Patents

Literature

49 results about "Calcium sulphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium sulfide is a chemical compound. It is a slightly water-soluble powder that crystallizes into cubes similar to rock salt.

Remediation conditioner for chromium-contaminated soil and remediation method adopting remediation conditioner

ActiveCN105950165AImprove passivation repair effectSimple structureAgriculture tools and machinesContaminated soil reclamationBiological activationCow dung

The invention relates to a remediation conditioner for chromium-contaminated soil and a remediation method adopting the remediation conditioner. The remediation conditioner comprises raw materials in percentage by weight as follows: 5%-25% of ferrous sulfate, 5%-25% of calcium polysulphide, 5%-30% of humic acid resin, 1%-2% of cow dung and 1%-25% of fungus residues, wherein the humic acid resin is prepared from sulfonated sodium humate, phenol-formaldehyde resin and calcium acetate through activation after crosslinking and curing. The remediation conditioner adopts a simple formula, is mainly used for remediating soil by removing chromium, has high chromium VI removal rate, can increase content of residual-form chromium, can improve the soil quality and improves the sustainable utilization capacity of the soil.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Method for removing iron and silicon impurities during regeneration of aluminum scraps

ActiveCN103740947AWon't affect yieldIron and silicon impurity elements are reducedProcess efficiency improvementManganeseBorax

The invention relates to a method for removing iron and silicon impurities during the regeneration of aluminum scraps, belonging to the field of impurity removal during the regeneration and recovery of non-ferrous metals. The method comprises the steps of putting 20-30% of borax, 20-30% of manganese chloride, 10-20% of calcium chloride, 10-20% of calcium oxide, 5-10% of magnesium carbonate, 5-10% of sulfur and 10-20% of filler into a stirring vessel, and mixing, so as to obtain iron removing flux; putting 30-50% of calcium sulfide, 20-40% of activated carbon, 5-10% of sulfur, 10-20% of calcium oxide and 10-20% of filler into a stirring vessel, and mixing, so as to obtain silicon removing flux; melting the aluminum scraps in a melting furnace, adding the iron removing flux into aluminum scrap molten liquid, stirring the aluminum scrap molten liquid, adding the silicon removing flux, stirring, and then, standing, so as to obtain aluminum scrap molten liquid; carrying out gas-blowing refining on the aluminum scrap molten liquid, and standing, thereby obtaining aluminum scrap melt in which iron and silicon impurity elements are removed. The method has the advantages that the yield of aluminum can not be affected, and the content of the iron and silicon impurity elements is lowered remarkably; the environment is not destroyed; the steps are simple.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

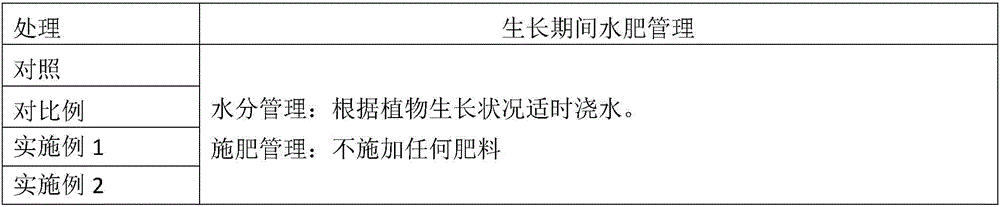

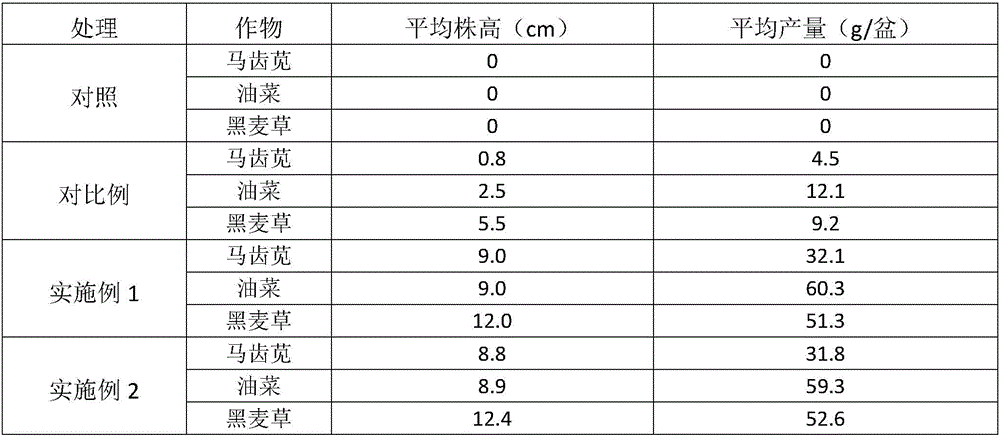

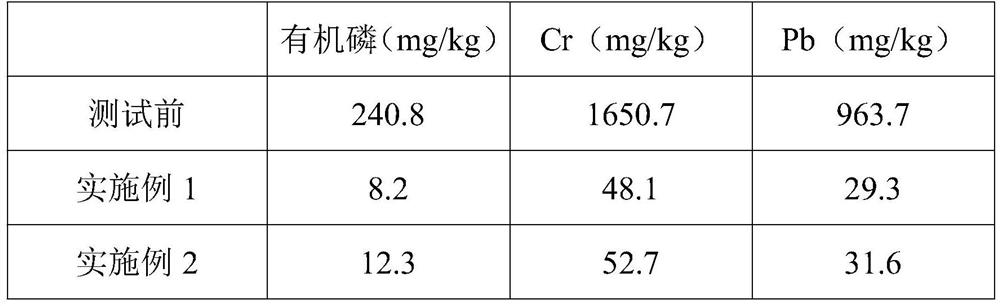

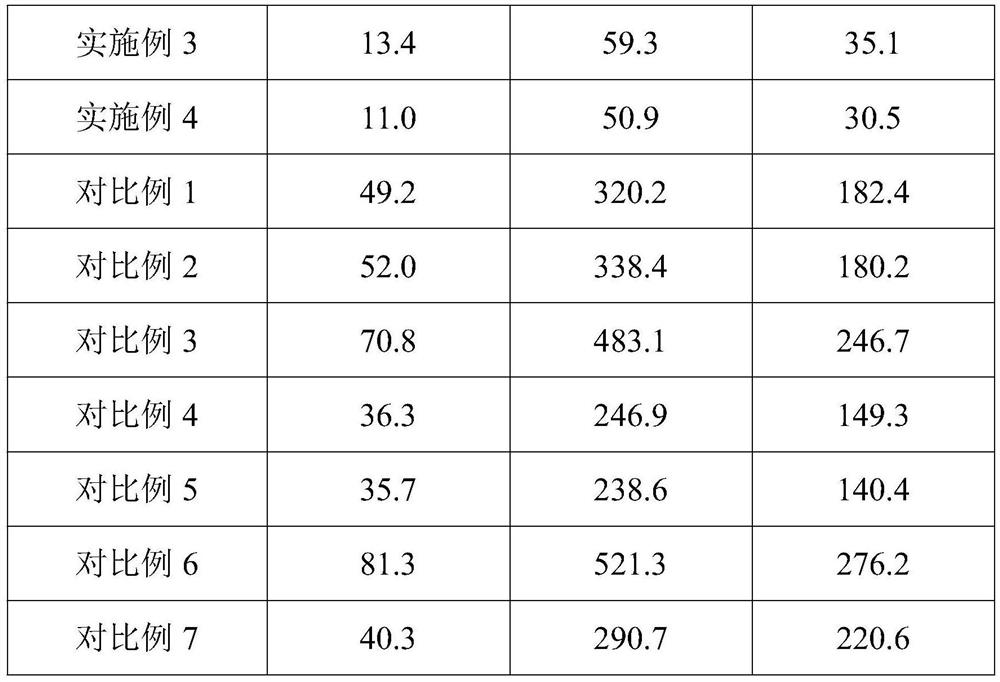

Soil remediation fertilizer and preparation method thereof

PendingCN112919971AEfficient repairCalcareous fertilisersAlkali orthophosphate fertiliserCellulosePhosphogypsum

The invention discloses a soil remediation fertilizer and a preparation method thereof. The soil remediation fertilizer is prepared from the following raw materials in parts by weight: 25-32 parts of modified phosphogypsum, 18-25 parts of urea, 12-18 parts of modified porous ceramsite, 6-11 parts of diatomite, 4-8 parts of plant ash, 3-7 parts of ammonium dihydrogen phosphate, 3-5 parts of fly ash, 2.5-3.5 parts of titanium dioxide, 1.8-3 parts of calcium polysulfide, 1-2 parts of ammonium chloride, 1-1.5 parts of chitosan, 0.2-0.6 part of sodium carboxymethyl cellulose and 0.1-0.5 part of fulvic acid. The soil remediation fertilizer disclosed by the invention can be used for effectively remediating farmlands polluted by organic phosphorus and heavy metals while giving nutrients to the farmlands; by adding the modified ardealite and the modified porous ceramsite, the remediation on farmland polluted by organic phosphorus and heavy metals is remarkably improved, the modified ardealite is acidic, the modified porous ceramsite is alkaline, and the modified ardealite and the modified porous ceramsite have a remarkable synergistic interaction effect.

Owner:GUANGXI UNIV

Method for extracting sodium carbonate and sodium thiocyanate from sodium alkali desulfurization liquid waste by using causticization-acidification method

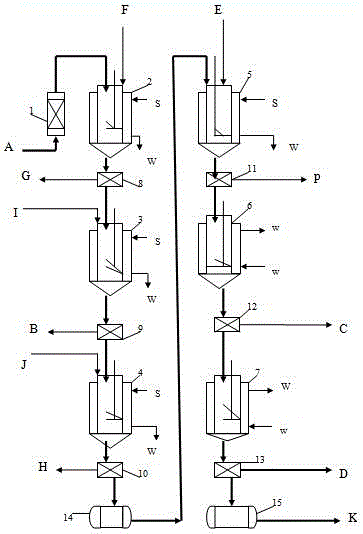

InactiveCN103601219AShort process routeLow operating costThiocyanic acidMultistage water/sewage treatmentSodium thiocyanateDecomposition

The inventi on discloses a method for extracting sodium carbonate and sodium thiocyanate from sodium alkali desulfurization liquid waste by using a causticization-acidification method and belongs to the technical field of desulfurization liquid waste treatment. The method comprises the following processes: pertreating liquid waste for removing impurities, heating for decomposing and discoloring, and carrying out oxidizing causticization-separation, acidification-separation, evaporation and concentration, and cooling crystallization-separation. The method is used for treating the desulfurization liquid waste generated in a production process of removing hydrogen sulfide and hydrogen cyanide out of coal gas or other gases by using a sodium alkali method. According to the method provided by the invention, sodium thiosulfate, sodium polysulfide and sodium sulfate in the sodium alkali desulfurization liquid waste can be converted into calcium sulfite, calcium sulphide and calcium sulfate precipitations at normal temperature through heating decomposition, oxidization and causticization; meanwhile, high-purity sodium carbonate and sodium thiocyanate are extracted, the sodium alkali is recovered to return a gas desulfurization system cycle, and the alkali consumption of the desulfurization operation is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

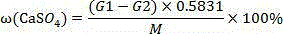

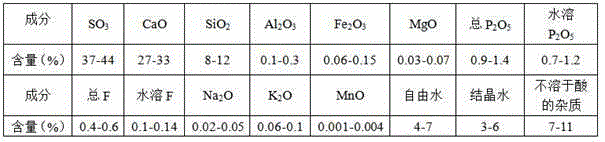

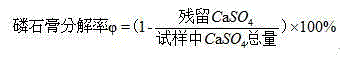

Method for preparing calcium sulphide by decomposing phosphogypsum through hydrogen sulfide tail gas

InactiveCN105129742AReduce processingImprove reducibilityMagnesium/calcium/strontium/barium sulfides/polysulfidesReductive decompositionThiourea

The invention discloses a method for preparing calcium sulphide by decomposing phosphogypsum through hydrogen sulfide tail gas, and belongs to the field of phosphogypsum resource utilization. The phosphogypsum is dried and ground so that the phosphogypsum can be reduced and decomposed under Co and H2S tail gas to prepare CaS, decomposing temperature is 700-950 DEG C, the decomposing rate of the phosphogypsum is larger than and equal to 95%, and the productivity of calcium sulfide can reach over 85%. The production process is simple and easy to implement, the raw material is a large amount of the solid waste phosphogypsum, the prepared calcium sulfide can be used for preparing thiourea, sodium sulfide, sulphur, sulfuric acid and other chemical products and can also be used in the industries such as environmental protection and heavy metal treatment, and a new concept is provided for comprehensive utilization of the phosphogypsum.

Owner:KUNMING UNIV OF SCI & TECH

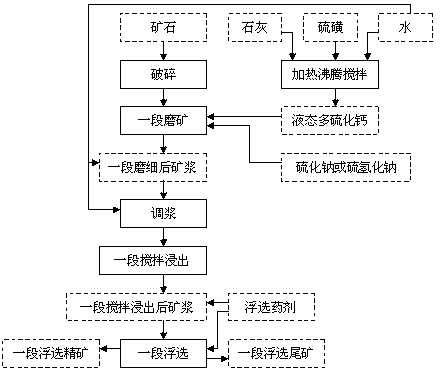

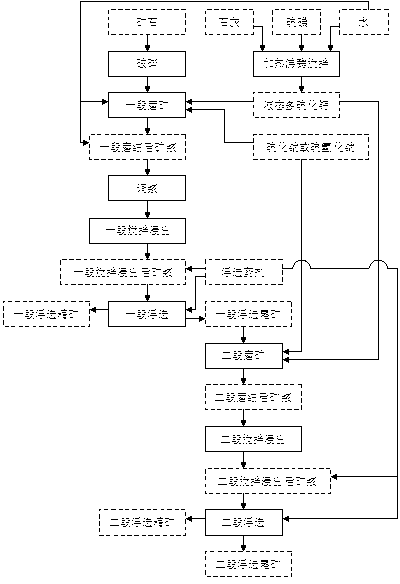

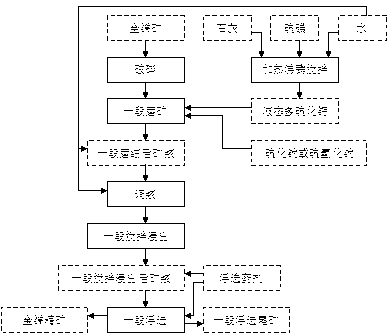

Method and technology for improving flotation effect by using polysulfide ion mixture

InactiveCN103252288AImprove vulcanization efficiencyImprove bindingFlotationWet separationAmmonium sulphideCalcium sulphide

A method for improving the flotation effect by using a polysulfide ion mixture is characterized in that the polysulfide ion mixture is used as the vulcanizing agent to modify the surfaces of target ores and the surfaces of target minerals exposed on the surfaces of the ores and further to improve the hydrophobicity of the surfaces of the target ores and / or the surfaces of the target minerals. The polysulfide ion body of the polysulfide ion mixture is the pentabasic polysulfide ion S52- and the quaternary polysulfide ion S42-, wherein the carrier of the pentabasic polysulfide ion S52- and the quaternary polysulfide ion S42- comprises at least one or any combination of more than one of calcium polysulfide, sodium polysulfide, ammonium polysulfide, sodium sulfide, sodium hydrosulfide and ammonium sulfide. The target ores are oxidized metal ores and oxysalt metal ores in a raw resource form and in a renewable resource form. The target minerals are all oxidized metal ore minerals and oxysalt metal ore minerals except for alkali metal and alkaline-earth metal.

