Patents

Literature

106results about How to "High Mooney viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

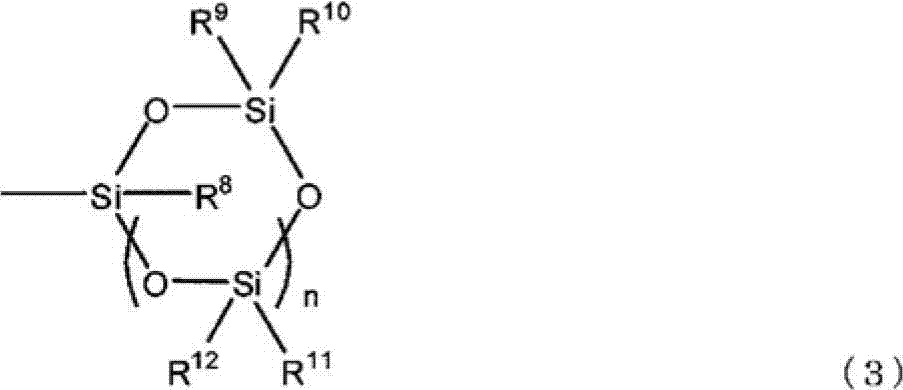

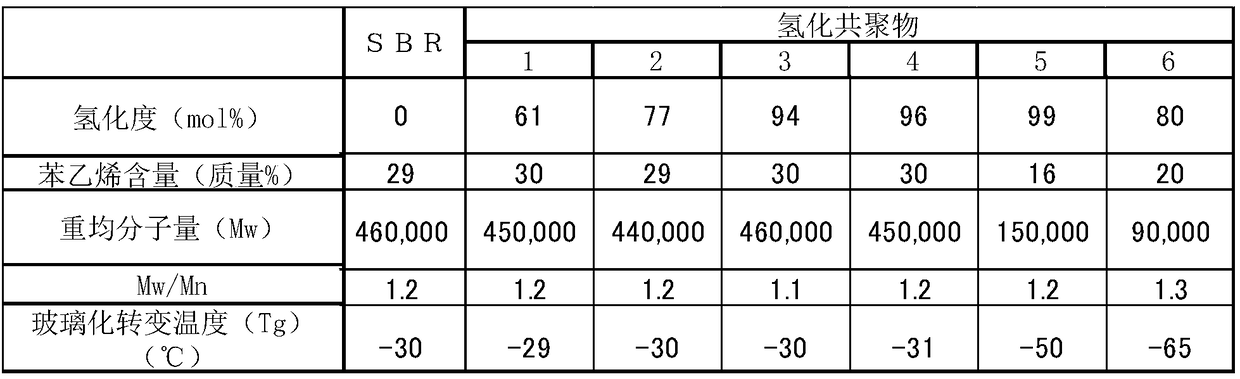

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

InactiveCN1578790ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

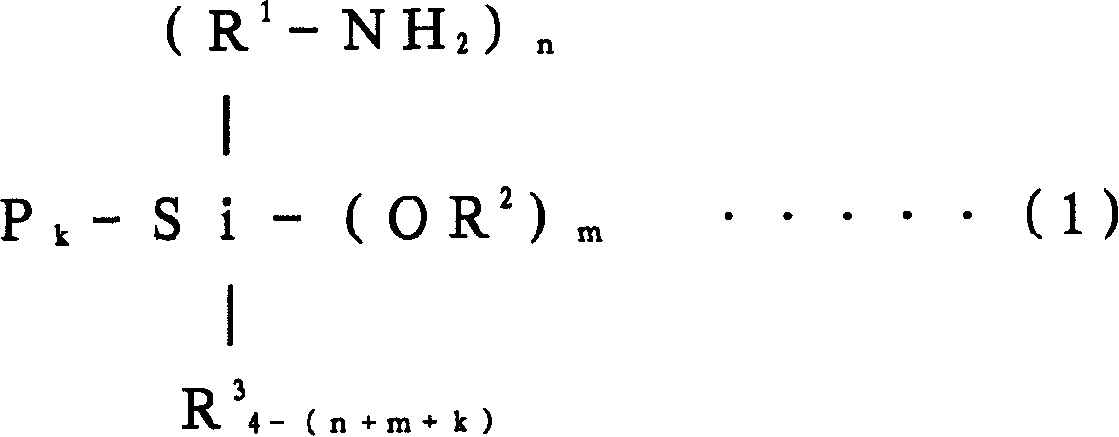

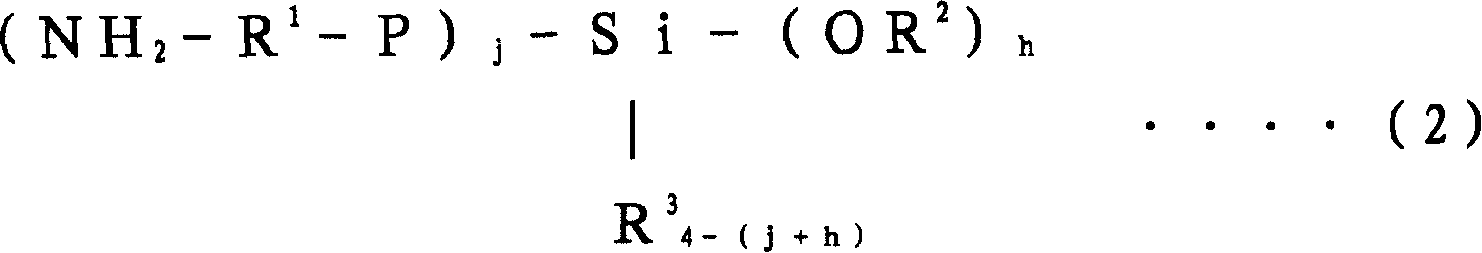

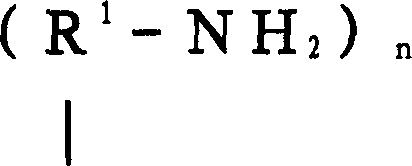

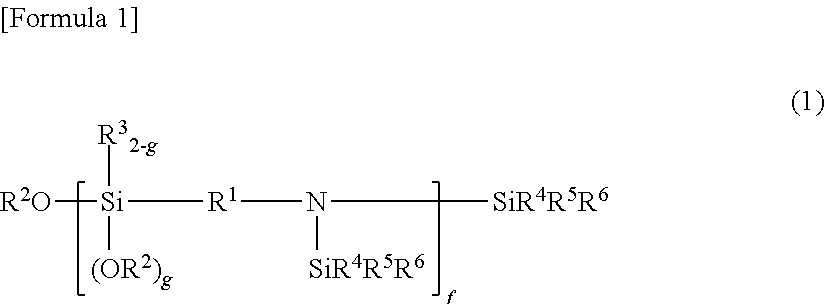

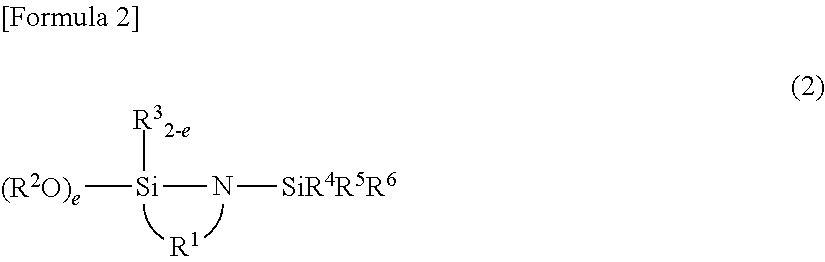

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

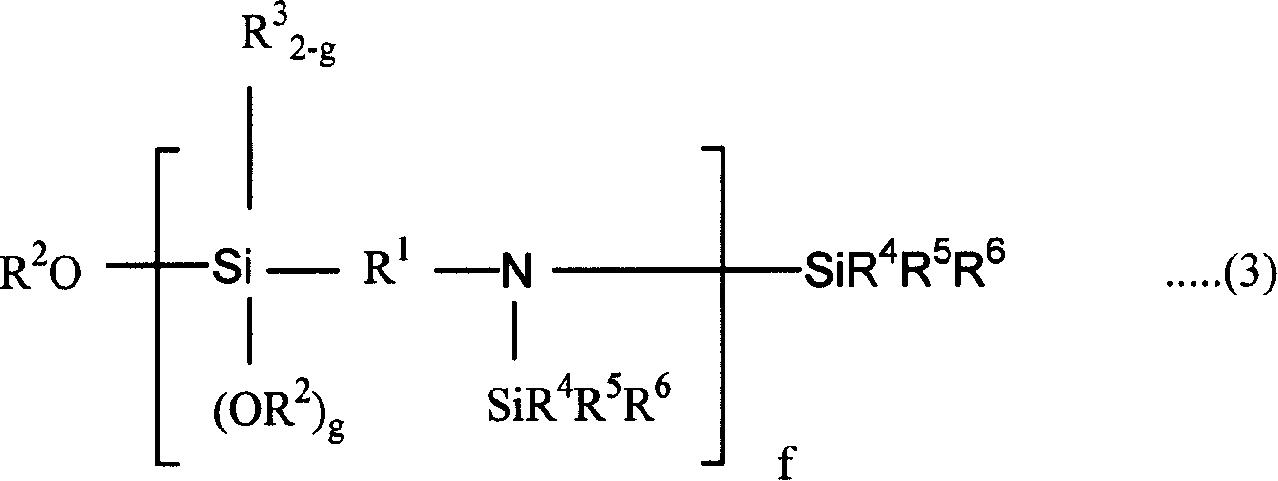

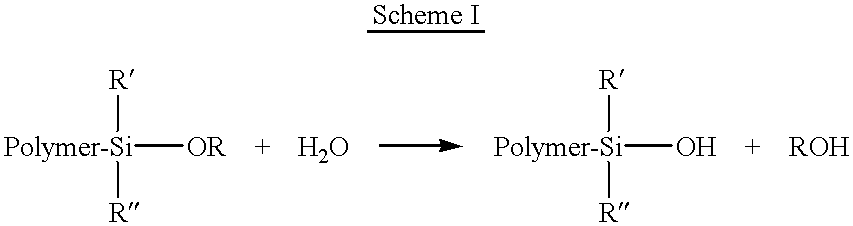

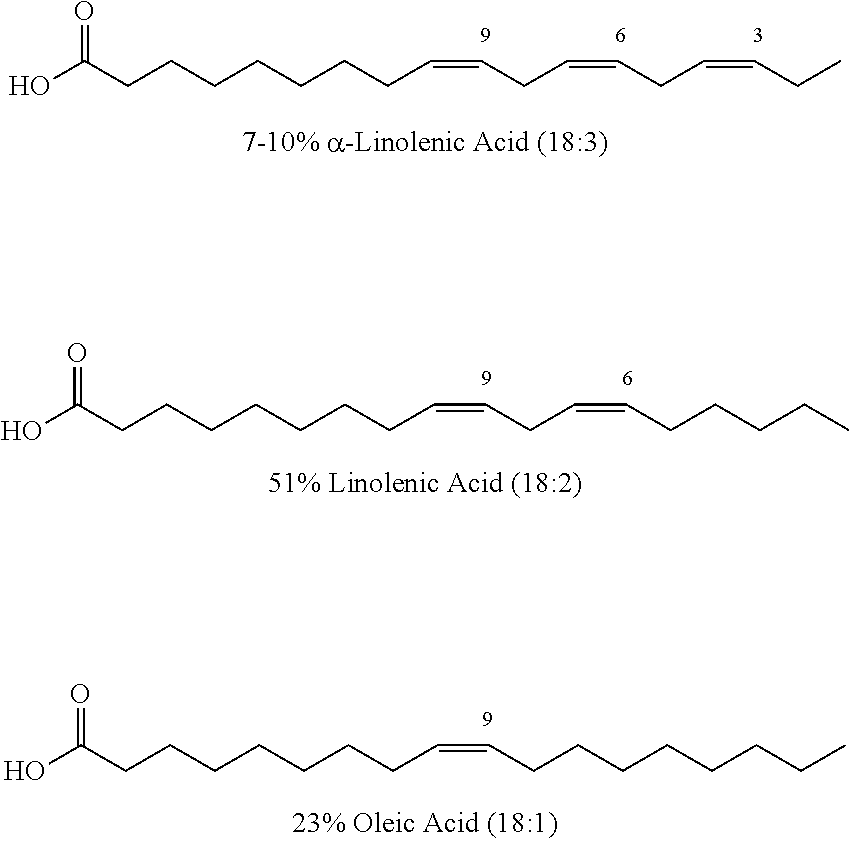

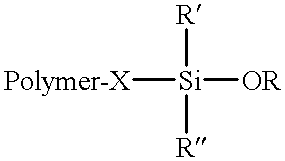

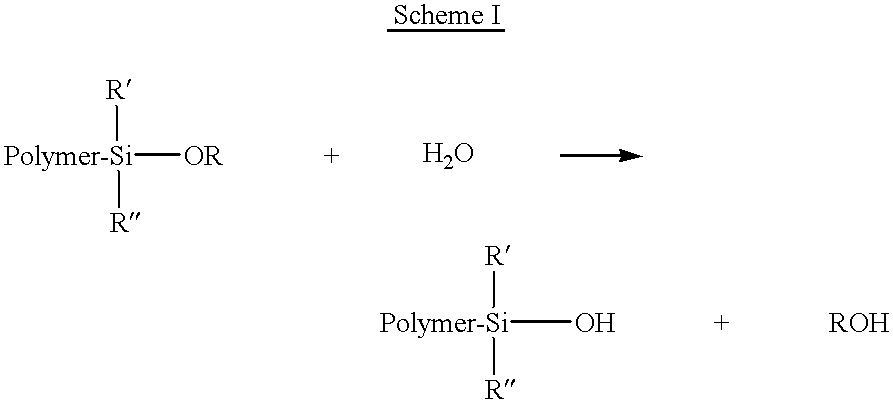

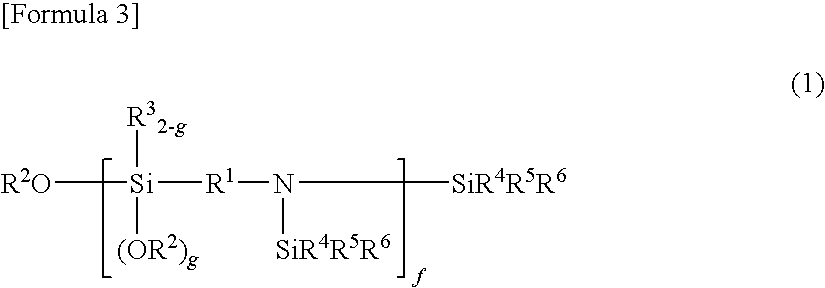

Method to control increase in viscosity during aging of siloxane modified polymers

A method for controlling any increase in Mooney viscosity during aging of siloxane-functionalized polymers includes the step of adding a viscosity stabilizing effective amount of a viscosity stabilizing agent selected