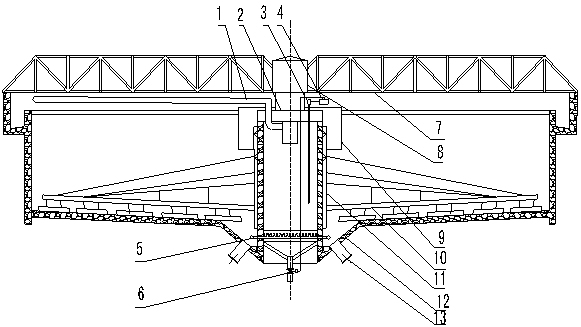

Coal slime classified concentration device

InactiveCN102205263AReduce the effect of settlementDoes not affect yieldWet separationFluidized bedSmall footprint

The invention discloses a coal slime classified concentration device which comprises a pool body, a bridge frame arranged on the top of the pool body, a rotating frame arranged in the pool body and a transmission device arranged at the upper part of the pool body and used for driving the rotating frame to rotate, wherein the center of the pool body is provided with a liquid-solid fluidized bed cylinder body the upper part of which is provided with a guide cylinder, the rotating frame is arranged on the outer part of the liquid-solid fluidized bed cylinder body, the liquid-solid fluidized bed cylinder body is internally provided with a concentration sensor connected with a controller, the lower part of the liquid-solid fluidized bed cylinder body is provided with a liquid distributor, a tapered guide groove is arranged below the liquid distributor, and a coarse particle bottom current discharging valve is arranged on a discharging hole of the tapered guide groove. The invention overcomes the defect of a concentrator used in first stage concentration in a coal slime two-concentrating and two-recycling process, and has the advantages of simple structure, small occupation area and lowcapital construction cost.

Owner:CHINA UNIV OF MINING & TECH

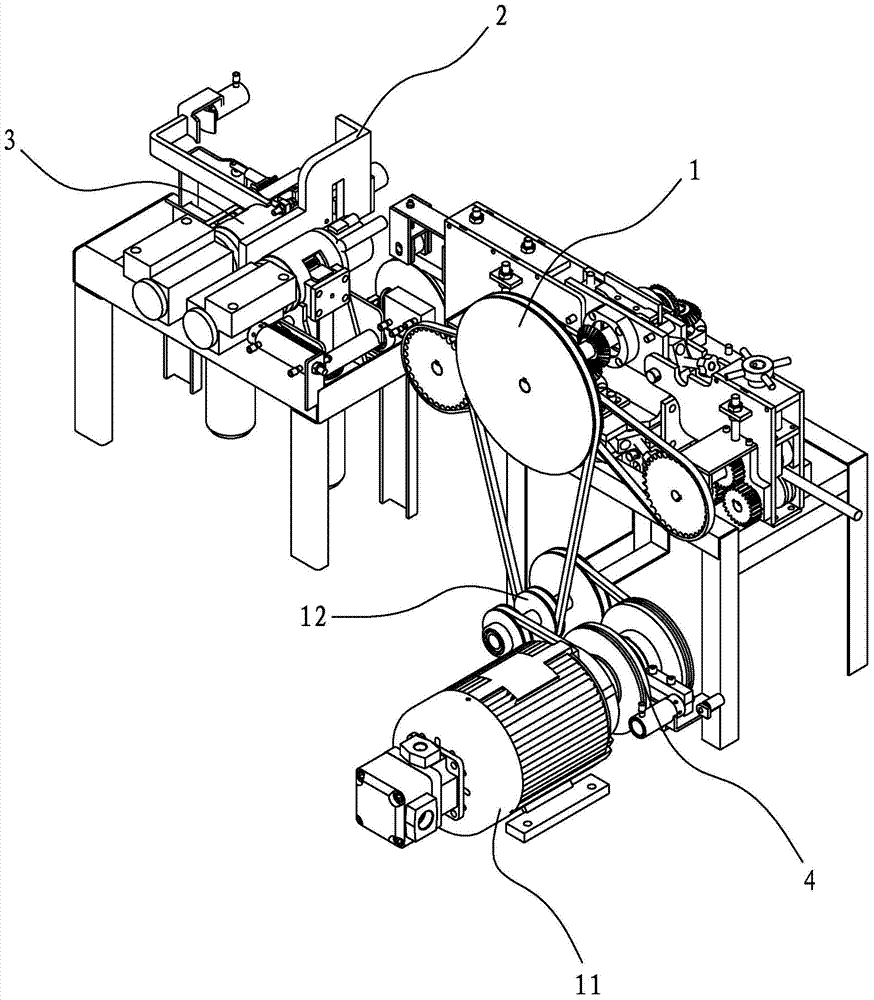

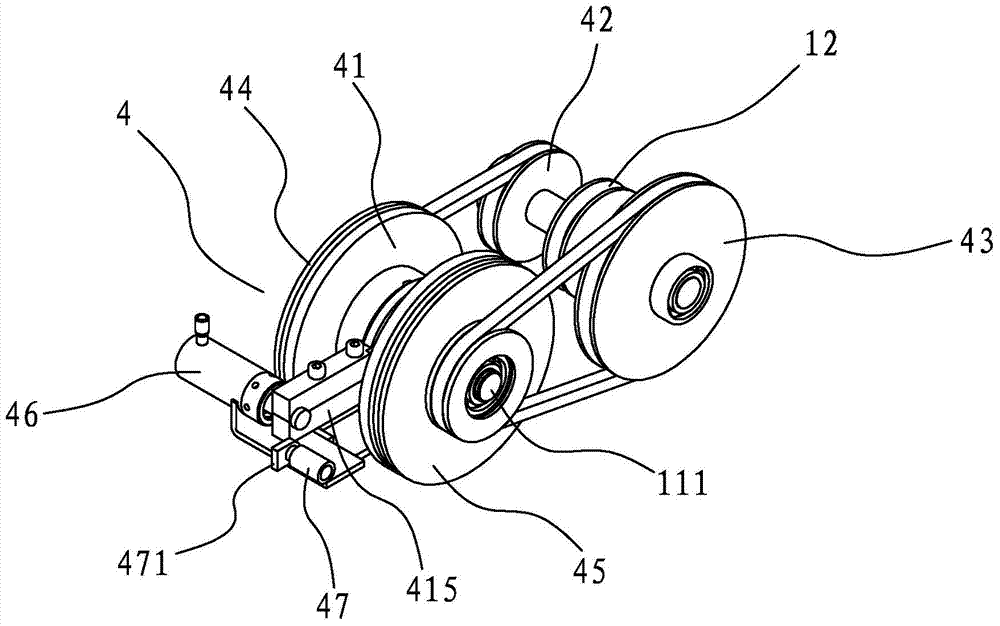

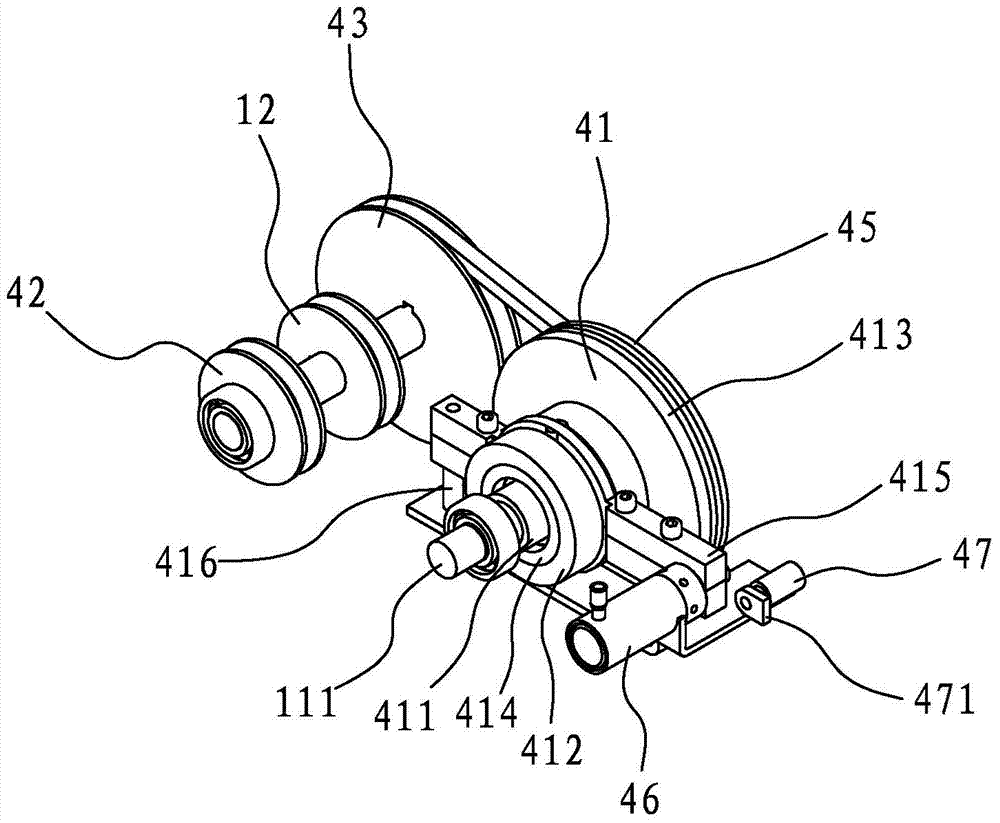

Automatic discharge speed-changing device of following type steel bar straightening bending-shearing machine

The invention discloses an automatic discharge speed-changing device of a following type steel bar straightening bending-shearing machine. The following type steel bar straightening bending-shearing machine comprises a feeding mechanism and further comprises a cutting device and / or bending device, wherein the feeding mechanism comprises a driving motor and a driving wheel, the automatic discharge speed-changing device is arranged between the driving motor and the driving wheel. The automatic discharge speed-changing device performs automatic speed regulation through a clutch device, enables a steel bar to be quickly fed, improves efficiency, reduces feeding speed during bending-shearing machining and ensures machining stability and quality, the efficiency problem of the following type steel bar straightening bending-shearing machine is solved, the machining efficiency and practicability of the following type steel bar straightening bending-shearing machine are improved, and popularization of the following type steel bar straightening bending-shearing machine is facilitated.

