Dual damascene type pore-free tyre segmental mold, dual damascene type pore-free tyre segmental mold pattern block and manufacturing method

A pattern block, no air hole technology, used in the field of tire molds, can solve the problems of complex cleaning process, difficult cleaning, and inability to clean thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

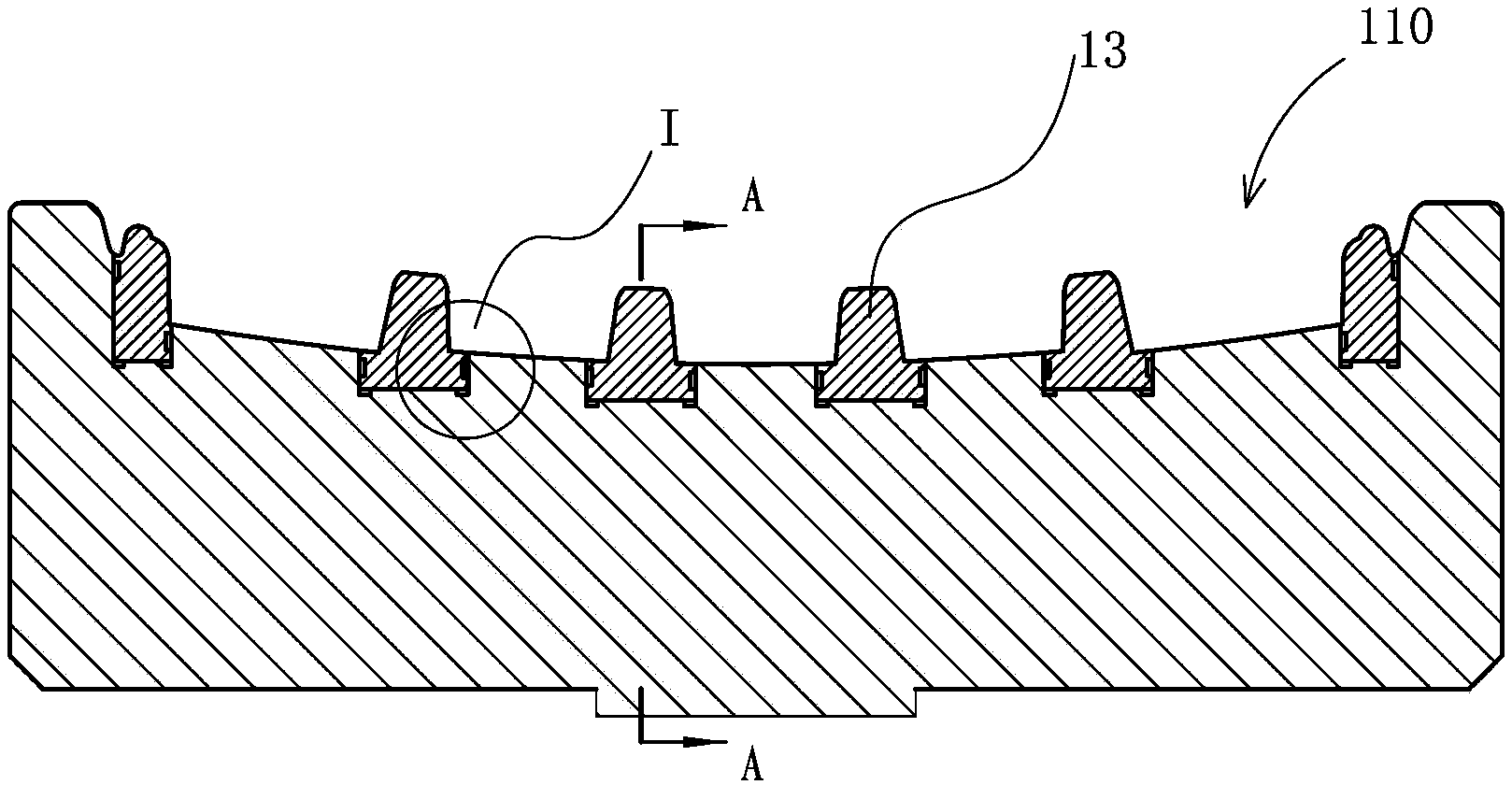

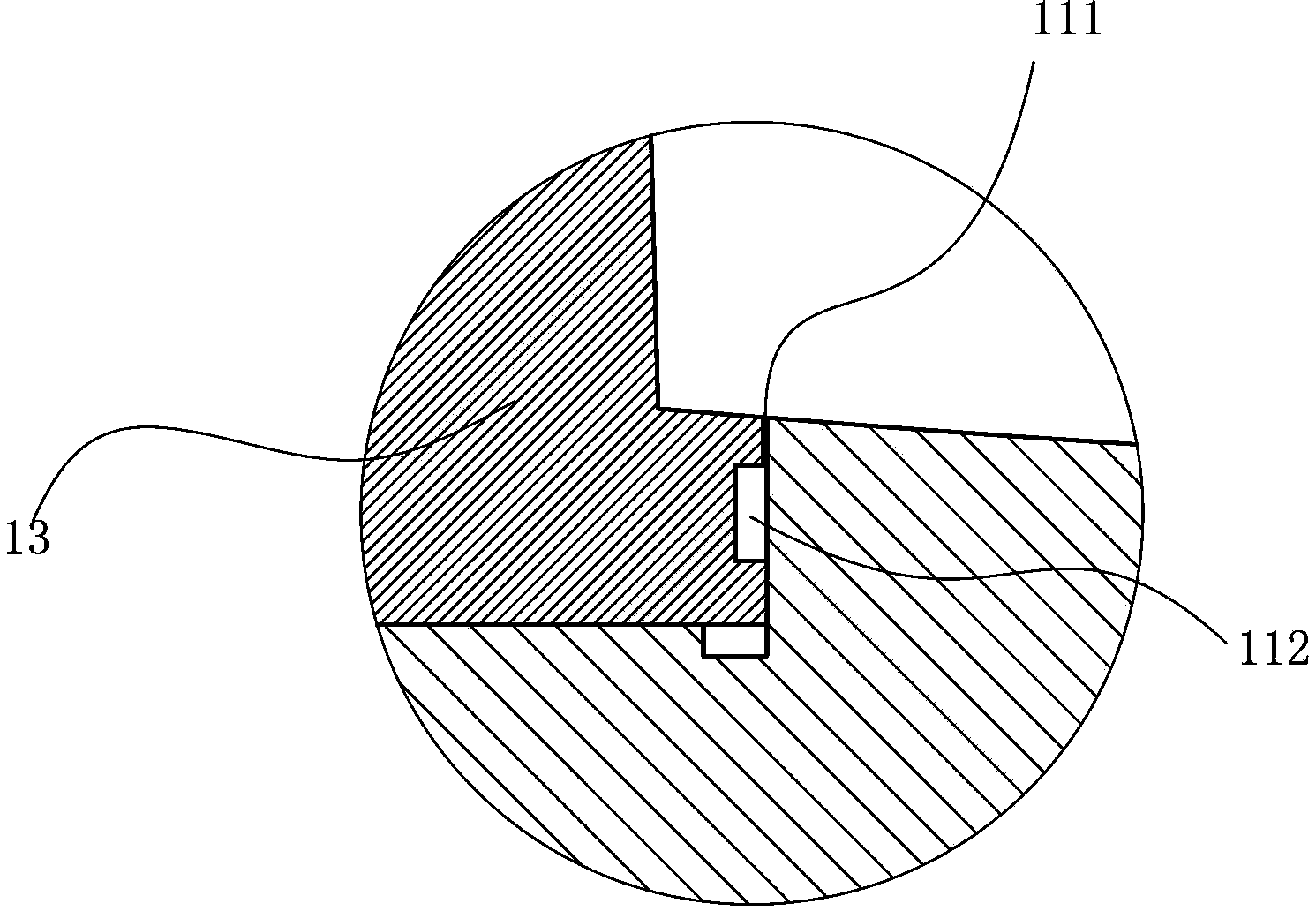

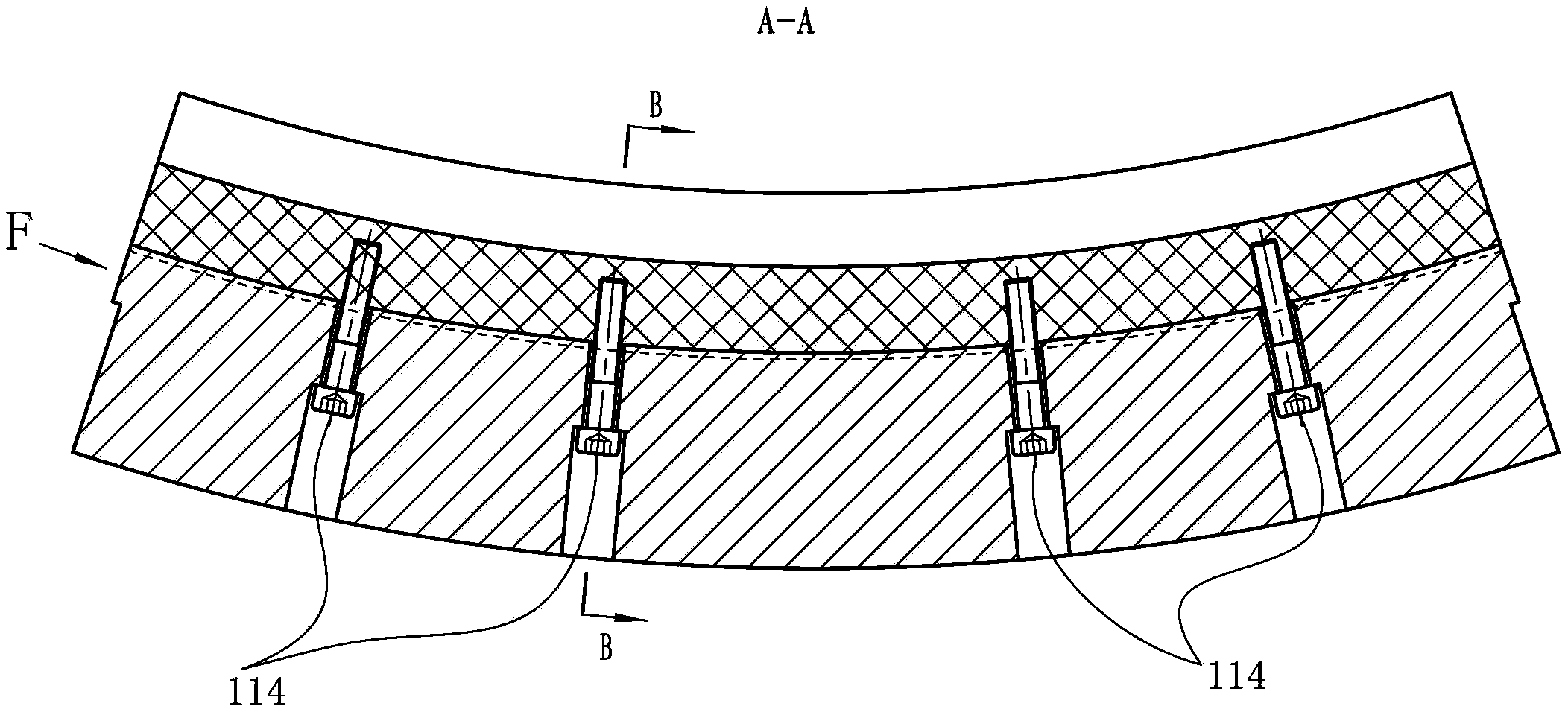

[0052] The present invention first proposes a bimetal inlaid airless tire active mold block, which is characterized in that the block includes a block body made of a first metal material and an inlay structure of a second metal material, and the block body is close to The inlay structure is set on the inner peripheral surface for forming the pattern surface to be assembled into a bimetal inlaid airless tire active mold block, the block is provided with a row connecting the inner peripheral surface and the outside of the active mold cavity The air channel, wherein the first metal material and the second metal material are both materials suitable for tire vulcanization, and the strength of the first metal material is higher than that of the second metal material. The invention also proposes a non-porous tire active mold using the aforementioned pattern blocks and a method for manufacturing the pattern blocks. The bimetal inlaid airless tire active mold block of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com