Owner:XINGMIN TECH ZHUZHOU

Anti-nodulation high-sulfur non-quenched and tempered steel smelting technology

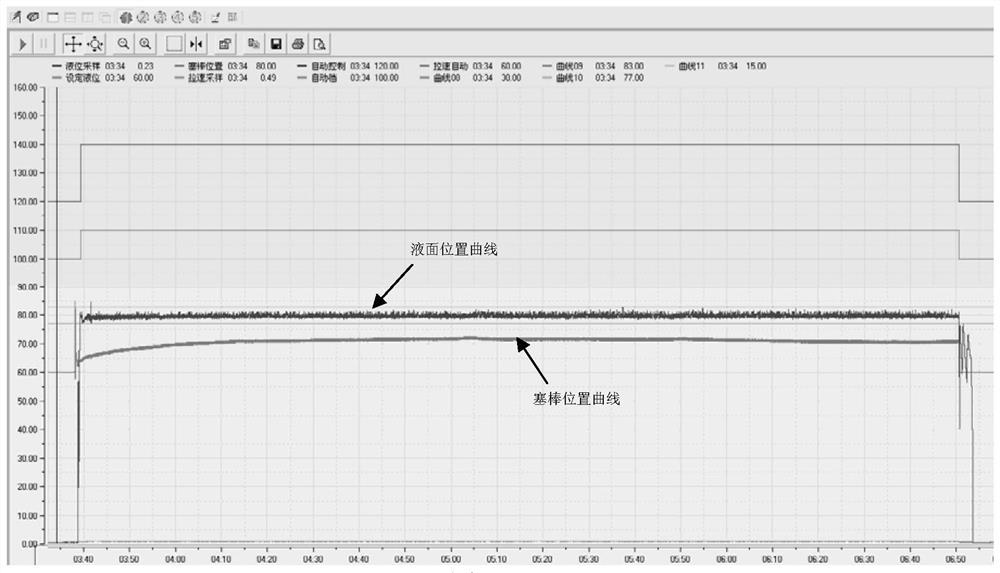

ActiveCN111663072AImprove adsorption capacityImprove liquidityProcess efficiency improvementElectric furnaceCalcium sulphideSmelting process

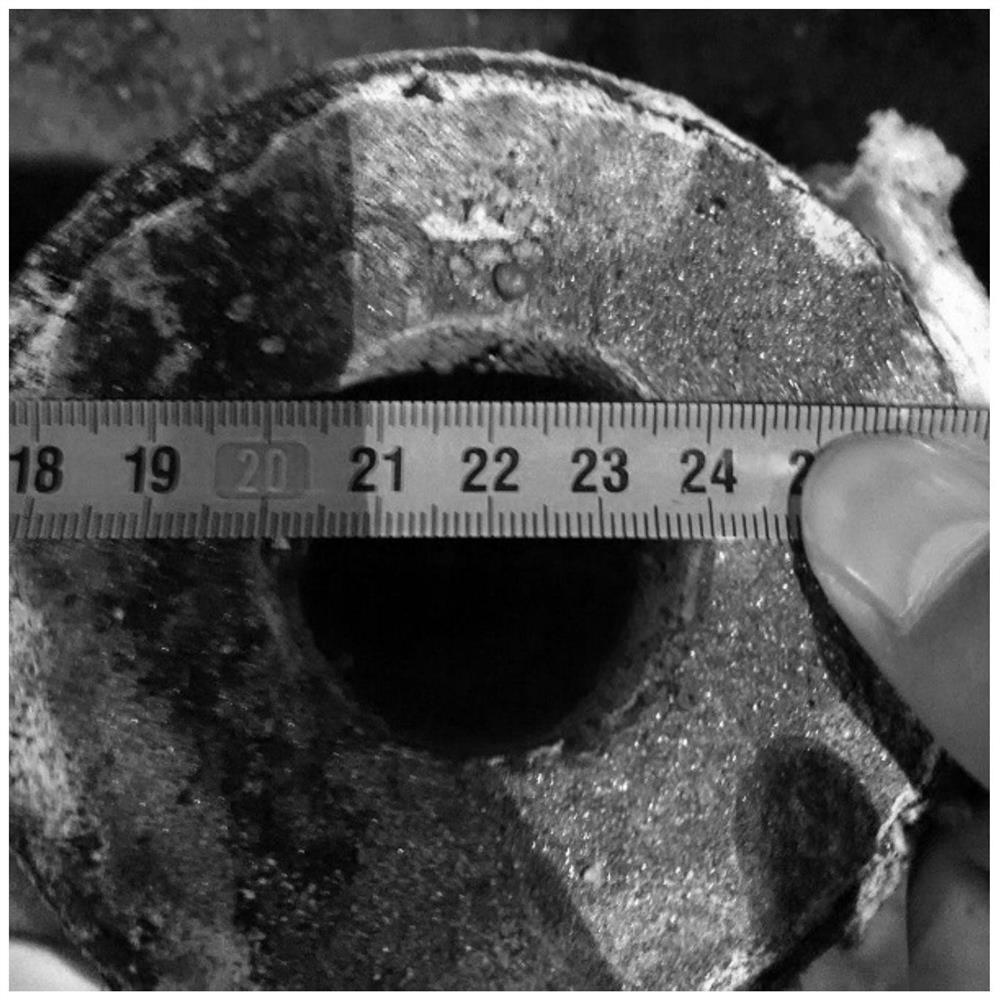

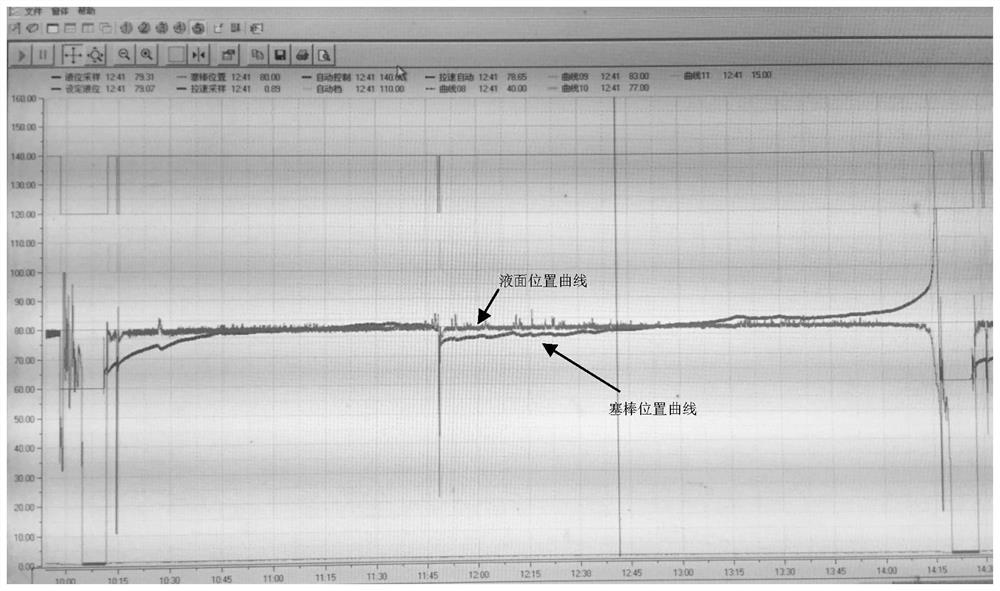

The invention belongs to the technical field of non-quenched and tempered steel smelting, particularly relates to an anti-nodulation high-sulfur non-quenched and tempered steel smelting technology, and aims to solve the problem that during the smelting process of specific steel composition, inclusion in steel finally wraps calcium sulfide in the form of high-melting-point magnesium aluminate spinel type inclusion to form composite inclusion. Control over refining slag in the key operating process is clear-cut, for example, during refining, the furnace clinker binary alkalinity (CaO / SiO2) 2.5-3.5 is controlled to improve the adsorption performance of the furnace clinker to the inclusions; through controlling the ternary alkalinity, the furnace clinker liquidity is improved, and the nodulation key factor can be ensured to be controlled during the continuous casting process through mutual collaboration. According to the anti-nodulation high-sulfur non-quenched and tempered steel smeltingtechnology, the wire feeding sequence and the time requirement after VD vacuum treatment are defined, conversion of oxide inclusion to low-melting-point inclusion is effectively controlled, at the same time, generation of plenty of high-melting-point sulfide inclusion is prevented, and finally, during the continuous casting process of molten steel, the pouring curve is steady, and the liquid surface does not fluctuate.

