Method and technology for improving flotation effect by using polysulfide ion mixture

A polysulfide ion and mixture technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve problems such as low vulcanization efficiency and poor flotation effect, achieve high vulcanization efficiency, low price, and facilitate industrialization promotion Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

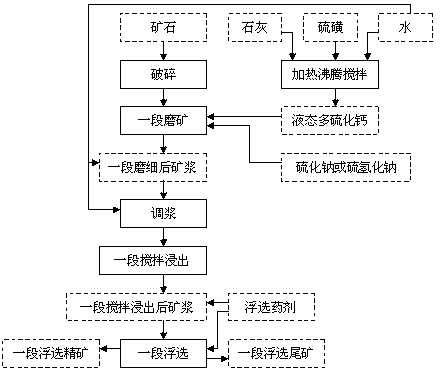

[0041] Example 1: The separation and smelting process of one-stage grinding + one-stage leaching + one-stage flotation using a polysulfide ion mixture as a vulcanizing agent

[0042] from figure 1 It can be seen that the present invention is a beneficiation and smelting process using a mixture of polysulfide ions as a vulcanizing agent. The ore is subjected to one-stage grinding + one-stage leaching + one-stage flotation. The specific process is: 1) adding polysulfide to the one-stage wet grinding process Sulfur ion mixture, to produce a stage of finely ground pulp; 2) Perform slurry adjustment and mechanical stirring and leaching on a stage of finely ground pulp to produce a stage of stirring and leaching pulp; 3) Add a flotation agent to a stage of stirring and leaching pulp The first stage of flotation produces a stage of flotation concentrate and a stage of flotation tailings; the first stage of flotation tailings is the ultimate tailings.

[0043] It can be seen that t...

Embodiment 2

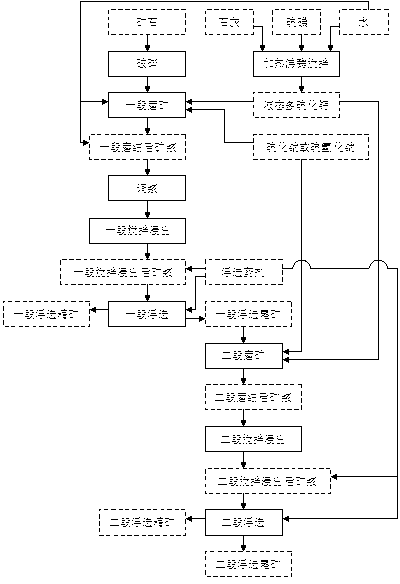

[0044] Embodiment 2: the beneficiation and smelting process of two-stage grinding + two-stage leaching + two-stage flotation using polysulfide ion mixture as vulcanizing agent

[0045] from figure 2 It can be seen that the present invention is a beneficiation and smelting process using a mixture of polysulfide ions as a vulcanizing agent. The ore is subjected to two-stage grinding + two-stage leaching + two-stage flotation. The specific process is: 1) in one-stage wet grinding Add polysulfide ion mixture in the process to produce one stage of finely ground pulp; 2) Perform slurry adjustment and mechanical and ultrasonic stirring leaching on one stage of finely ground pulp to produce one stage of stirring and leaching pulp; 3) For one stage of stirring and leaching pulp, Add flotation reagents for one-stage flotation, and produce one-stage flotation concentrate and one-stage flotation tailings; 4) Add polysulfide ion mixture to the first-stage flotation tailings, and perform...

Embodiment 3

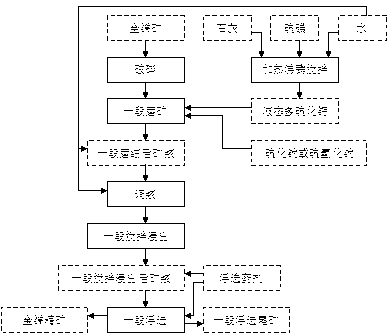

[0047] Embodiment 3: the beneficiation and smelting process of antimony-gold ore using polysulfide ion mixture as sulfidation agent

[0048] from image 3 It can be seen that the present invention is a beneficiation and smelting process of antimony-gold ore using a polysulfide ion mixture as a vulcanizing agent. The target mineral composition of the antimony-gold mine is: antimony grade 0.45%, gold grade 4 g / t; antimony minerals mainly include stibnite and antimony oxide ore; gold minerals are mainly elemental gold; the occurrence particle size of antimony minerals and gold minerals is -200 mesh accounts for 80%, and -325 mesh accounts for 20%.

[0049] The specific process and effect are as follows: add liquid calcium polysulfide (1000 g / ton) and sodium sulfide (2000 g / ton) in the first stage grinding process, and conduct a stage grinding of gold antimony ore according to the liquid-solid ratio of 1:3, and control the grinding process. The ore particle size -200 mesh acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com