Magnesium oxide and zinc oxide blended vulcanizing agent for neoprene vulcanization and preparation method thereof

A chloroprene rubber and magnesium oxide technology, applied in the field of vulcanizing agent for chloroprene rubber vulcanization, can solve the problems of reducing the influence of rubber scorch performance, increasing the risk of rubber scorching, reducing activity, etc., so as to improve dispersibility and reduce coke The effect of burning danger and high vulcanization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to a preparation method of a magnesium oxide zinc oxide compound vulcanizing agent for chloroprene rubber vulcanization, the method comprising the following steps:

[0033] a. Take active zinc oxide and active magnesium oxide and mix, and mark it as substance A; pour the dispersant into 30ml of absolute ethanol solution and stir, and mark it as substance B after completely dissolving;

[0034] b. Put substance A in a high-shear emulsifier, and disperse it evenly at a speed of 2000-3000r / min, so that zinc oxide adheres to the surface of magnesium oxide; evenly spray substance B on the magnesium oxide zinc oxide in a state of high-speed stirring and mixing In the solid powder, the dispersant can be uniformly coated on the surface of the solid powder to form a coating film, and dispersed for 10-30 minutes to obtain a composite of magnesium oxide and zinc oxide;

[0035] c. Put the compound system obtained in step b in a constant temperature stirrer,...

Embodiment 2

[0037] Each of the following examples relates to the magnesium oxide zinc oxide compound vulcanizing agent used for chloroprene rubber vulcanization, which all adopts the preparation method of Example 1, and the difference lies in the consumption of each raw material composition, as shown in the following table:

[0038]

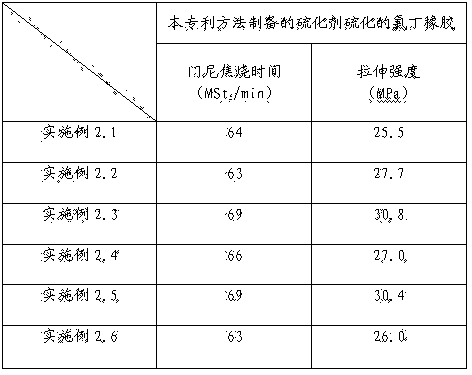

[0039]The compound vulcanizing agent obtained in the above examples was used to vulcanize neoprene rubber, and the performance evaluation of the vulcanized neoprene rubber was carried out. The Mooney scorch time was measured by a Mooney viscometer, and the tensile strength was tested according to the national standard GB / T528-1998. The results are shown in the table below.

[0040]

[0041] The chloroprene rubber is vulcanized with the superior product of the traditional powder vulcanizing agent, and the obtained chloroprene rubber has a Mooney scorch time of 30-60MSt 5 / min, the tensile strength is ≥24.0MPa. The results of each embodiment shown in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com