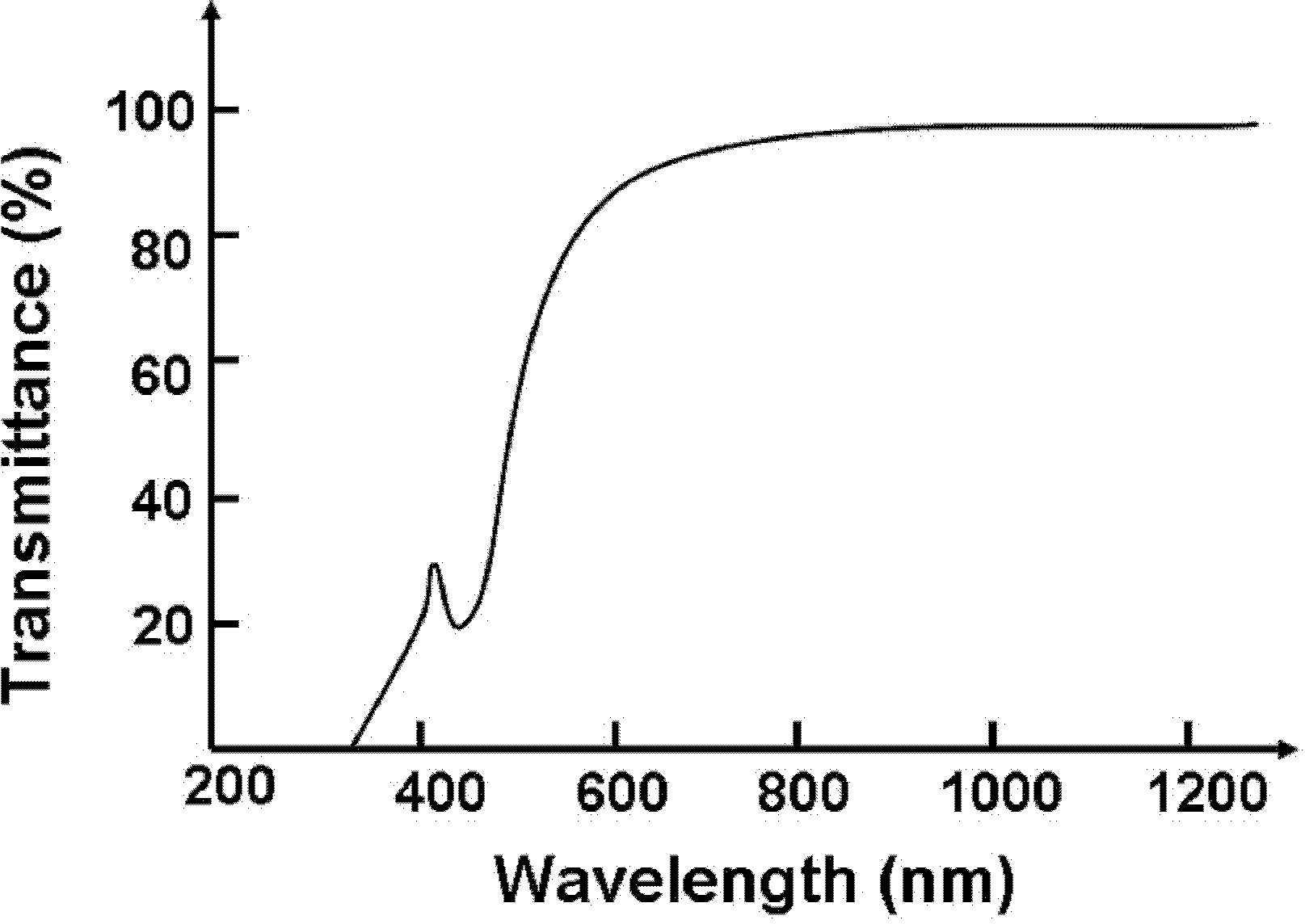

Amber alumina silicate glass

A kind of aluminosilicate glass, amber technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of fragility, quality and durability aging, poor glass strength and impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described below in conjunction with embodiment.

[0020] According to the mass percentage of the following oxides in amber aluminosilicate glass: SiO 2 65%;Al 2 o 3 13.5%; Na 2 O 13.5%; K 2 O 1.5%; MgO 3.5%; CaO 2.5%; WO 3 0.08%; SO 3 0.3%.

[0021] The following raw materials were weighed, prepared and mixed uniformly to form an amber aluminosilicate glass batch:

[0022] Feldspar 312g, silica sand 52g, dolomite 36.8g, limestone 1.9g, soda ash 90.8g, iron oxide 0.16g, tungsten disulfide 0.05g, calcium sulfide 2g, carbon powder 0.4g, mix well and put into corundum crucible for melting system, the melting temperature is 1660°C, and the melting atmosphere is controlled to be reducing, according to the Fe content in the molten glass 2+ / Fe 3+ Ratio to control the amount of carbon added, when Fe 2+ / Fe 3+ When £0.6, increase the amount of carbon powder, when Fe 2+ / Fe 3+ When 30.6, stop increasing the content of carbon powder; and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com