Method of preparing carboxyl styrene butadiene rubber through emulsion polymerization

A technology of carboxylated styrene-butadiene rubber and emulsion polymerization, which is applied in the field of surface-grafted carboxylated styrene-butadiene rubber raw materials by emulsion polymerization, which can solve problems such as unstable physical and mechanical properties, unstable characterization data, and uneven product mixing. Achieve the effect of improving the application range, controlling the combined acid index, and improving the modulus stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

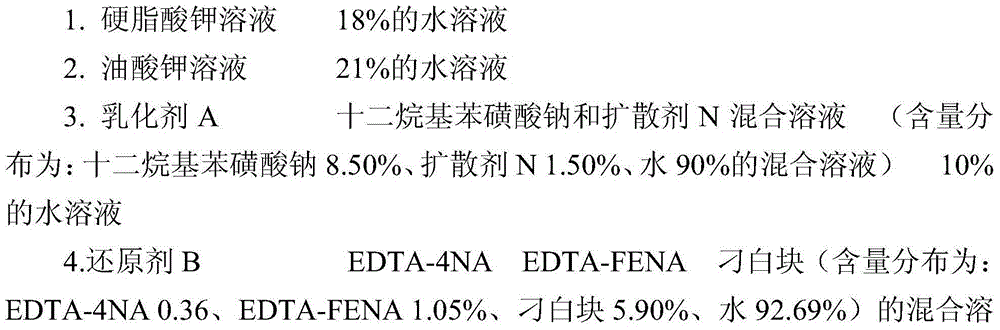

Method used

Image

Examples

Embodiment 1

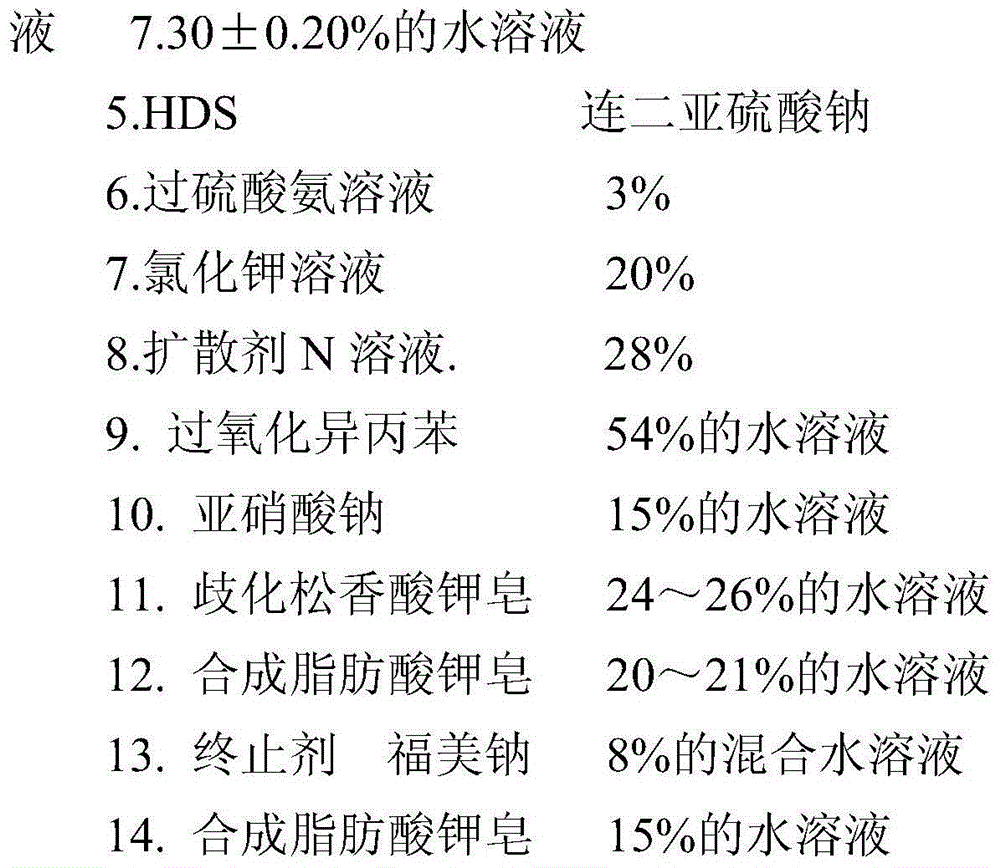

[0034] Add 5100 milliliters of water into a 10-liter reactor, add 38.09 grams of emulsifier A4 and 8.5 grams of reducing agent B, disperse and dissolve under stirring, add 467 grams of styrene, 4.65 grams of tert-dodecyl mercaptan, and Sodium disulfite 0.1692 grams, after nitrogen inflation-vacuum replacement, add 0.4726 grams of cumene peroxide, then add 1243 grams of butadiene, control the temperature to 11.5-12.5 ℃ for reaction, when the conversion rate reaches 55%, add emulsifier to synthesize fatty acid Continue the reaction after 105 grams of potassium soap, 25.65 grams of acrylic acid, and 0.45 grams of tertiary dodecyl mercaptan. When the reaction conversion rate reaches more than 68%, add 32 grams of terminators, degas after 30 minutes, and obtain latex, then coagulate and wash , dehydration, drying, and the results of glue sample testing are shown in Table 1:

[0035] Table 1

[0036]

Embodiment 2

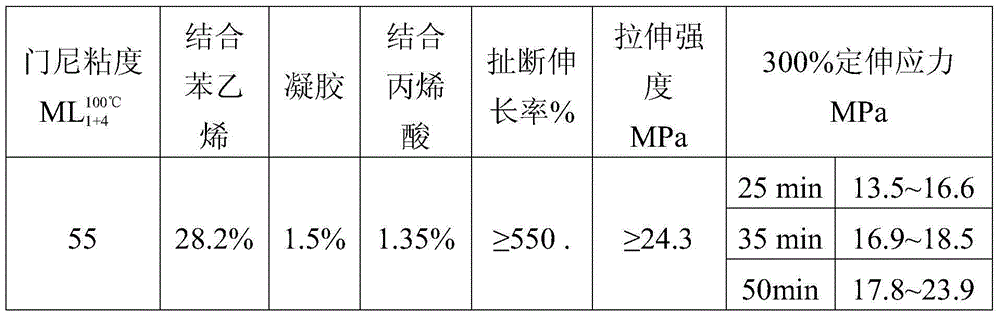

