Method for decomposing gypsum through synergistic fluidization

A gypsum and fluidization technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of uneconomical material consumption and energy consumption, low decomposition rate of gypsum, and low space-time yield, so as to save production costs and simplify production. Equipment structure, the effect of increasing space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

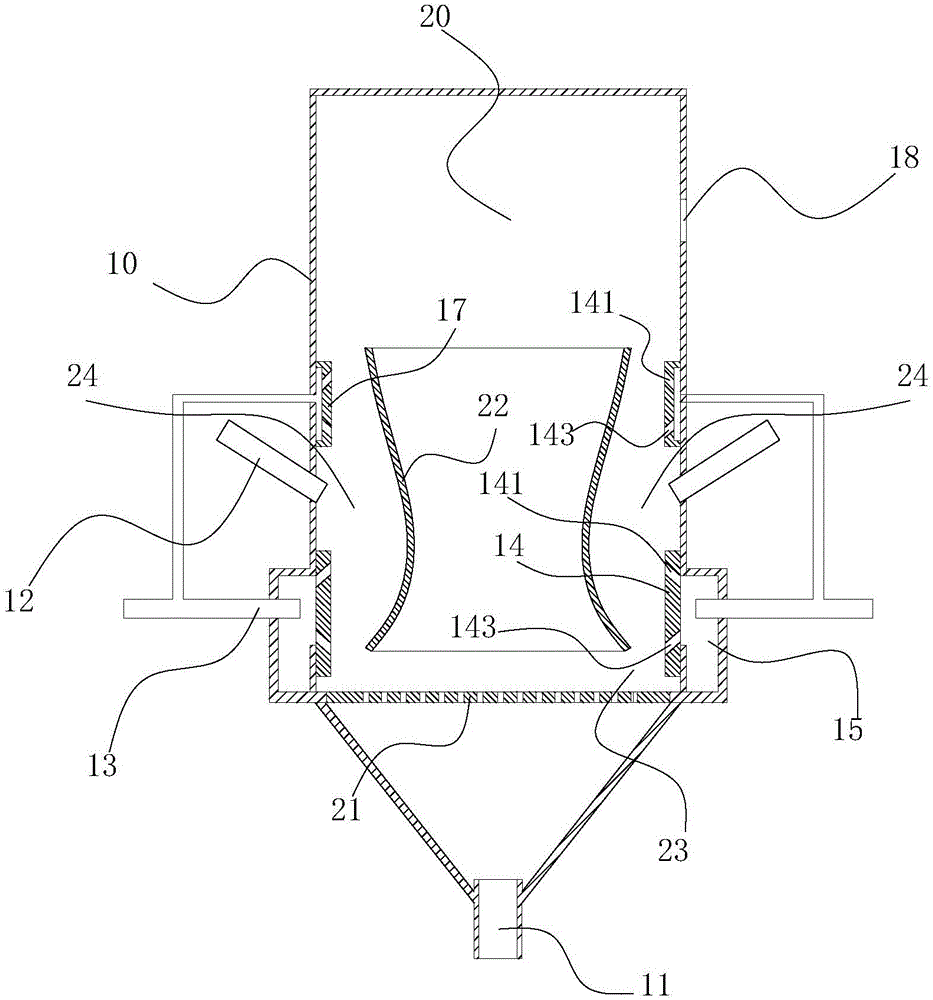

Image

Examples

Embodiment 1

[0050] The average particle size of phosphogypsum particles is 5 μm, the average particle size of quartz sand particles is 100 μm, the mass ratio of phosphogypsum to quartz sand is 2:1; The molar ratio of carbon monoxide to phosphogypsum is 1:1; the reaction temperature is 500°C, and the residence time of solid reactants is 2min. The decomposition rate of gypsum is 96%, and the mole fraction of sulfur dioxide in the reacted gas is 7%.

Embodiment 2

[0052] The average particle size of desulfurized gypsum particles is 20 μm, the average particle size of chalcopyrite particles is 200 μm, the mass ratio of desulfurized gypsum to chalcopyrite is 1:1; %, the molar ratio of hydrogen to desulfurized gypsum is 3:1; the reaction temperature is 600°C, and the residence time of the solid reactant is 5min. The decomposition rate of gypsum is 97%, and the mole fraction of sulfur dioxide in the reacted gas is 9%.

Embodiment 3

[0054] The average particle size of phosphogypsum particles is 30 μm, the average particle size of quartz sand particles is 500 μm, and the mass ratio of phosphogypsum to quartz sand is 0.5:1; the molar fraction of carbon monoxide in the mixed gas introduced into the air inlet pipe 11 is 40%, The molar ratio of carbon monoxide to phosphogypsum is 4:1; the reaction temperature is 750°C, and the residence time of the solid reactant is 15 minutes. The decomposition rate of gypsum is 99%, and the mole fraction of sulfur dioxide in the reacted gas is 16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com