Method for preparing polyisoprene rubber latex

A technology of polyisoprene and rubber latex, which is applied in the field of rubber, can solve the problems of low efficiency in removing solvent and water, and achieve the effects of avoiding changes in performance and appearance, reducing energy consumption, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

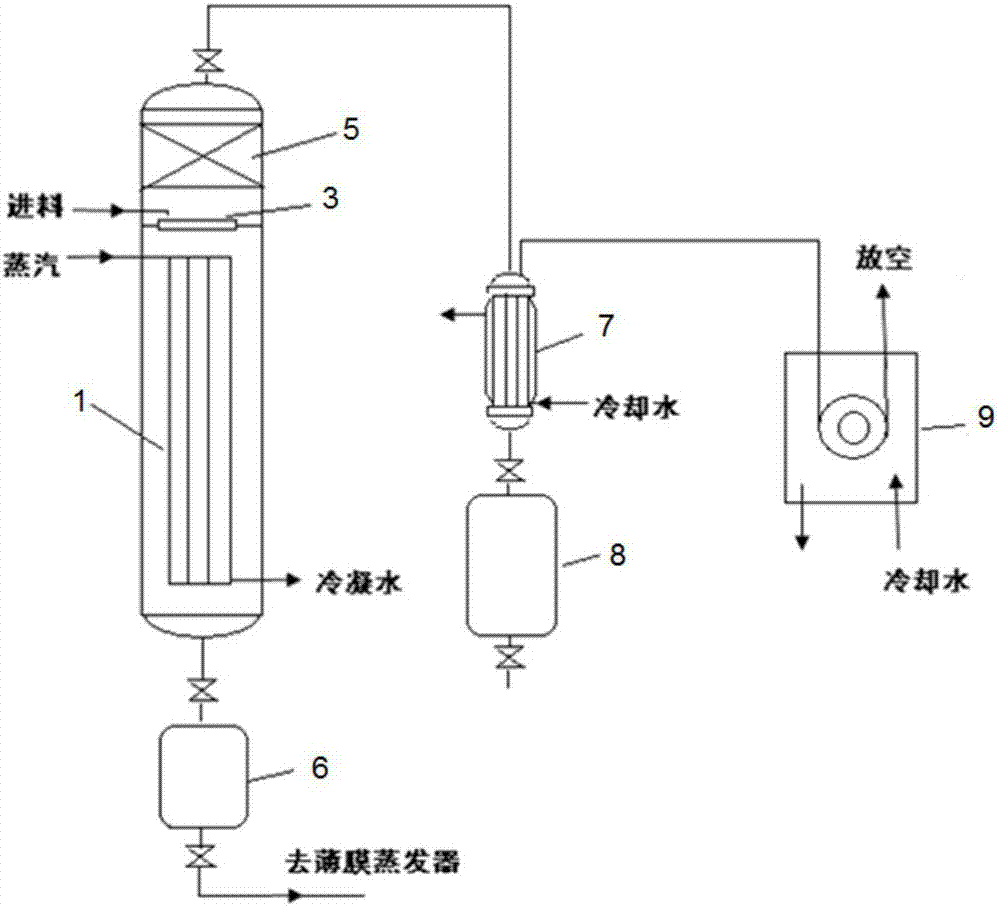

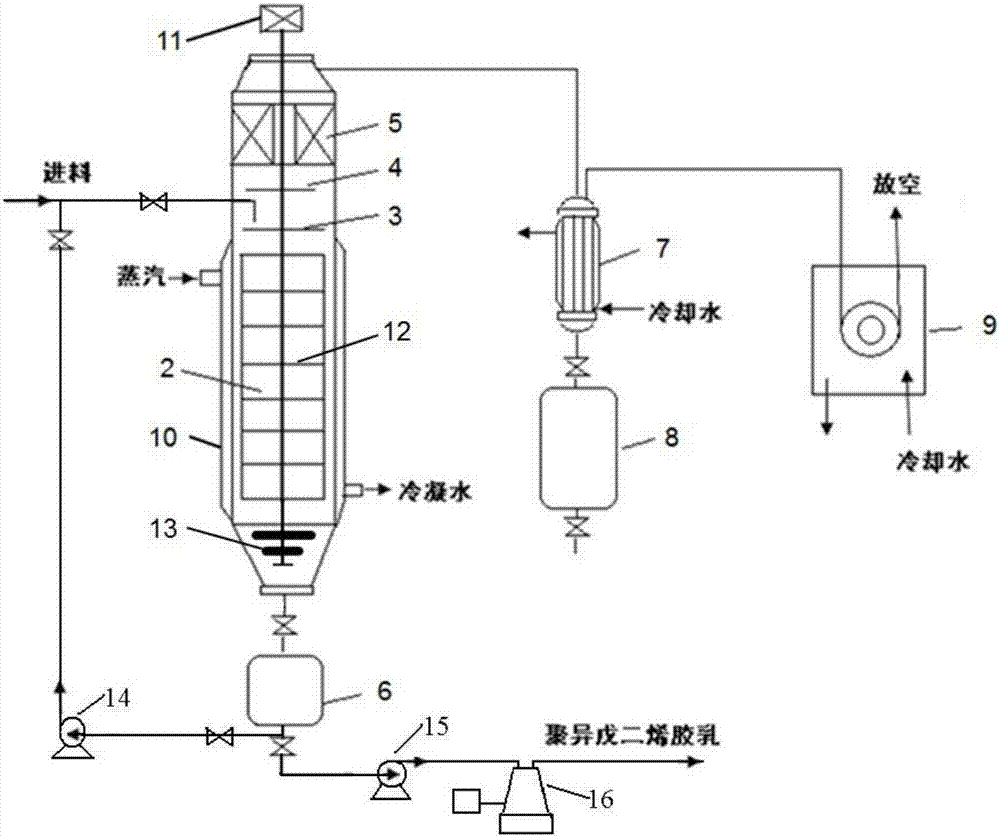

Method used

Image

Examples

preparation example 1

[0065] (1) Preparation of polyisoprene rubber solution

[0066] Add 25kg of refined isoprene and 225kg of dry cyclohexane to the 500L jacketed polymerization reactor fully replaced by high-purity nitrogen, mix well, heat to 40°C while stirring, and add 105.0ml of n-butyllithium to the solution solution (0.8mol / L, the solvent is cyclohexane) to remove impurities in the polymerization system, then add 37.0mL n-butyllithium solution (0.8mol / L, the solvent is cyclohexane) to the solution, and the temperature of the solution is controlled at 50 Within the range of ±5°C, the pressure in the polymerization reactor was controlled to be 0.2±0.05MPa (gauge pressure) and reacted for 180 minutes. After the reaction, add deionized water equimolar with the active organic lithium initiator and continue to stir for 10 minutes to terminate the polymerization reaction, then add a cyclohexane solution of 2,6-di-tert-butyl-p-cresol with a concentration of 20% by weight (wherein, the amount of 2,...

preparation example 2

[0070] Carry out according to preparation example 1 preparation process, difference is, in step (1), polymerization reaction process is continuous reaction process, adopts 3 stills to be connected in series, and the residence time of every still is 1.0 hour, and organic solvent adopts as hexane, obtains concentration: 10% by weight polyisoprene rubber solution. Sampling and analysis of the Mooney viscosity of polyisoprene rubber is 65, the weight average molecular weight is 1.76 million, and the molecular weight distribution index is 2.21. The cis-1,4-structure content of polyisoprene rubber is determined by NMR spectrometer as 84.9%, trans 1,4-structure content is 10.3%, 3,4-structure content is 4.8%. The conversion of isoprene was 100%, as determined by weighing method. The gel content in the polymer was zero.

[0071] And, change the add-on of organic solvent in step (1) and the add-on of water in step (2), make in the gained polyisoprene rubber emulsion (coded as II), th...

preparation example 3

[0073] According to the preparation process of Preparation Example 1, the difference is that the amount of organic solvent added in step (1) and the amount of water added in step (2) are changed so that in the obtained polyisoprene rubber emulsion (coded as III) , the content of the polyisoprene rubber solution is 40% by volume (wherein the content of the organic solvent is about 80% by weight), and the content of water is 60% by volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com