Owner:ZENITH STEEL GROUP CORP +1

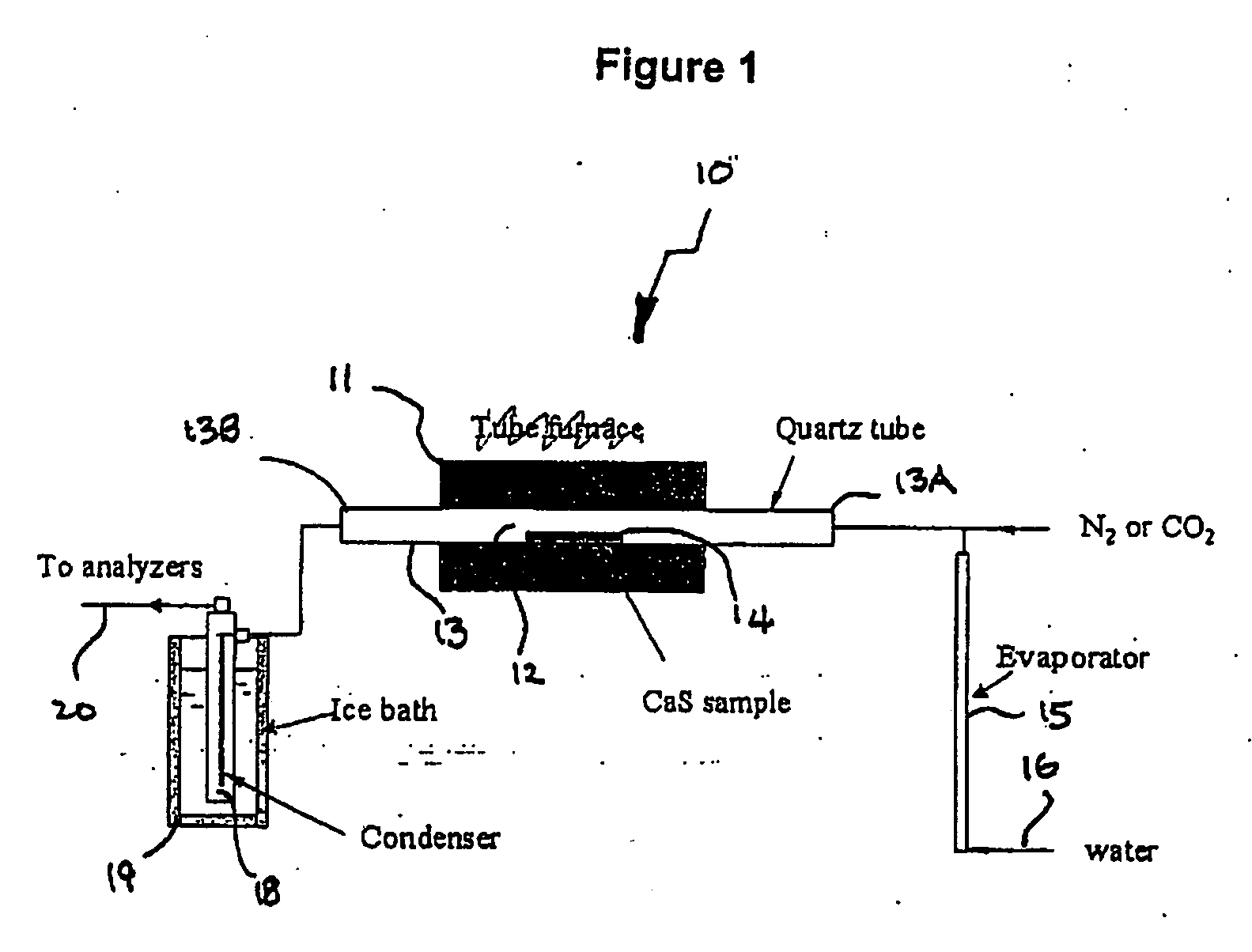

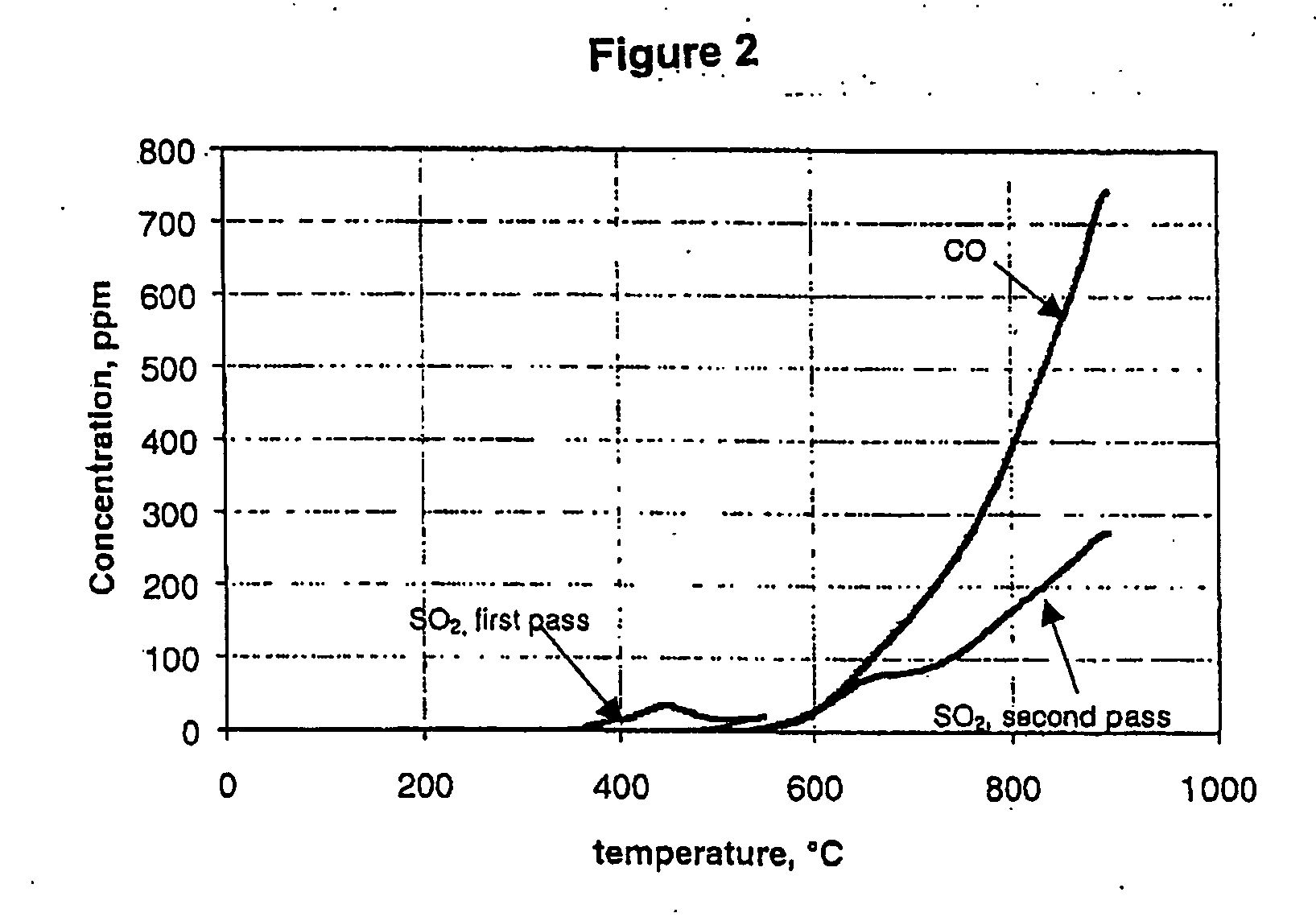

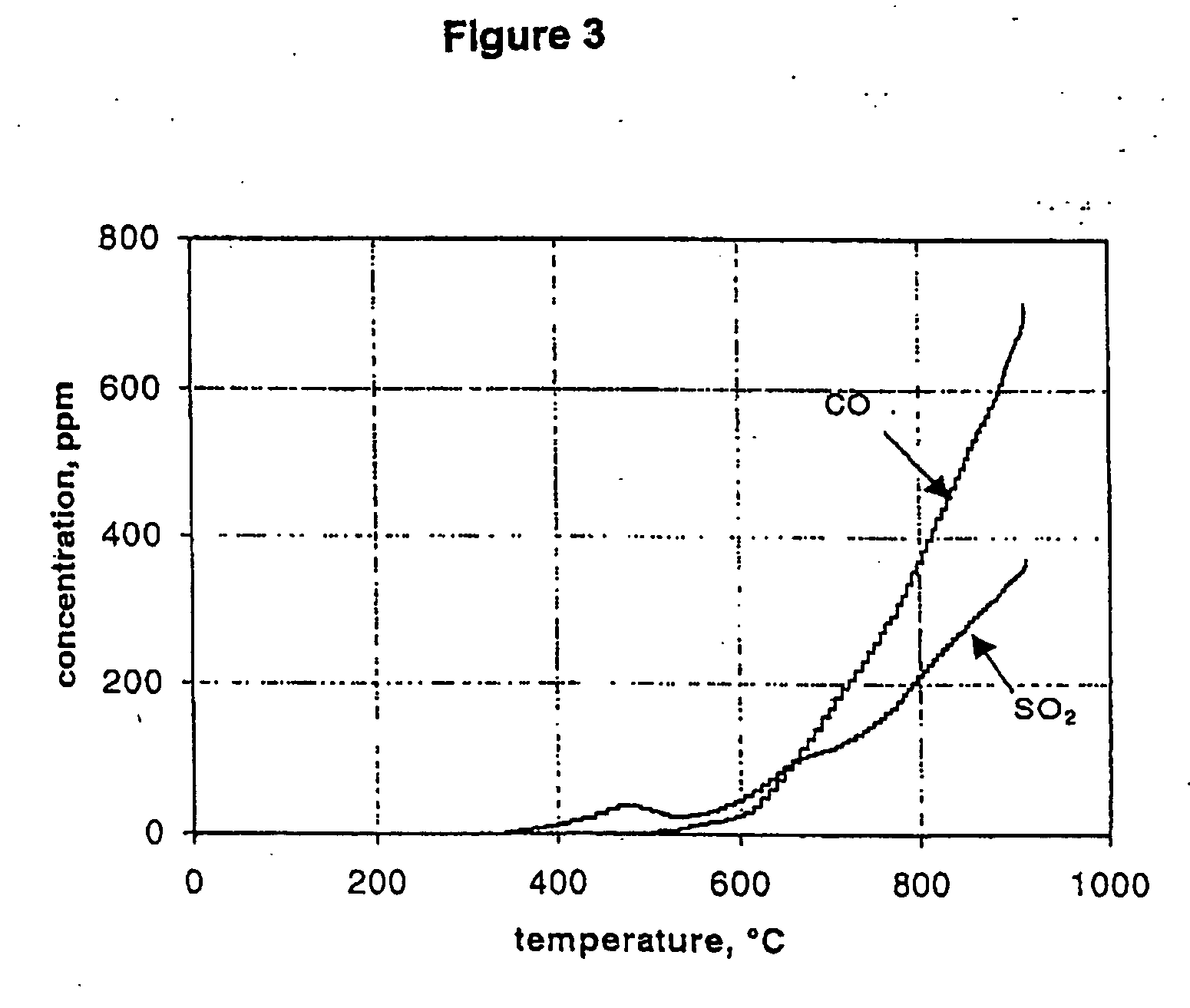

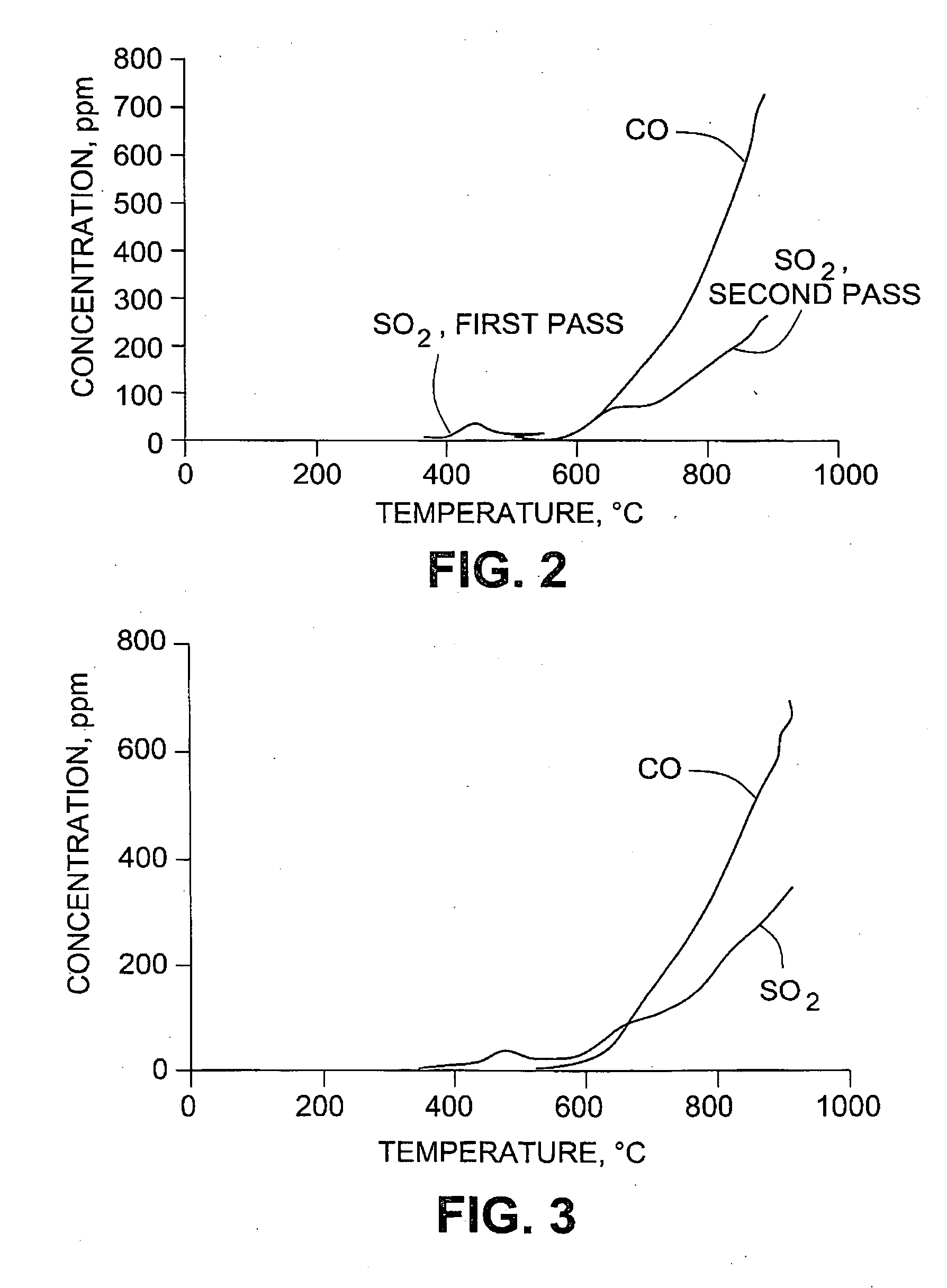

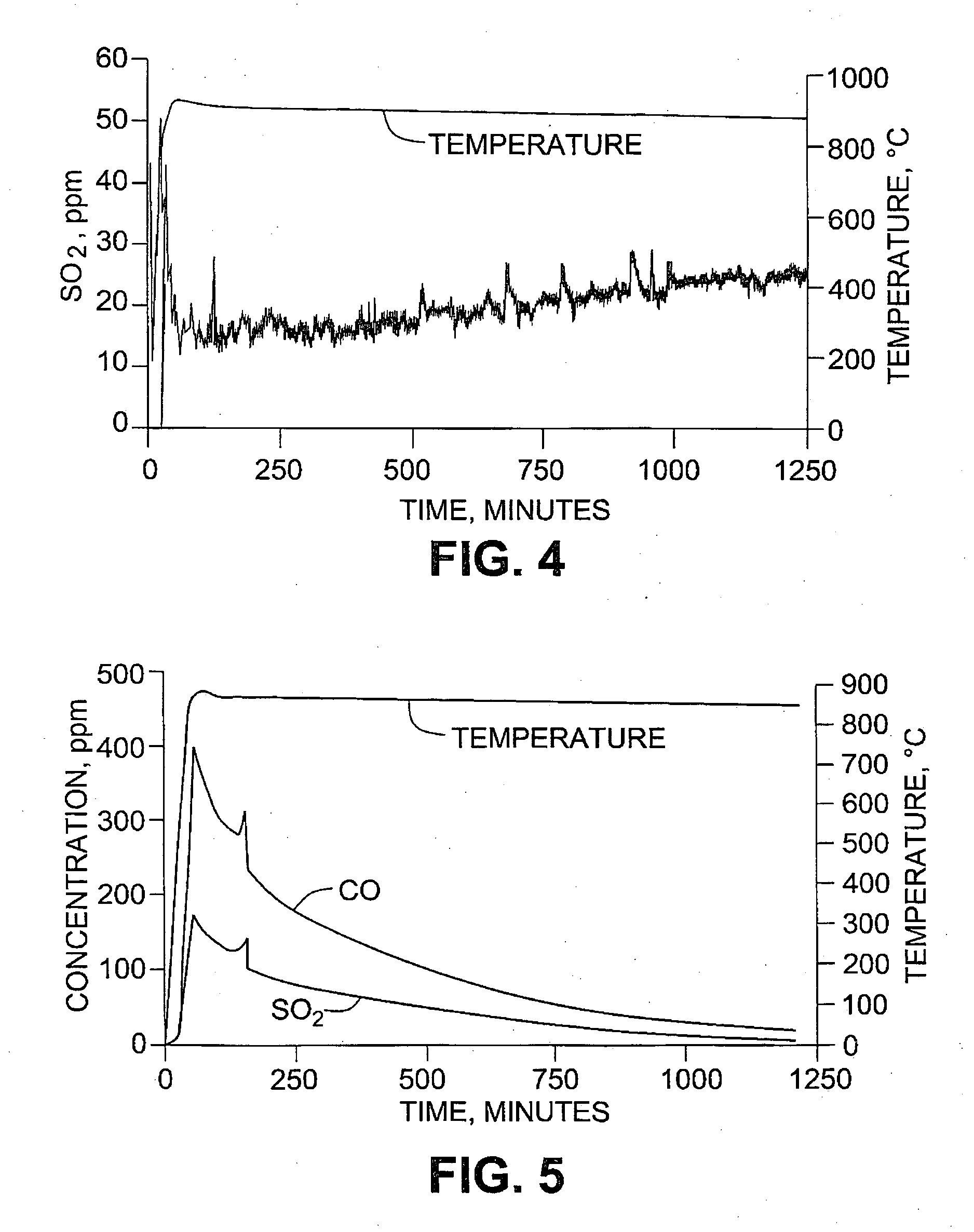

Regeneration of calcium oxide or calcium carbonate from waste calcium sulphide

InactiveUS20070031311A1Dispersed particle separationSulfur compoundsCalcium sulphideAlternative process

An alternative process whereby the calcium sulphide formed in an IGCC system from calcium oxide and / or calcium carbonate can be safely and more or less quantitatively converted by reaction with carbon dioxide to calcium carbonate and / or calcium oxide together with sulphur dioxide The calcium oxide and / or calcium carbonate can be reused in the IGCC system, and the sulphur dioxide can be converted to a useful product, such as sulphuric acid. One result of this process is that since the furnace ashes do not contain a significant level of calcium sulphide, they can be safely disposed of in a land fill site.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Repairing agent for repairing hexavalent chromium contaminated soil and method for repairing hexavalent chromium contaminated soil by using repairing agent

ActiveCN111718718AImprove practicalityAvoid multiple fixesContaminated soil reclamationOrganic fertilisersCalcium sulphideSoil science

The invention provides a repairing agent for repairing hexavalent chromium contaminated soil and a method for repairing hexavalent chromium contaminated soil by using the repairing agent. The repairing agent can reduce hexavalent chromium and prevent trivalent chromium from being converted into hexavalent chromium. The repairing agent for repairing hexavalent chromium contaminated soil comprises the following components in percentage by weight: 20-35% of a calcium polysulfide solution with the concentration of 29%; 10-20% of a curing agent; 50-655 of water; the method for repairing hexavalentchromium contaminated soil comprises the following steps: S1, preparing a repairing agent, specifically, stirring and mixing a calcium polysulfide solution with the concentration of 29%, a smashed curing agent and water to be uniform according to the proportion, and obtaining the repairing agent and putting into a medicine storage device for use; S2, preparing materials, namely digging to-be-repaired soil from the contaminated land for later use; S3, performing primary repairing treatment, specifically, using a soil remediation machine for conducting rolling crushing and drug application on to-be-repaired soil in the repairing process; and S4, performing repairing post-treatment is conducted, specifically, using soil remediation machine for stirring the primarily repaired soil in the repairing process.

Owner:福建省环境保护设计院有限公司

Method for purifying byproducts of soda ash and sodium sulphide by utilizing methane

InactiveCN102311824AHigh purityImprove qualityGaseous fuelsAlkali metal sulfides/polysulfidesDistillationWaste material

The invention provides a method for purifying byproducts of soda ash and sodium sulphide by utilizing methane. The method comprises the following steps of: introducing methane into sodium hydroxide solution at a flow rate of 200-240m<3> / h, controlling reaction pressure to be 1.2-1.8MPa, reacting to generate calcium carbonate and calcium sulphide, filtering to obtain sodium carbonate and sodium sulphide filtrates, and carrying out reduced-pressure distillation to obtain the soda ash and sodium sulphide products. The method provided by the invention is simple to operate and is convenient to popularize and apply, and carbon dioxide and hydrogen sulphide impurities which are contained in methane are effectively absorbed, thus purity and quality of methane are improved; and meanwhile, waste materials are changed into things of value, sodium carbonate and sodium sulphide products with higher economic benefit are obtained, and potential economic value of methane is effectively developed.

Owner:王嘉兴

Method for removing iron and silicon impurities during regeneration of aluminum scraps

ActiveCN103740947BWon't affect yieldIron and silicon impurity elements are reducedProcess efficiency improvementManganeseBorax

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Cored wire core compound and its manufacture method

InactiveCN101060022ALow vapor pressureIncrease profitConductive materialCable/conductor manufactureYarnAluminate

The related core compound of core-spun yarn comprises calcium powder, calloy powder and calcium aluminate, wherein the preparation method including: mixing the lime powder and aluminum particle, and vacuum refining. The elemental calcium and calcium-aluminum alloy have high melting point and density fit to reduce the vapor pressure and decrease the molten steel splash. Specially, the calcium aluminate exists in molten steel as molten state, and has less density than the molten steel to adsorb the impurity for cleaning the molten steel.

Owner:马长慧

Method for decomposing gypsum through synergistic fluidization

InactiveCN105858620ASpeed up decompositionImprove decomposition efficiencySulfur compoundsEnergy inputPrillDecomposition

The invention relates to the technical field of gypsum decomposition and provides a method for decomposing gypsum through synergistic fluidization. The method comprises the steps of 1, uniformly mixing gypsum granulated raw materials with fluidizing agent particles, adding the gypsum granulated raw materials and the fluidizing agent particles into a bed body, and raising the temperature of the bed body to the set temperature; 2, introducing a gas mixture of a gas phase reducing agent and fluidization gas through a gas inlet pipe; 3, under the action of wind power of the gas mixture, making mixed particles of gypsum and a fluidizing agent enter and suspend in an isolator, and making the gas phase reducing agent be in contact with and react with the gypsum particles, so that calcium oxide particles, calcium sulphide particles and sulfur dioxide gas are obtained; 4, carrying the calcium oxide particles, the calcium sulphide particles and a small amount of gypsum particles obtained after the reaction out of the bed body with gas, while making the fluidizing agent and gypsum particles which are not involved into the reaction fall back to the bottom of the bed body through a gap between the isolator and the side wall of the bed body for reutilization; 5, introducing inert gas through a secondary air inlet structure. By means of the method, the space-time yield of sulfur dioxide is high, decomposition efficiency is high, and production cost is low.