from the group consisting of alkyl alkoxysilanes of the structural formulawherein R1 is selected from the group consisting of C1 to C20 alkyl, C4 to C10 cycloalkyl, or C5 to C20 aromatic groups, wherein R2 may be the same as or different from R1 and is selected from the group consisting of C1 to C20 alkyl, C4 to C10 cycloalkyl, or C5 to C20 aromatic groups, and wherein n is an integer from 1 to 3. The method provides for the stabilization of Mooney viscosity of siloxane-functionalized polymers at any given level upon aging. The viscosity stabilizing agents react with the siloxane-functionalized polymers during hydrolysis of the siloxane end groups to form moisture stabilized polymers.

Owner:BRIDGESTONE CORP

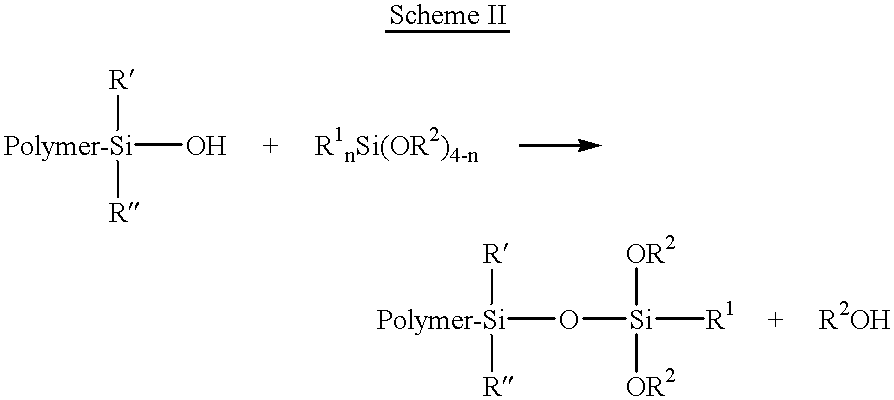

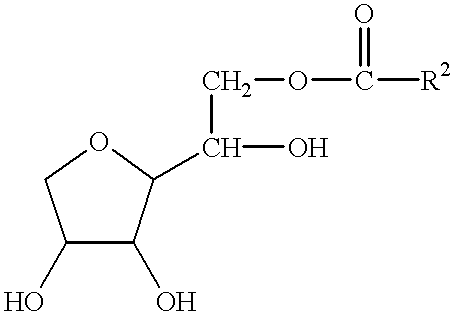

Triglyceride containing solution polymerization prepared styrene/butadiene elastomer and tire with component

InactiveUS20130289183A1High Mooney viscosityHigh molecular weightSpecial tyresInksElastomerTriglyceride

This invention relates to vegetable oil extended rubber containing soy oil and tire with a component of such oil extended rubber.

