Electrophotographic developing agent

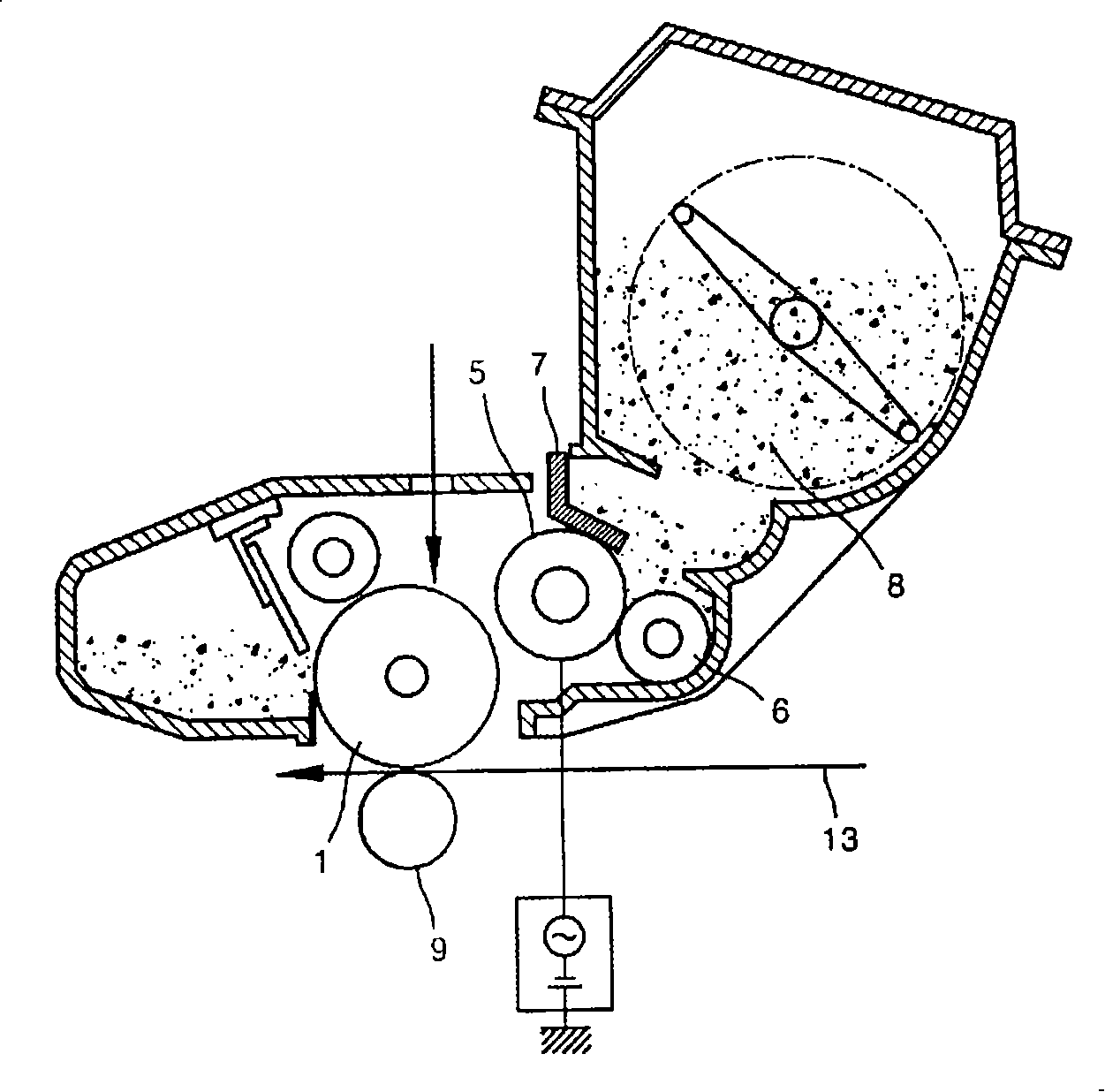

一种电子照相、显影剂的技术,应用在显影剂、电记录术、仪器等方向,能够解决耐久性和图像质量劣化等问题,达到改进图像光泽、改进熔合性能、保证耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