Owner:冯广建

Repairing agent for repairing hexavalent chromium contaminated soil and method for repairing hexavalent chromium contaminated soil by using repairing agent

ActiveCN111718718AImprove practicalityAvoid multiple fixesContaminated soil reclamationOrganic fertilisersCalcium sulphideSoil science

The invention provides a repairing agent for repairing hexavalent chromium contaminated soil and a method for repairing hexavalent chromium contaminated soil by using the repairing agent. The repairing agent can reduce hexavalent chromium and prevent trivalent chromium from being converted into hexavalent chromium. The repairing agent for repairing hexavalent chromium contaminated soil comprises the following components in percentage by weight: 20-35% of a calcium polysulfide solution with the concentration of 29%; 10-20% of a curing agent; 50-655 of water; the method for repairing hexavalentchromium contaminated soil comprises the following steps: S1, preparing a repairing agent, specifically, stirring and mixing a calcium polysulfide solution with the concentration of 29%, a smashed curing agent and water to be uniform according to the proportion, and obtaining the repairing agent and putting into a medicine storage device for use; S2, preparing materials, namely digging to-be-repaired soil from the contaminated land for later use; S3, performing primary repairing treatment, specifically, using a soil remediation machine for conducting rolling crushing and drug application on to-be-repaired soil in the repairing process; and S4, performing repairing post-treatment is conducted, specifically, using soil remediation machine for stirring the primarily repaired soil in the repairing process.

Owner:福建省环境保护设计院有限公司

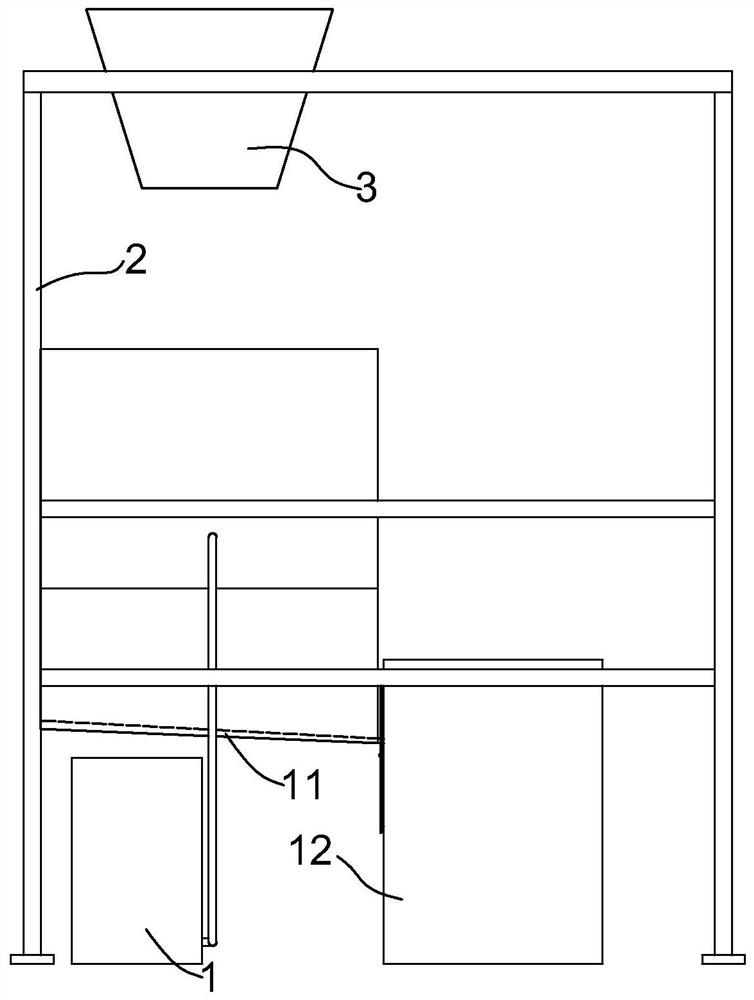

Rapid high-precision distribution device with breaking device

PendingCN108557289AControl precisionControl the output speedLarge containersConveyor partsSolid particleEngineering

The invention discloses a rapid high-precision distribution device. The rapid high-precision distribution device comprises a belt-type conveying device, a material cabin, a material blocking device, aweighing hopper, and a control system. The material cabin is cooperatively installed above a conveying belt, and the bottom thereof is slightly higher than the conveying belt. The material cabin is used for storing a material, and comprises a material cabin body and a cabin door. The material blocking device is cooperatively and fixedly installed with the conveying belt, positioned above the conveying belt, and perpendicular to the conveying belt. The material cabin is positioned behind a moving direction of the conveying belt. The weighing hopper is cooperatively installed below the tail endof the conveying belt. The control system is used for receiving data of the weighing hopper, calculating, and controlling the work of the belt-type conveying device, the cabin door and the material blocking device. The device is capable of realizing rapid-speed feeding, intermediate-speed feeding, slow-speed feeding, and accurate feeding; high in feeding precision, rapid in speed, and suitable for solid particles, powder, and an adhesion mixture; and small in repetitive control precision deviation without a loose material.