Owner:KERNS MICHAEL LESTER +3

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

InactiveCN1789293ALow hysteresis lossLow abrasion resistanceSpecial tyresRolling resistance optimizationPolymer scienceAlkoxy group

Disclosed are a conjugated diolefin (co)polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co)polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:JSR CORPORATIOON

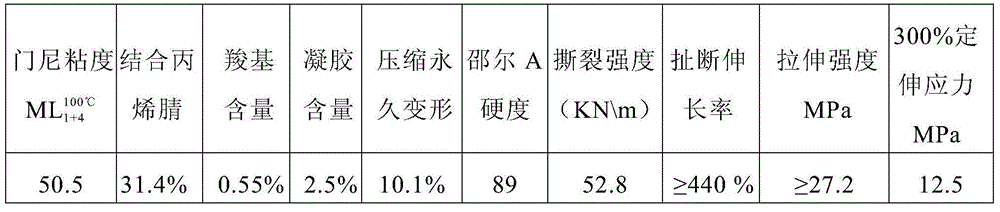

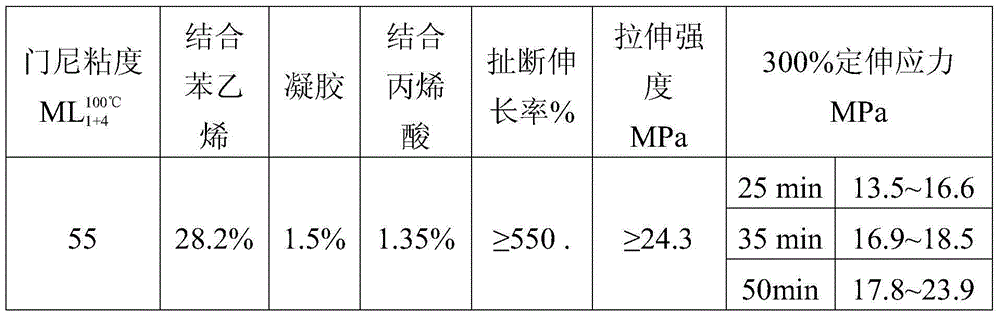

Preparation method of carboxyl nitrile rubber through emulsion polymerization

The invention relates to a preparation method of carboxyl nitrile rubber through emulsion polymerization. According to the preparation method, acrylonitrile, an emulsifier, an adjusting agent, and an initiator are added into a polymerization kettle, then butadiene is added, emulsion polymerization is carried out under stirring, and in the late phase of emulsion polymerization, unsaturated carboxylic acid and / or anhydride thereof is added into the polymerization kettle. The obtained carboxyl nitrile rubber has a low content of gel and a two-layer molecular structure, the index of conjugated acid is controllable; during the processing process, a three-dimensional network structure can be easily formed, thus the mechanical and physical properties of rubber products made of the carboxyl nitrile rubber are good; after processing, the Mooney viscosity is increased, the crosslinking degree of finished products is good, and especially, the elongation at break is prominently improved.

Owner:PETROCHINA CO LTD

Semi-steel wire radial tire undertread calendering sizing compound

The invention relates to calendering belt compound in a semi-steel wire radial tyre. The main points are as follows: the belt glue stuff is prepared from various materials which comprise natural rubber (code: SMR20), carbon black N326, carbon black N660, white carbon black, a silane coupling agent, zinc oxide, an antioxidant 4020, an antioxidant RD, resorcinol-80, a binding agent RA-65, an accelerator DZ, insoluble sulfur IS-7020 and a scorch retarder CTP.

Owner:SICHUAN TYRE & RUBBER CO LTD

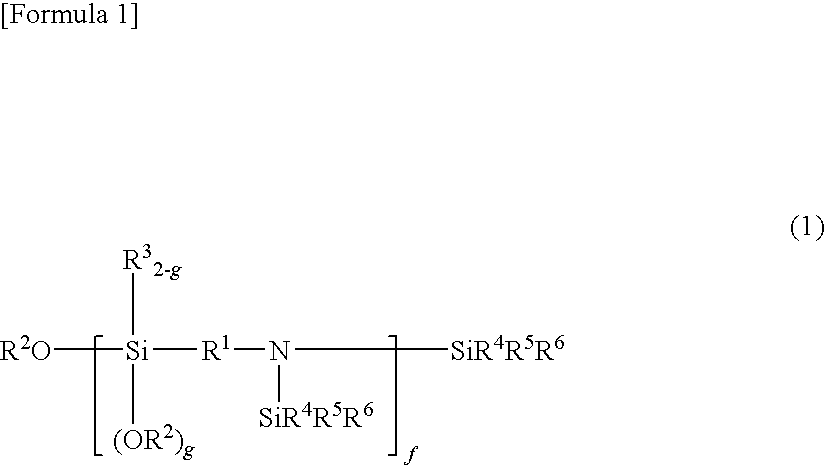

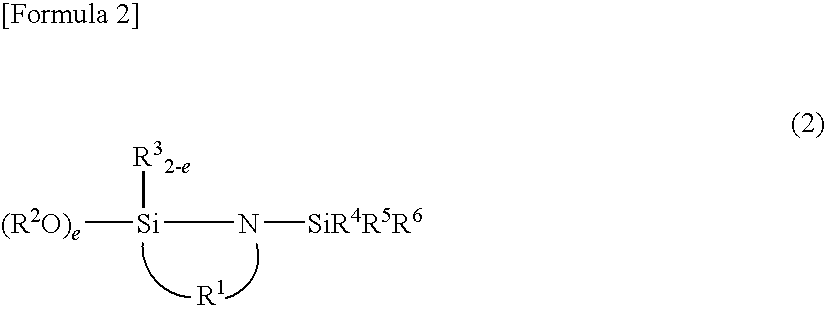

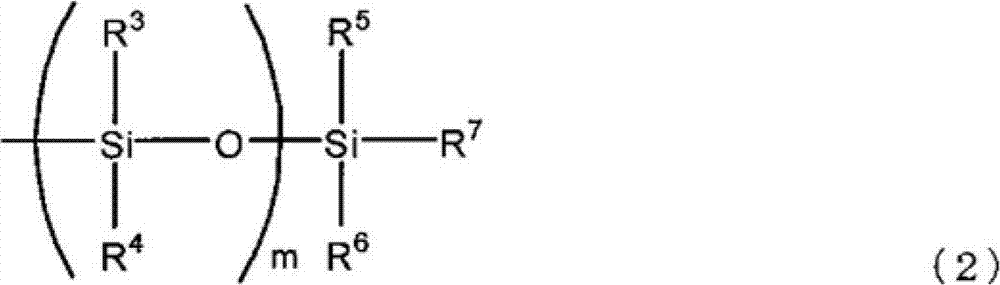

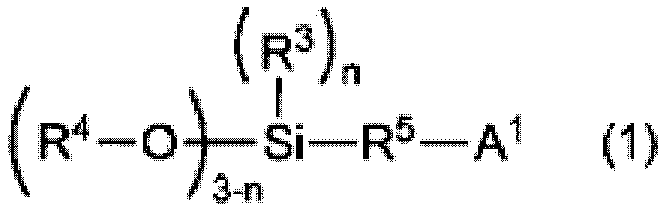

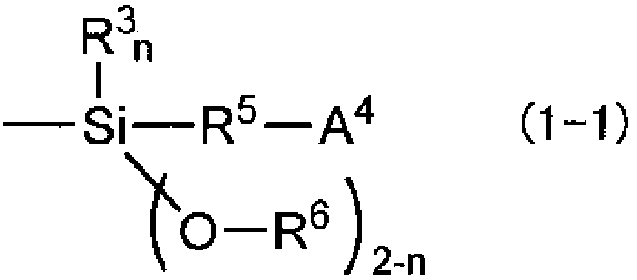

Method for producing modified conjugated diene based (CO)polymer, modified conjugated diene based (CO)polymer, and rubber composition

The method for producing a modified conjugated diene based (co)polymer, according to the present invention comprises(a) obtaining a primarily modified polymer by carrying out a primary modification reaction wherein at least one member selected from the group consisting of an alkoxysilane compound and a silanol compound is introduced into the active alkali metal terminal of a conjugated diene based (co)polymer having an active alkali metal terminal, and(b) obtaining a secondarily modified polymer (a modified conjugated diene based (co)polymer) by subjecting the above-obtained primarily modified polymer to reactions comprising (b1) and (b2).(b1): a reaction with a condensation accelerator comprising a metal element.(b2): a reaction with at least one member selected from the group consisting of inorganic acids and metal halides.

Owner:ENEOS MATERIALS CORP +1

Method to control increase in viscosity during aging of siloxane modified polymers

InactiveUS6279632B1Reduce rateReduce hydrolysis rateSilicon organic compoundsSpecial tyresEnd-groupMooney viscosity

A method for controlling any increase in Mooney viscosity during aging of siloxane-functionalized polymers includes the step of adding a viscosity stabilizing effective amount of a long chain alcohol preferably selected from the group consisting of aliphatic, cycloaliphatic, and aromatic alcohols having more carbon atoms than the hydrolyzable substituent on the siloxane end groups. The method provides for the stabilization of Mooney viscosity of siloxane-functionalized polymers at any given level upon aging. The long chain alcohols react with the siloxane-functionalized polymers prior to hydrolysis of the siloxane end groups to form moisture stabilized polymers.

