Method of grafting and modifying rubber latex containing poly conjugated dialkene by in situ hybridization of silicon

A technology of polyconjugated diene and conjugated diene, which is applied in the field of silicon in-situ graft hybridization modification latex containing polyconjugated diene, can solve the problems of unstable emulsion, complicated operation process, etc. Not tight, avoid the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

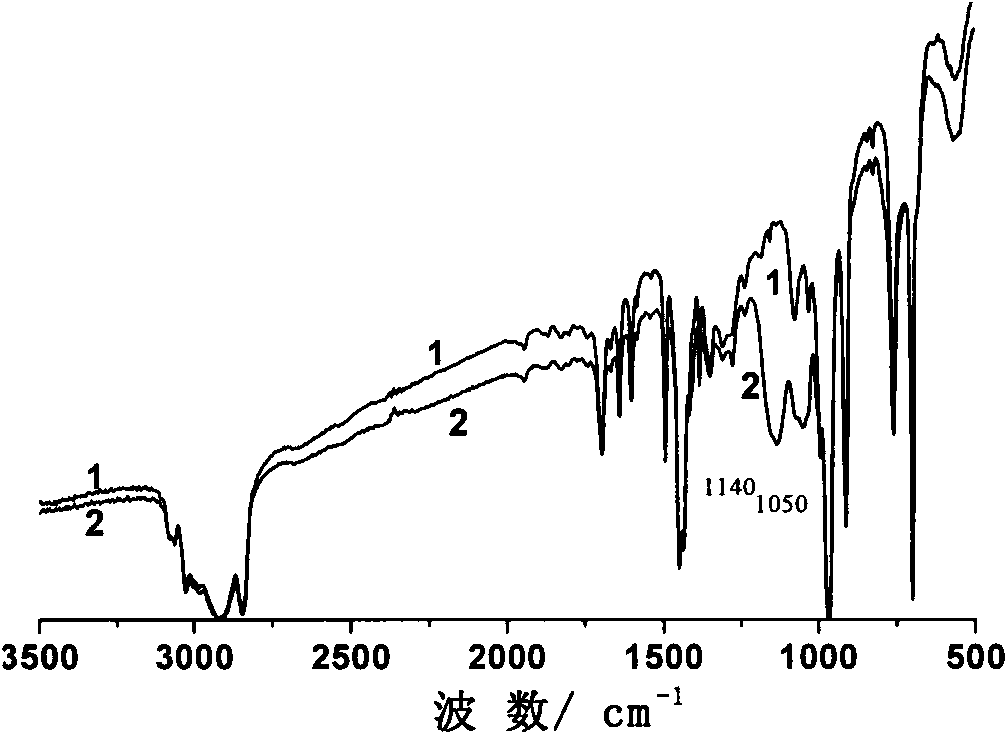

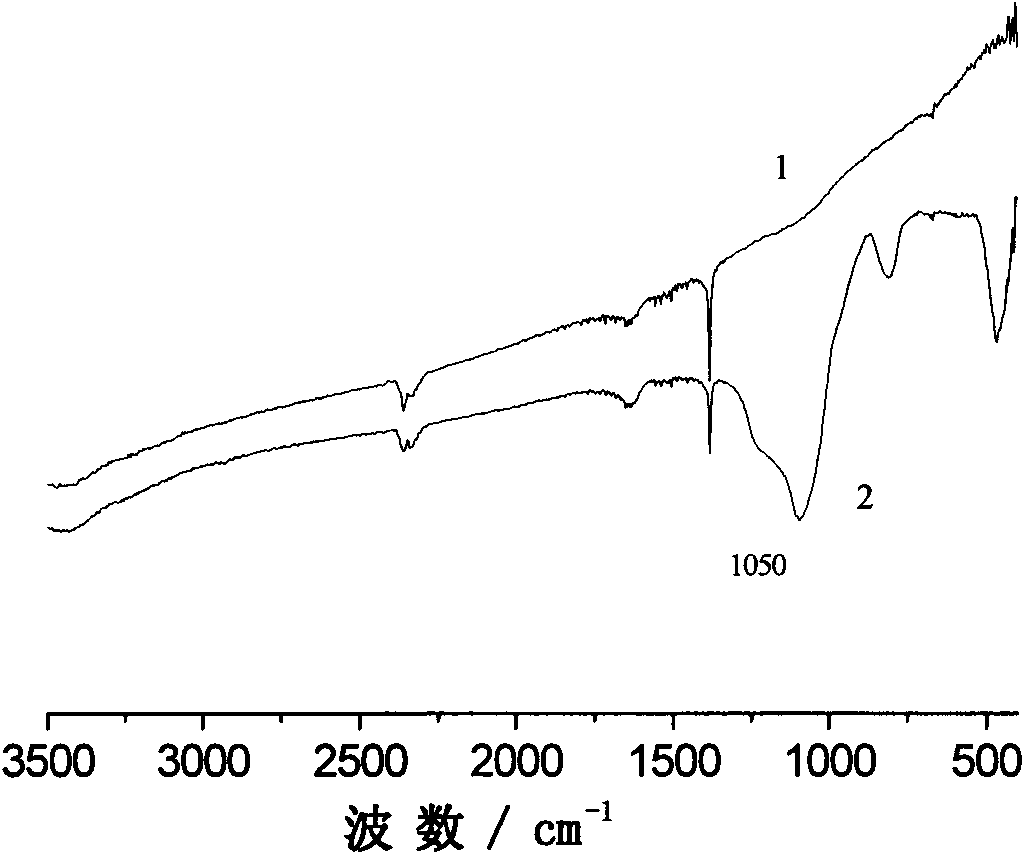

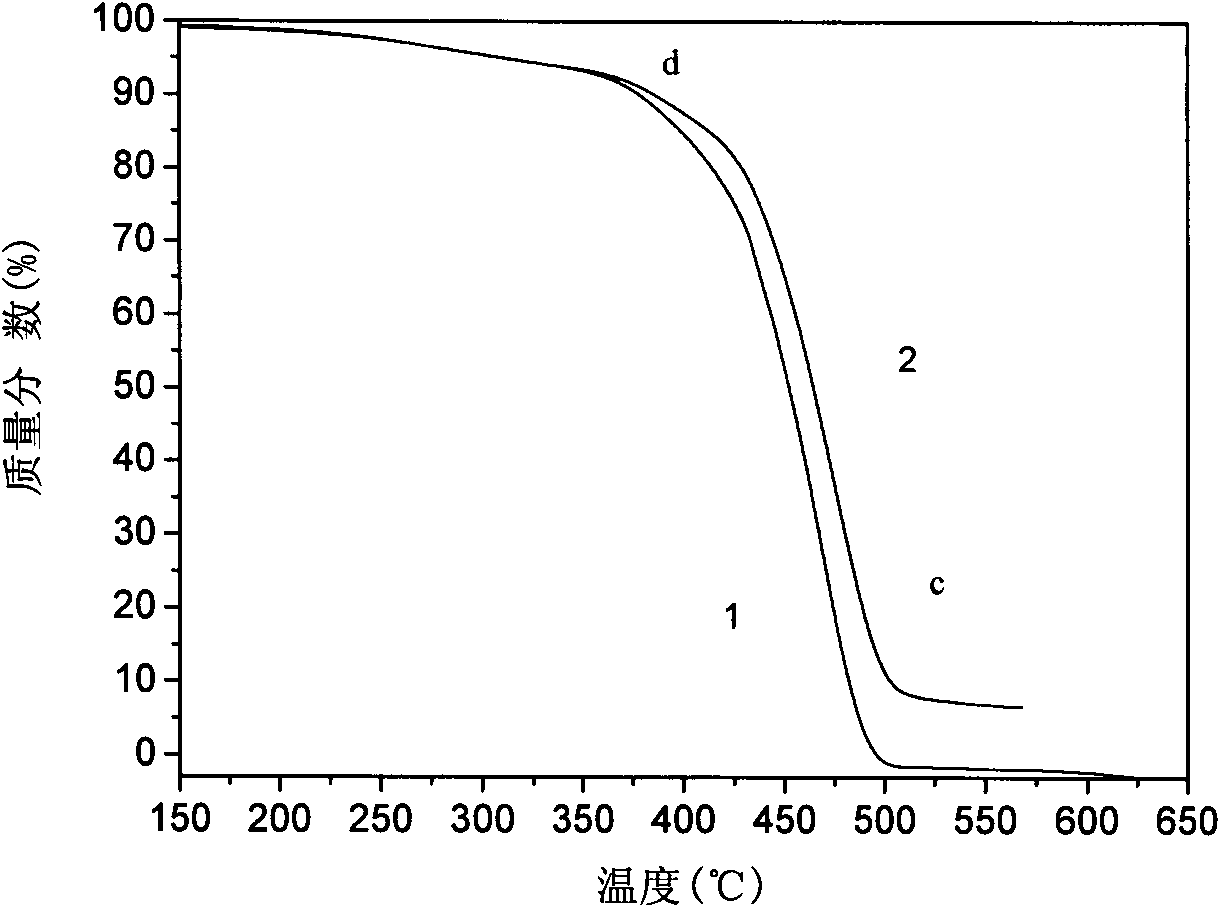

[0039] Add 50g of dry glue SBR1500 latex and 8g of VTES into a four-necked flask, stir and mix well, heat up to 68°C, then add dropwise a mixed solution of 0.1g of benzoyl peroxide and 50g of abietic acid soap (concentration: 22%) , reacted under stirring conditions for 350 minutes; after the reaction, the system was cooled down, and then the latex was coagulated and vacuum-dried. After testing, the utilization rate of VTES can reach 90.4%. Compared with the unmodified raw rubber tensile strength (196.2kpa) and Mooney viscosity (56), the modified raw rubber tensile strength is 238.8kpa, an increase of 21.7%. , Mooney viscosity 62.9, only increased by 12.7%. SEM test shows that there are no large particles of silica in the modified compound.

Embodiment 2

