Emulsion polymerization method for preparing tractable butadiene styrene rubber

A technology of emulsion polymerization and styrene-butadiene rubber, which is applied in the field of emulsion polymerization to prepare styrene-butadiene rubber. It can solve the problems of affecting vulcanization strength, molecular chain breakage, product surface cracking, etc., and achieves good physical and mechanical properties and improved Mooney viscosity. , The effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

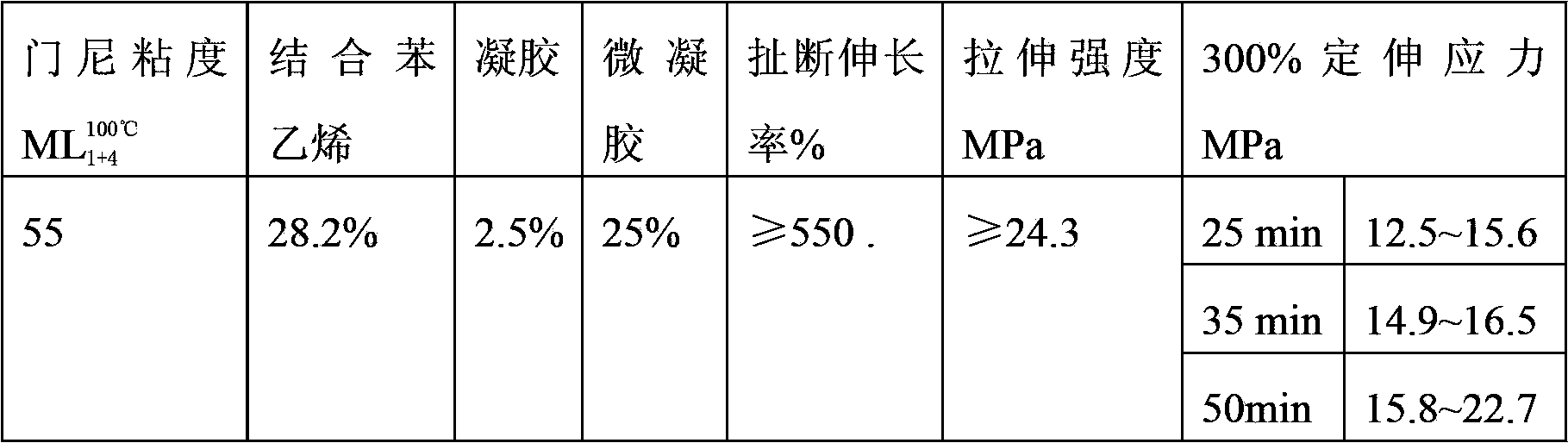

[0060] Add 5100 ml of water to a 10-liter reactor, then add 333.09 grams of CP-10 and 8.5 grams of CP-50, disperse and dissolve under stirring, add 380 grams of styrene, 4.1 grams of tertiary dodecyl mercaptan, and sodium dithionite 0.1692g, after nitrogen inflation-vacuum replacement, add cumene peroxide 0.4726g, then add butadiene 1243g, control the temperature to 12°C for reaction, when the conversion rate reaches 30-36%, add emulsifier CP-10105g , 0.55 grams of tertiary dodecyl mercaptan, 30.6 grams of aliphatic ether polysulfide and 87 grams of styrene and continue to react. When the conversion rate reaches 50 ± 3%, add 105 grams of emulsifier CP-10, 0.45 grams of tertiary dodecyl mercaptan Continue the reaction after 1 gram, add 32 grams of terminator after the reaction conversion reaches more than 75%, degas after 30 minutes, then condense, dry, and the results after the glue sample detection are shown in Table 1:

[0061] Table 1

[0062]