Owner:BRIDGESTONE CORP

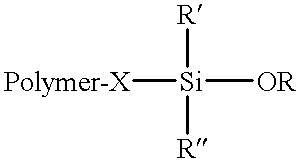

Method of grafting and modifying rubber latex containing poly conjugated dialkene by in situ hybridization of silicon

ActiveCN102020752AAvoid the phenomenon that the interface is not tightly bondedTightly boundAlkaneTO-18

A method of grafting and modifying rubber latex containing poly conjugated dialkene by in situ hybridization of silicon includes the following steps taking 100 parts by mass of rubber latex containing poly conjugated dialkene, adding from 4 to 25 parts of organic siloxane monomers with unsaturated bond into the rubber latex containing poly conjugated dialkene, stirring sufficiently to obtain uniform mixture, adding from 0.20 to 0.36 parts of initiators with stirring at the temperature of 5-85 DEG C for carrying out graft polymerization reaction for 5 to 8 hours, and agglomerating and drying the grafted and modified rubber latex. The structure formula of organo-sillicone monomers with unsaturated bond is Y-Si(R1R2R3), wherein Y- is unsaturated aliphatic chain segment with 2 to 18 carbons, R1- is alkoxy with 1 to 12 carbons, aryloxya with 6 to 12 carbons or silicide with 3 to 12 carbons, and R2 and R3 are the same groups as R1 or can also be saturated chain segment with 1 to 20 carbons or annular alkane or aromatic hydrocarbon with 1 to 8 carbons.

Owner:PETROCHINA CO LTD

Method of preparing carboxyl styrene butadiene rubber through emulsion polymerization

The invention relates to a method of preparing carboxyl styrene butadiene rubber through emulsion polymerization. According to the method, styrene, an emulsifier, a conditioning agent, and an initiator are added into a polymerization kettle, then butadiene is added to carry out emulsion polymerization under stirring, and in the later period of reactions, unsaturated carboxylic acid and / or unsaturated carboxylic anhydride are added into the polymerization kettle. The prepared carboxyl styrene butadiene rubber has a low gel content, a controllable combined acid index, and a dual layer molecular structure; during the processing process, a three dimensional net-like structure can be formed easily; the mechanical and physical properties of rubber product are good, after processing, Mooney viscosity is increased, the crosslinking degree of finished product is good, and especially, the elongation at break is obviously improved.

Owner:PETROCHINA CO LTD

Method for producing modified conjugated diene based (CO)polymer, modified conjugated diene based (CO)polymer, and rubber composition

The method for producing a modified conjugated diene based (co)polymer, according to the present invention comprises a step of reacting a conjugated diene based (co)polymer with a metal halide compound to obtain a modified conjugated diene based (co)polymer, the conjugated diene based (co)polymer having a weight-average molecular weight of 150,000 to 2,000,000 and being obtained by bonding, to a polymer having at least a conjugated diene unit, an alkoxysilyl group and an optionally protected primary amino group. The method can satisfactorily produce a conjugated diene based (co)polymer which has a high Mooney viscosity, excellent shape stability and good processability.

Owner:ENEOS MATERIALS CORP

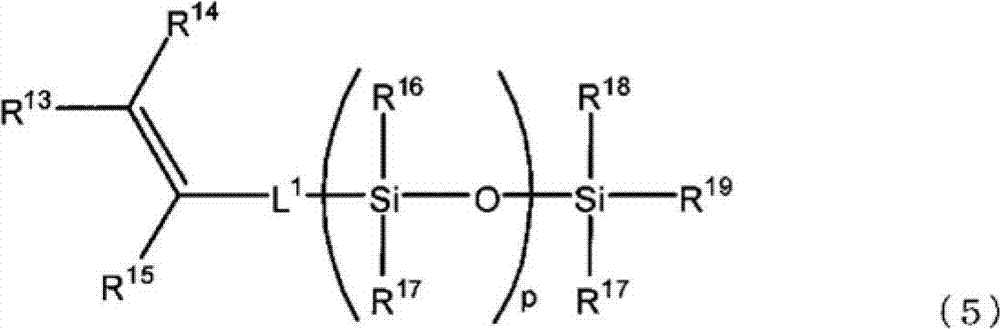

Ring-opening polymer of cyclopentene and method for producing same

Provided is a ring-opening polymer of cyclopentene which is characterized by having a cis ratio of the cyclopentene-origin structural units of 30% or greater and a weight-average molecular weight (Mw) of 100,000-1,000,000 and carrying an oxysilyl group at an end of the polymer chain. The ring-opening polymer of cyclopentene can be produced by ring-opening polymerizing cyclopentene in the presence of, for example, a compound of a transition metal belonging to group 6 in the periodic table, an organoaluminum compound represented by general formula (1) and an oxysilyl group-containing olefinic unsaturated hydrocarbon. (R1)3-xAl(OR2)x (1)In general formula (1), R1 and R2 represent a C1-20 hydrocarbon group; and x satisfies the requirement 0<x<3.

Owner:ZEON CORP

Tetrafluoroethylene-propylene fluorine-containing elastic body and preparing method thereof

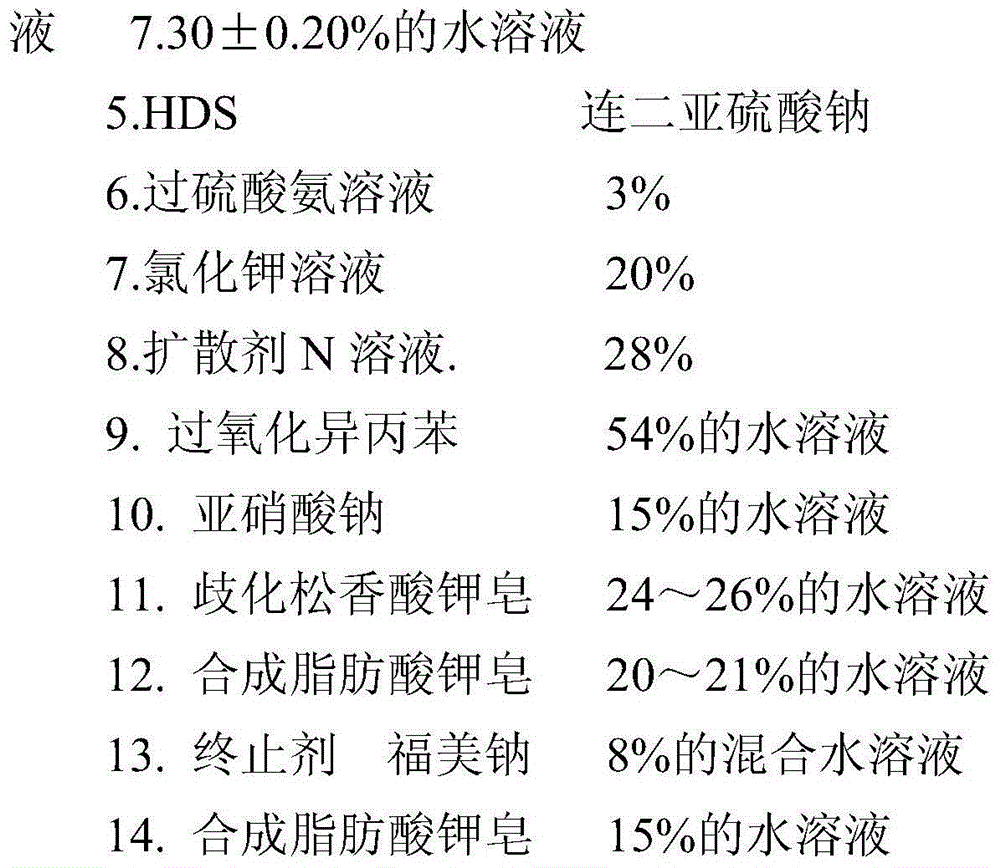

An tetrafluoroethylene-propylene fluorine-containing elastomer and its preparation method includes: (1) providing an aqueous dispersions of comonomer, which includes: (a) tetrafluoroethylene, propylene and one or more kind of other comonomers, (b) oxidation-reduction system, which includes: water-soluble inorganic peroxide initiator, water-soluble iron salt reductant, coordination agent, water-soluble inorganic aid reducer, (c) water-soluble metal hydroxide pH modifier, and (d) emulsifier. Its characteristic is (2) under the polymerization temperature of 10~50deg.C and polymerization pressure of 3.1~8MPa, the monomers take polymerization.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

Emulsion polymerization method for preparing tractable butadiene styrene rubber

The invention relates to an emulsion polymerization method for preparing a tractable butadiene styrene rubber. The polymerization method comprises at least the following steps: adding part of styrene (an oil phase) and part of an emulsifier (an aqueous phase), a regulator and an initiator into a polymerization kettle; adding butadiene; carrying out emulsion polymerization with stirring; and when conversion rate of the polymerization reaction in the middle stage reaches 30-60%, refilling the emulsifier, the crosslinking agent, styrene and the regulator by one or more times. The styrene butadiene rubber prepared by the method provided by the invention has high micro gel content and low gel content; coupled with the electron cloud effect of the pi bonds in the benzene ring of the molecular chain, a three-dimensional net shape structure is easy to form in the processing process; and the rubber product has good physical and mechanical properties, increased Mooney viscosity, and correspondingly increased tensile strength and 300% stretching strength.

