Fly ash chelating agent and preparation method thereof

The technology of chelating agent and fly ash is applied in the field of liquid mixed chelating agent of hazardous waste landfill standard and its preparation field, which can solve the problems of less complexing center, high energy consumption, increase the volume of landfill, etc. Strong ability to chelate heavy metals, easy biodegradation, and the effect of improving chelation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

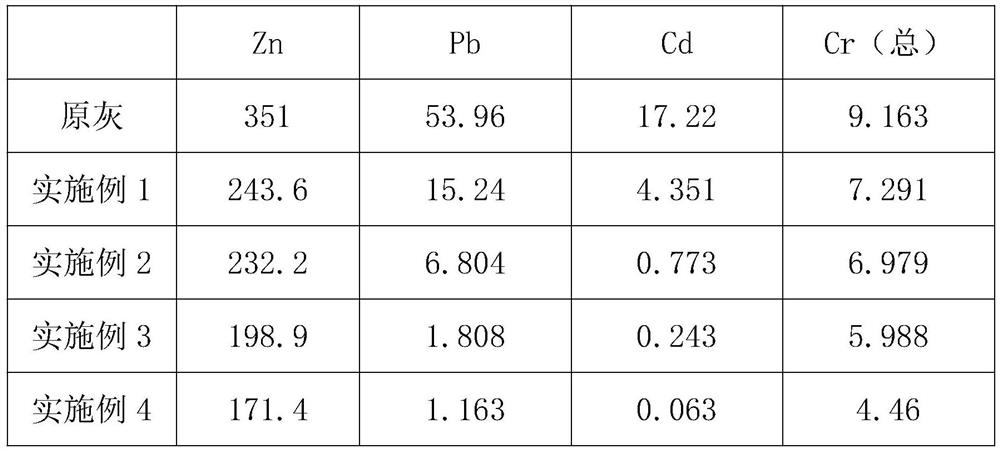

Examples

Embodiment 1

[0016] Weigh 60kg of deionized water, 3kg of 0,0-diisopropyl phosphorodithioate, 1.8kg of 2,3-dithiosuccinic acid, 3-chloro-2-hydroxypropyltrimethylammonium chloride 6kg, sodium trimethyldithiocarbamate 1.2kg, calcium polysulfide 1.8kg, polyaluminum chloride 0.18kg, 0,0-diisopropyl dithiophosphoric acid ammonium, 2,3-dithiobutyl Add diacid, 3-chloro-2-hydroxypropyltrimethylammonium chloride, sodium trimethyldithiocarbamate and calcium polysulfide into deionized water, stir for 0.5 hours to obtain a mixed solution; then add polychlorinated Al can be stirred for 1 hour.

Embodiment 2

[0018] Weigh 60kg of deionized water, 3.6kg of 0,0-diisopropyl phosphorodithioate, 2.4kg of 2,3-dithiosuccinic acid, 3-chloro-2-hydroxypropyl trimethyl chloride Ammonium 9kg, sodium trimethyldithiocarbamate 1.5kg, calcium polysulfide 2.4kg, polyaluminum chloride 0.24kg, first 0,0-diisopropyl dithiophosphoric acid ammonium, 2,3-dithio Add succinic acid, 3-chloro-2-hydroxypropyltrimethylammonium chloride, sodium trimethyldithiocarbamate and calcium polysulfide into deionized water and stir for 0.5 hours to obtain a mixed solution; then add polychloric acid Alumina was stirred for 1 hour.

Embodiment 3

[0020] Weigh 60kg of deionized water, 4.2kg of 0,0-diisopropyl phosphorodithioate, 3.0kg of 2,3-dithiosuccinic acid, 3-chloro-2-hydroxypropyl trimethyl chloride Ammonium 10.8kg, sodium trimethyldithiocarbamate 1.8kg, calcium polysulfide 3.0kg, polyaluminum chloride 0.30kg, 0,0-diisopropyl dithiophosphoric acid ammonium, 2,3-disulfide Add butyl succinic acid, 3-chloro-2-hydroxypropyltrimethylammonium chloride, sodium trimethyldithiocarbamate and calcium polysulfide into deionized water and stir for 0.5 hours to obtain a mixed solution; then add polymerization Aluminum chloride was stirred for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com