Application of hydrogenation catalyst prevulcanization method in residue hydrotreating switchable reactor system

A technology of hydrogenation catalyst and reactor system, which is used in hydrocarbon oil cracking, petroleum industry, processing hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

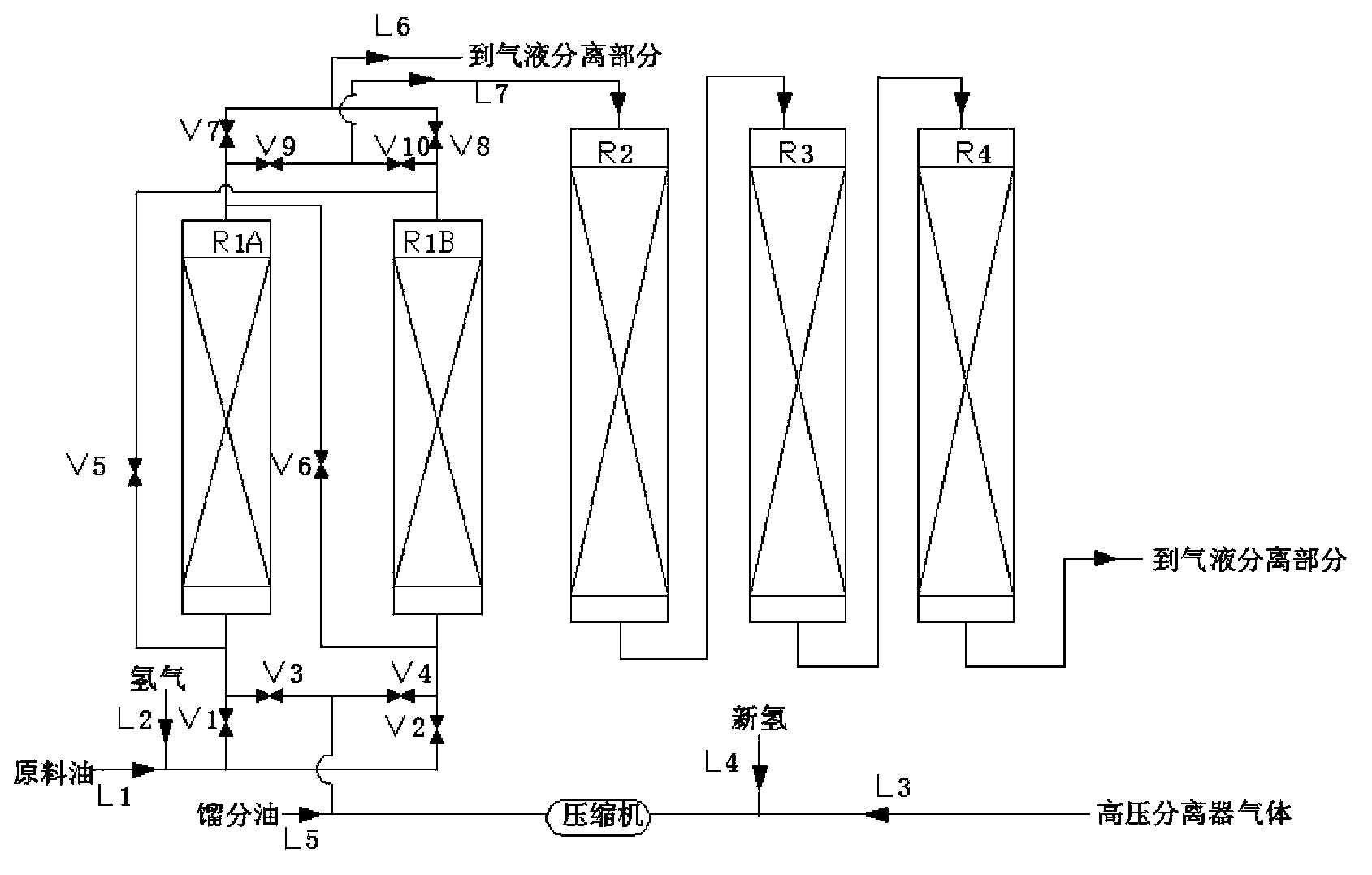

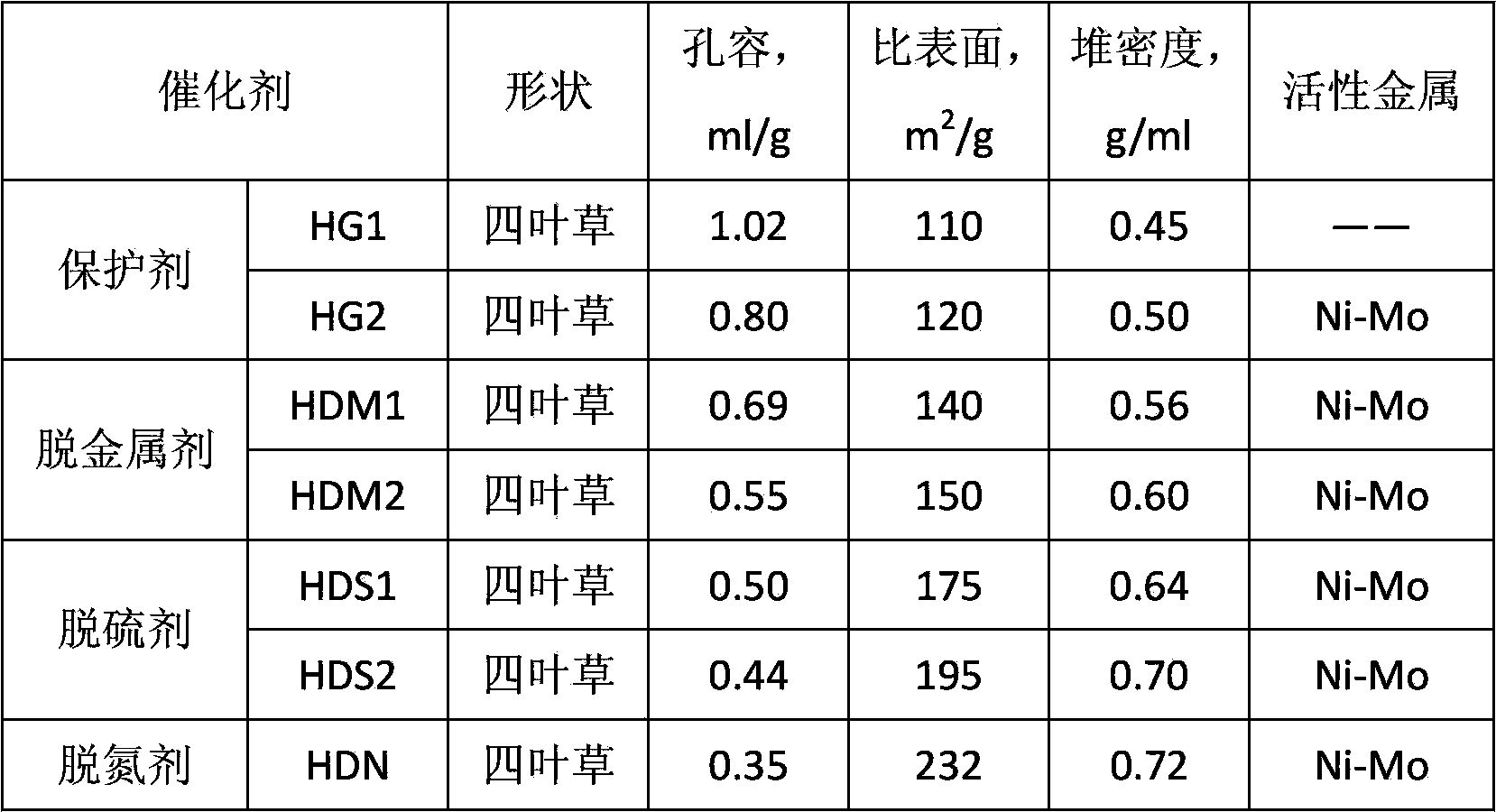

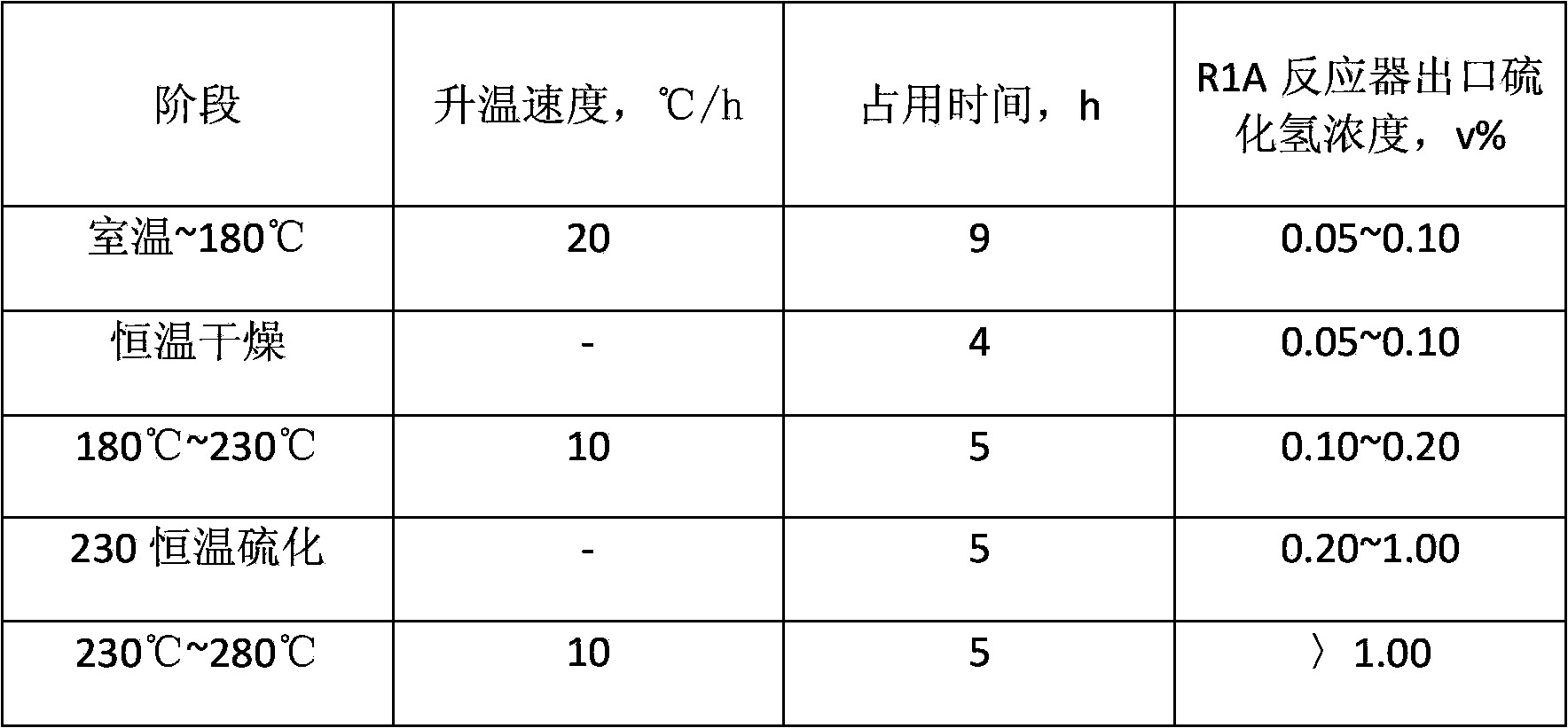

[0017] according to figure 1 In the flow chart in the middle, a set of test equipment is built in the laboratory. R1A and R1B are each filled with 100ml of protective catalyst and 100ml of demetallization catalyst, and R2, R3, and R4 are respectively filled with 200ml of desulfurization catalyst, high-activity desulfurization catalyst and denitrification catalyst. Table 1. The operating conditions of the device are pressure 18MPa, liquid space velocity 0.20h -1 , hydrogen oil ratio (v / v) 800. The purity of the new hydrogen is 99v%, and the raw material oil is sand light and slag-reduced. The properties of raw materials and product control indicators are shown in Table 2. The high-pressure separator gas comes from another set of hot high-pressure separator of the diesel plant in operation, and is washed with water before entering the switchable reactor for sulfidation.

[0018] Table 1 Catalyst properties

[0019]

[0020] Table 2 Properties of feedstock oil and indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com