Owner:PETROCHINA CO LTD

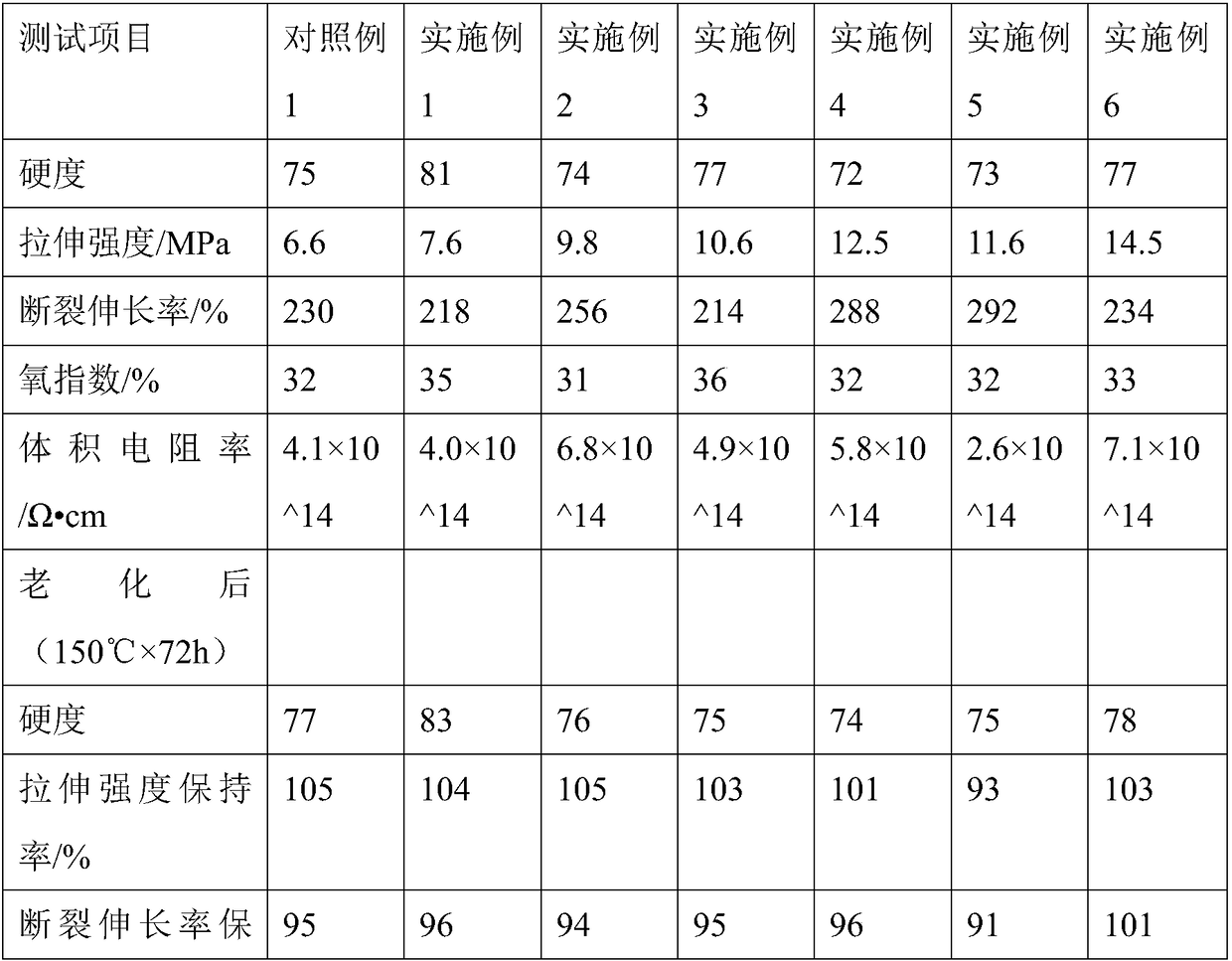

Rubber composition, processing method, application and method for producing flame-retardant products

ActiveCN108299743AReduced mechanical propertiesReduced processing performanceCold airPolymer science

The invention discloses rubber composition, a processing method thereof and an application of the composition to processing of flame-retardant products. The rubber composition is prepared from a rubber matrix and essential components, wherein the rubber matrix contains a parts of branched polyethylene and b parts of EPM rubber and EPDM rubber, a is larger than 0 and smaller than or equal to 100 parts, and b is larger than or equal to 0 and smaller than 100 parts; the essential components comprise 1.5-10 parts of a crosslinking agent and 40-300 parts of a flame retardant. The rubber compositionapplies to production of flame-retardant products such as flame-retardant cables, flame-retardant cold air hoses of automobiles, flame-retardant sealing strips, high-temperature-resistant flame-retardant conveyor belts, flame-retardant waterproof rolls and the like, and the flame-retardant products have good flame retardance and mechanical properties.

Owner:HANGZHOU XINGLU TECH CO LTD +1

Pneumatic tire

The present invention provides a pneumatic tire that achieves a balanced improvement in fuel economy, abrasion resistance, and processability. A pneumatic tire formed from a rubber composition, the rubber composition containing a rubber component including a hydrogenated copolymer and a general purpose rubber, the hydrogenated copolymer containing a structural unit derived from an aromatic vinyl compound and a structural unit derived from a conjugated diene compound, the hydrogenated copolymer having a degree of hydrogenation of the conjugated diene portion of 30 to 100 mol %, a weight averagemolecular weight of 50,000 to 2,000,000, and a styrene content of 5% to 50% by mass, the general purpose rubber being at least one selected from the group consisting of natural rubber, polyisoprene rubber, styrene-butadiene rubber, and polybutadiene rubber, the rubber component including, based on 100% by mass thereof, 10% to 80% by mass of the hydrogenated copolymer.

Owner:SUMITOMO RUBBER IND LTD

Method of controlling halogen substitution site in halogenated butyl rubber

The invention discloses a method of controlling a halogen substitution site in halogenated butyl rubber, belonging to the technical field of chemistry and chemical engineering. The method comprises the following steps of: firstly, adding a certain amount of water into alkane liquor of butyl rubber, uniformly mixing to form emulsion; then, mixing the emulsion with a halogen to carry out halogenation reaction, in-situ extracting and halogenating haloid acid generated in the halogenation reaction process by utilizing water in the system to achieve the effect of lowering acid concentration in an organic phase to inhibit halogen substitution site transformation (transforming a secondary site into a primary site); and finally, ending the reaction process by using alkaline liquor to neutralize reaction liquid. The process is characterized in that a substitution site transformation phenomenon is effectively inhibited by introducing an appropriate amount of water (mass fraction of water being controlled to 0.5%-5.0%) into the reaction liquid, primary-site halogen mole fraction in a product is greater than 98%, halogenation degree (halogen mass fraction) can be regulated and controlled, degree of unsaturation and Mooney viscosity indexes are excellent, and conditions are provided for producing high-quality halogenated butyl rubber.

Owner:TSINGHUA UNIV

Method for producing modified conjugated diene based (CO)polymer, modified conjugated diene based (CO)polymer, and rubber composition

ActiveUS20120108737A1High Mooney viscosityImproved shape stabilitySpecial tyresPolymer scienceMooney viscosity

The method for producing a modified conjugated diene based (co)polymer, according to the present invention comprises a step of reacting a conjugated diene based (co)polymer with a metal halide compound to obtain a modified conjugated diene based (co)polymer, the conjugated diene based (co)polymer having a weight-average molecular weight of 150,000 to 2,000,000 and being obtained by bonding, to a polymer having at least a conjugated diene unit, an alkoxysilyl group and an optionally protected primary amino group. The method can satisfactorily produce a conjugated diene based (co)polymer which has a high Mooney viscosity, excellent shape stability and good processability.

Owner:ENEOS MATERIALS CORP

Thermoplastic olefin compositions and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2–C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2–C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2–C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2–C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Tire inner liner rubber, application serving as tire inner liner rubber and preparation method of tire inner liner rubber

InactiveCN109517284AReduced ozone resistanceExcellent ozone resistanceSpecial tyresChlorinated polyethyleneButyl rubber

The invention discloses tire inner liner rubber, application serving as tire inner liner rubber and a preparation method of the tire inner liner rubber. The tire inner liner rubber comprises the following raw materials in relative parts by weight: 30-40 parts of natural rubber, 65-75 parts of brominated butyl rubber, 20-30 parts of butyl reclaimed rubber, 5-20 parts of chlorinated polyethylene composite rubber, 2-5 parts of a dispersing agent, 3-5 parts of a tackifier, 0.2-0.5 part of magnesium oxide, 5-10 parts of a homogenizing agent, 10-15 parts of a softening agent, 60-70 parts of a filling agent, 20-30 parts of an air stopper, 0.5-1 part of a vulcanizing agent, 1-1.5 parts of an accelerant and 3-5 parts of an activating agent. The tire inner liner rubber disclosed by the invention canreplace brominated butyl rubber, the performance is improved, and the cost is greatly reduced.

Owner:SHANDONG RIKE CHEM

Elastomer blend and use in tires

InactiveUS6166140AImprove propertiesAdvantageously producedConfectioneryPress rollersElastomerPolymer science

High viscosity elastomers are often difficult to utilize in rubber compositions without first creating a pre-blend of the high viscosity elastomer and a rubber processing oil to reduce their overall viscosity. This invention relates to utilization of a specialized pre-blend of high viscosity and low viscosity elastomers for use in rubber compositions and to the resulting rubber composition. The use of such resulting rubber composition may be for component(s) of tires, particularly including tire treads. The specialized pre-blend of high and low viscosity elastomers is required to be created by blending individual latices or, alternatively, by blending individual polymerizates of elastomers with diverse viscosities.