Owner:郑州鼎源自动化科技有限公司

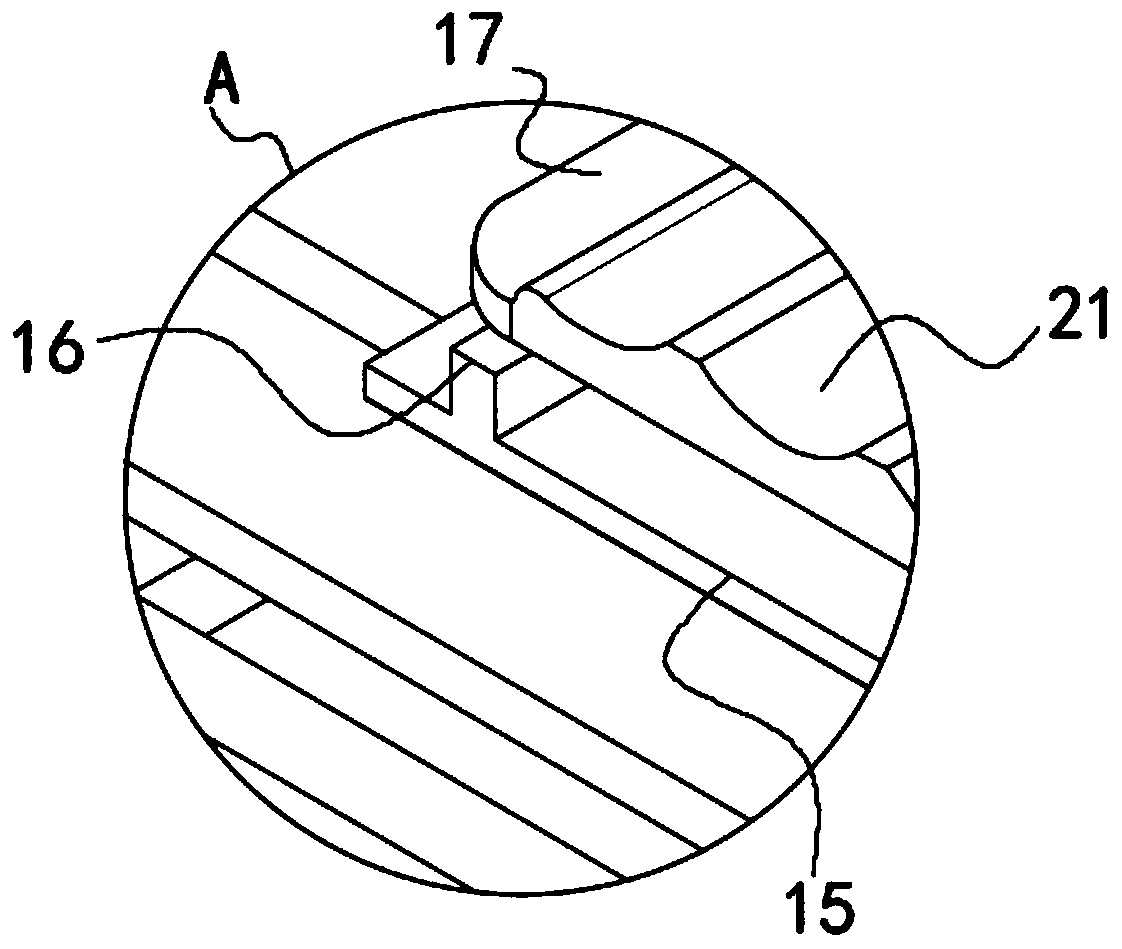

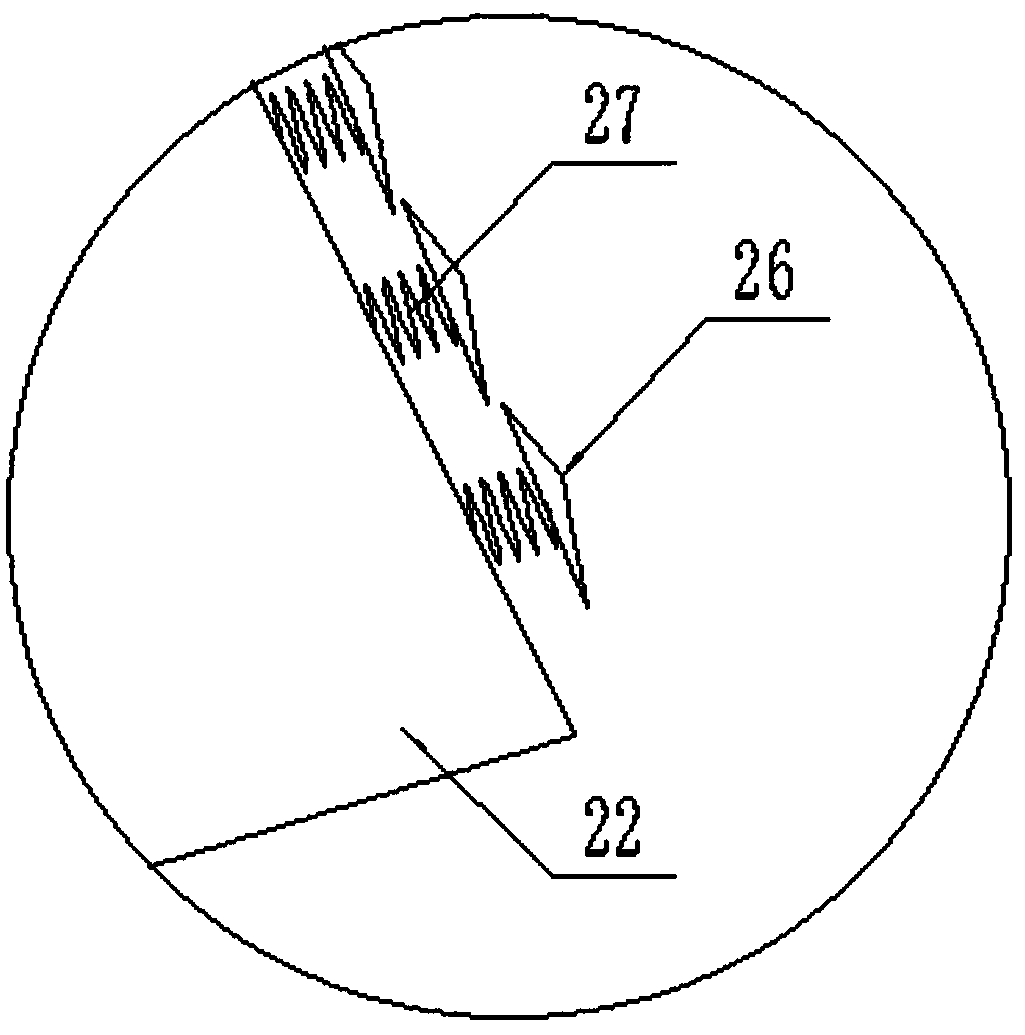

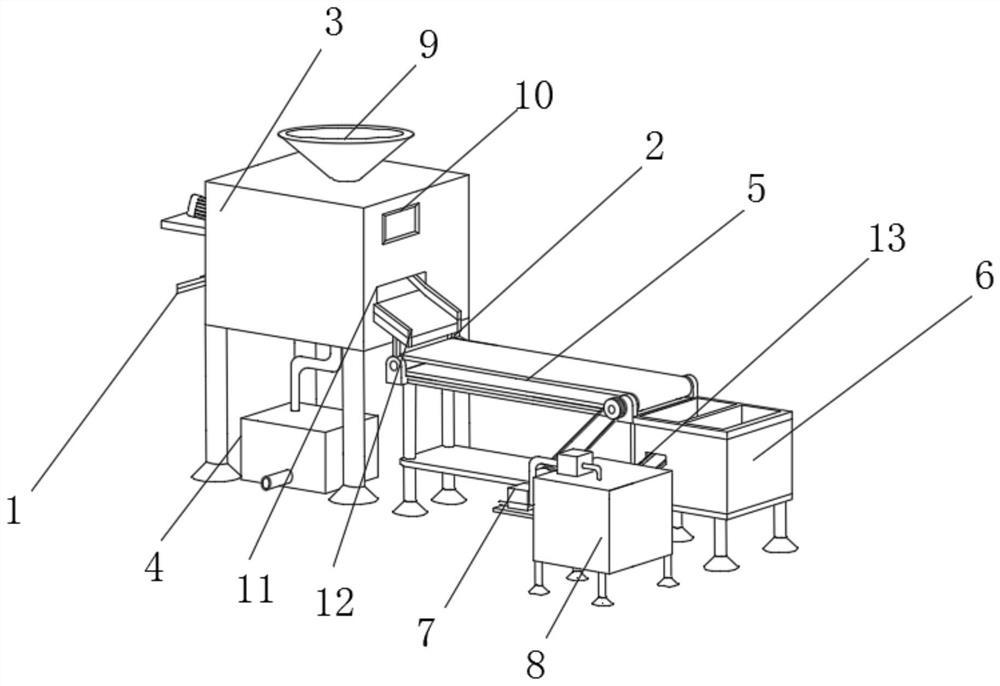

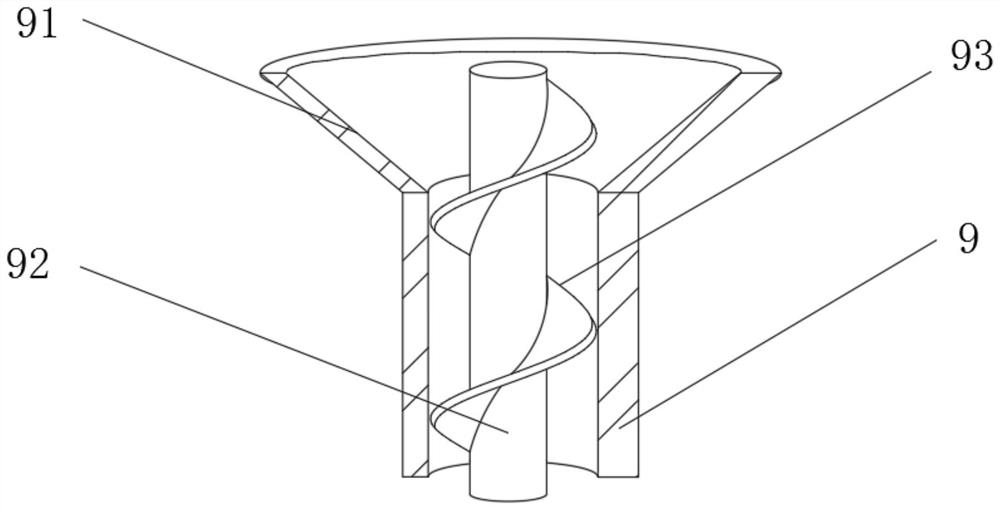

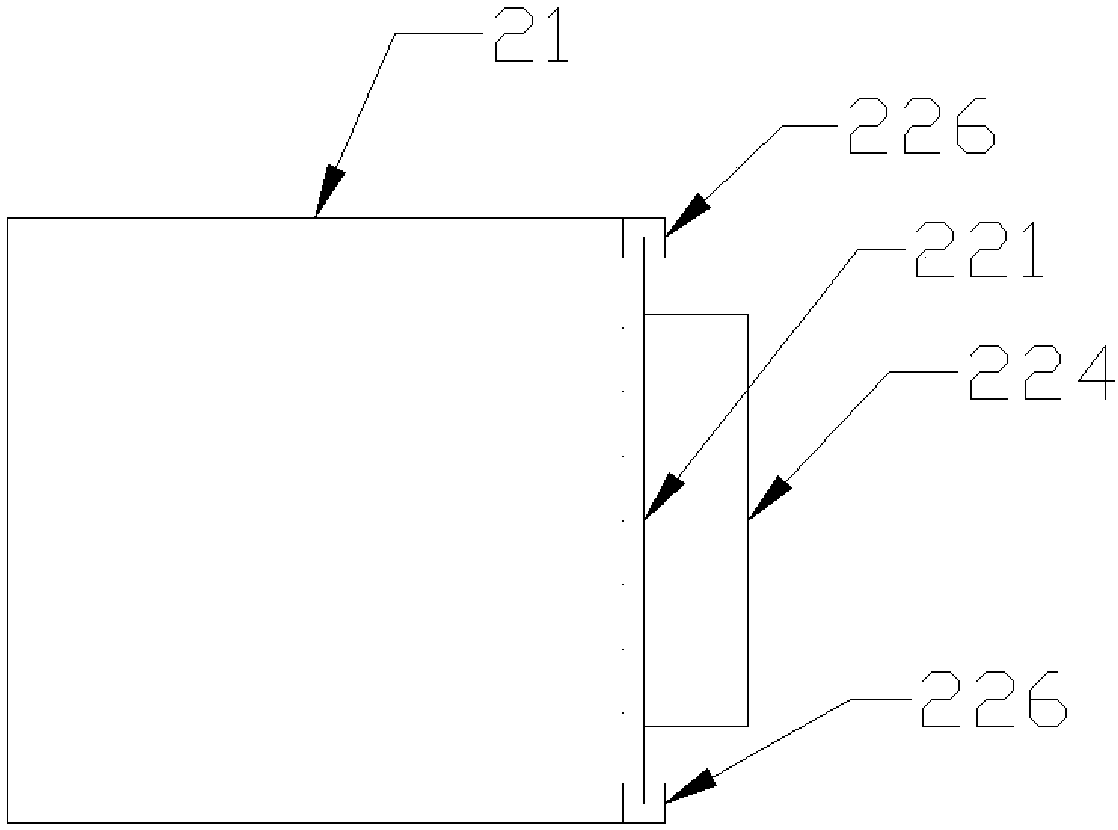

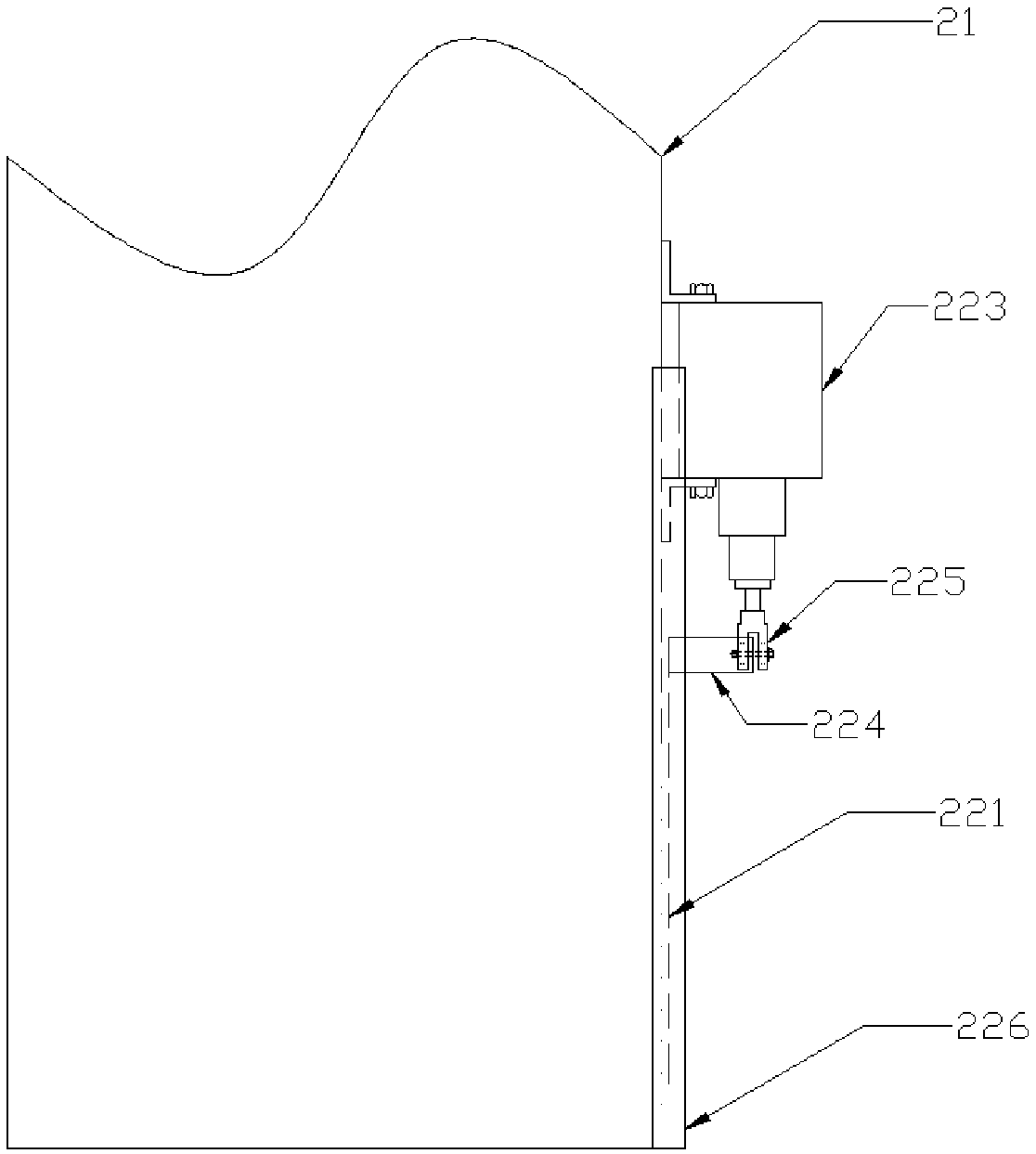

Spiral sieve with buffering type feeding channel

InactiveCN107649357ASlow down the feeding speedAvoid wear and tearSievingScreeningMachineSupport plane

The invention discloses a spiral sieve with a buffering type feeding channel. The spiral sieve comprises a machine body and the feeding channel. The machine body is composed of three sections of unitsthe same in structure, and the three sections of units are arranged in a ladder-like manner and include the first unit, the second unit and the third unit from top to bottom in sequence. Each unit comprises a supporting frame and a sieve box. A material inlet is formed in the upper end of the first unit, the upper end of the material inlet is connected with a feeding barrel, and the feeding channel is vertically arranged in the feeding barrel and is spirally arranged. The lower end of the feeding channel is provided with a guide-out port, the guide-out port is correspondingly formed over thesieve box in the first unit, a plurality of electric heating pipes are evenly arranged on the inner wall of the feeding barrel and connected with a heater through wires, and the heater is arranged onthe outer side of the feeding barrel. By means of the above manner, the spiral sieve can reduce the material feeding speed, and spiral shaft abrasion caused when materials collide with the sieve faceis prevented.

Owner:WUXI YUNENG COAL DRESSING MACHINERY PLANT

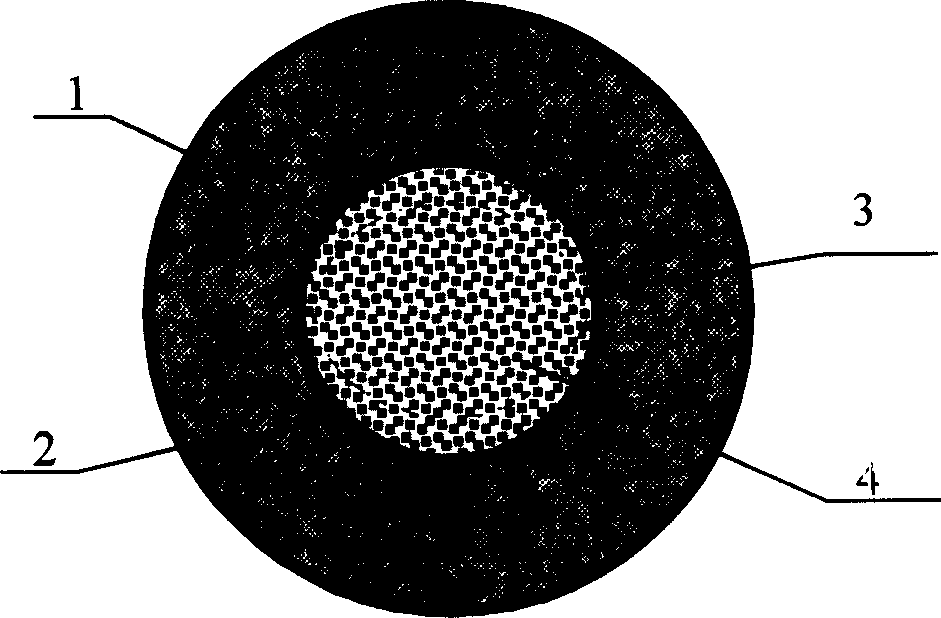