Owner:SICHUAN UNIV

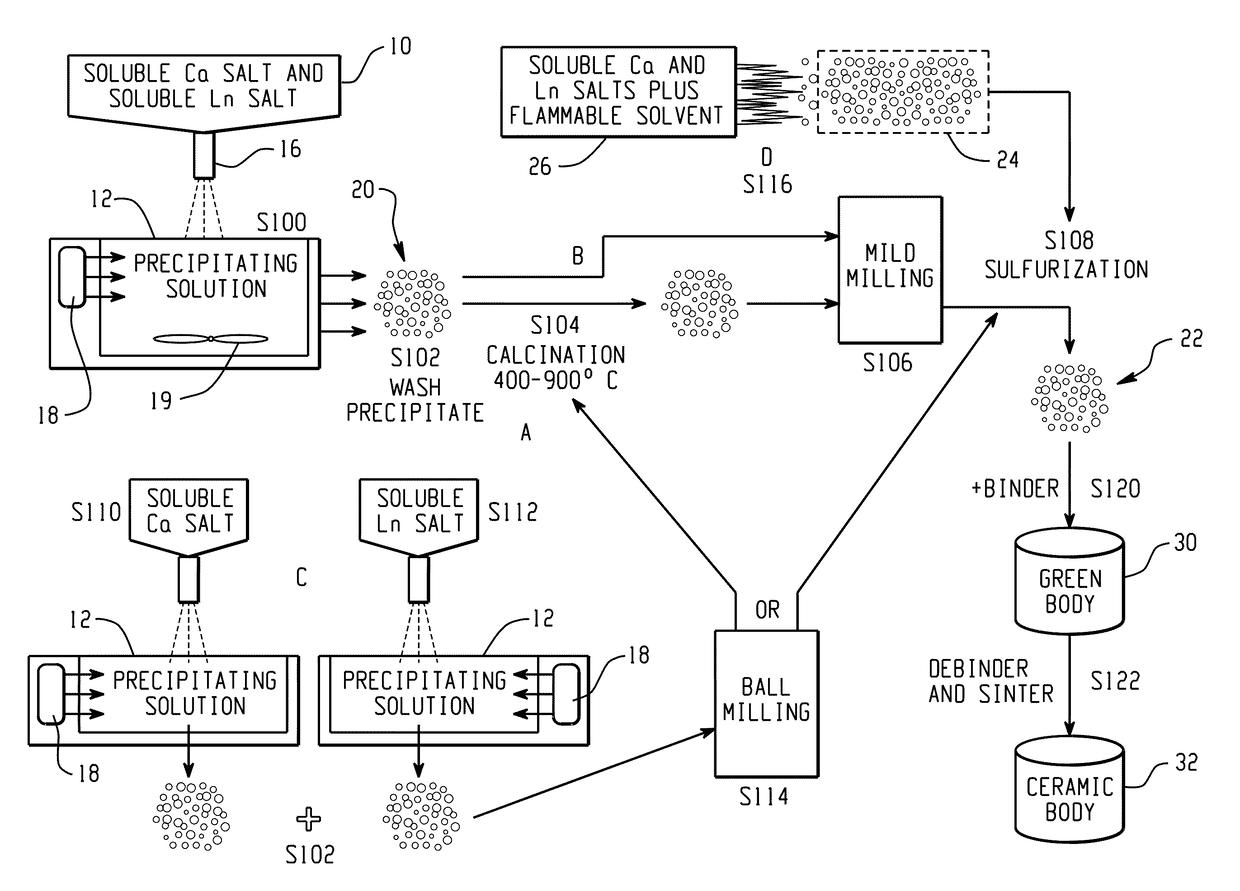

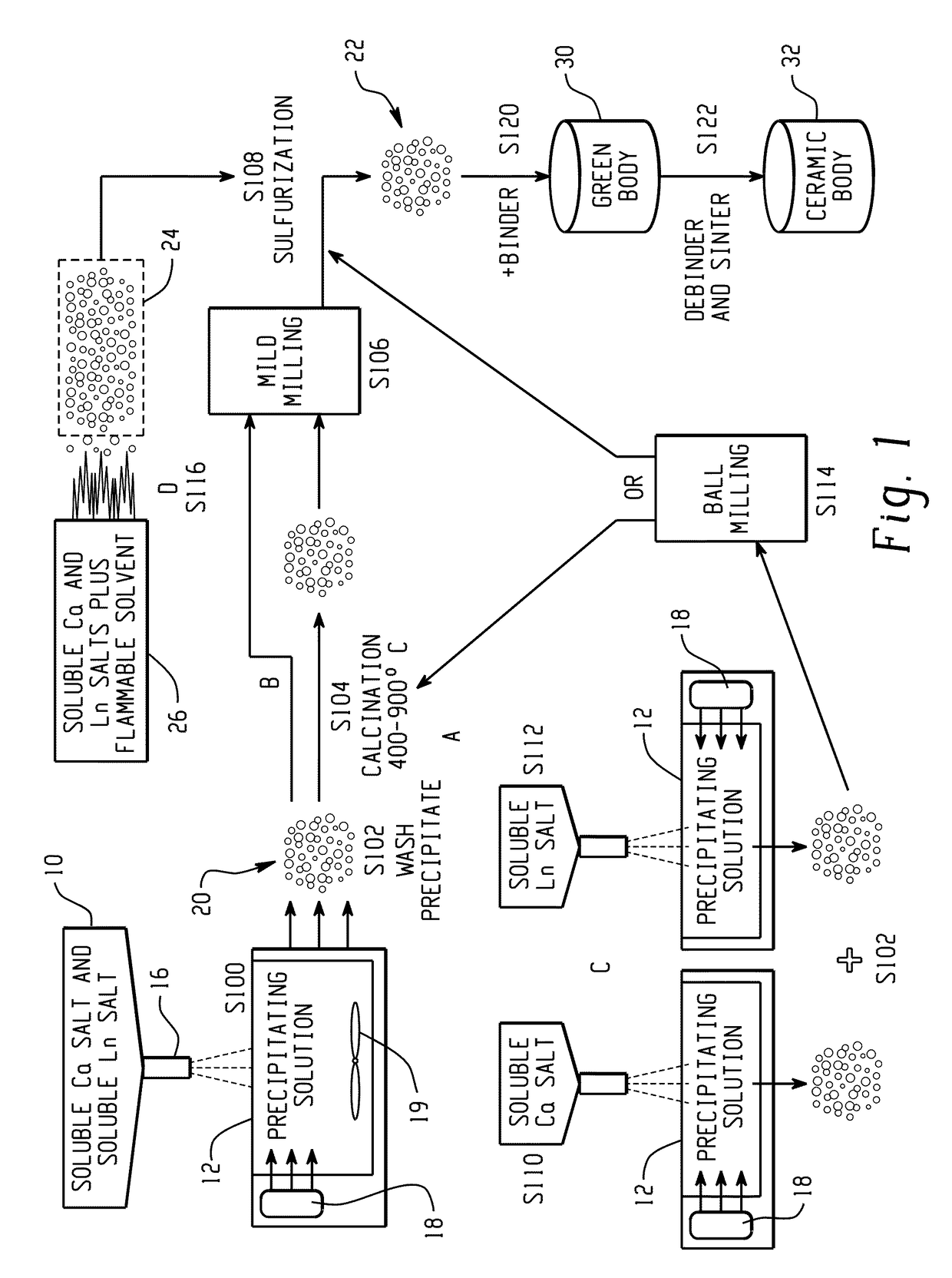

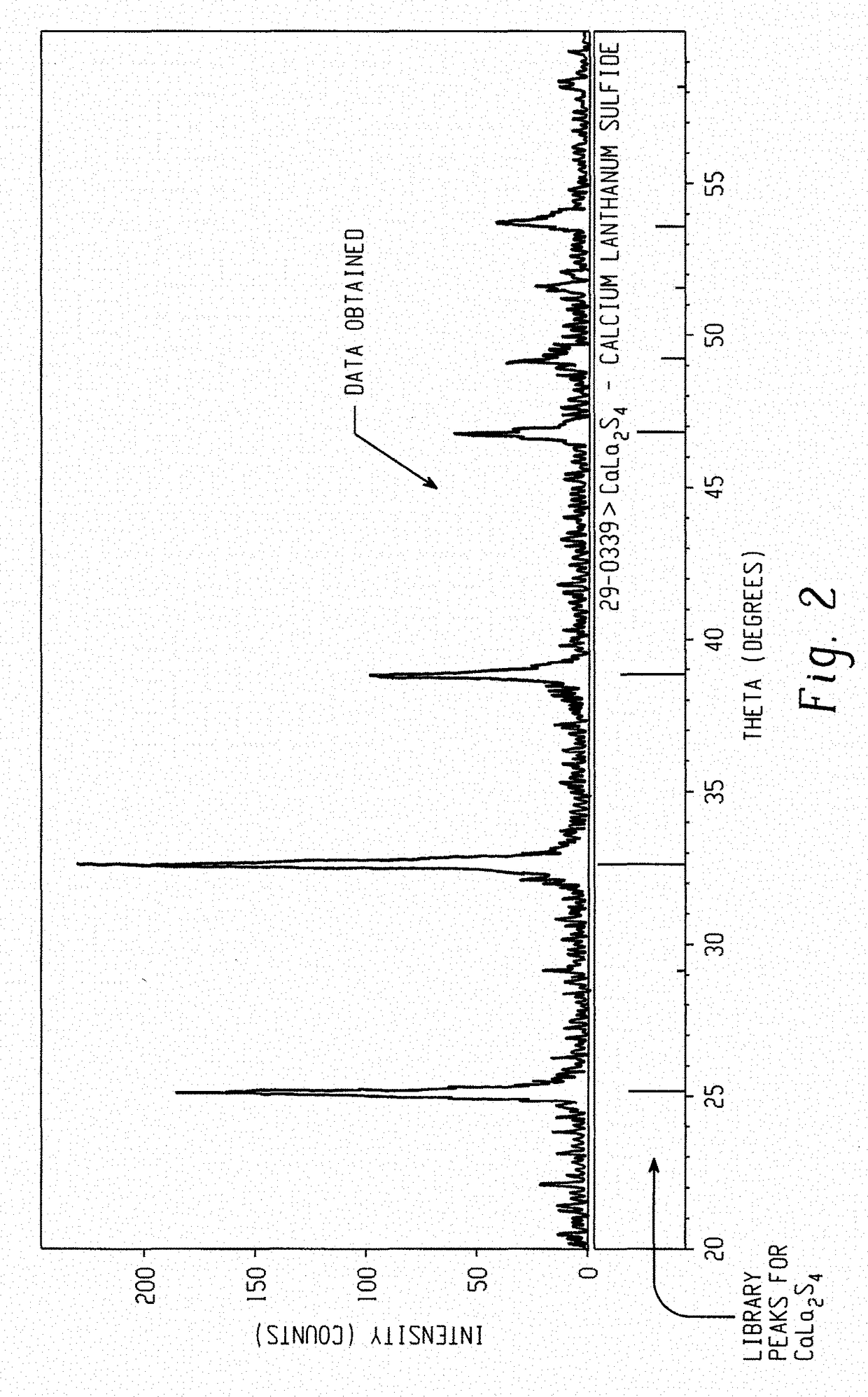

Calcium lanthanoid sulfide powders, methods of making, and ceramic bodies formed therefrom

A method of preparing a fine powder of calcium lanthanoid sulfide is disclosed. The method includes spraying soluble calcium and lanthanoid salts into at least one precipitating solution to form a precipitate comprising insoluble calcium and lanthanoid salts, optionally, oxidizing the precipitate comprising insoluble calcium and lanthanoid salts, and sulfurizing the optionally oxidized precipitate to form a fine powder of calcium lanthanoid sulfide. An alternative method for forming the powder is by flame pyrolysis. The calcium lanthanoid sulfide powder produced by either method can have an impurity concentration of less than 100 ppm, a carbon concentration of less than 200 ppm, a BET surface area of at least 50 m2 / g, and an average particle size of less than 100 nm.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Environment-friendly type smelting agent and preparation method thereof

The invention discloses an environmental-friendly type smelting agent. The environment-friendly type smelting agent comprises, by mass, the following components of 10-15 wt% of potassium chloride, 25-35 wt% of potassium titanium fluoride, 5-10 wt% of calcium sulphide, 5-15 wt% of magnesium fluoride, 20-40 wt% of potassium fluoborate, 5-15 wt% of potassium aluminium fluoride and 10-40 wt% of sodium chloride. According to the smelting agent prepared with a special technology, the components are uniform; impurities are completely eliminated; besides, by means of the smelting agent prepared witha special ratio, efficient adsorption and dissolution can be conducted on slag, and rapid separation of slag and the melt is achieved; the smelting agent prepared can be used for rapid smelting of aluminum and aluminum alloys; and in addition, the smelting agent can play an aluminum slag-eliminating part and a molten aluminum oxidation-preventing part.

Owner:江苏轩辕特种材料科技有限公司

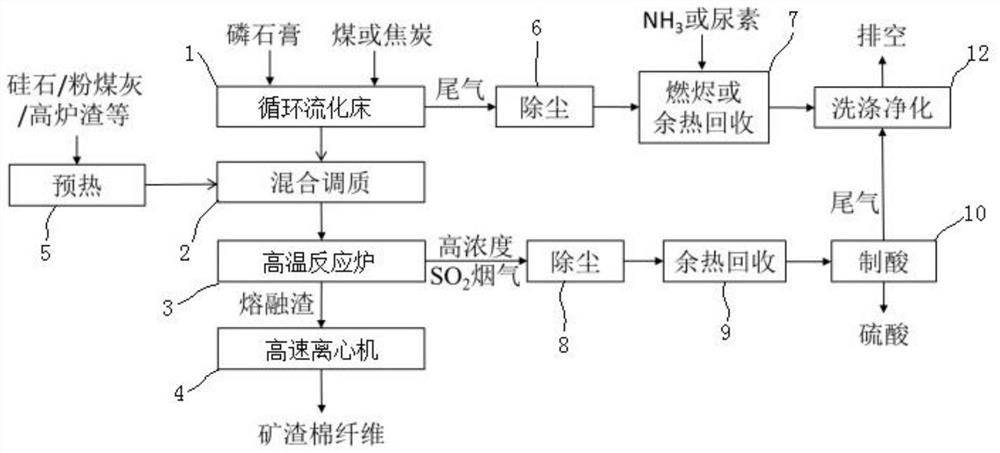

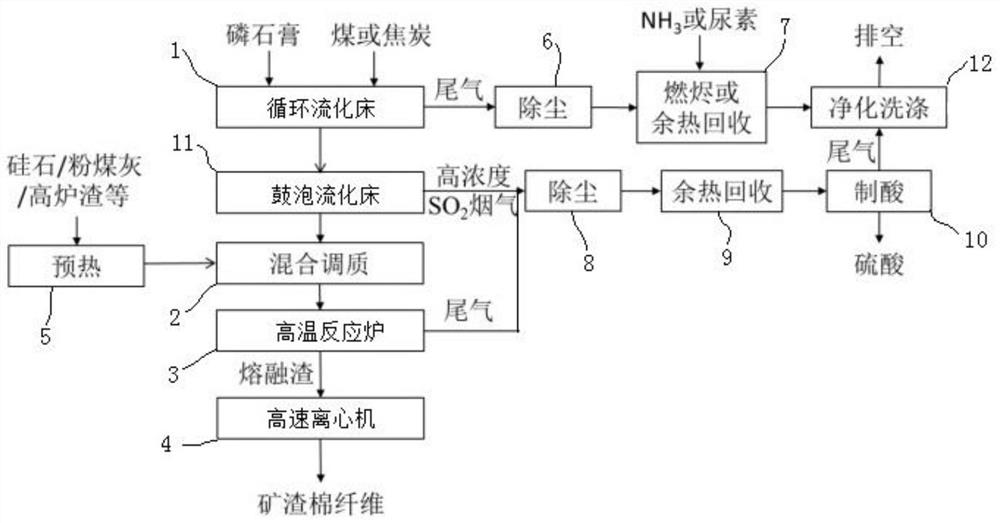

Method and device for segmentally preparing sulfuric acid and mineral cotton fibers from ardealite

PendingCN113860269AIncrease concentrationQuality improvementGlass making apparatusSulfur compoundsCalcium sulphideFlue gas

The invention discloses a method and a device for segmentally preparing sulfuric acid and mineral cotton fibers from ardealite, and relates to the technical field of segmentally preparing sulfuric acid from ardealite and high-valued utilization of cinder of ardealite. The method comprises the following steps: reducing ardealite into a mixture of calcium sulfide and calcium sulfate through a circulating fluidized bed, mixing the mixture with preheated powdery compound materials of silicon, aluminum and magnesium, and feeding the mixture into a high-temperature reaction furnace for roasting and melting, or feeding the mixture into a bubbling fluidized bed for roasting and decomposing; and conducting mixing with preheated powdery compound materials of silicon, aluminum and magnesium, feeding the mixture into a high-temperature reaction furnace for melting, and preparing slag cotton fiber products with high additional value from molten slag through a blowing or centrifuging process. High-concentration SO2 flue gas is prepared in the roasting process and is used for preparing sulfuric acid. The material directly enters the reaction in the form of powder, and the reaction in each section is more complete through a sectional method, so that the concentration of the prepared SO2 flue gas is higher, the obtained slag cotton fiber is finer and better in quality, and the high value-added utilization of the ardealite cinders is realized.

Owner:云南云天化环保科技有限公司 +1

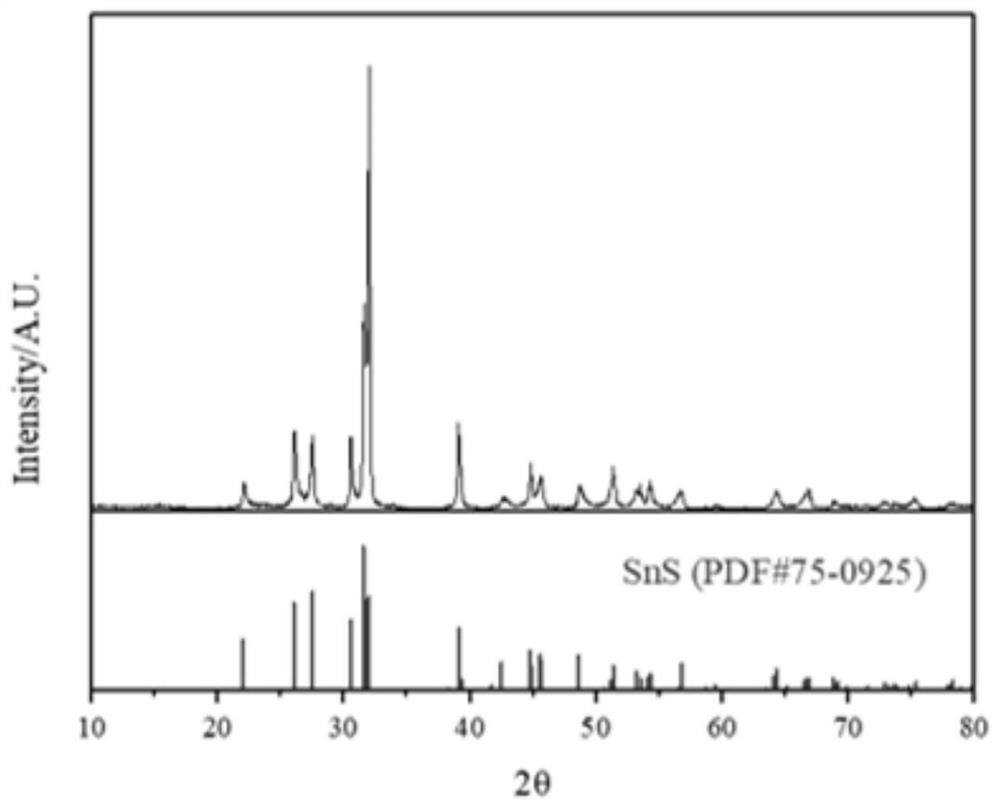

Method for preparing nano stannous sulfide from tin-containing electronic waste by one-step method

ActiveCN112391533ARealize secondary useAchieve sustainable developmentTin compoundsNanotechnologyCalcium sulphidePhysical chemistry

The invention discloses a method for preparing nano stannous sulfide from tin-containing electronic waste by a one-step method. The method comprises the following steps that the tin-containing electronic waste and an additive composed of calcium sulfide and silicon dioxide are uniformly mixed and then are subjected to agglomeration, agglomerates are placed in a reducing atmosphere to be subjectedto reduction roasting at 750 DEG C-900 DEG C, roasted volatile matters enter a weak reducing atmosphere to be subjected to reduction roasting at 450 DEG C-700 DEG C, and nano stannous sulfide powder is obtained. According to the method, the tin-containing electronic waste serves as the raw material, tin is efficiently recycled, the high-purity nano stannous sulfide powder material is prepared, waste utilization is achieved, the economic additional value is high, and the method is easy to operate, low in production cost, environmentally friendly and capable of meeting the industrial productionrequirement.