Owner:THE GOODYEAR TIRE & RUBBER CO

Elastomer blend and use in tires

High viscosity elastomers are often difficult to utilize in rubber compositions without first creating a pre-blend of the high viscosity elastomer and a rubber processing oil to reduce their overall viscosity. This invention relates to utilization of a specialized pre-blend of high viscosity and low viscosity elastomers for use in rubber compositions and to the resulting rubber composition. The use of such resulting rubber composition may be for component(s) of tires, particularly including tire treads. The specialized pre-blend of high and low viscosity elastomers is required to be created by blending individual latices or, alternatively, by blending individual polymerizates of elastomers with diverse viscosities.

Owner:THE GOODYEAR TIRE & RUBBER CO

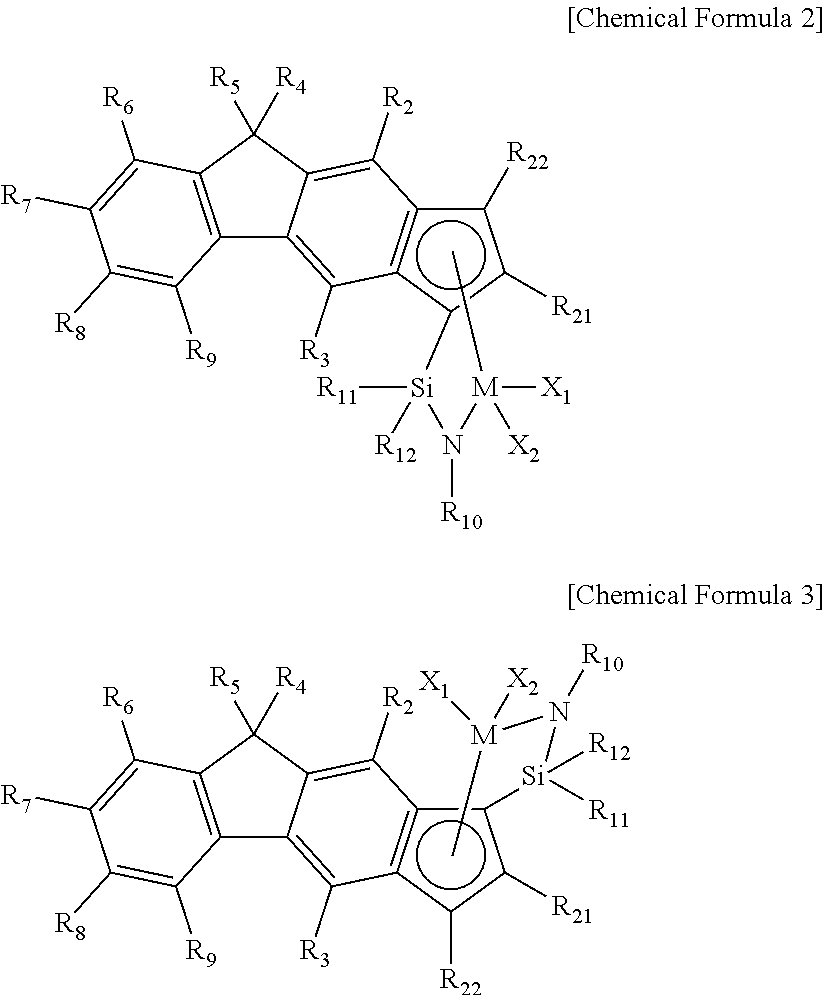

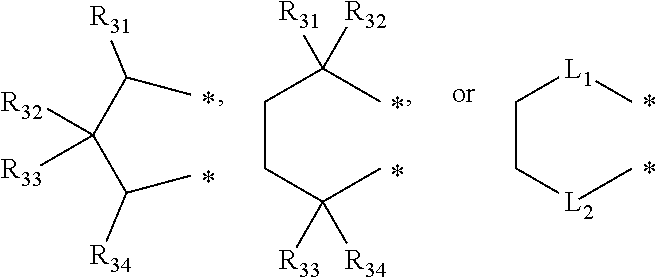

Method of Preparing Ethylene-alpha-Olefin-Diene Copolymer

ActiveUS20140179885A1Improve thermal stabilityHigh catalytic activityTitanium organic compoundsMetallocenesPolymer sciencePtru catalyst

Owner:SK GEO CENTRIC CO LTD +1

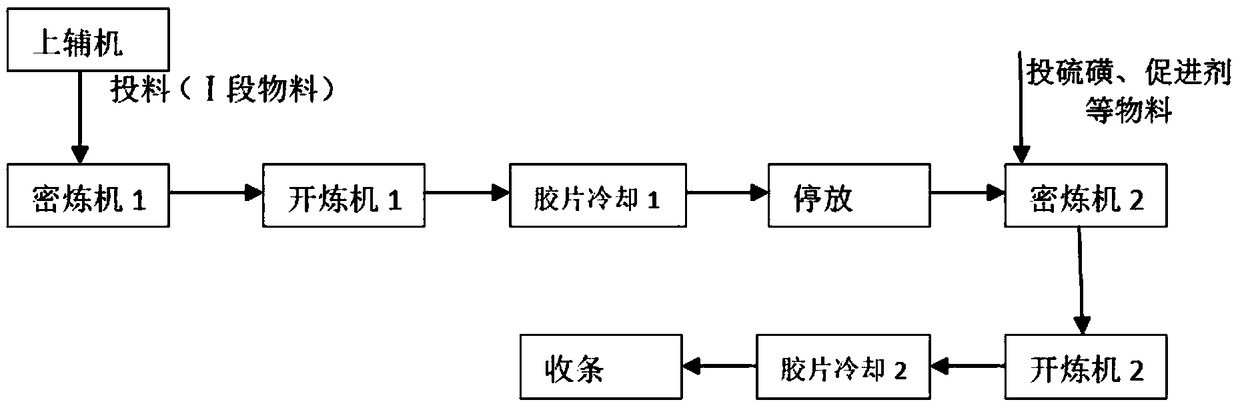

Production technology for chloroprene rubber

Relating to the rubber field, the invention discloses a production technology for chloroprene rubber. The technology comprises the processes of: rubber drying, plastication, mixing, semi-finished product cutting and vulcanization. According to the method, by strictly controlling the rubber drying temperature and time in the rubber drying process, the quality of the dried rubber material is improved. The mixing process adopts a two-stage mixing process, well controls the mixing time and discharge temperature, so that scorching phenomenon of chloroprene rubber is significantly reduced, and the rubber guiding, discharge and batch-out of an open mill are smooth, and no roll sticking phenomenon appears. The vulcanization process adopts N-tert-butyl-2-bisbenzothiazole sulfenamide as a vulcanization accelerator, which is safe and pollution-free and has no harm to the human body. The technological process adopts a drum type vulcanizing machine, the vulcanization efficiency and quality are greatly improved, and the produced product has high Mooney viscosity and good quality. The technological method has the advantages of good technology, simple operation, and good technological stability, thus being suitable for factory automation production.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

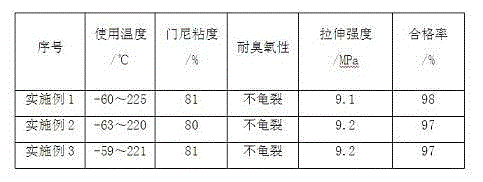

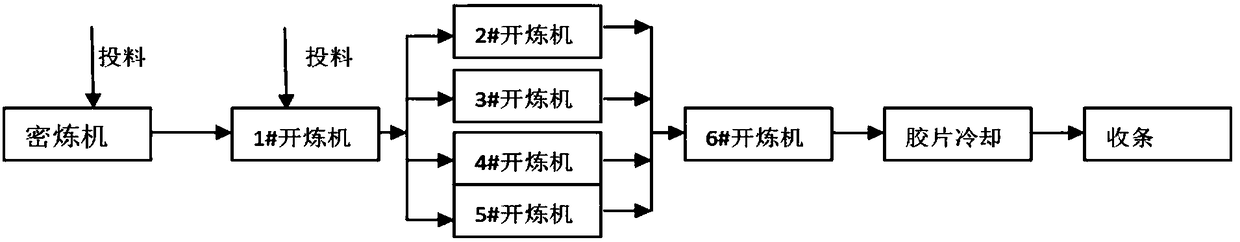

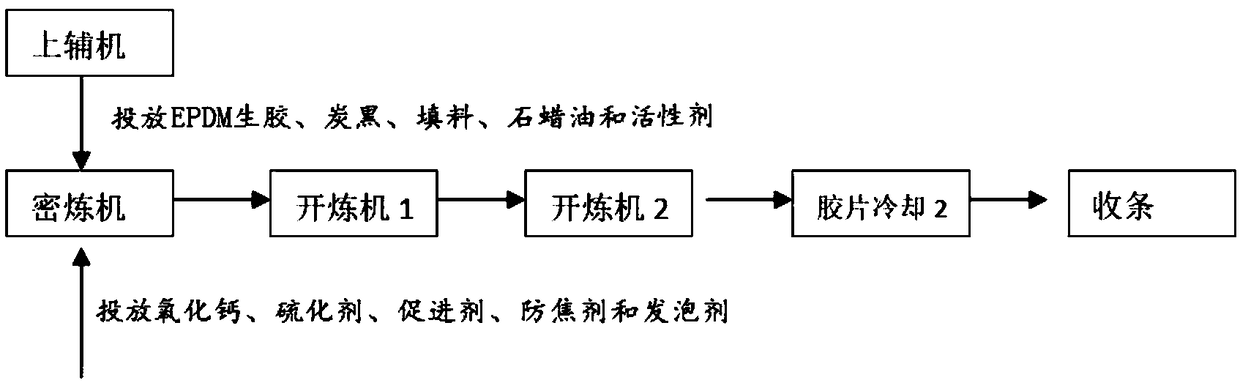

One-step continuously-mixed rubber compound for automobile sealing strips and preparation method thereof