Coated wire with flexible coating

The flexible coated wire includes outer coating of steel belt, powder material layer comprising alloy powder, metal powder or non-metal powder coated inside the outer coating, and core wire inside the powder material layer, and has one flexible coating with asphalt as adhesive coated on the surface of the core wire. The flexible coated wire features that after outer coating fails, the flexible coating and the sintered powder material layer will further protect the magnesium core wire and the magnesium core wire may be further inserted into the bottom of molten iron ladle to add magnesium in controlled amount and raised efficiency. In addition, the present invention makes it possible to realize the spheroidization and inoculation of molten iron with only one coated wire in low apparatus cost and realize clean production and high efficiency application

Owner:包头文鑫实业有限公司

Energy-saving and high-efficiency plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

Concrete spouting device

ActiveCN109624060AChange heightReduce sizeCeramic shaping apparatusEngineeringMechanical engineering

The invention discloses a concrete spouting device, and belongs to the technical field of concrete pipe production. According to main points of the technical scheme, the concrete spouting device comprises a material drum, the material drum comprises a drum body with a discharging port formed in the lower end, the drum body is internally provided with a valve assembly, and the valve assembly comprises a valve which vertically and slides in the drum body and opens and closes the discharging port. The concrete spouting device has the effect of adjusting the spouting speed.