Owner:CENT SOUTH UNIV

Facial mask special for preventing acnes

InactiveCN103932929AReduce secretionEffective massage effectCosmetic preparationsToilet preparationsCalcium sulphideAluminum magnesium silicate

The invention discloses a facial mask special for preventing acnes, which is used for treating andpreventing acnes, and belongs to skincare series. The facial mask comprises the main ingredients: calcium sulphide, aluminum-magnesium silicate, light calcium carbonate, glycerol, tween-60, zinc oxide, olive oil, methylparaben, essence, and the like. The materials can be prepared into a finished product-facial mask special for preventing the acnes by virtue of a certain special process. The facial mask disclosed by the invention achieves good treatment and prevention effect on acnes, and has skincare effect.

Owner:TIANJIN JUNRU TECH

Regeneration of calcium oxide or calcium carbonate from waste calcium sulphide

InactiveUS20050095190A1Calcium/strontium/barium carbonatesSolvent extractionCalcium sulphideAlternative process

An alternative process whereby the calcium sulphide formed in an integrated gasification combined cycle (IGCC) system from calcium oxide and / or calcium carbonate can be safely and more or less quantitatively converted by reaction with carbon dioxide to calcium carbonate and / or calcium oxide together with sulphur dioxide. The calcium oxide and / or calcium carbonate can be reused in the integrated gasification combined cycle (IGCC) system, and the sulphur dioxide can be converted to a useful product, such as sulphuric acid. One result of this process is that since the furnace ashes do not contain a significant level of calcium sulphide, they can be safely disposed of in a land fill site.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

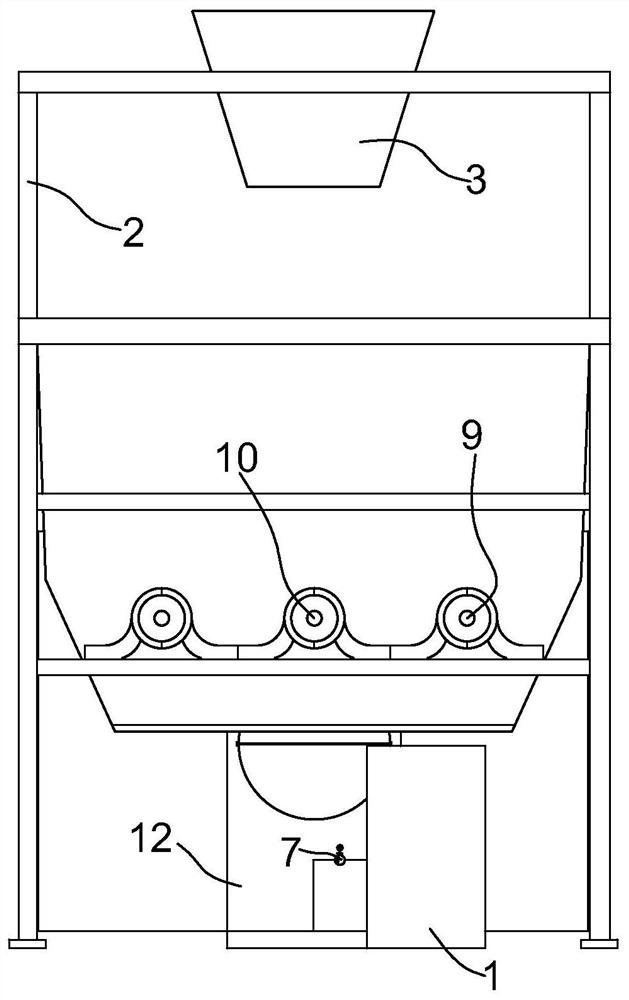

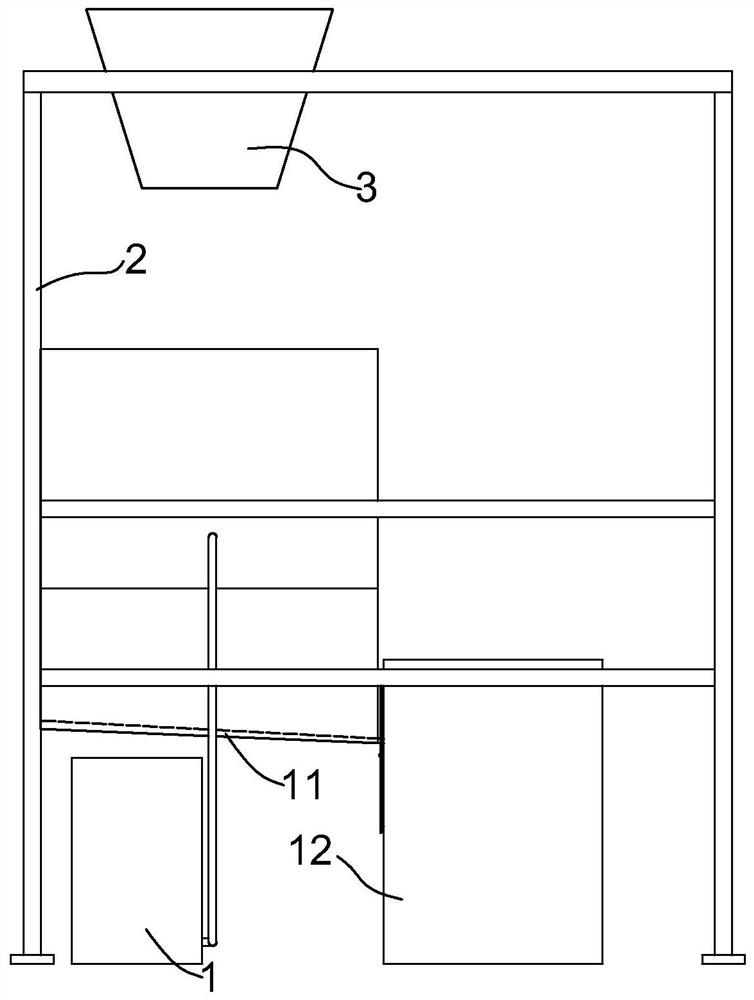

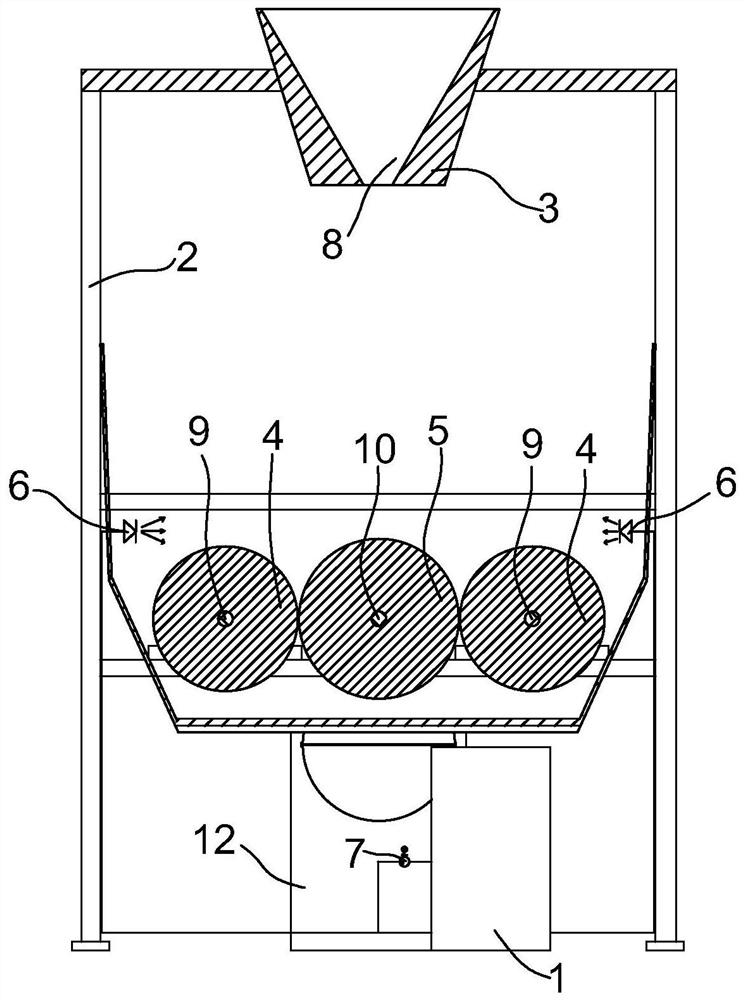

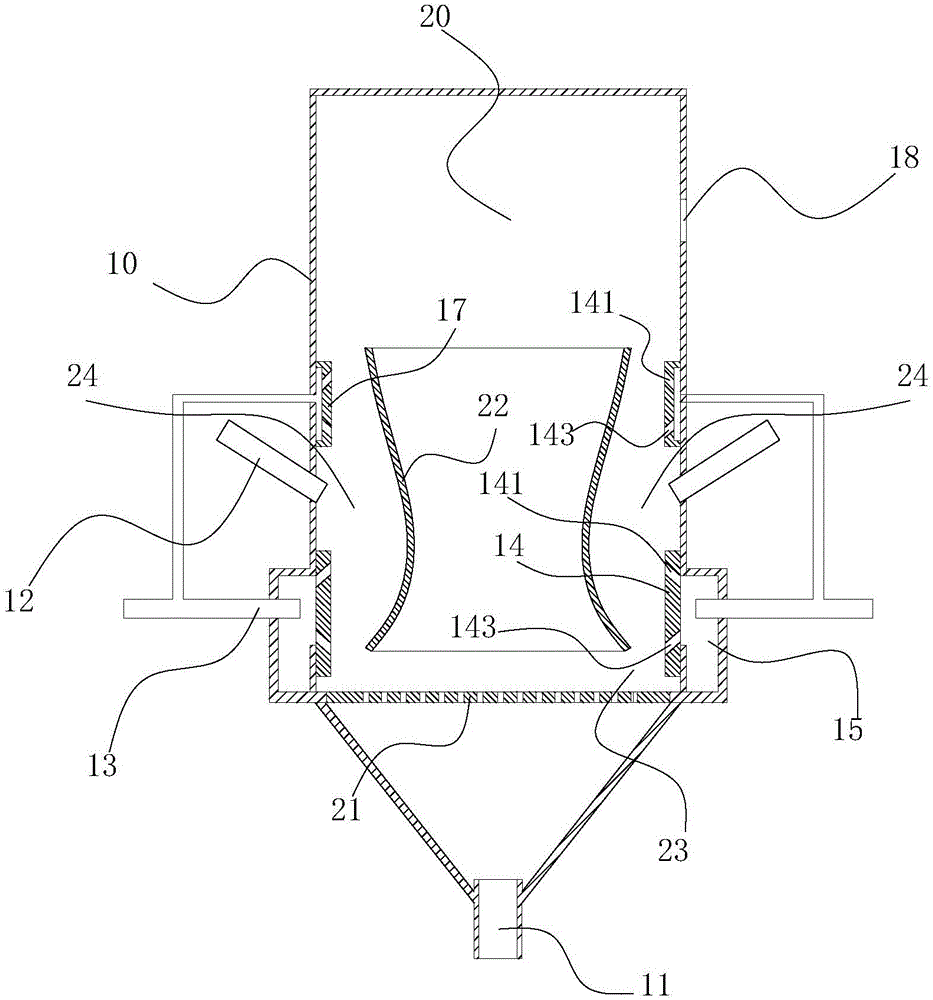

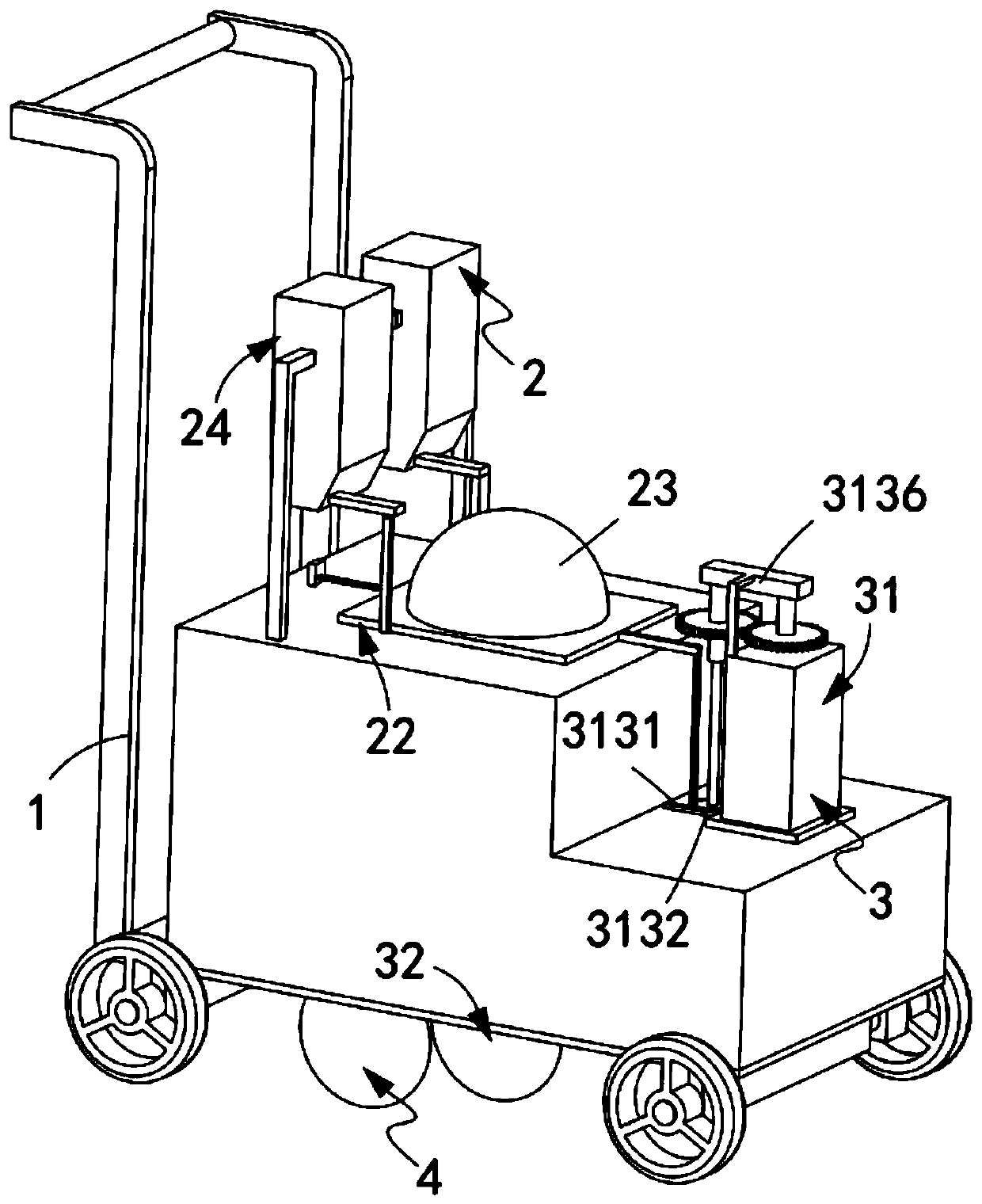

Reflective road marking line synthesis marking device

ActiveCN111395141AQuality improvementEvenly blendedRoads maintainenceCalcium sulphideReflection illumination

The invention relates to a reflective road marking line synthesis marking device which comprises a marking vehicle and a marking line coating production device, a glass bead discharging device and a coating marking device which are installed on the marking vehicle. The marking line coating production device comprises a reaction tank, a discharging assembly, a transfer box, a supply assembly and amixing assembly. The glass bead discharging device comprises a discharging assembly and a material pressing assembly arranged below the discharging assembly, and the material pressing assembly conducts uniform material pressing work on glass beads. The coating marking device is arranged on one side of the glass bead discharging device, and the coating marking device is bonded with the glass beadson the material pressing assembly in the rotating process and continues to rotate to scribe the composition on the ground. Therefore, technical problems that the calcium sulfide long-afterglow luminescent material layer, the glass bead layer, the retro-reflection lighting material layer and the protective coating are sequentially brushed, the work is tedious, and the working efficiency is low aresolved.