[0041] Add 45g of dry glue SBR1500 latex and 2.5g of MPTS into a four-neck flask, stir and mix well, heat up to 65°C, then add 0.13g of benzoyl peroxide, and react for 420 minutes under stirring conditions; Cool down, then coagulate the latex, and vacuum dry. After testing, the utilization rate of VTES can reach 88.0%. Compared with the unmodified raw rubber tensile strength (196.2kpa) and Mooney viscosity (56), the modified raw rubber tensile strength is 236.9kpa, an increase of 20.7%. , Mooney viscosity 61.2, only increased by 9.7%. SEM test shows that there are no large particles of silica in the modified compound.

Embodiment 3

[0043] Add 56g of dry glue SBR1500 latex and 12g of VTMS into a four-neck flask, stir and mix well, cool down to 8°C, then add 0.15g of dicumyl hydroperoxide and 0.015g of ferrous sulfate, and react under stirring for 400 Minutes; the latex is coagulated at the end of the reaction and dried in vacuum. After testing, the utilization rate of VTES can reach 92.0%. Compared with the unmodified raw rubber tensile strength (196.2kpa) and Mooney viscosity (56), the modified raw rubber tensile strength is 241.6kpa, an increase of 23.1%. , Mooney viscosity 64.4, increased by 15.5%. SEM test shows that there are no large particles of silica in the modified compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com