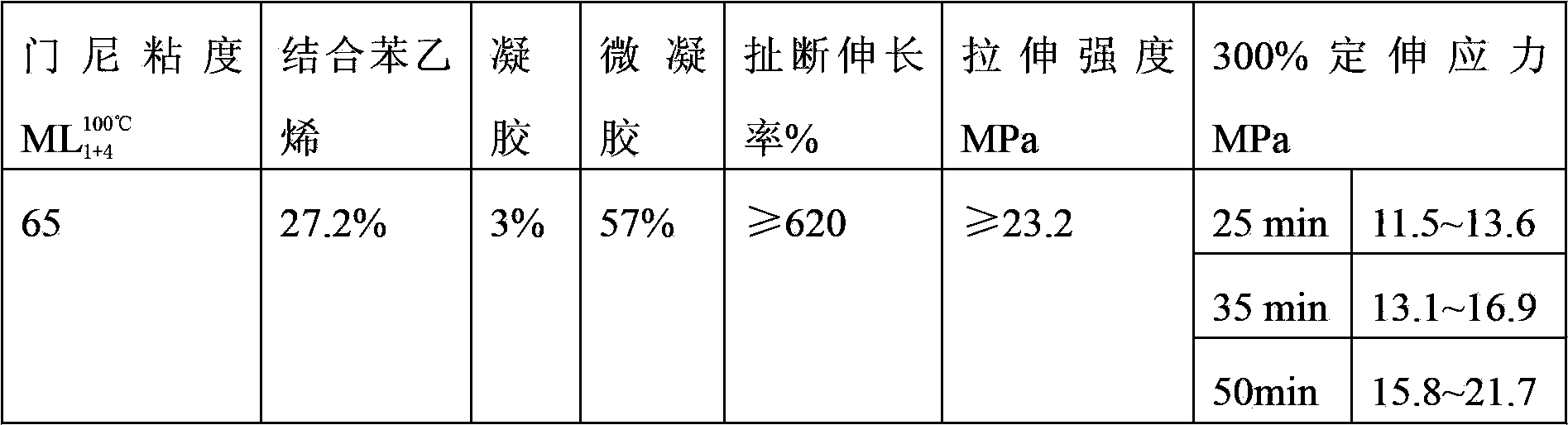

Embodiment 2

[0064] at 3M 3 Add 1600 kilograms of water to the reaction kettle, then add 56.75 kilograms of potassium stearate solution and 53.89 kilograms of potassium oleate solution, 20 kilograms of potassium chloride solution, and 14.28 kilograms of diffusing agent N solution, and disperse and dissolve under stirring. 2.6 kilograms of mercaptans, add 200 kilograms of styrene, 46 kilograms of ammonium persulfate solution, 576 kilograms of butadiene, and control the temperature to 8 ° C for reaction. When the conversion rate reaches 30-36%, add 10.5 grams of emulsifier potassium stearate solution , 7.5 kilograms of potassium oleate solution, 16 kilograms of aliphatic ether polysulfides and 54 kilograms of styrene continue to react, and when the conversion rate reaches 50 ± 3%, add 10.5 kilograms of emulsifier potassium stearate solution and 7.5 kilograms of potassium oleate solution Continue to react after 1 kg, add 48 kg of terminator when the reaction conversion rate reaches more than ...

Embodiment 3

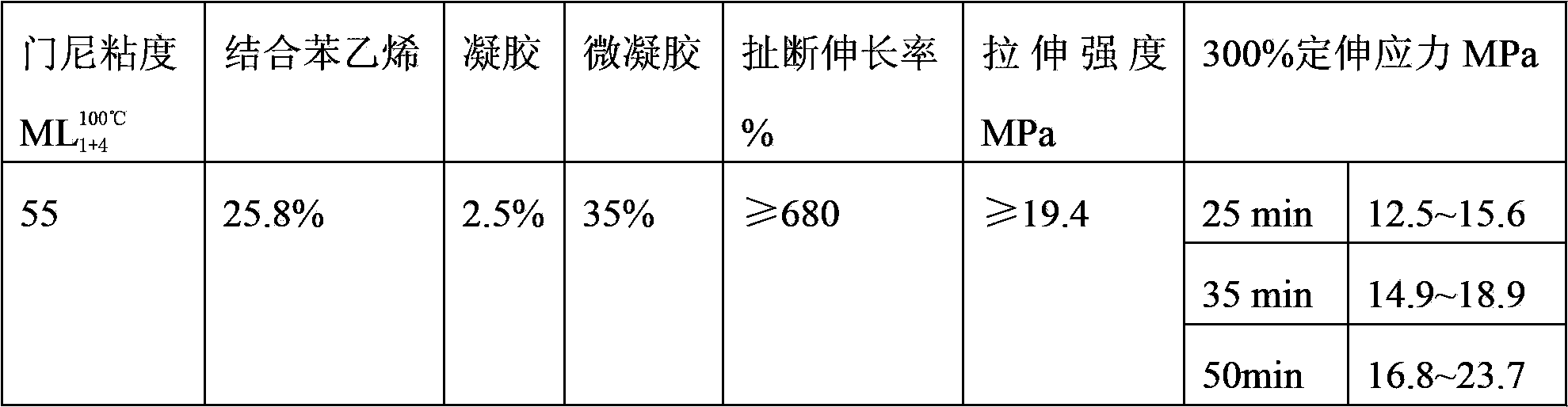

[0068] Add 4449 ml of water into a 10-liter reactor, then add 98.56 g of CP-103 and 15.37 g of CP-50, disperse and dissolve under stirring, add 400.59 g of styrene, 4.1 g of tert-dodecyl mercaptan, and 0.17 g of sodium dithionite gram, nitrogen inflation-after vacuum replacement, add 0.856 grams of dicumyl peroxide, then add 1440 grams of butadiene, control the temperature to 5±0.5°C for reaction, when the conversion rate reaches 30-36%, add emulsifier CP- 10 75 grams, 0.65 grams of tertiary dodecyl mercaptan, 31.5 grams of aliphatic ether polysulfides and 54 grams of styrene, and then continue the reaction. When the conversion rate reaches 50±3%, add emulsifier CP-10 75 grams, tertiary ten Continue to react after 0.35 grams of dicarbon mercaptan, add 35 grams of terminators when the reaction conversion rate reaches more than 80 ± 2%, degas after 30 minutes, then condense, dry, and the results after the glue sample detection are shown in Table 3:

[0069] table 3

[0070] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com