Owner:ZHEJIANG ZHONGXIN NEW MATERIAL CO LTD

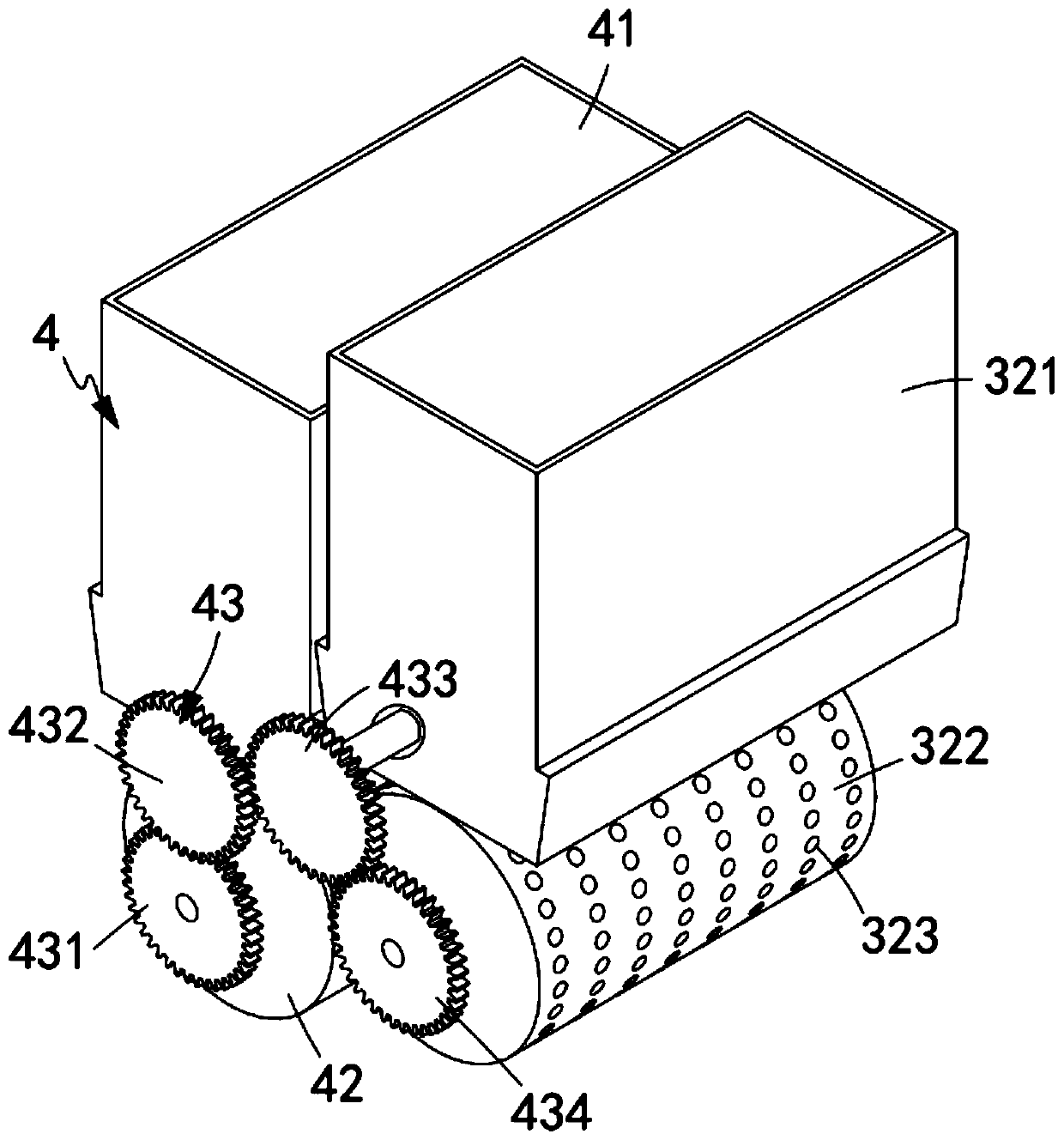

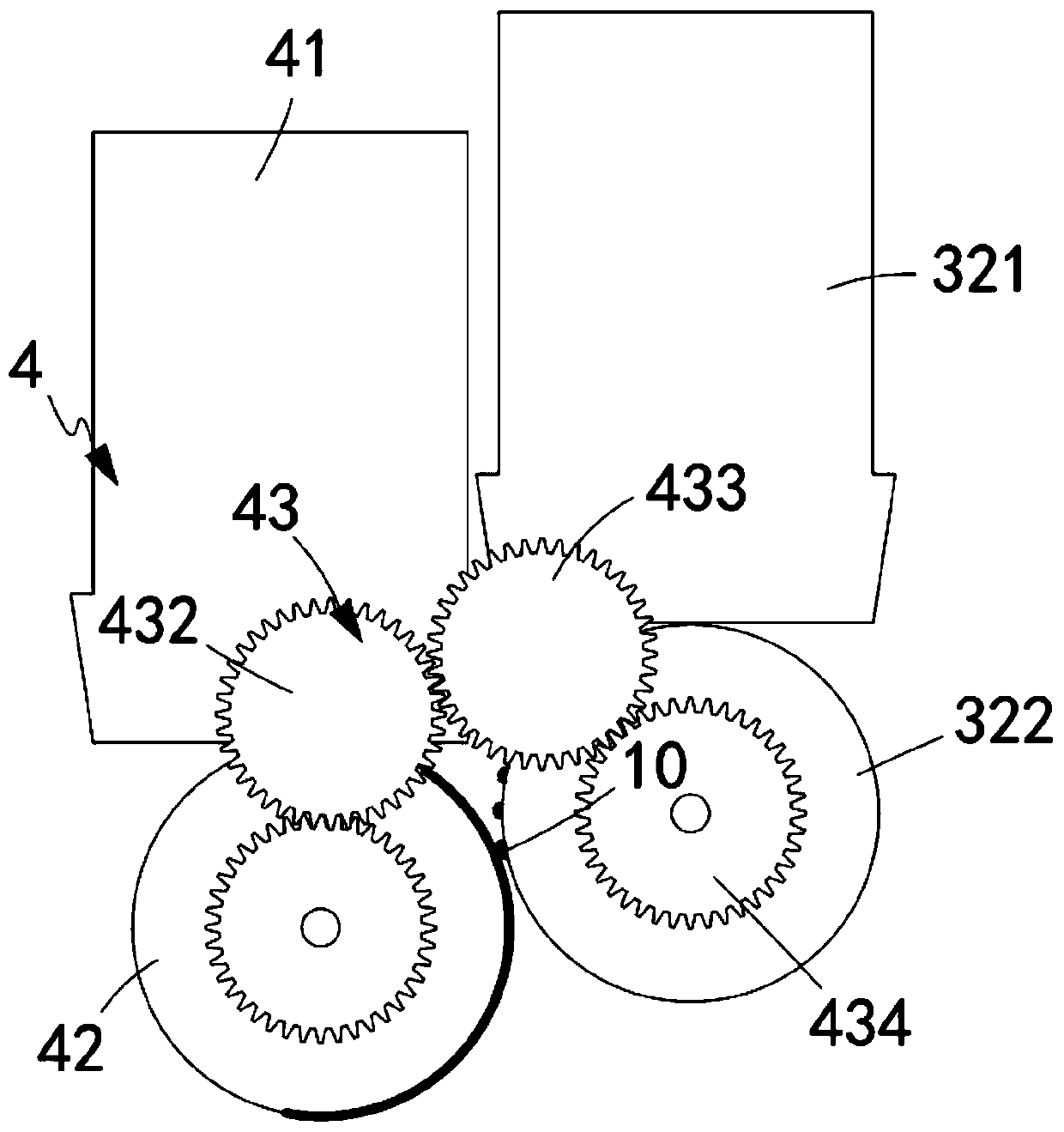

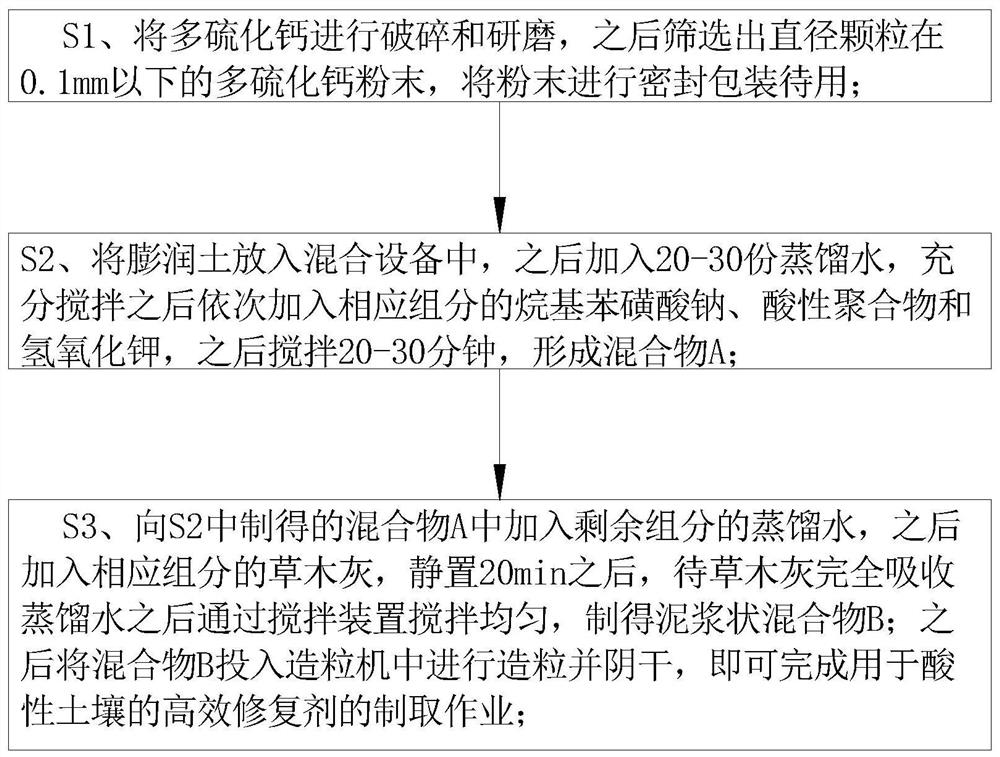

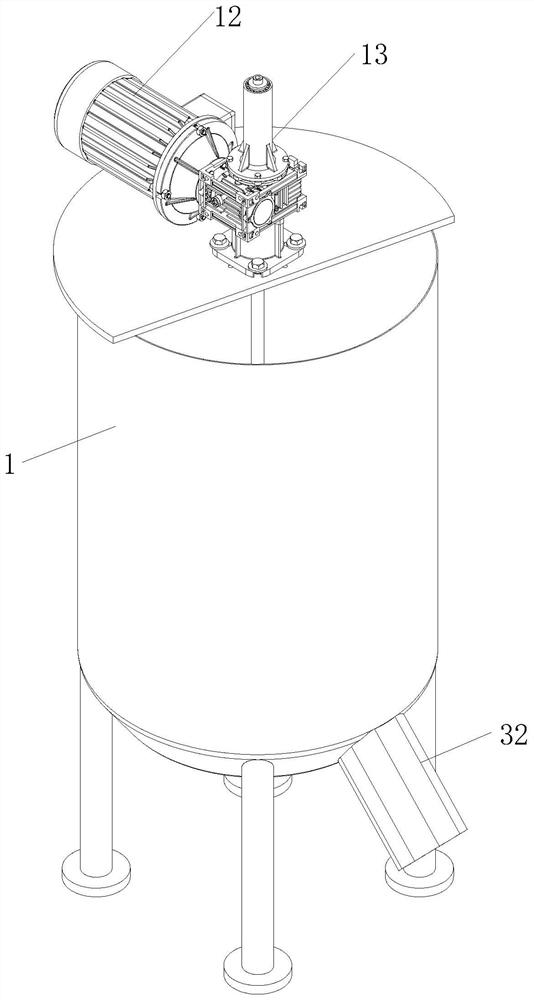

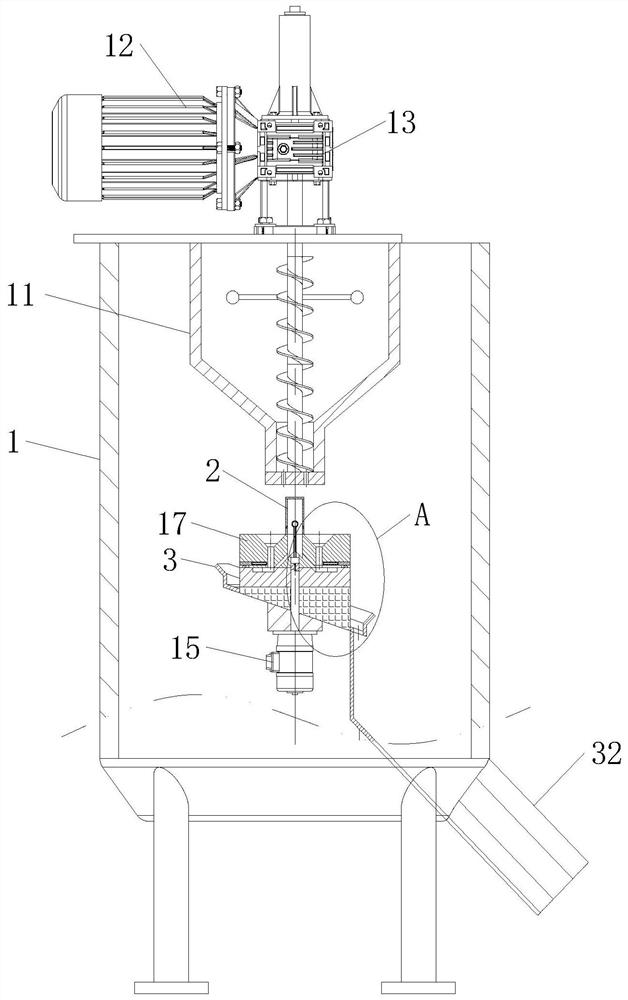

Efficient repairing agent for acid soil and preparation method of efficient repairing agent

ActiveCN113462394AReduce bondingEnsure granulation uniformityAgriculture tools and machinesOther chemical processesPotassium hydroxidePhosphoric acid

The invention belongs to the technical field of agricultural cultivated land improvement and protection application products, and particularly relates to an efficient repairing agent for acid soil and a preparation method of the efficient repairing agent. The efficient repairing agent comprises the following components in parts by weight: 110-150 parts of calcium polysulfide; 80-120 parts of bentonite; 15-20 parts of sodium alkyl benzene sulfonate; 5-15 parts of an acidic polymer; 0.5-3 parts of trisodium phosphate; 25-50 parts of plant ash; 8-10 parts of potassium hydroxide; and 60-80 parts of distilled water. A granulator used in repair agent forming comprises a body, an extrusion unit is fixedly connected to the top of the body through a support, and a millstone is fixedly connected to the position, corresponding to the bottom of the extrusion unit, in the body through a support; a rotating disc is arranged at the top of the millstone; a group of material dropping holes are uniformly distributed in the circumference, corresponding to the discharge hole of the extrusion unit, of the rotating disc; and a group of spiral grooves are circumferentially and uniformly distributed at the top, corresponding to the material dropping holes, of the millstone. According to the device, the rotating disc is matched with the spiral groove to continuously rotate and rub the particles, so that the granulation uniformity of the particles is ensured, the shape and size consistency of the particles is improved, and the granulation quality of the soil remediation agent particles is further improved.