Owner:嘉善嘉诚混凝土制管有限公司

Precision overprinting mechanism of unit-type flexo machine

ActiveCN103909723APrevent slippingImprove flexographic printing qualityRotary letterpress machinesEngineeringOverprinting

The invention discloses a precision overprinting mechanism of a unit-type flexo machine. The precision overprinting mechanism comprises a roller and a base roller. The base roller is arranged below the roller, and slightly contact with the base plate during printing. The precision overprinting mechanism is characterized in that a pressing roller is arranged below the base roller; the pressing roller is arranged movably, is pushed through a pneumatic element, and contacts with the base roller during printing; a print length adjusting device is arranged on a feeding and conveying channel before a print is pressed through the roller for printing and is driven through a motor; a photoelectric tracker is arranged on a discharging and conveying channel after the print is printed; the motor is controlled according to output of the photoelectric tracker. The precision overprinting mechanism is designed for high-quality flexo printing for films, and is adaptive to flexo printing for paper.

Owner:ZHEJIANG FANGBANG MACHINERY

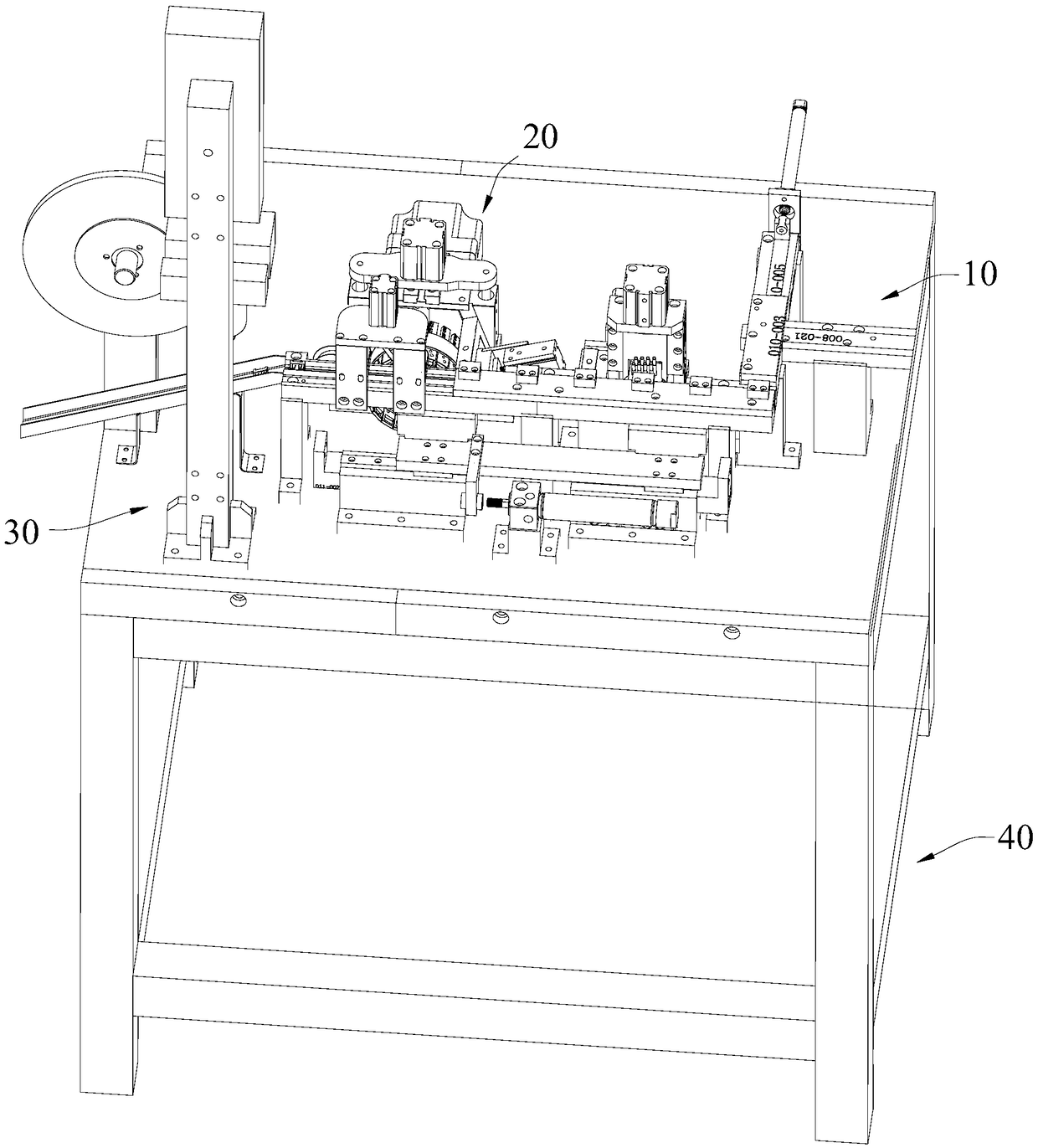

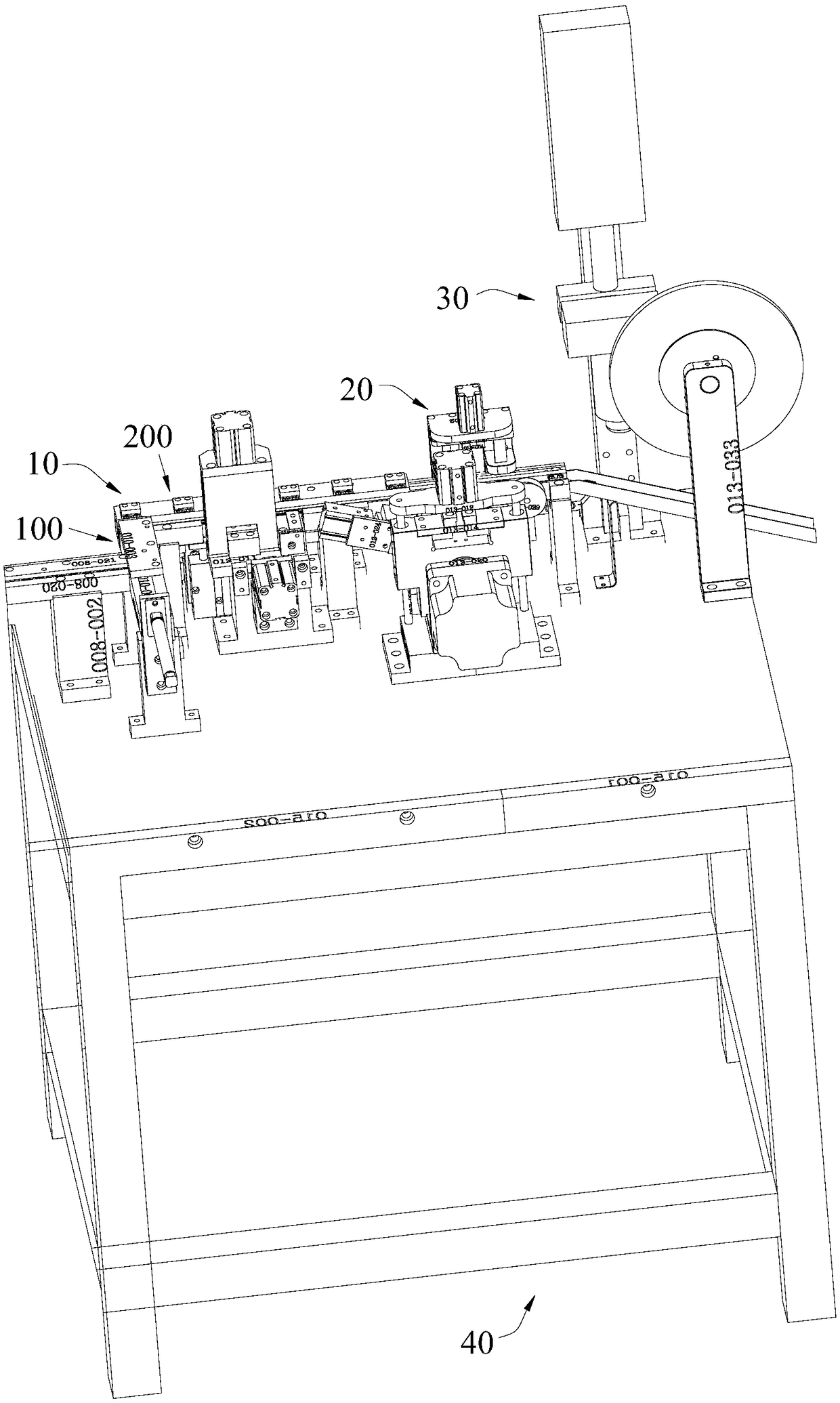

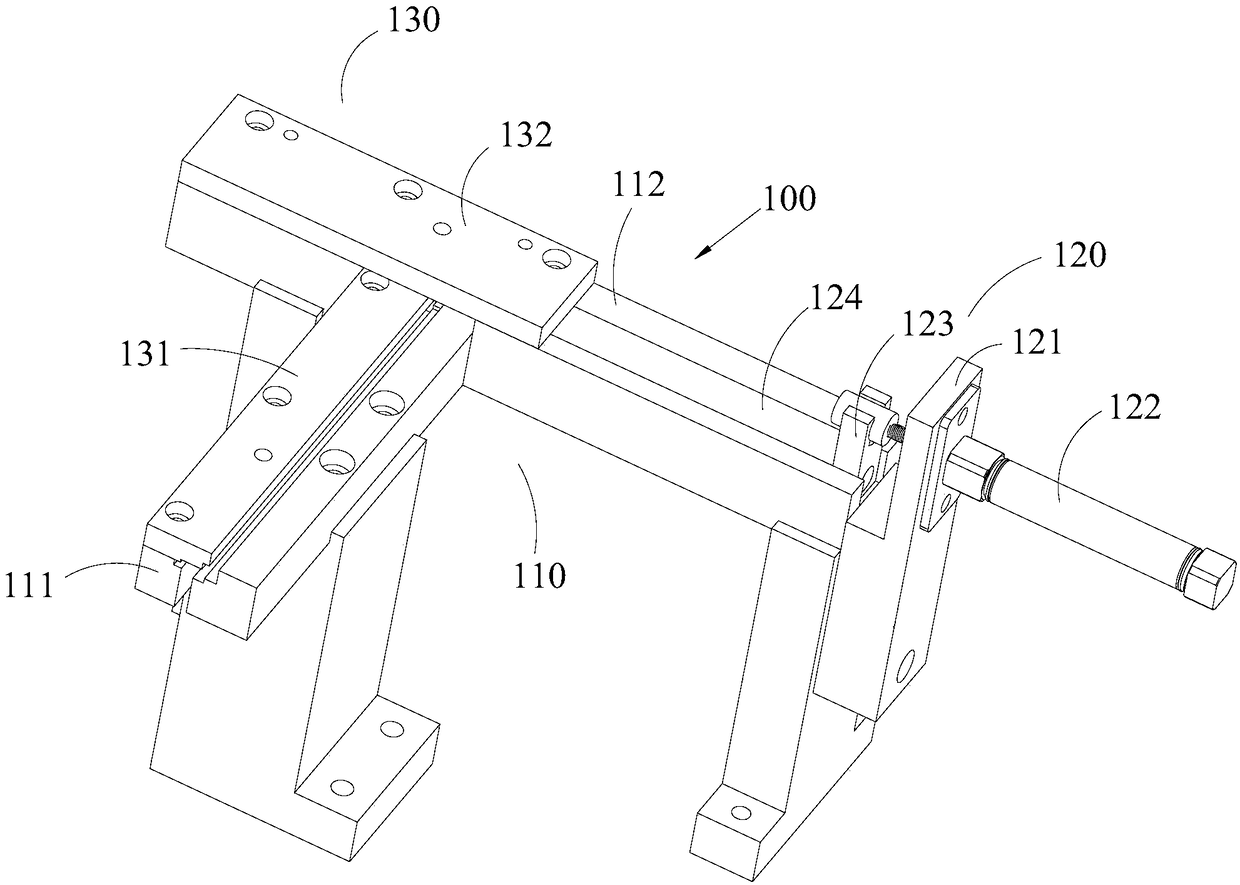

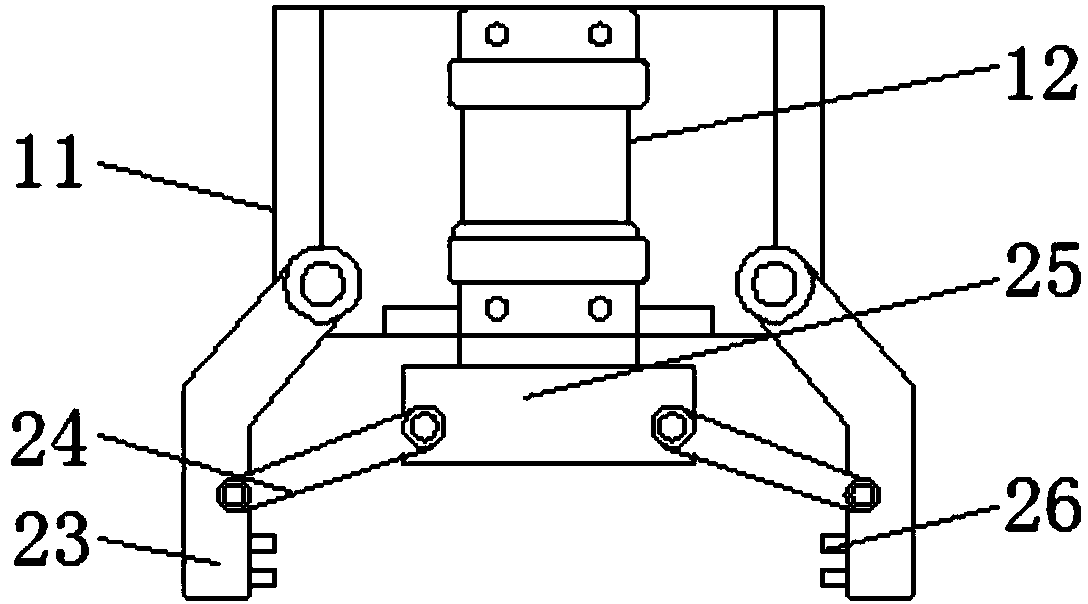

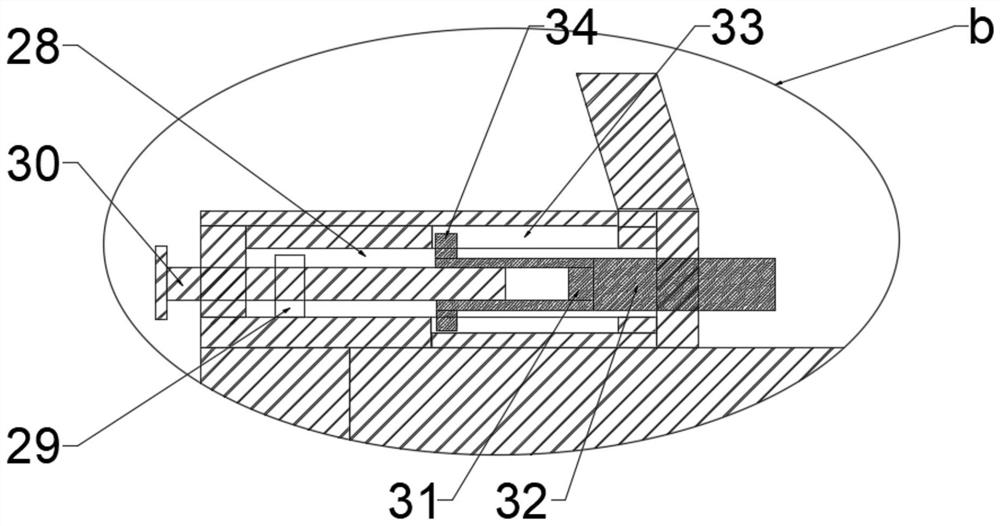

USB data line plug feeding mechanism and detection module

PendingCN109229684AImprove feeding efficiencySlow down the feeding speedConveyorsConveyor partsEngineeringUSB

The invention discloses a USB data line plug feeding mechanism and a USB data line plug feeding detection module. The USB data line plug feeding mechanism comprises a feeding supporting frame, a transverse feeding device and a longitudinal feeding device, wherein the transverse feeding device and the longitudinal feeding device are arranged on the feeding supporting frame respectively; the transverse feeding device comprises a feeding assembly and a pushing assembly; the feeding assembly comprises a first feeding plate and a second feeding plate; the first feeding plate is connected with the second feeding plate; the