Preparation and application of a tobacco sheet additive with both flavoring and coloring effects

A technology of tobacco flakes and additives, applied in the fields of tobacco, application, and preparation of tobacco, can solve the problems of affecting cigarette smoking, uncomfortable aftertaste, and many oral residues, and achieve bright color, harmonious tobacco aroma, and less oral residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

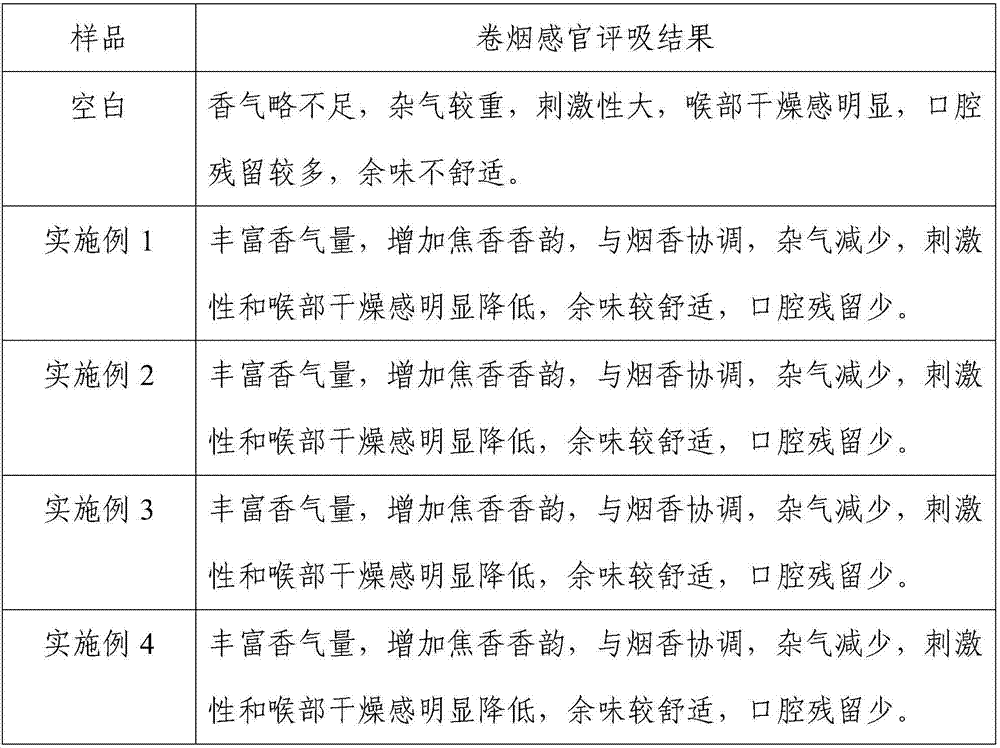

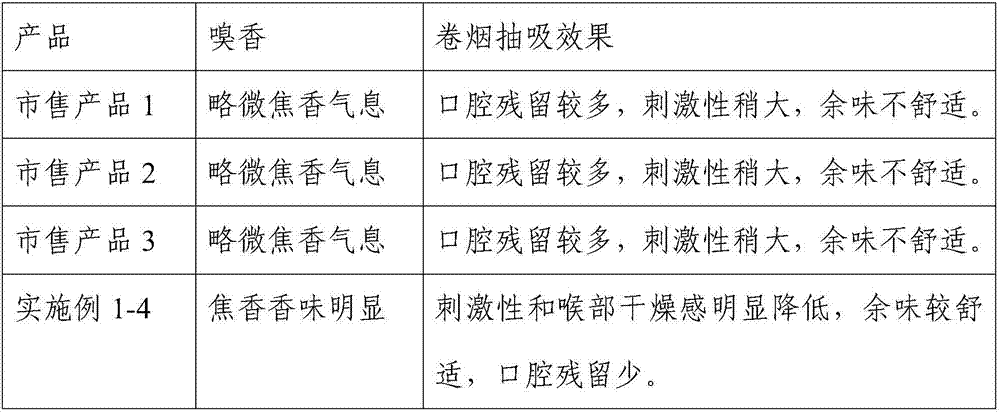

Examples

Embodiment 1

[0020] Embodiment 1, a tobacco sheet additive having both flavoring and coloring effects, the specific preparation method is as follows:

[0021] (1) After the chestnut shells are removed from impurities, washed and dried, they are pulverized and passed through a 20-mesh sieve for subsequent use;

[0022] (2) Put step (1) through crushing and sieving to obtain chestnut shell powder and water in a container according to the ratio of material to liquid of 1:20, add 0.5% of the total mass of cellulase to the mixed material liquid, at pH 5.5 1. Enzymolysis treatment at 55°C for 2.5 hours, then cooled to room temperature;

[0023] (3) Add respectively 5.0% glucose and 1.0% compound amino acid (compound amino acid is composed of glutamic acid, alanine, proline according to 1:1) to the enzymolysis solution in step (2) : 2 mass ratio mixed), after mixing, adjust the pH to 12 with food-grade concentrated ammonia solution, quickly heat up to 100 ° C, heat treatment under constant stirr...

Embodiment 2

[0024] Embodiment 2, a kind of tobacco sheet additive that has both flavoring and coloring effects, the specific preparation method is as follows:

[0025] (1) After removing impurities, cleaning and drying the chestnut shells, pulverize them and pass through a 40-mesh sieve for subsequent use;

[0026] (2) The chestnut shell powder obtained by crushing and sieving in step (1) and water are placed in a container according to the ratio of solid to liquid of 1:15, and 0.6% of the total mass of cellulase is added to the mixed material liquid. Enzymolysis treatment at pH 4.0 and temperature 50°C for 2.0 hours, then cooled to room temperature;

[0027] (3) In the enzymolysis solution in step (2), add respectively the compound amino acid that accounts for the glucose of system gross mass 3.0% and 0.5% (compound amino acid is made of glutamic acid, alanine, proline according to mass ratio 1 : 2:4 ratio), after mixing, use food-grade sodium hydroxide aqueous solution to adjust the pH...

Embodiment 3

[0028] Embodiment 3, a tobacco sheet additive having both flavoring and coloring effects, the specific preparation method is as follows:

[0029] (1) After removing impurities, cleaning and drying the chestnut shells, pulverize them and pass through a 40-mesh sieve for subsequent use;

[0030] (2) The chestnut shell powder and water obtained by crushing and sieving in step (1) are placed in a container according to the ratio of solid to liquid of 1:10, and 0.3% of cellulase is added to the mixed material liquid, and the Enzymolysis treatment at pH 5.0 and temperature 45°C for 2.0 hours, then cooled to room temperature;

[0031](3) In the enzymolysis solution in step (2), add respectively the compound amino acid that accounts for the glucose of 4.0% system gross mass and 0.8% (the compound amino acid is made of glutamic acid, alanine, proline according to the mass The ratio is 1:1:4), after mixing, adjust the pH to 8.5 with food-grade potassium hydroxide aqueous solution, quic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com