One-step continuously-mixed rubber compound for automobile sealing strips and preparation method thereof

A technology for automotive sealing strips and compounded rubber, which is applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc. It can solve the problems of dead rubber and other problems, and achieve reduced parking steps, short production cycle, and high vulcanization performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The embodiment of the present invention discloses a one-step continuous mixing rubber compound for automobile sealing strips and a preparation method thereof, and the adopted technical scheme is as follows:

[0058] A one-step continuous mixing rubber compound for automobile sealing strips, the raw materials in parts by weight consist of: 65 parts of EPDM raw rubber (4770), 35 parts of EPDM raw rubber (4570), 190 parts of N-550 carbon black , 100 parts of calcium carbonate, 120 parts of paraffin oil, 8 parts of zinc oxide, 1 part of stearic acid, 2 parts of polyethylene glycol, 12 parts of calcium oxide, 1.2 parts of sulfur, 0.3 parts of accelerator M, 0.5 parts of accelerator TMTD, Accelerator ETU 0.9 parts, accelerator ZDBC 1.45 parts, accelerator DM 1.2 parts, accelerator CBS 1 part, anti-scorch agent E-800.7 parts.

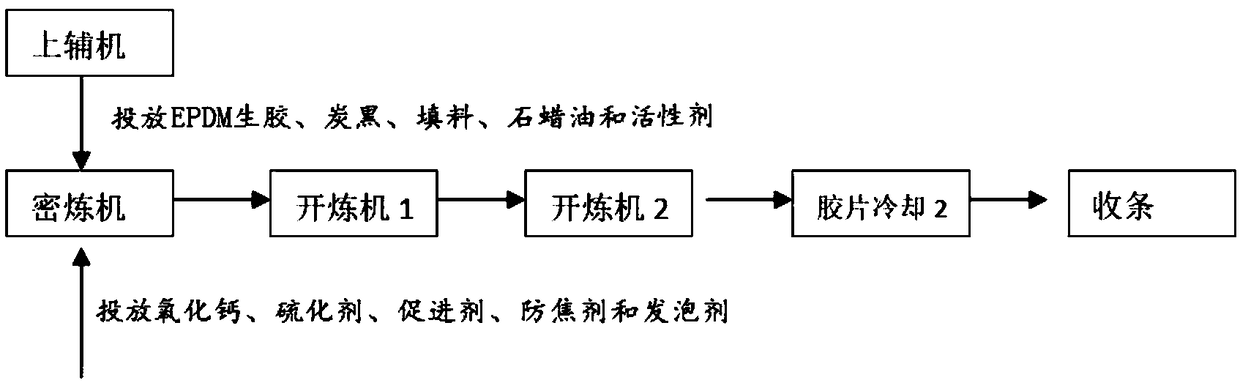

[0059] The preparation method of the compound rubber for automobile sealing strips by one-step continuous mixing is based on the above-mentioned compon...

Embodiment 2

[0075] The embodiment of the present invention discloses a one-step continuous mixing rubber compound for automobile sealing strips and a preparation method thereof, and the adopted technical scheme is as follows:

[0076] A one-step continuous mixing rubber compound for automobile sealing strips, the raw materials in parts by weight consist of: 100 parts of EPDM raw rubber (8600), 70 parts of N-550 carbon black, 40 parts of calcium carbonate, and 70 parts of paraffin oil 1 part, zinc oxide 8 parts, stearic acid 1 part, dispersant 1 part, calcium oxide 5 parts, sulfur 1.2 parts, accelerator M 1.3 parts, accelerator ETU 0.5 parts, accelerator ZDBC 1.3 parts, accelerator DPTT 0.8 parts , 0.9 parts of accelerator ZDEC, 0.6 parts of vulcanizing agent DTDM, 3 parts of foaming agent OBSH, 1 part of accelerator CBS, 0.9 parts of anti-scorch agent E-80.

[0077] The preparation method of the compound rubber for automobile sealing strips by one-step continuous mixing is based on the ab...

Embodiment 3

[0089] The embodiment of the present invention discloses a one-step continuous mixing rubber compound for automobile sealing strips and a preparation method thereof, and the adopted technical scheme is as follows:

[0090] A one-step continuous mixing rubber compound for automobile sealing strips, the raw materials in parts by weight consist of: 40 parts of EPDM raw rubber (4770), 60 parts of EPDM raw rubber (4570), 160 parts of carbon black N-550 , 80 parts of calcium carbonate, 100 parts of paraffin oil, 6 parts of zinc oxide, 1 part of stearic acid, 1 part of polyethylene glycol, 8 parts of calcium oxide, 1.3 parts of sulfur, 0.3 parts of accelerator M, 0.6 parts of accelerator TMTD, 1 part of accelerator ETU, 1.5 parts of accelerator ZDBC, 1.45 parts of accelerator DM, 1 part of accelerator CBS, 0.8 parts of anti-scorch agent E-80.

[0091] The preparation method of the compound rubber for automobile sealing strips by one-step continuous mixing is based on the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com