longitudinal feeding device comprises a first driving assembly, a second driving assembly and a conveying assembly; the first driving assembly is arranged on the feeding supporting frame. According to the USB data line plug feeding mechanism and the USB data line plug feeding detection module, through arrangement of the transverse feeding device and the longitudinal feeding device, 90-degree conveying can be achieved and the USB data line plug feeding efficiency is improved; in addition, in the existing feeding process, sequential feeding can be achieved, so that the USB data line plug feeding speed is reduced, and the USB data line plug producing efficiency is reduced.

Owner:HUIZHOU DEHONG TECH CO LTD

Energy-saving efficient plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

Fertilization mechanism for rotary cultivator

InactiveCN107836148AHas the effect of mixed fertilizerImprove uniformitySpadesPloughsAgricultural engineeringDrive motor

The invention discloses a fertilizing mechanism for a rotary tiller, which comprises a fertilizer bin, a fixing seat and a lower feeding bin, the fixing seat is fixedly installed with the rotary tiller, and the top of the inner chamber of the fertilizer bin is equipped with a detachable Stirrer, the bottom of the stirrer is provided with an upper filter screen and a lower filter screen in sequence, and a screw feeder is installed at the bottom of the lower filter screen, and the lower end of the screw feeder extends to the lower feeder, and the lower feeder A drive motor is installed inside, and a baffle is installed with bolts on the other side of the fertilizer bin, and a soil return device that can move up and down is connected to the lower end of the baffle. The device installs a detachable stirrer in the fertilizer bin, so that the fertilizer bin of the fertilization mechanism has the function of mixing fertilizers, and the screw feeder drives the stirred fertilizer to be fed in a spiral, so that the feeding speed is more stable; the soil returning device The falling fertilizer can be covered in time to prevent the fertilizer from becoming invalid under the sun exposure or being washed away by rainwater, reducing manpower and material resources.