ActiveCN109370065AHigh Mooney viscosityVulcanization stabilityChemical industryPolymer scienceActive agent

The invention discloses a one-step continuously-mixed rubber compound for automobile sealing strips and a preparation method thereof. The rubber compound comprises the following raw materials in partsby weight: 100 parts of EPDM (Ethylene-Propylene-Diene Monomer) raw rubber, 60-200 parts of carbon black, 30-100 parts of filler, 60-120 parts of paraffin oil, 7-12 parts of active agent, 8-12 partsof calcium oxide, 1-2.5 parts of vulcanizing agent, 4.3-10.9 parts of accelerator, 0.6-1 part of anti-scorching agent and 0-4 parts of foaming agent. The rubber compound disclosed by the invention hasthe beneficial effects that the rubber compound is stable in Mooney viscosity and vulcanization performance and good in consistency and when the rubber compound is used for the production of the automobile sealing strips, the obtained product is smooth in surface, few in particles and high in dimensional stability; and the preparation method disclosed by the invention has the beneficial effects of low cost, high efficiency, energy conservation and consumption reduction and has a broad market development prospect in the field of high-end automobile sealing strip preparation.

Owner:ZHEJIANG XIANTONG RUBBER & PLASTIC CO LTD

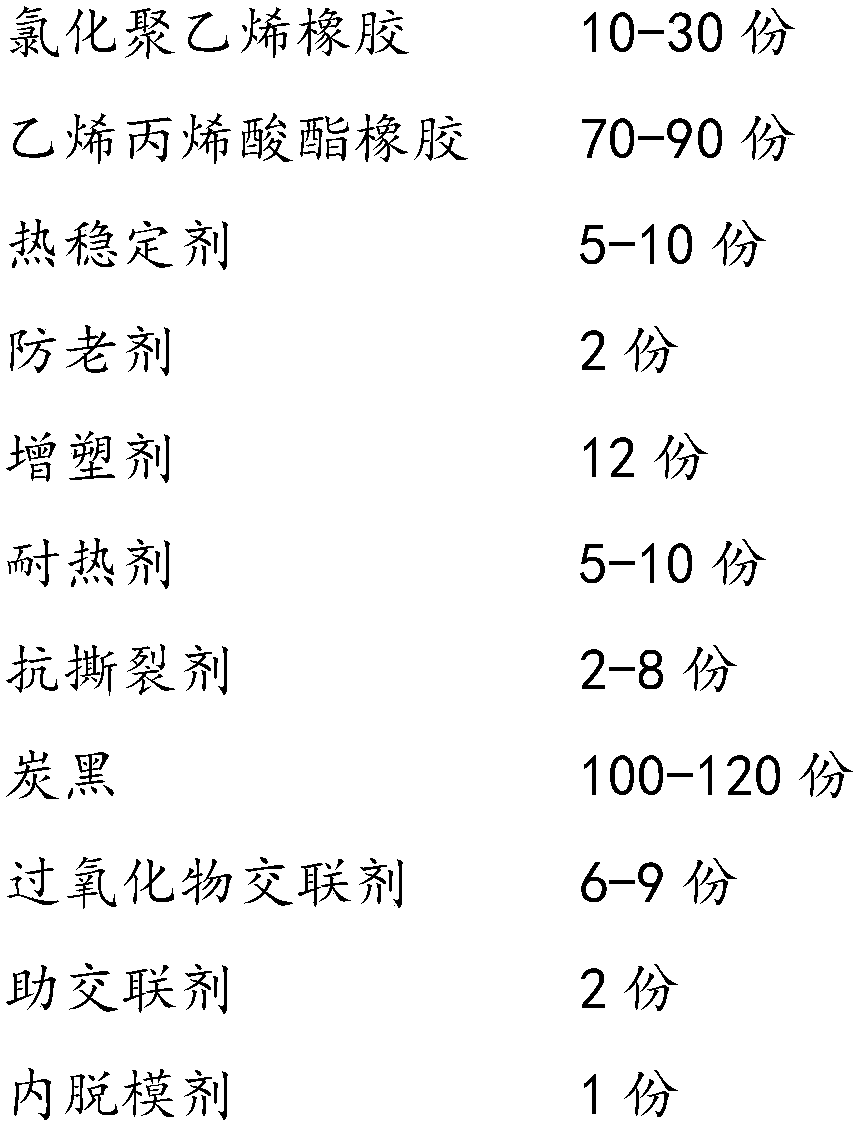

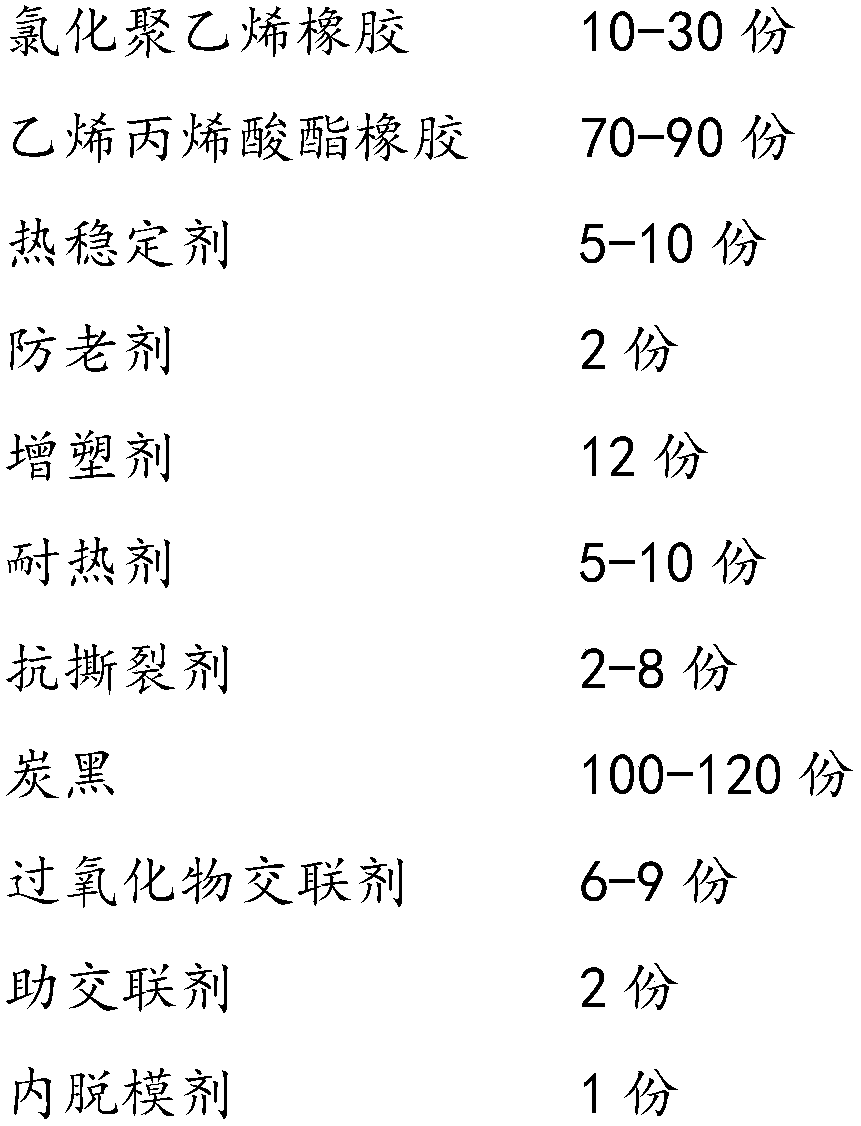

Rubber composition used for automobile cooling pipe and preparation method thereof

The invention relates to a rubber composition used for an automobile cooling pipe. The rubber composition comprises the following components in parts by weight: 10 to 30 parts of chlorinated polyethylene rubber, 70 to 90 parts of ethylene acrylate rubber, 5 to 10 parts of a heat stabilizer, 2 parts of an anti-aging agent, 12 parts of a plasticizer, 5 to 10 parts of a heat resistant agent, 2 to 8 parts of a tear resistant agent, 100 to 120 parts of carbon black, 6 to 9 parts of a peroxide crosslinking agent, 2 parts of an auxiliary crosslinking agent and 1 part of an internal releasing agent. According to the invention, AEM rubber is used as a main material and combines with CM rubber, and through advantage complementation of different rubber performances and optimization of a filling system, a composition combining the ethylene acrylate rubber with the chlorinated polyethylene rubber is manufactured, so the Mooney viscosity of the AEM rubber is enhanced, and the extrusion process performance and the high-temperature tear resistance of AEM are improved; and the heat stabilizer, the heat resistant agent, the reactive extraction-resistant anti-aging agent MC and the tear resistant agent are added, so the composition is endowed with temperature resistance as same as the AEM rubber, while the extrusion process performance and the high-temperature tear resistance are improved, and the material cost is reduced.

