Synthesis method of bimodal-distribution ethylene-propylene-nonconjugated diene random copolymer

A non-conjugated diene and bimodal distribution technology is applied in the field of synthesis of bimodal ethylene-propylene-non-conjugated diene random copolymers, which can solve the problems of wide molecular weight distribution of ethylene-propylene copolymers and achieve molecular weight The effect of moderate distribution and high Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Synthesis of Modified Vanadium Catalyst

[0031] Take a 100ml bottle with an inlet tube at the bottom, two-corner ground mouth bottle, conduct anhydrous and anaerobic treatment under vacuum and heating, then add 50ml of dry hexane, inject high-purity nitrogen for bubbling, and then use dry medical glass Add 1ml (0.0105mol) of vanadyl trichloride into the needle tube, and after stirring for 10 minutes, slowly add 0.0158mol of O-(2-ethylhexyl)-2-ethylhexyl phosphate diluted with 5ml of hexane dropwise, While bubbling high-purity nitrogen gas, the reaction stopped after 30 minutes to obtain a modified vanadium catalyst solution with a concentration of 0.2 mol / L. The reaction vessel was sealed and stored away from light.

Embodiment 2

[0033] Polymerization was carried out in a 5L stainless steel jacketed reactor. Prepare ethylene, propylene, and hydrogen through a mixing device at a ratio of 1:3.2:0.22, and then fully mix them uniformly through a circulating compressor. The polymerization is carried out in a 5L polymerization kettle, which is anhydrous and anhydrous Oxygen treatment for 1 hour, the inert gas used is high-purity nitrogen, then add 2000ml of dry hexane (water content≤10ppm) to it, which contains 4ml of norbornene (ENB), open the circulation compressor, and feed into the polymerization tank Mixed gas, the mixed gas flow rate is 150L / hour, the mixed gas dissolved in hexane is saturated, then the modified vanadium catalyst hexane solution of 1ml (0.2mmol) is added successively, and sesquialuminum is added, so that the Al / V ratio is 10 / 1, the polymerization temperature is 30°C, the polymerization pressure is 0.5MPa, and the polymerization reaction time is 1 hour. After the polymerization reactio...

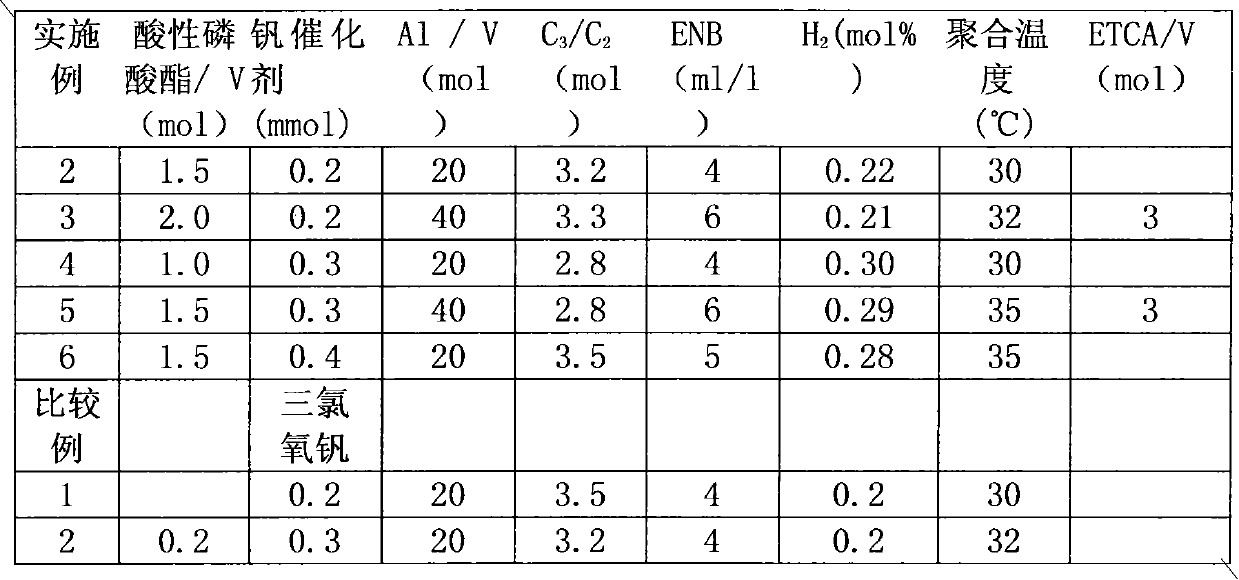

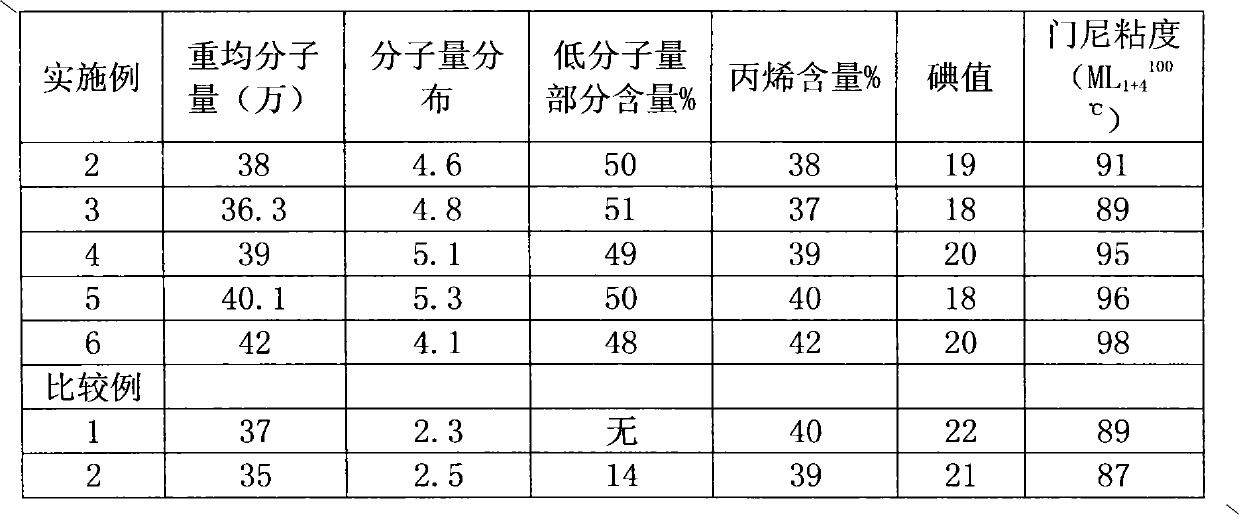

Embodiment 3-6

[0035] Polymerization operation process is identical with embodiment 1, and wherein, embodiment 3,5 adds activator respectively, and the activator dose that embodiment 3,5 adds is 5mL / 1000mL hexane (ETCA / V=3), all the other conditions are shown in table 1, The analysis results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com