[0038] at 3M 3 Add 1600 kilograms of water to the reaction kettle, then add 67.25 kilograms of potassium stearate solution and 61.39 kilograms of potassium oleate solution, 20 kilograms of potassium chloride solution, and 14.28 kilograms of diffusing agent N solution, disperse and dissolve under stirring, positive dodecyl 2.6 kilograms of mercaptans, add 254 kilograms of styrene, 46 kilograms of ammonium persulfate solution, and 576 kilograms of butadiene, and control the temperature to 7.5-8.5° C. for reaction. When the conversion rate reaches 52%, add emulsifier to synthesize 25.5 kilograms of potassium fatty acid solution Continue to react with 17.22 kilograms of methacrylic acid, and add 38 kilograms of terminator sodium nitrite solution after the reaction conversion rate reaches more than 70%, flash degassing after 30 minutes, obtain latex, then coagulate, wash, dehydrate, dry, The results of the glue sample test are shown in Table 2:

[0039] Table 2

[0040]

Embodiment 3

[0042] Add 4449 milliliters of water into a 10-liter reactor, add 473.56 grams of emulsifier A and 15.37 grams of reducing agent B, disperse and dissolve under stirring, add 454.59 grams of styrene, 4.75 grams of tertiary dodecyl mercaptan, and Sodium disulfite 0.179 grams, after nitrogen inflation-vacuum replacement, add 0.856 grams of dicumyl peroxide, then add 1440 grams of butadiene, control the temperature to 4.5-5.5 ℃ for reaction, when the conversion rate reaches 60%, add an emulsifier to synthesize Continue to react after 75 grams of potassium fatty acid solution, 25.9 grams of fumaric acid, 0.35 grams of tert-dodecyl mercaptan, add 35 grams of terminators after the reaction conversion ratio reaches more than 72%, degas after 30 minutes, obtain latex, and then After coagulation, washing, dehydration, and drying, the results of glue sample testing are shown in Table 3:

[0043] table 3

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com