Owner:QINGDAO SUNSONG CO LTD

Method for preparing high 1,4-cis polybutadiene having controlled cold flow

The present invention relates to a method for preparing a high 1,4-cis polybutadiene having a controlled cold flow and, more particularly, to a novel method for preparing a high 1,4-cis polybutadiene having a controlled cold flow that involves initiating polymerization of a 1,3-butadiene in the presence of a non-polar solvent using, as a polymerization catalyst, a complex prepared by mixing a neodymium compound with or without a conjugated diene compound, a halogenated organoaluminum compound or a halogenated organic compound, and an organoaluminum compound irrespective of the addition order of the catalyst; and adding an organoborane compound as a cold flow controller of 1,4-cis polybutadiene after a predetermined time of the polymerization. Accordingly, a high 1,4-cis polybutadiene having an efficiently controlled cold flow can be prepared without causing a significant increase in the Mooney viscosity (molecular weight), an odor (bad smell), and a reduction in 1,4-cis content and polymerization yield.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Method for preparing EVA elastomer

The invention discloses a method for preparing EVA elastomer. The method included the step of controlling the pressure of ethylene to make the ethylene completely liquefied in a single reactor with alcohols as a solvent, so that the ethylene and the vinyl acetate are subjected to liquid-liquid single-phase copolymerization and the EVA elastomer is obtained. According to the method based on the existing EVA-elastomer-solution polymerization process, the pressure of ethylene is controlled to make the ethylene completely liquefied so that the liquid-liquid copolymerization can improve the comonomer contact efficiency as well as the solubility of ethylene in the liquid phase, complete the solution single-phase copolymerization, and greatly improve the monomer copolymerization rate and the diffusion as well as the initiator efficiency of the free radicals in the copolymer solution. According to the application requirements of different polymerization products, by adjusting the solvent, the method greatly improves the copolymerization rate and the high solid content of a high-viscosity system. Using the single-reactor process, the method is also capable of avoiding the high-cost and complex-manipulation problem resulting from a raw-material process device of the multi-reactor process. Therefore, the method has high industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

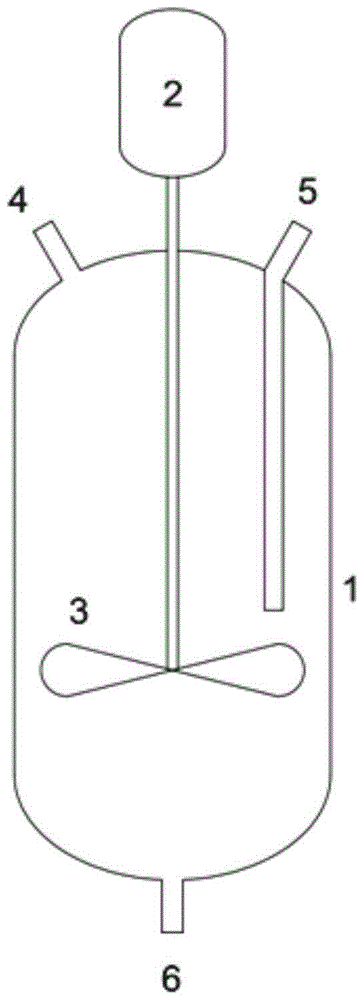

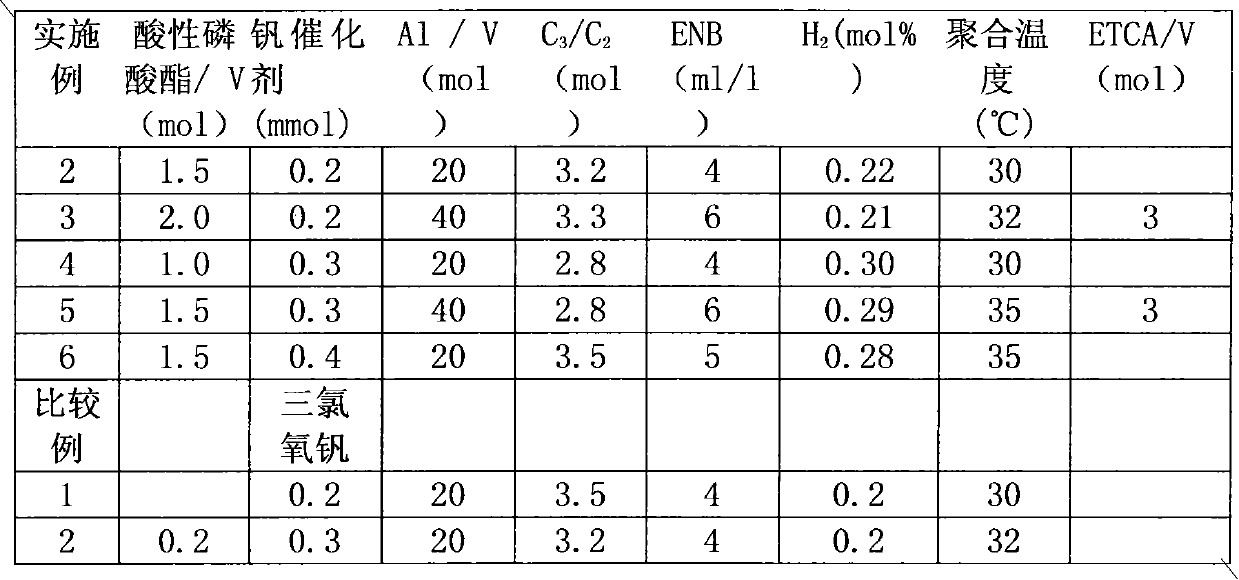

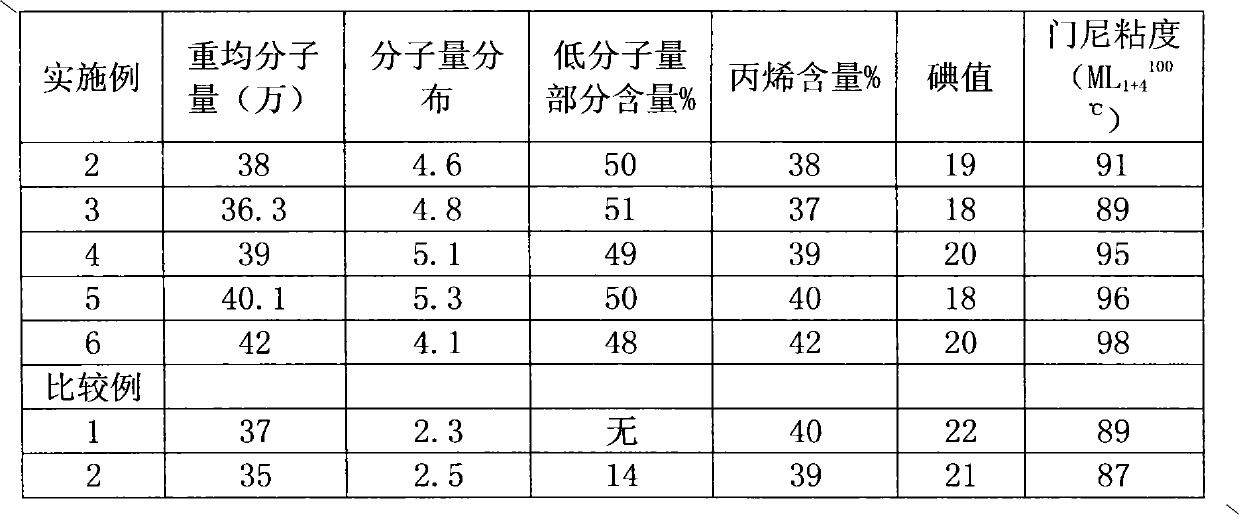

Synthesis method of bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer

ActiveCN102558414AHigh Mooney viscosityModerate molecular weight distributionPhosphateSynthesis methods

The invention relates to a synthesis method of a bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer, which comprises the following steps: introducing a gas mixture of ethylene, propylene and hydrogen into a reaction kettle, adding a primary catalyst, a cocatalyst and an activating agent, and adding the non-conjugated diene for polymerization at 25-45 DEG C under the pressure of 0.3-0.6 MPa. The propylene / ethylene mol ratio is 1-6; the hydrogen accounts for 0.05-0.5 mol% in the comonomer; the addition amount of the non-conjugated diene in every 1000mL of hexane is 2-10mL; the acidic-phosphate modified vanadium compound is used as the primary catalyst, the halogenated alkyl aluminum is used as the cocatalyst, and the mol ratio of Al in the cocatalyst to V in the primary catalyst is (1-100) / 1; the activating agent is ethyl trichloroacetate, and the mol ratio of the activating agent and the vanadium compound is (1-10) / 1; and the copolymer has high Mooney viscosity and moderate molecular weight distribution, and is used in processing rubber of automobile seals.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com