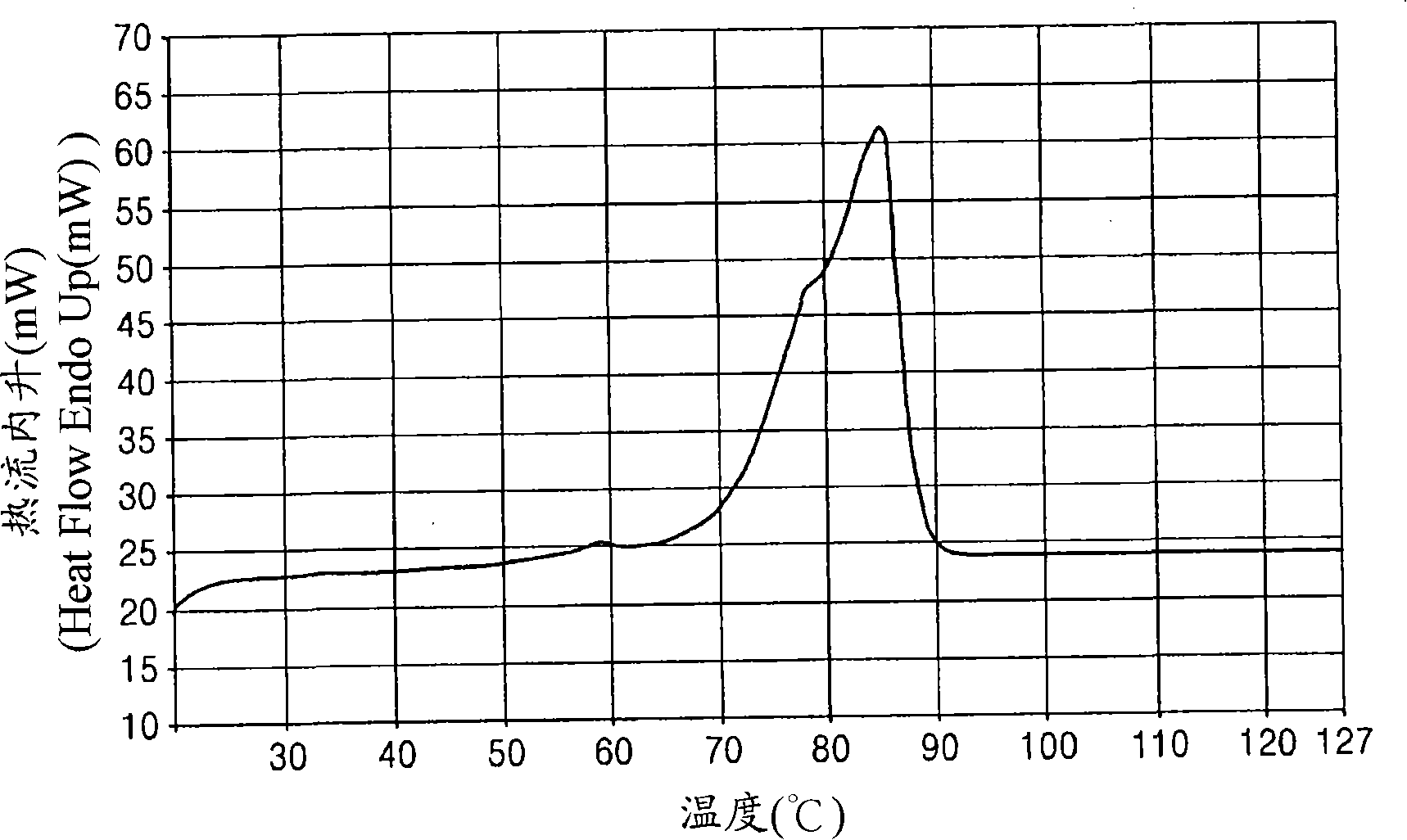

[0082] Using a Henschel mixer, 92 parts by weight of high-viscosity polyester resin and low-viscosity polyester resin shown in Table 1 (weight ratio 6:4, manufactured by Mitsubishi Rayon Co., Ltd.), 3 parts by weight of black colorant mogul- L (manufactured by Cabot Corporation), 2 parts by weight of charge control agent T-77 (manufactured by Hodogaya), and 3 parts by weight of carnauba wax (manufactured by Toa Kasei Co., Ltd.). Then, the resulting mixture was placed in a twin-screw extruder, and it was melt-extruded at 130°C. The extruded product was cooled to coagulate, and then the resulting kneaded intermediate material was pulverized using a mechanical mill (SR-15) and classified using a classifier to obtain an untreated toner having an average particle diameter of about 8 μm .

Embodiment 2

[0084] An untreated toner was prepared in the same manner as in Example 1, except that the mixing ratio of the high-viscosity polyester resin and the low-viscosity polyester resin was 5:5.

Embodiment 3

[0086] An untreated toner was prepared in the same manner as in Example 1, except that the mixing ratio of the high-viscosity polyester resin and the low-viscosity polyester resin was 3:7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com