Method of grafting and modifying rubber latex containing poly conjugated dialkene by in situ hybridization of silicon

A technology for polyconjugated diene and conjugated diene, which is applied in the field of silicon in-situ graft hybridization modification latex containing polyconjugated diene, can solve the problems of complex operation process, unstable emulsion and the like, and achieves easy avoidance. Agglomeration, avoiding the effect of loose bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

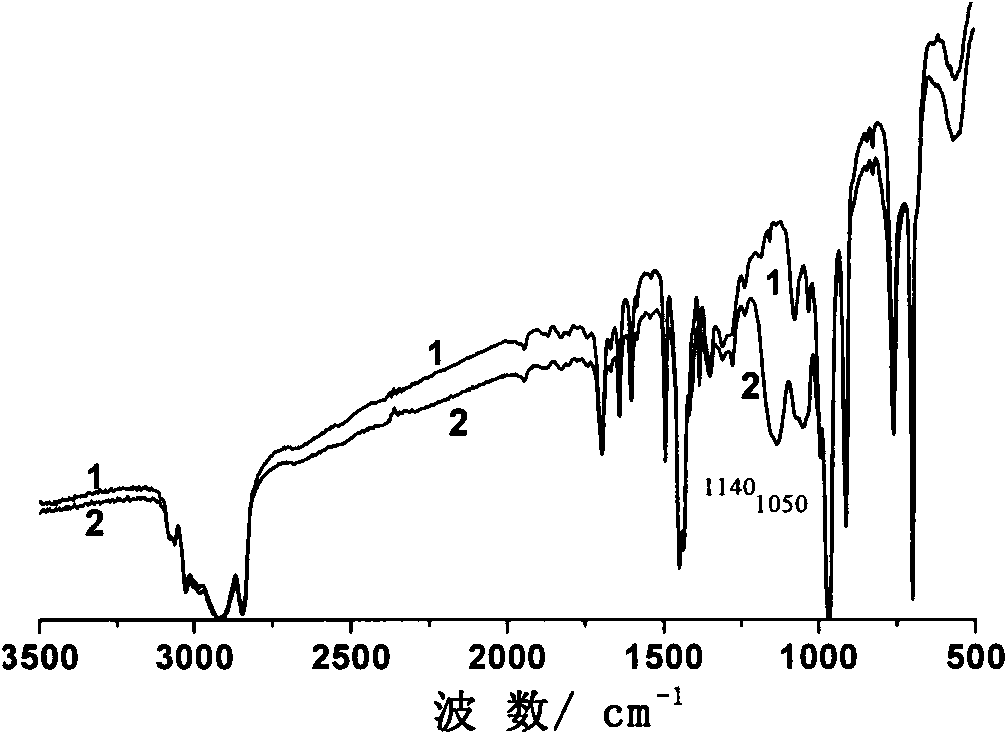

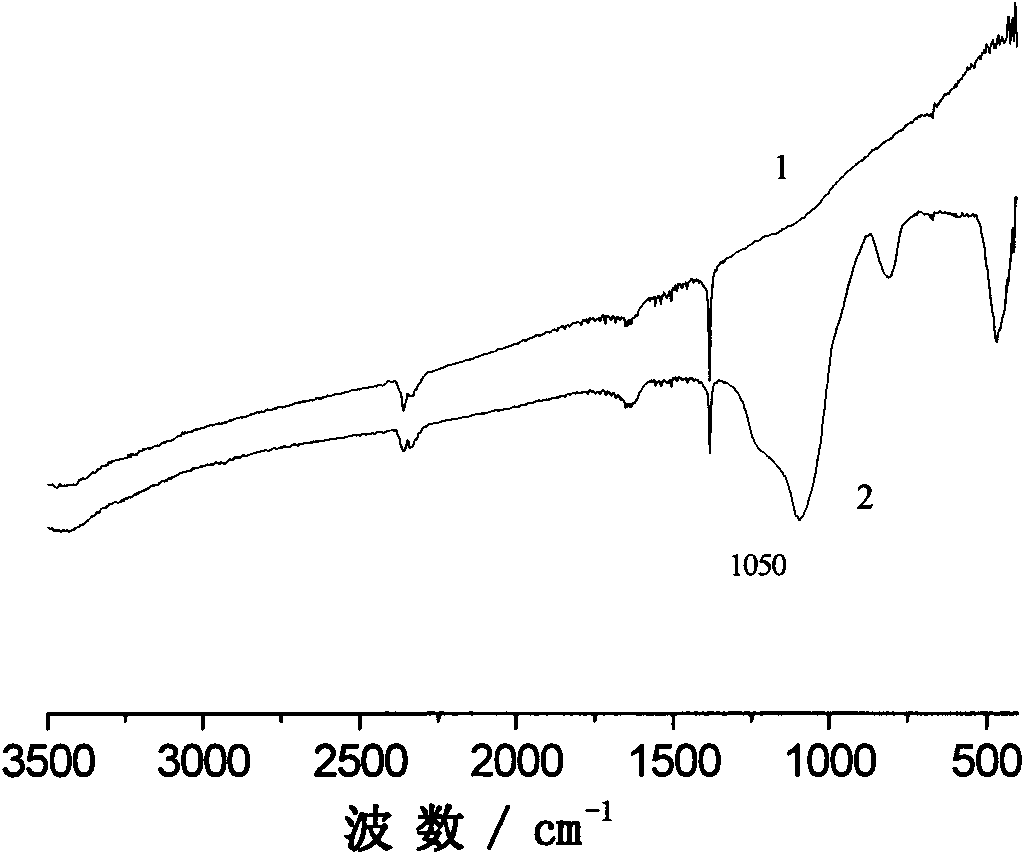

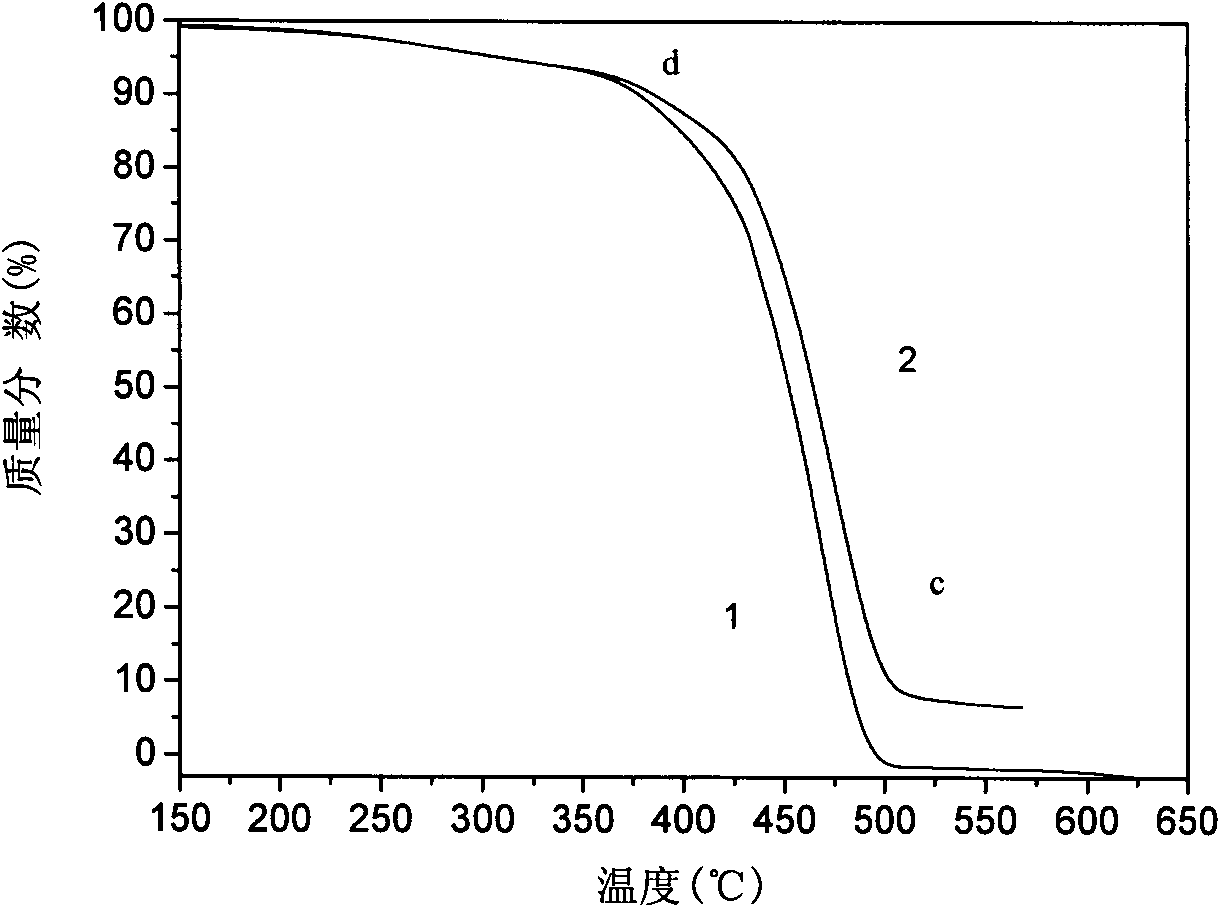

[0039] Add 50g of dry glue SBR1500 latex and 8g of VTES into a four-necked flask, stir and mix well, heat up to 68°C, then add dropwise a mixed solution of 0.1g of benzoyl peroxide and 50g of abietic acid soap (concentration: 22%) , reacted under stirring conditions for 350 minutes; after the reaction, the system was cooled down, and then the latex was coagulated and vacuum-dried. After testing, the utilization rate of VTES can reach 90.4%. Compared with the unmodified raw rubber tensile strength (196.2kpa) and Mooney viscosity (56), the modified raw rubber tensile strength is 238.8kpa, an increase of 21.7%. , Mooney viscosity 62.9, only increased by 12.7%. SEM test shows that there are no large particles of silica in the modified compound.