Owner:湖南一田农业机械有限公司

Automatic packaging equipment

InactiveCN107902112AEvenly packedSlow down the feeding speedConveyorsSolid materialMotor shaftPulley

The invention discloses an automatic packaging equipment, which comprises a frame body, a mounting plate, a fixing plate, a support plate and a material distribution bin. The mounting plate is installed at the middle position above the frame body, and a first motor is installed at the lower end. , the inside of the installation plate is equipped with a roller, and the outside of the roller is installed with a conveyor belt, the output end of the first motor is installed with a rotating shaft, and the rotating shaft is connected to the roller through a pulley mechanism, and the fixed plate is installed close to Springs are evenly installed above and below one side of the plate, and fixed blocks are installed on the ends of the springs far away from the fixed plate, and rotating rollers are installed on the inner sides of the fixed blocks. The invention is equipped with a second motor, a rotating rod and a material distribution block. The second motor drives the material distribution block to rotate through the rotating rod, which can not only delay the speed of tea blanking, but also make the tea blanking more uniform, so that each tea leaves There is less variation in the quality of tea added to the box and more uniform packaging.

Owner:徐素香

Asphalt pavement paving material mixing device

ActiveCN111877091AEasy accessGood removal effectRoads maintainenceRoad surfaceMechanical engineering

The invention relates to the technical field of asphalt pavement laying, in particular to an asphalt pavement laying material mixing device. The device comprises a shell, a feeding mechanism, a collecting mechanism, a stirring mechanism, a first screening mechanism, a second screening mechanism and a shaking mechanism. Materials are prevented from sliding down and being blocked through the feedingmechanism, the materials are preliminarily screened and filtered through the first screening mechanism, fine gravel is removed, the screened gravel is further screened under the action of the secondscreening mechanism, resource waste is reduced, the first screening mechanism is prevented from being blocked under the action of the shaking mechanism, and the screening efficiency is improved. Through work of the second screening mechanism, fallen gravel particles fall in a classified mode and are collected and stored under the action of the collecting mechanism, subsequent use is facilitated, mixing, stirring and blending of materials are facilitated under the action of the stirring mechanism, and subsequent pavement laying is facilitated; meanwhile, the stirring mechanism is beneficial toproviding power for the first screening mechanism to rotate.

Owner:福建省华实建工集团有限公司 +1

Mine stone crushing and dust removing equipment

PendingCN113976220ASlow down the feeding speedIncrease the feeding speedSievingDispersed particle filtrationMining engineeringDust control

The invention discloses mine stone crushing and dust removing equipment which solves the problems that the feeding rate of ore is not easy to control and ore crushing is not facilitated in the existing mine stone crushing and dust removing equipment, and is technically characterized in that the mine stone crushing and dust removing equipment comprises a machine body, a feeding port is formed in the upper side of the machine body, and a groove is formed in the upper side of the machine body; a fixed plate is arranged in the groove, a threaded rod is slidably connected into the fixed plate, the end of the threaded rod is connected with a movable rod through threads, sliding blocks are connected to the two sides of the movable rod, a baffle is connected to the inner side of the movable rod, a first sliding groove is formed in the inner side of the groove, and the sliding blocks are slidably connected into the first sliding groove. The threaded rod is manually rotated, the threaded rod drives the sliding block to slide inwards in the first sliding groove through the movable rod, the movable rod drives the baffle to move inwards, and therefore the discharging speed of the feeding port can be reduced, the threaded rod is reversely rotated, the movable rod drives the baffle to move outwards, the discharging speed of the feeding port can be increased, and ore crushing is facilitated.

