Method for preparing calcium sulphide by decomposing phosphogypsum through hydrogen sulfide tail gas

A technology of tail gas decomposition and phosphogypsum, which is applied in the field of phosphogypsum resource utilization, to achieve the effects of reducing tail gas treatment, enhancing reducibility, and alleviating the shortage of sulfur resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

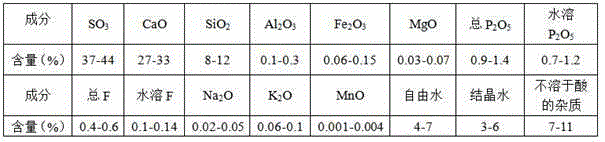

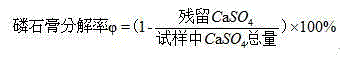

[0022] The method for preparing calcium sulfide by decomposing phosphogypsum with hydrogen sulfide tail gas described in this example uses CO and H 2 S tail gas is a reducing atmosphere; the percentage of CO in it is 99.9%, H 2 H in S exhaust gas 2 The percentage of S is 10%, the gas flow rate of CO is 8ml / min, and the gas flow rate of H 2 The gas flow rate of the S tail gas is 72ml / min; it specifically includes the following steps:

[0023] (1) Phosphogypsum is naturally air-dried, crushed, ground, and sieved to obtain phosphogypsum powder with a particle size of 100 mesh;

[0024] (2) Place the phosphogypsum powder in a tube furnace for reduction and decomposition, and introduce CO and H 2 The mixed gas of S tail gas is used as the reducing agent, the furnace temperature is controlled at 800°C, and the SO in the furnace gas is continuously detected online with a flue gas analyzer. 2 volume percentage, SO 2 The volume percentage is 5%-8%, until the reaction is complete (...

Embodiment 2

[0034] The method for preparing calcium sulfide by decomposing phosphogypsum with hydrogen sulfide tail gas described in this example uses CO and H 2 S tail gas is a reducing atmosphere; the percentage of CO in it is 99.9%, H 2 H in S exhaust gas 2 The percentage content of S is 15%,

[0035] Where the gas flow rate of CO is 9ml / min, H 2 The gas flow rate of the S tail gas is 81ml / min; it specifically includes the following steps:

[0036] (1) Phosphogypsum is naturally air-dried, crushed, ground, and sieved to obtain phosphogypsum powder with a particle size of 110 mesh;

[0037] (2) Place the phosphogypsum powder in a tube furnace for reduction and decomposition, and introduce CO and H 2 The mixed gas of S tail gas is used as the reducing agent, the furnace temperature is controlled at 900°C, and the SO in the furnace gas is continuously detected online with a flue gas analyzer. 2 volume percentage, SO 2 The volume percentage is 8%-10%, until the reaction is complete (...

Embodiment 3

[0047] The method for preparing calcium sulfide by decomposing phosphogypsum with hydrogen sulfide tail gas described in this example uses CO and H 2 S tail gas is a reducing atmosphere; the percentage of CO in it is 99.9%, H 2 H in S exhaust gas 2 The percentage content of S is 15%,

[0048] Where the gas flow rate of CO is 10ml / min, H 2 The gas flow rate of the S tail gas is 90ml / min; it specifically includes the following steps:

[0049] (1) Phosphogypsum is naturally air-dried, crushed, ground, and sieved to obtain phosphogypsum powder with a particle size of 120 mesh;

[0050] (2) Place the phosphogypsum powder in a tube furnace for reduction and decomposition, and introduce CO and H 2 The mixed gas of S tail gas is used as the reducing agent, the furnace temperature is controlled at 950°C, and the SO in the furnace gas is continuously detected online with a flue gas analyzer. 2 volume percentage, SO 2 The volume percentage is 9%-11%, until the reaction is complete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com