Owner:黑龙江沃坤农业科技有限公司

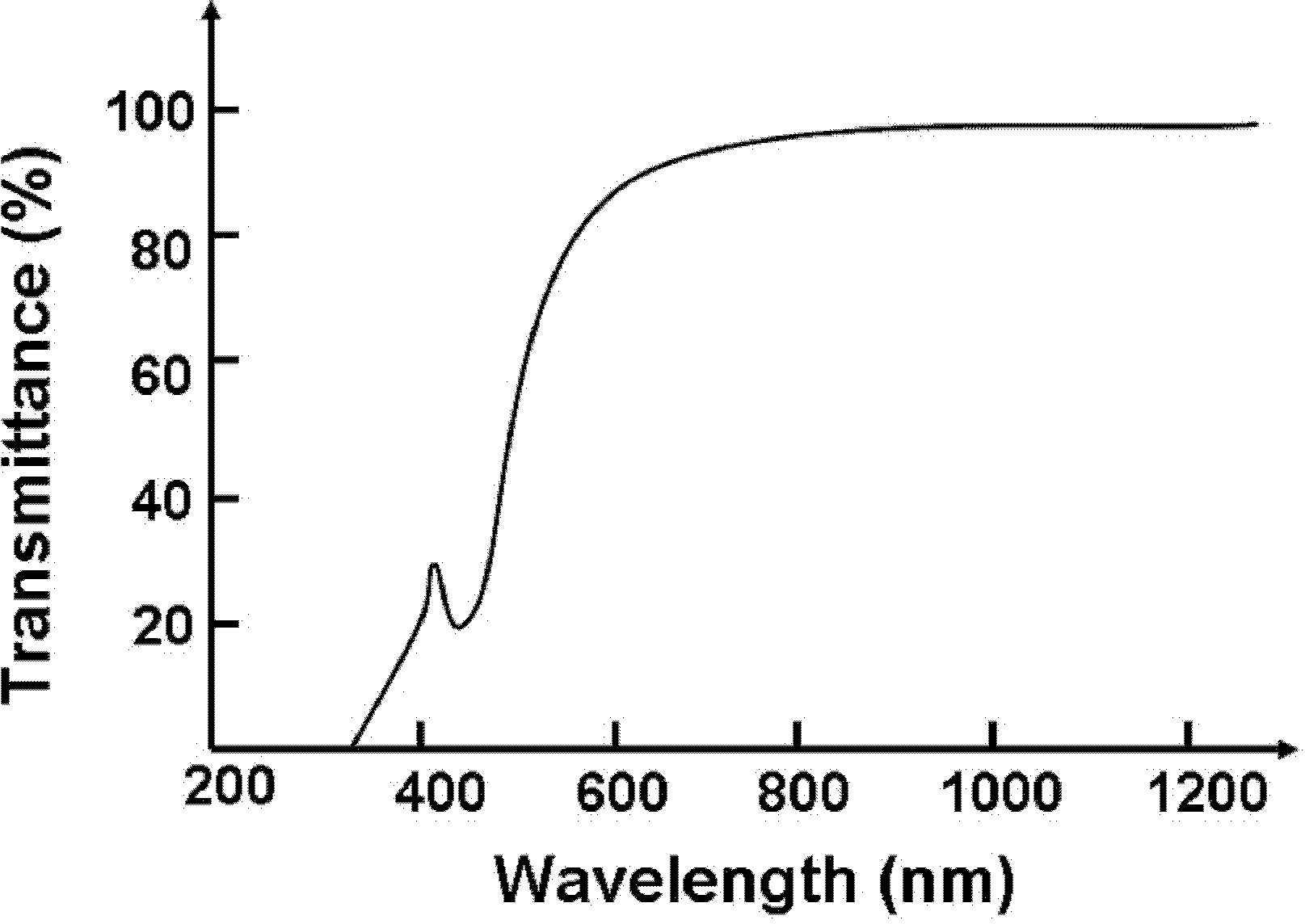

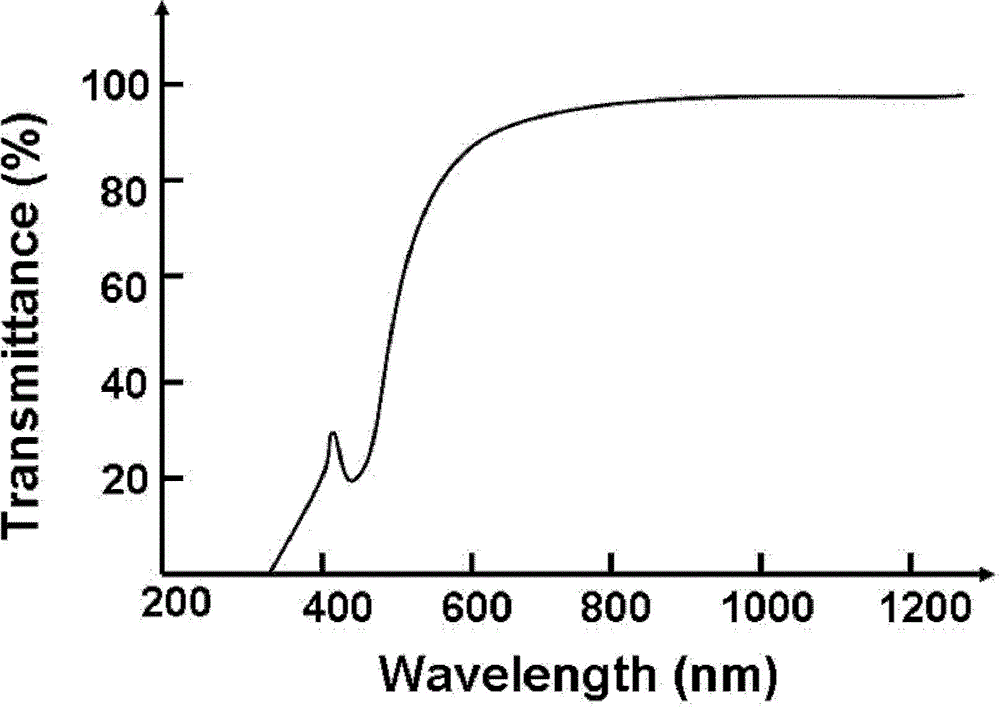

Amber alumina silicate glass

ActiveCN103395985AAchieve the purpose of coloringGlass furnace apparatusCalcium sulphideSilicate glass

The invention discloses a piece of amber alumina silicate glass. The amber alumina silicate glass is characterized by also comprising the following components: 0.06%-0.3wt.% of WO3, and 0.2%-0.5wt.% of SO3. The invention also provides a preparation method for the amber alumina silicate glass. The preparation method comprises the following steps of adding 0.001wt.%-0.05wt.% of tungsten disulfide and 0.1wt.%-5wt.% calcium sulphide, relative to the total amount of batch, into the batch of normal alumina silicate glass so as to form the batch of the amber alumina silicate glass, and preparing the amber alumina silicate glass according to a known technology, wherein the melting temperature is 1630-1680 DEG C, the glass mold temperature is 1580-1620 DEG C, and the annealing temperature is 660-680 DEG C. The prepared amber alumina silicate glass comprises no harmful components, and has less environment pollution.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

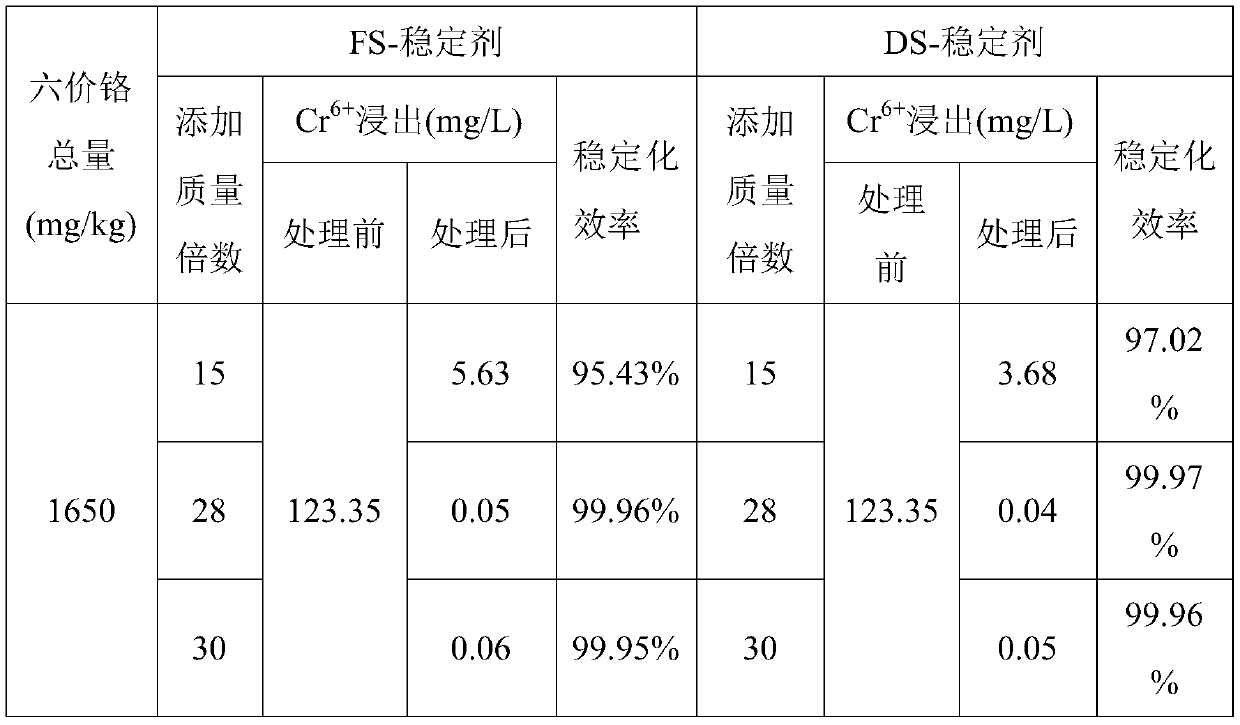

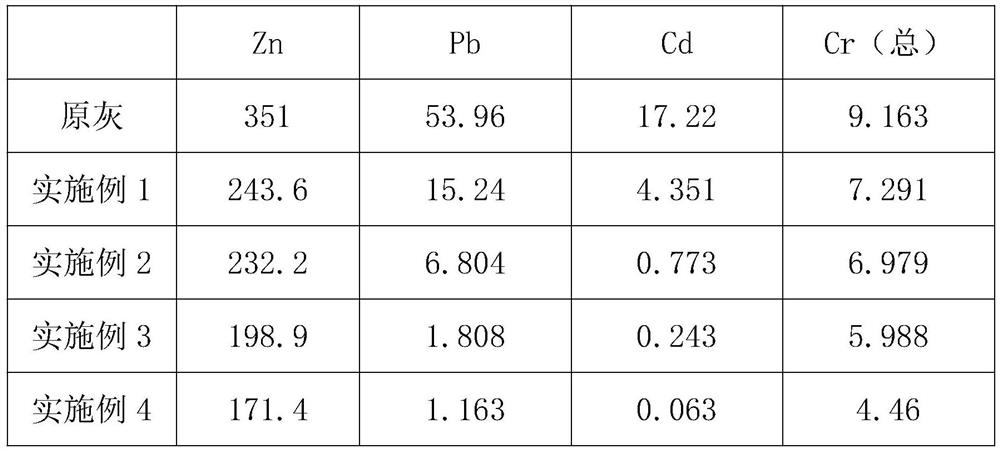

Stabilizing agent for repairing heavy metal chromium pollution, and preparation method and application thereof

ActiveCN111218289ACause secondary pollutionAchieve fixContaminated soil reclamationOrganic fertilisersPolyvinyl alcoholGroundwater remediation

Owner:HUNAN JINLV ENVIRONMENTAL PROTECTION CO LTD

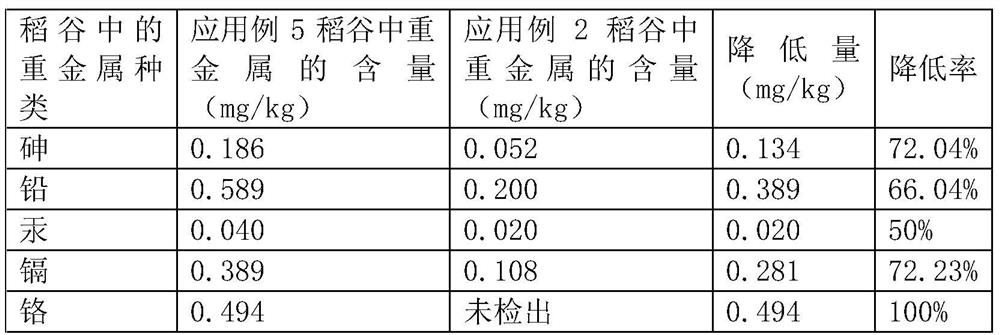

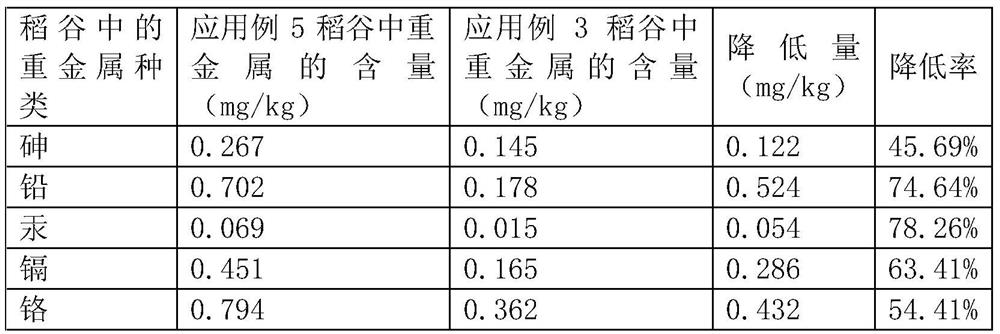

Passivating agent for inhibiting absorption of rice and reducing heavy metal content of rice, and application and use method thereof

ActiveCN113174262AInhibition of absorption responseLow chemical activitySuperphosphatesAgriculture tools and machinesPhosphateManganese oxide

The invention relates to the field of environmental chemistry, and particularly discloses a passivating agent for inhibiting rice from absorbing and reducing the heavy metal content of rice, and application and a use method thereof. The passivating agent is formed by mixing the following raw materials in parts by weight: 10-20 parts of phosphate; 5-10 parts of an inorganic alkaline substance; 5-10 parts of calcium polysulfide; 10-20 parts of a silicon fertilizer; 10-20 parts of an inorganic flocculant; 15-25 parts of iron oxide; and 10-20 parts of manganese oxide. The passivating agent is applied to a rice field containing heavy metal, and the heavy metal is one or a combination of more of lead, cadmium, arsenic, mercury and chromium. The use method of the passivating agent comprises the following steps: S1, intertilling a rice field, and scattering the passivating agent at the same time; and S2, soaking in water. The passivating agent disclosed by the invention has the advantages of inhibiting the heavy metal absorption of the rice and reducing the heavy metal content in the rice.