Owner:ZHUZHOU TIANQIAO SHUNCHEN COAL PREPARATION MACHINERY

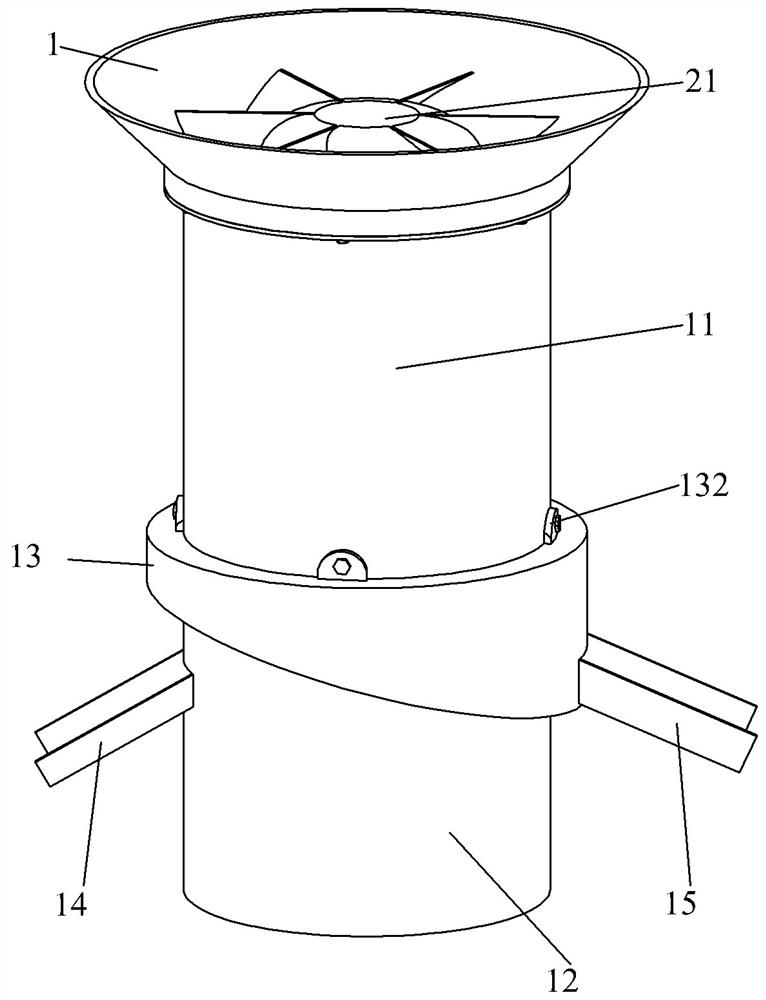

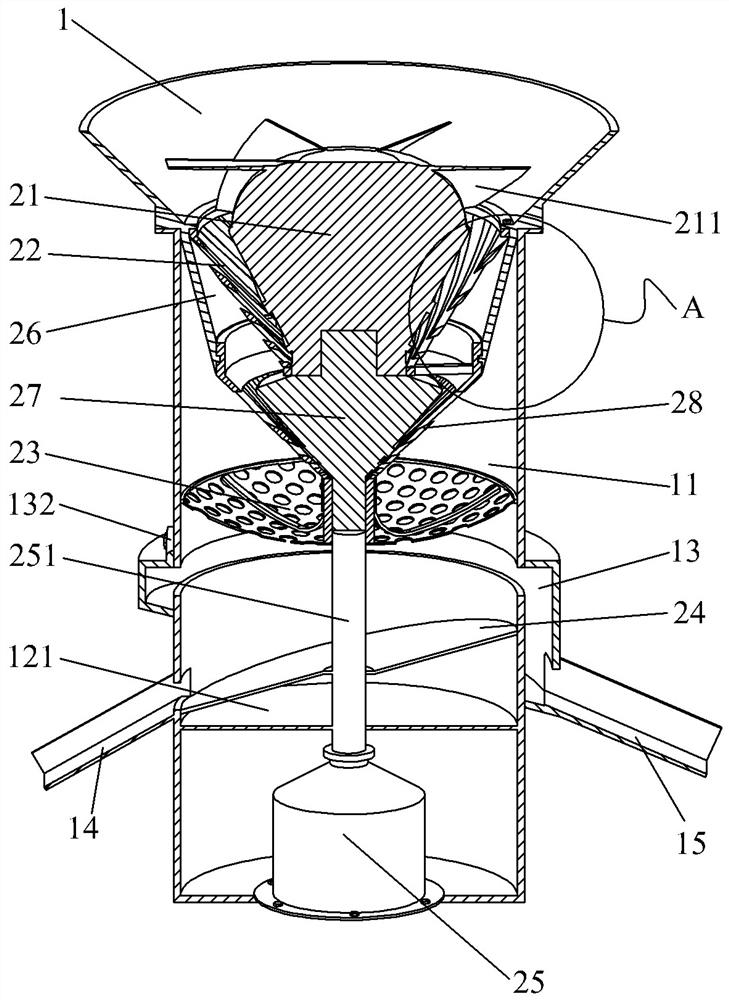

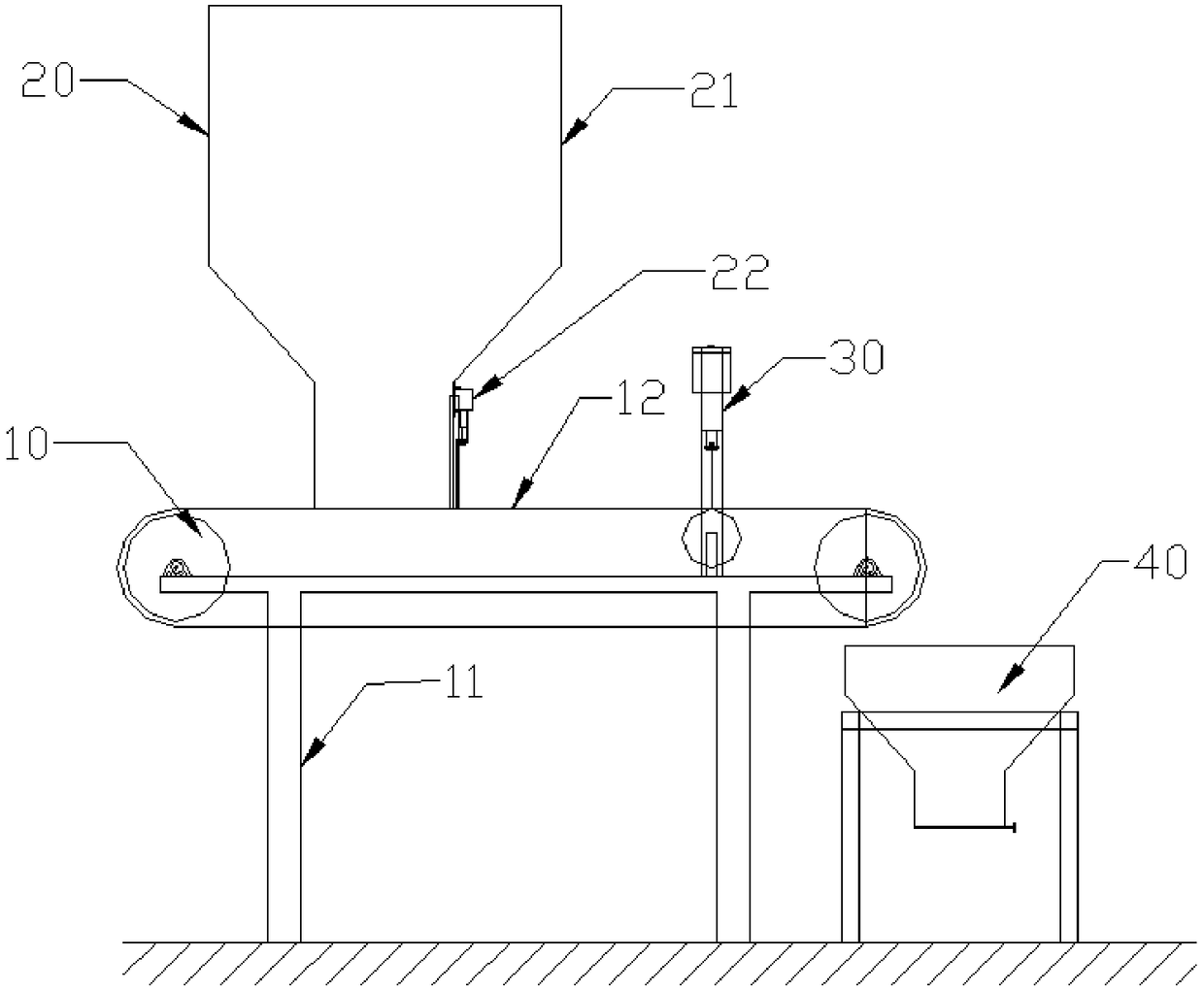

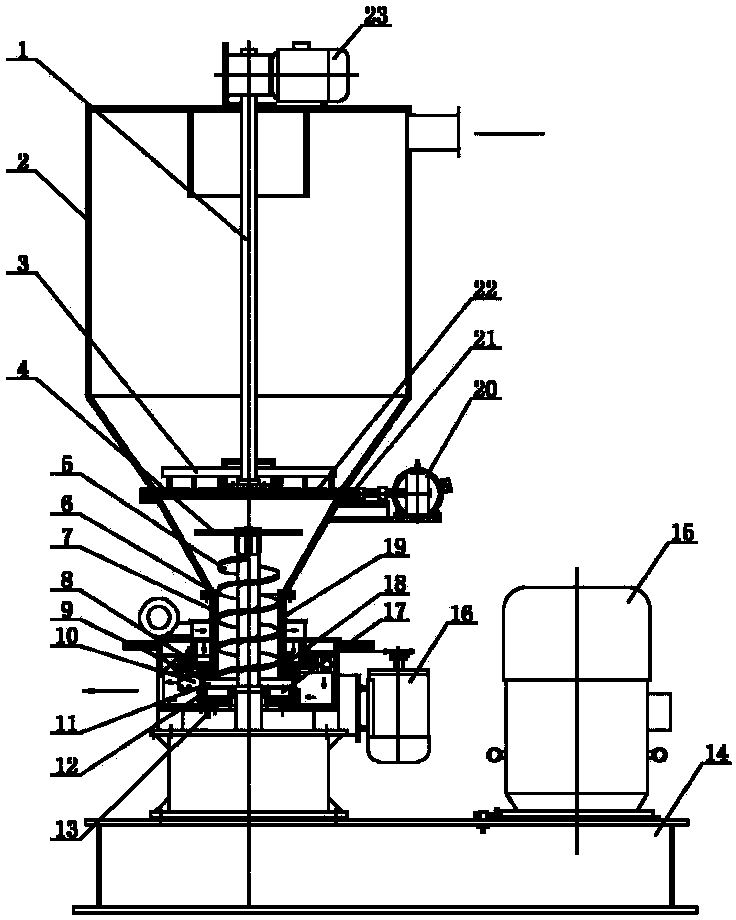

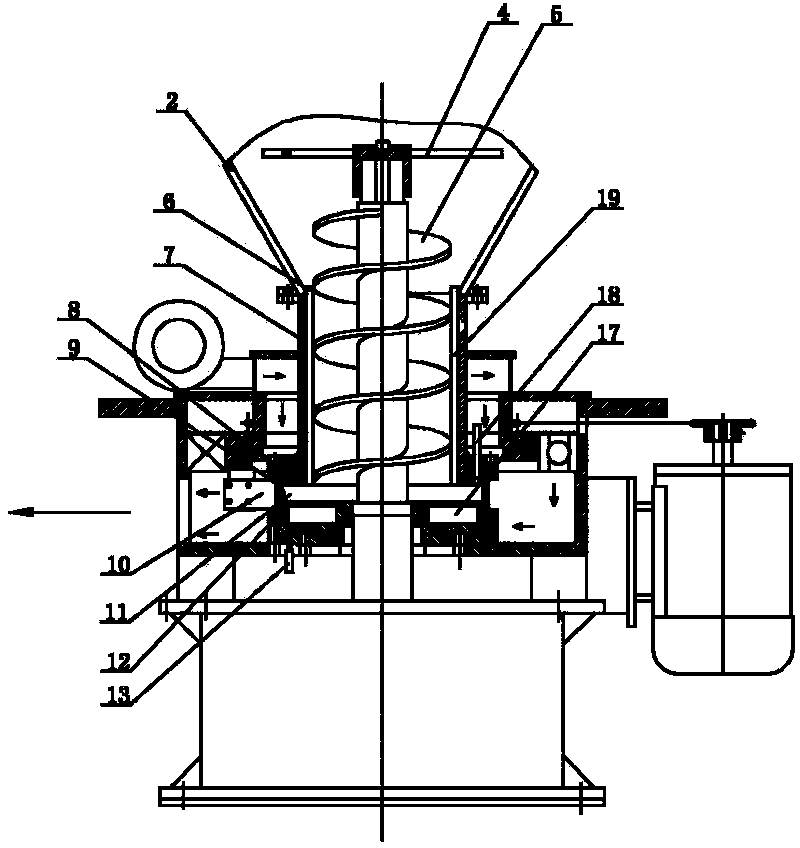

Drying agent feeding device capable of controlling feeding speed efficiently

ActiveCN107323741AReduce labor intensityFeeding speed controllableSievingScreeningAutomatic controlDesiccant

The invention relates to a drying agent feeding device capable of controlling the feeding speed efficiently. The drying agent feeding device comprises a rack, a screening feeding device, a vibration device and a compression rod device; and the rack is of a U-shaped structure, the upper end of the screening feeding device is connected with the compression rod device, the vibration device is located on the left side of the screening feeding device, the left end of the vibration device is mounted on the left side face of the rack, and the compression rod device is connected with the top of the rack. The drying agent feeding device can solve the problems that, at present, the working efficiency is low, the labor intensity is high, manual control over the feeding amount and the feeding speed of a drying agent are difficult in the manual feeding process of the drying agent, achieves the function that the drying agent feeding speed can be automatically controlled, and has the advantages of being high in working efficiency, low in labor intensity, capable of automatically controlling the feeding amount of the drying agent, controllable in feeding speed and the like.

Owner:南通北外滩建设工程有限公司

PC particle board raw material smashing processing device

The invention discloses a PC particle board raw material smashing processing device. The PC particle board raw material smashing processing device comprises a smashing assembly, a hopper pipeline, a stirring box body, a screening throttle assembly, and a partition stirring assembly. The screening throttle assembly and the partition stirring assembly are mounted on the stirring box body. The hopperpipeline is mounted at the top of the stirring box body. The hopper pipeline communicates with an inner cavity of the stirring box body. The smashing assembly is mounted at the top of the hopper pipeline. The partition stirring assembly comprises an unloading round plate, an unloading hole, stirring rods, a rotating shaft, and a servo motor b. The servo motor b is fixed to the middle of the bottom of the stirring box body by screws. According to the PC particle board raw material smashing processing device, the grinding effect is improved, materials are smashed, and therefore subsequent uniform material stirring is facilitated. Large impurities in the materials can be screened out. The feeding speed is reduced. The large amount of stirring materials is avoided. The materials can be partitioned and stirred, and therefore stirring is more uniform, and stirring efficiency is improved.

Owner:JIANGSU GUOWEIXING PLASTIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com