Production technology for chloroprene rubber

A neoprene raw rubber, production process technology, applied in the field of rubber, can solve the problems of low Mooney viscosity of neoprene products, not suitable for automatic production, poor process stability, etc., to reduce scorching phenomenon, improve vulcanization efficiency and Good quality, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Baking: select the raw neoprene rubber and put it into the bake machine for bake, control the bake temperature to 45℃, and control the bake time to 4h;

[0020] (2) Plasticizing: Weigh 25kg of the rubber compound after drying in step (1) and put it in the open mill, control the plasticizing temperature to 55℃, and control the plasticizing time to 7min;

[0021] (3) Mixing: Add the raw rubber produced in step (2) to the internal mixer, mix for a short time for 4 minutes, and quickly discharge the rubber. After parking for 3 minutes, perform two-stage mixing and control the mixer rotor Rotation speed is 75r / min, add zinc oxide and Na-22 on the open mill, then discharge the next piece, control the discharge temperature to 40℃;

[0022] (4) Semi-finished product cutting: After cooling the film produced in step (3) to room temperature, sprinkle zinc stearate on the surface of the film, and then cut it;

[0023] (5) Vulcanization: Put the film prepared in step (4) into a drum vul...

Embodiment 2

[0024] Example 2: The rest is the same as Example 1, but the difference is that in the step (1), the glue baking temperature is controlled to 48°C, and the glue baking time is controlled to 5h; in the step (2), the plasticizing temperature is controlled to 58°C, Control the plasticizing time to 8min; in the step (3), control the speed of the mixer rotor to 78r / min, and control the discharge temperature to 45°C; in the step (3), control the vulcanization temperature to 170°C, and control The curing time is 6min.

Embodiment 3

[0025] Example 3: The rest is the same as Example 1, except that in the step (1), the temperature of the glue is controlled to be 50°C, and the time of the glue is controlled to be 5h; in the step (2), the temperature of the plasticizing is controlled to 60°C , Control the plasticizing time to 9min; in the step (3), control the mixer rotor speed to 80r / min, and control the discharge temperature to 50°C; in the step (3), control the vulcanization temperature to 175°C, Control the curing time to 7min.

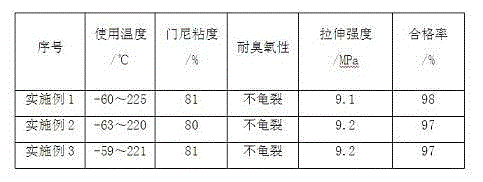

[0026] After the above process steps, take out the ethylene propylene rubber sample for testing:

[0027]

[0028] It can be seen from the above data that the produced chloroprene rubber has a wide temperature range, high Mooney viscosity, low viscosity, good ozone resistance, no cracking, high tensile strength, all above 9.0MPa, this process produces The product has a high qualification rate and good process stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com