Owner:SHANGHAI CAIFENG FEED PHOSPHORUS & CALCIUM

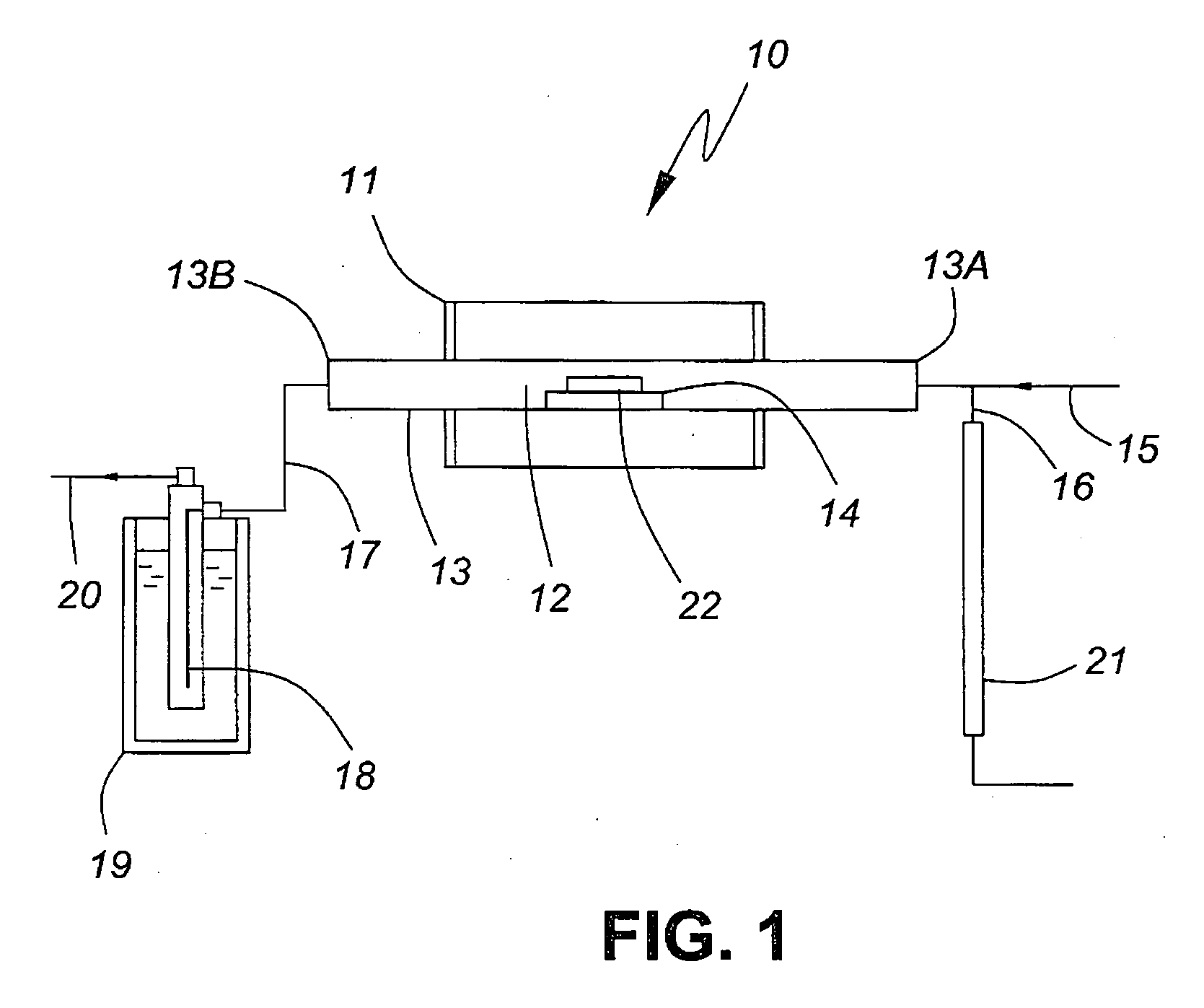

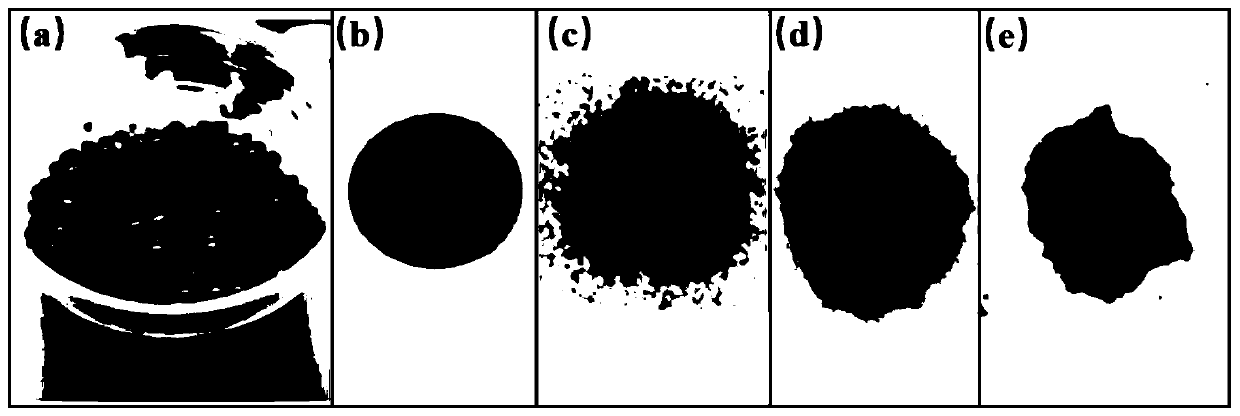

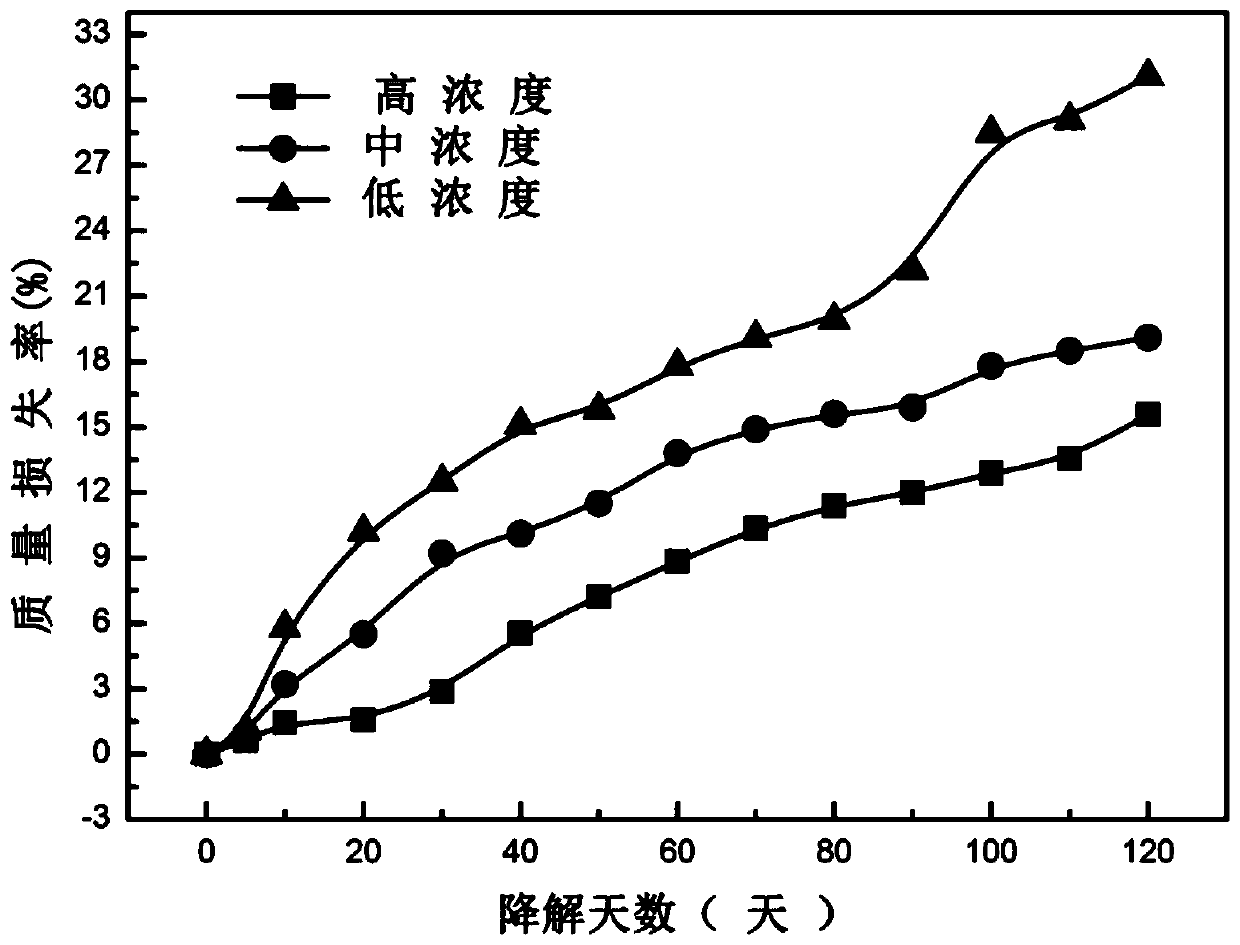

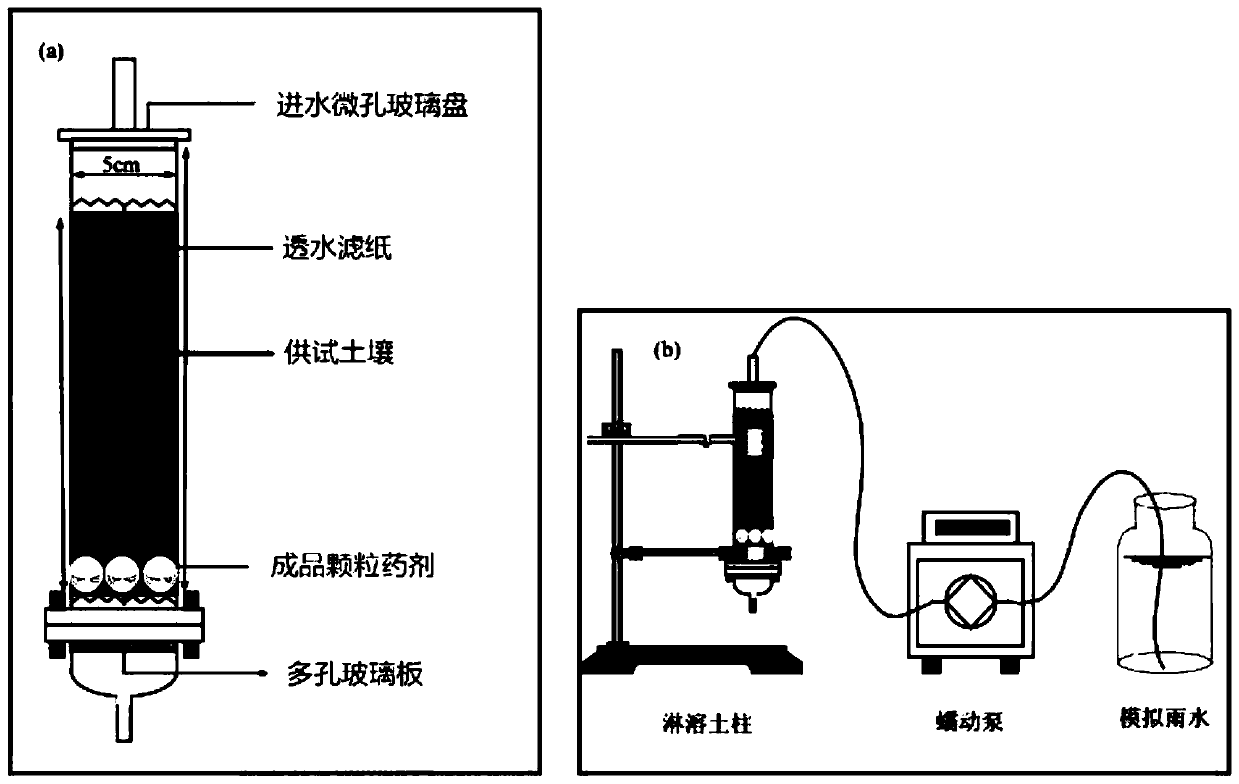

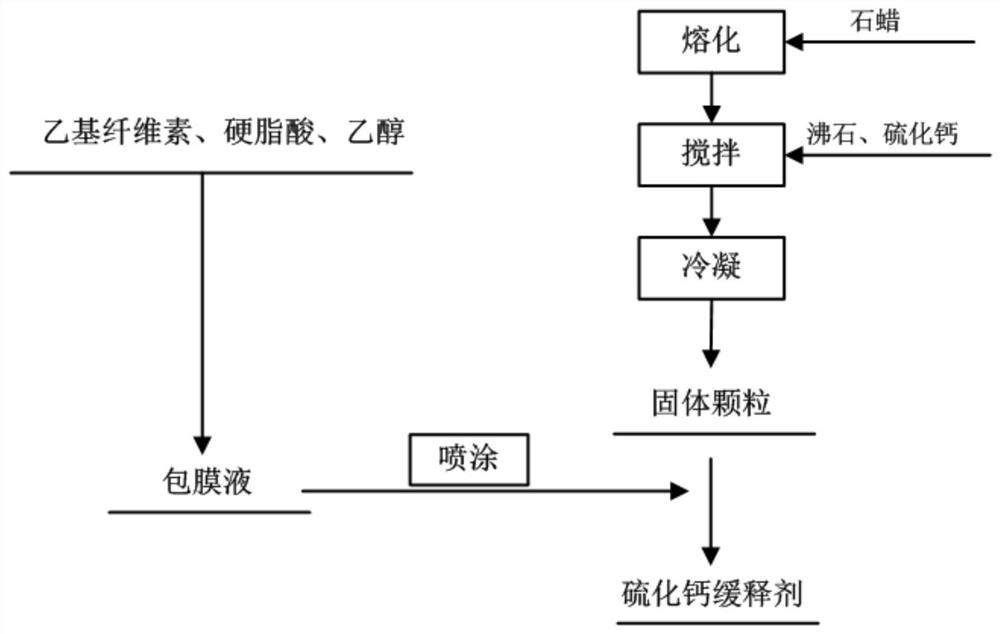

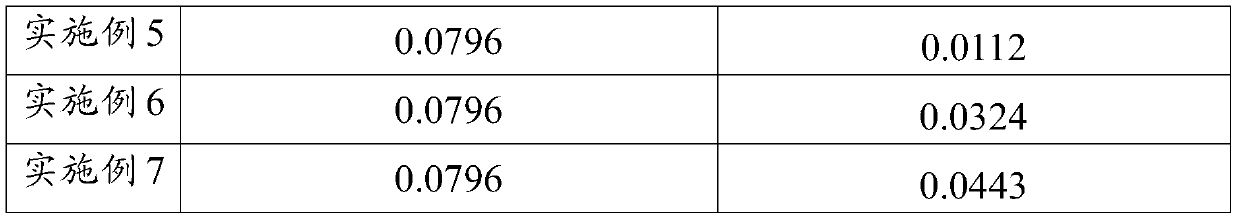

Calcium sulfide-based slow-release vulcanizing agent as well as preparation method and application thereof

ActiveCN113332756AReduce releaseGood sustained release effectSedimentation separationCalcium sulphideCellulose

The invention discloses a calcium sulfide-based slow-release vulcanizing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing molten paraffin with zeolite particles and calcium sulfide particles, carrying out auxiliary cooling molding through a mold to obtain solid particles, spraying a coating liquid containing ethyl cellulose and stearic acid on the surfaces of the solid particles, and volatilizing a solvent at room temperature to obtain the calcium sulfide-based slow-release vulcanizing agent. The calcium sulfide-based slow-release vulcanizing agent can stably slowly release, vulcanize and deeply precipitate heavy metal ions in an acid solution system, is high in utilization rate, can avoid secondary pollution caused by H2S escape, is particularly suitable for purifying the heavy metal ions in an acid solution, and is simple and efficient in preparation process, low in raw material cost, and large-scale production and application are facilitated.

Owner:CENT SOUTH UNIV

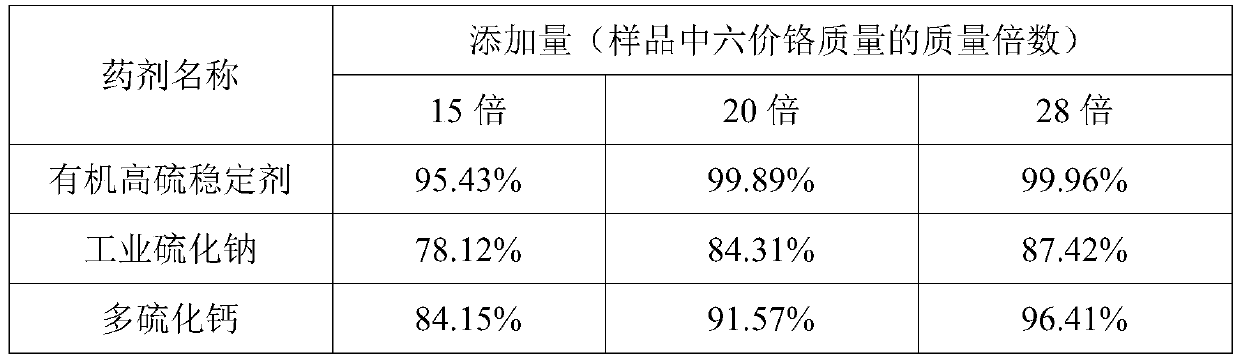

Method for synthesizing organic high-sulfur stabilizer from industrial waste sulfur slag

InactiveCN110643368AEasy to synthesizeReduce energy consumptionOrganic fertilisersSoil conditioning compositionsPtru catalystSlag

The invention discloses a method for synthesizing an organic high-sulfur stabilizer from industrial waste sulfur slag. The method comprises the following steps: uniformly mixing the sulfur slag with adeodorant, a cosolvent, an alkali metal sulfide, a catalyst and a solvent, stirring and reacting the obtained mixture, and adding a purifying agent to precipitate and remove impurities in order to obtain the organic high-sulfur stabilizer with a high sulfur content and a good stability. The method has the advantages of low raw material cost, mild reaction conditions, and realization of recyclingof the waste sulfur slag. The prepared organic high-sulfur stabilizer is applied to remediation of heavy metal contaminated soil, can efficiently reduce high-valence heavy metals in soil, and particularly has a good stabilization effect on hexavalent chromium reducibility; and compared with common chalcogenide agents such as calcium polysulfide and sodium sulfide in the prior art, the organic high-sulfur stabilizer of the invention has the advantages of great reduction of the dosage of a vulcanizing agent and reduction of the remediation cost of heavy metal contaminated soil under the condition that the same stabilization effect is achieved.

Owner:长沙工研院环保有限公司

Resource recycling method of construction waste and remediation agent for heavy metal polluted soil

ActiveCN106623379BReduce pollutionReduce processing costsConstruction waste recoverySolid waste disposalWaste treatmentMetal contamination

Owner:甘肃天农一禾农业有限公司

Method for extracting sodium carbonate and sodium thiocyanate from sodium-alkali desulfurization waste liquid by causticization-acidification

InactiveCN103601219BShort process routeLow operating costThiocyanic acidMultistage water/sewage treatmentLiquid wasteDecomposition

The inventi on discloses a method for extracting sodium carbonate and sodium thiocyanate from sodium alkali desulfurization liquid waste by using a causticization-acidification method and belongs to the technical field of desulfurization liquid waste treatment. The method comprises the following processes: pertreating liquid waste for removing impurities, heating for decomposing and discoloring, and carrying out oxidizing causticization-separation, acidification-separation, evaporation and concentration, and cooling crystallization-separation. The method is used for treating the desulfurization liquid waste generated in a production process of removing hydrogen sulfide and hydrogen cyanide out of coal gas or other gases by using a sodium alkali method. According to the method provided by the invention, sodium thiosulfate, sodium polysulfide and sodium sulfate in the sodium alkali desulfurization liquid waste can be converted into calcium sulfite, calcium sulphide and calcium sulfate precipitations at normal temperature through heating decomposition, oxidization and causticization; meanwhile, high-purity sodium carbonate and sodium thiocyanate are extracted, the sodium alkali is recovered to return a gas desulfurization system cycle, and the alkali consumption of the desulfurization operation is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

An amber aluminosilicate glass

ActiveCN103395985BAchieve the purpose of coloringGlass furnace apparatusCalcium sulphideSilicate glass

The invention discloses a piece of amber alumina silicate glass. The amber alumina silicate glass is characterized by also comprising the following components: 0.06%-0.3wt.% of WO3, and 0.2%-0.5wt.% of SO3. The invention also provides a preparation method for the amber alumina silicate glass. The preparation method comprises the following steps of adding 0.001wt.%-0.05wt.% of tungsten disulfide and 0.1wt.%-5wt.% calcium sulphide, relative to the total amount of batch, into the batch of normal alumina silicate glass so as to form the batch of the amber alumina silicate glass, and preparing the amber alumina silicate glass according to a known technology, wherein the melting temperature is 1630-1680 DEG C, the glass mold temperature is 1580-1620 DEG C, and the annealing temperature is 660-680 DEG C. The prepared amber alumina silicate glass comprises no harmful components, and has less environment pollution.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Fly ash chelating agent and preparation method thereof

PendingCN114404861AHigh molecular weightStrong flocculation functionChemical protectionButanedioic acidThio-

The invention provides a fly ash chelating agent and a preparation method thereof. The fly ash chelating agent is prepared from the following components in percentage by weight: 5 percent to 8 percent of 0, 0-diisopropyl ammonium dithiophosphate, 3 percent to 7 percent of 2, 3-dithiosuccinic acid, 10 percent to 20 percent of 3-chloro-2-hydroxypropyl trimethyl ammonium chloride, 2 percent to 4 percent of sodium trimethyldithiocarbamate, 3 percent to 7 percent of calcium polysulfide, 0.3 percent to 0.7 percent of an additive and 60 percent to 70 percent of water. The preparation method of the fly ash chelating agent comprises the following steps: adding 0, 0-diisopropyl ammonium dithiophosphate, 2, 3-dithiosuccinic acid, 3-chloro-2-hydroxypropyl trimethyl ammonium chloride, sodium trimethyldithiocarbamate and calcium polysulfide into water, stirring to obtain a mixed solution, adding the additive, and stirring to obtain the fly ash chelating agent. The preparation method of the chelating agent is very simple, and the chelating agent is an organic sulfur compound chelating agent and has the advantages of large molecular weight, strong flocculation function and strong heavy metal chelating capability; the additive of the chelating agent is polyaluminum chloride, so that the chelating capacity of the chelating agent is improved, the toxicity of the heavy metal chelating agent is reduced, and the product and the preparation process are environment-friendly, safe and non-toxic.

Owner:江西鸿运环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com