Rubber composition used for automobile cooling pipe and preparation method thereof

A rubber composition and automobile cooling technology, applied in the field of chemical materials, can solve problems such as easy adhesion and deformation of tube blanks, poor tearing performance, and missing pieces of tube blanks, so as to improve extrusion process performance and high temperature tearing performance, extrusion Process and high-temperature tearability improvement, material cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

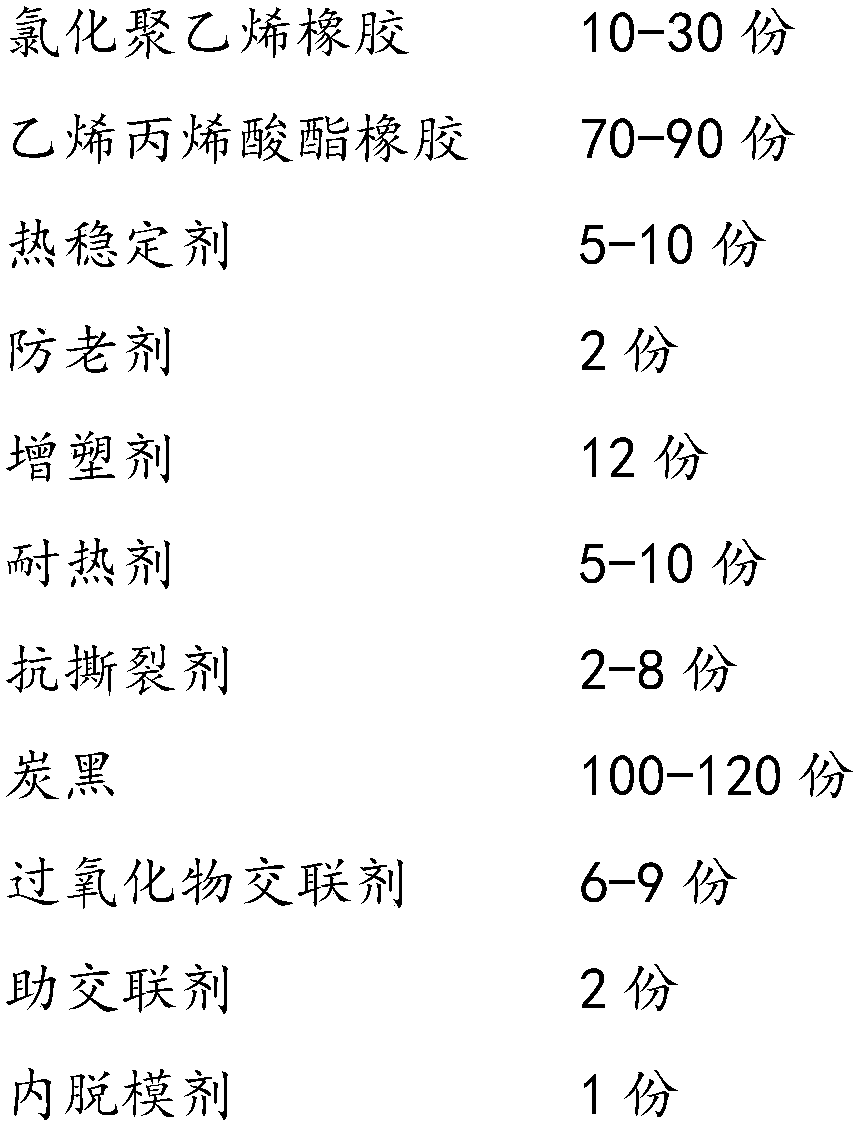

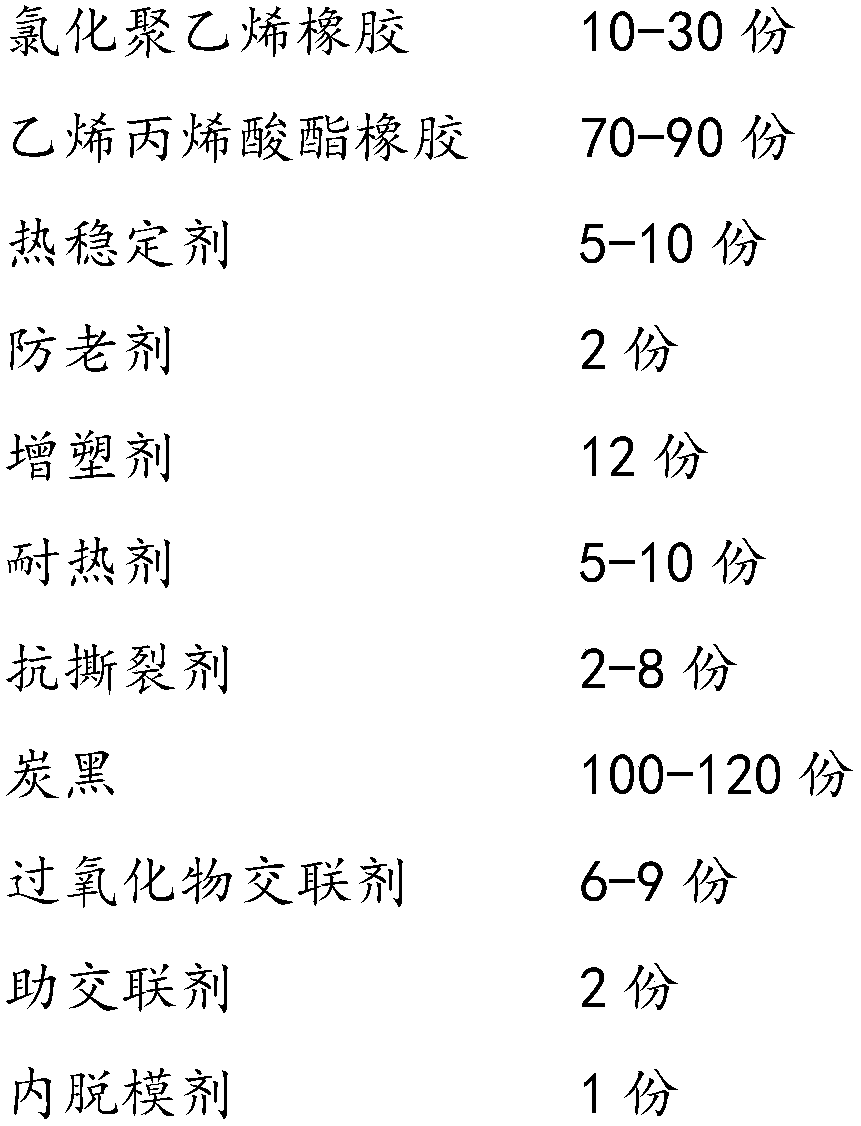

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of preparation method of rubber composition, comprises the steps:

[0031] (1) Put chlorinated polyethylene rubber, ethylene acrylate rubber, anti-tearing agent, heat stabilizer, anti-aging agent, and 1 / 2 carbon black into the internal mixer for pressurized mixing. When the temperature reaches 115-120 At ℃, discharge the mixed rubber materials to the open mill for upper and lower sheets, and park for 16-24 hours before use.

[0032] Anti-tearing agent, heat stabilizer, and anti-aging agent are used in small amounts in the formula and are difficult to disperse. As the most critical raw materials in the formula, they need to be mixed with rubber and carbon black in advance. The longer the mixing time, the better the dispersion. However, during the mixing process, the rubber mixture will heat up due to shear friction. When the temperature exceeds 120°C, the viscosity of ethylene acrylate rubber will drop too much, and the shear f...

Embodiment 1-5

[0039] Embodiment 1-5 rubber composition is prepared according to the following processing methods:

[0040] (1) Put chlorinated polyethylene rubber, ethylene acrylate rubber, cerium oxide, lithium carbonate, aramid short fiber, carbon fiber micropowder, antioxidant MC, carbon black N990 into the internal mixer for pressurized mixing, when the temperature reaches When the temperature is 115-120 ℃, discharge the mixed rubber material to the upper and lower sheets of the open mill, and park it for 16-24 hours before use;

[0041] (2) Put the chlorinated polyethylene rubber / ethylene acrylate rubber mixture, SRP66, N660 carbon black, and plasticizer RS-735 in step 1 into the internal mixer for mixing, and add crosslinking aid when the temperature rises to 90°C Agent HAV-2 and peroxide cross-linking agent Perkadox 14-40B continue to mix, when the temperature reaches 105-110°C, discharge the mixed rubber to the open mill for 2-3 minutes, and then On the tablet press, it is pressed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com