Method for preparing nano stannous sulfide from tin-containing electronic waste by one-step method

A technology of electronic waste and stannous sulfide, applied in chemical instruments and methods, tin compounds, nanotechnology, etc., can solve the problems of harsh preparation conditions, low economic added value, and low output, and achieve the effect of efficient and selective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

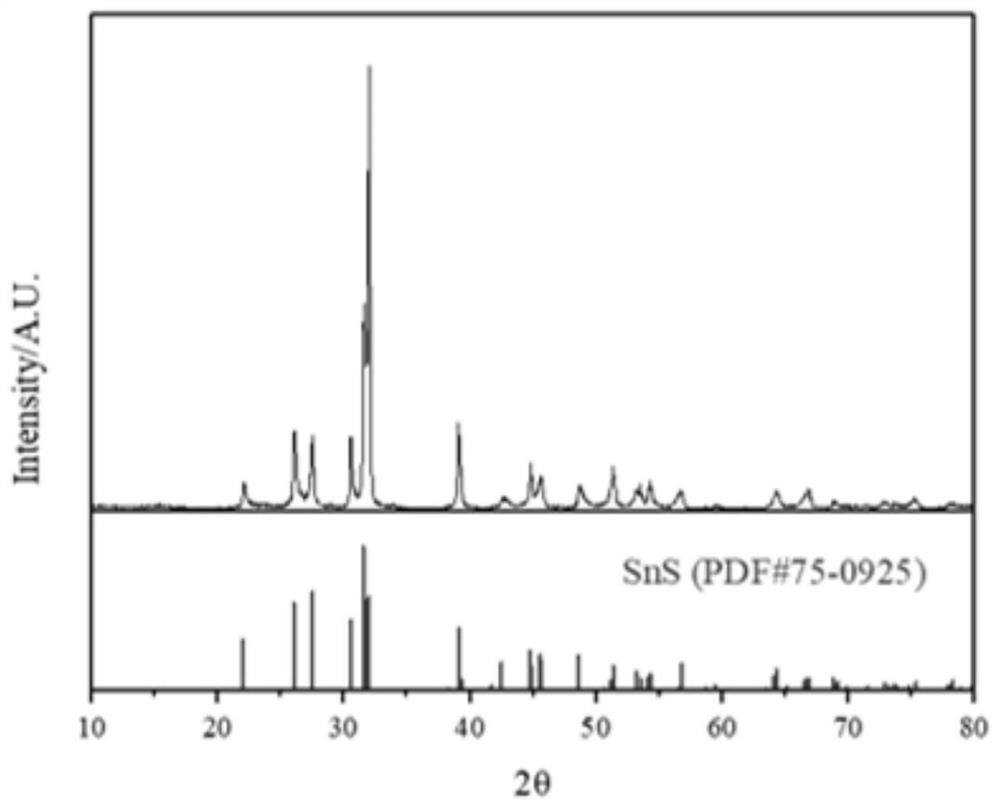

Image

Examples

Embodiment 1

[0025]Taking tin containing electron waste heat dissipating slag as raw materials (9.2% tin content, 0.5% organic content), adding composite additives (composite additives as a mixture of calcium sulfide, silica) according to Sn / S = 2.0, mixture of sulfide, silica For CA / Si = 2.2), mix it with a mixture, then placed the drying mass in two-stage controllable atmosphere calcination furnace to perform control atmosphere roast; material is placed in a roast area, a piece of roasting strong reduction Sexual atmosphere CO and CO2Mixed atmosphere, concentration is Co / (CO + CO2= 10 vol.%, The calcination temperature is 900 ° C, the gas flow rate is 0.3m / s; the volatile product enters the two-stage roasting area with the air flow, and the two-stage roasting reductive atmosphere is CO and CO.2Mixed atmosphere, concentration is Co / (CO + CO2= 5Vol.%, The calcination temperature is 700 ° C, the gas flow rate is 0.5 m / s; the product can be separated from the segment area, the tin reco...

Embodiment 2

[0027]Using tin-containing electronic waste pyrolysis slag as raw material (tin content 9.2%, organic content 0.5%), add compound additives according to the amount of Sn / S=1.5 (composite additives are a mixture of calcium sulfide and silicon dioxide, and the ratio Ca / Si=2.0), mix it well and form agglomerates, then place the dried agglomerates in a two-stage controlled atmosphere roasting furnace for controlled atmosphere roasting; the material is placed in a roasting zone, and the roasting is strong reduction. Sexual atmosphere is CO and CO2Mixed atmosphere, concentration is CO / (CO+CO2)=10vol.%, the roasting temperature is 850℃, the gas flow rate is 0.3m / s; the volatile products enter the second-stage roasting zone with the gas flow, and the weakly reducing atmosphere for the second-stage roasting is CO and CO2Mixed atmosphere, concentration is CO / (CO+CO2)=3vol.%, the roasting temperature is 650℃, the gas flow rate is 0.4m / s; the product can be separated and collected in the second...

Embodiment 3

[0029]Using tin-containing electronic waste pyrolysis slag as raw material (tin content 9.2%, organic content 0.5%), add composite additives according to the amount of Sn / S = 1.8 (composite additives are a mixture of calcium sulfide and silica, and the ratio Ca / Si=2.1), mix well and form agglomerates, then place the dried agglomerates in a two-stage controlled atmosphere roasting furnace for controlled atmosphere roasting; the material is placed in a roasting zone, and the roasting is strong in reducing. Atmosphere is CO and CO2Mixed atmosphere, concentration is CO / (CO+CO2)=8vol.%, the roasting temperature is 800℃, the gas flow rate is 0.2m / s; the volatile products enter the second-stage roasting zone with the gas flow, and the weakly reducing atmosphere of the second-stage roasting is CO and CO2Mixed atmosphere, concentration is CO / (CO+CO2)=2vol.%, the roasting temperature is 550℃, the gas flow rate is 0.2m / s; the product can be separated and collected in the second stage area, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com