Embodiment 2

[0041] Add 45g of dry glue SBR1500 latex and 2.5g of MPTS into a four-neck flask, stir and mix well, heat up to 65°C, then add 0.13g of benzoyl peroxide, and react for 420 minutes under stirring conditions; Cool down, then coagulate the latex, and vacuum dry. After testing, the utilization rate of VTES can reach 88.0%. Compared with the unmodified raw rubber tensile strength (196.2kpa) and Mooney viscosity (56), the modified raw rubber tensile strength is 236.9kpa, an increase of 20.7%. , Mooney viscosity 61.2, only increased by 9.7%. SEM test shows that there are no large particles of silica in the modified compound.

Embodiment 3

[0043] Add 56g of dry glue SBR1500 latex and 12g of VTMS into a four-neck flask, stir and mix well, cool down to 8°C, then add 0.15g of dicumyl hydroperoxide and 0.015g of ferrous sulfate, and react under stirring for 400 Minutes; the latex is coagulated at the end of the reaction and dried in vacuum. After testing, the utilization rate of VTES can reach 92.0%. Compared with the unmodified raw rubber tensile strength (196.2kpa) and Mooney viscosity (56), the modified raw rubber tensile strength is 241.6kpa, an increase of 23.1%. , Mooney viscosity 64.4, increased by 15.5%. SEM test shows that there are no large particles of silica in the modified compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com