High-nitrile SAN resin and production method thereof

A production method and high nitrile technology, applied in the petrochemical field, can solve the problems of uneven reaction system, low thermal stability, increased viscosity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

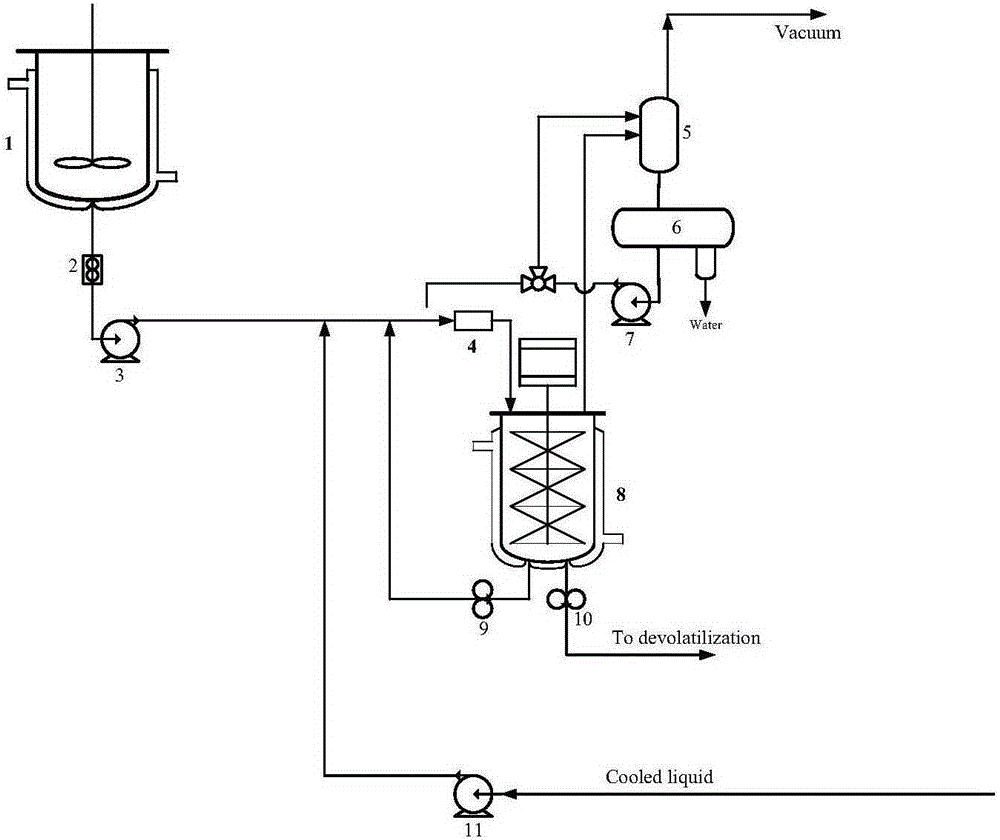

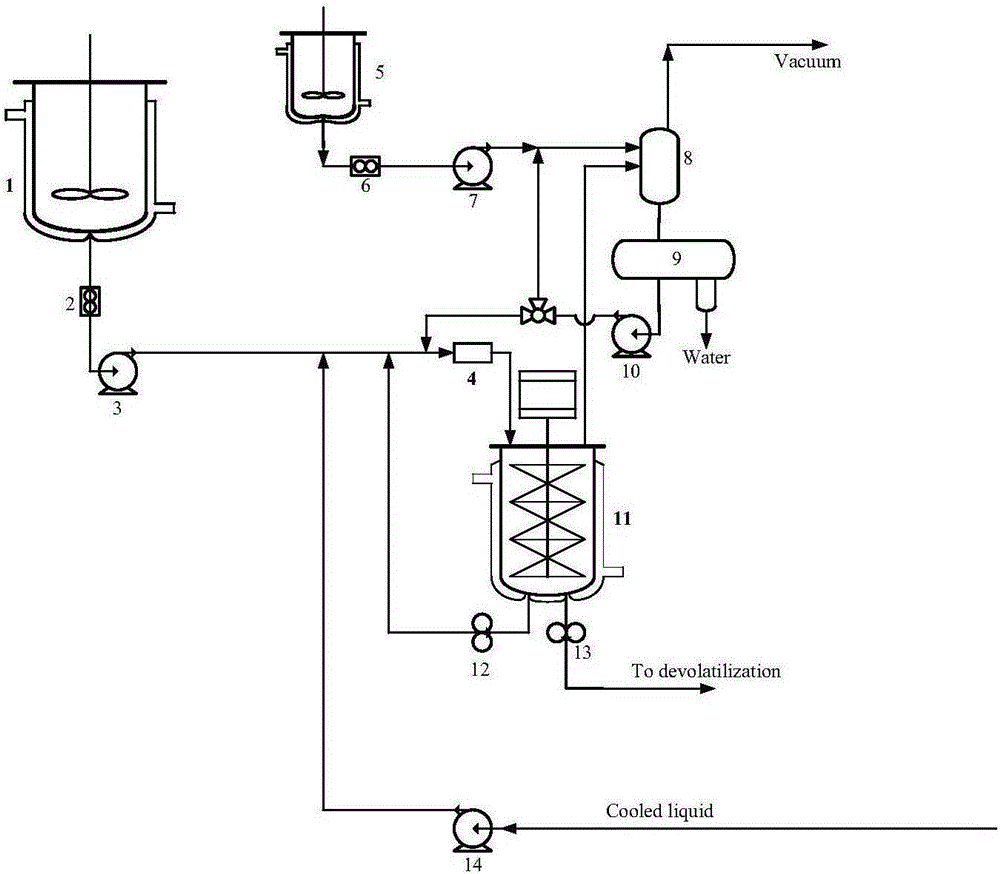

Method used

Image

Examples

Embodiment 1

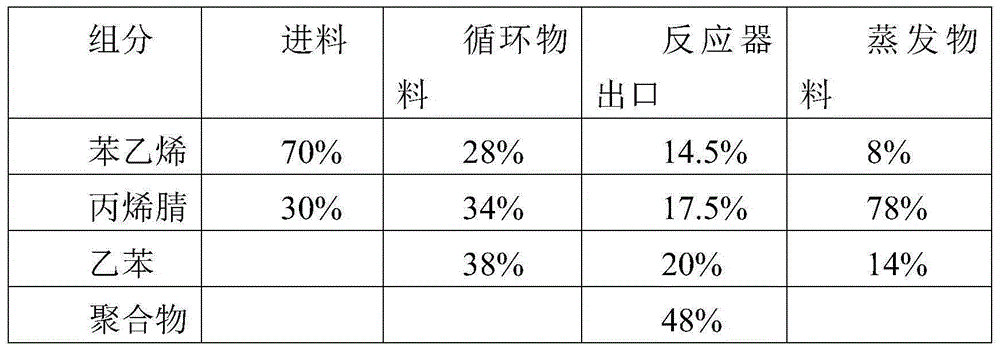

[0052] In the monomer preparation tank, mix 70% styrene (styrene 1) and all acrylonitrile, introduce into the static mixer through flow meter and liquid pump, and the remaining 30% styrene (styrene 2) pass flow meter and liquid The pump is introduced into the condenser, where it is mixed with the evaporated material and then enters the static mixer. The mixed materials in this static mixture also include the circulating material pumped up by the high-viscosity gear pump from the bottom of the reactor, and the recycled liquid material condensed by devolatilization. These materials are completely mixed in the static mixer and then enter in the reactor. The two-part reaction monomer mixture was fed at a total feed rate of 15 L / hr. Continuous thermally initiated bulk copolymerization was carried out in a vertical stirred tank reactor with a volume of 40 L.

[0053] The composition of the total fresh feed monomer mixture was 66 parts by weight styrene, 34 parts by weight acrylonit...

Embodiment 2

[0060] The preparation process of SAN is the same as that of Example 1, except that styrene 1 mixed with acrylonitrile accounts for 75% and styrene 2 accounts for 25% in the reaction monomer. The obtained SAN polymer characterization analysis results are shown in Table 2.

Embodiment 3

[0062] The preparation process of SAN is the same as that of Example 1, except that styrene 1 mixed with acrylonitrile accounts for 80% and styrene 2 accounts for 20% in the reaction monomer. The obtained SAN polymer characterization analysis results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com