Preparation method of printing-preventing auxiliary agent for reactive dye printing prevention

A technology of reactive dyes and active agents, applied in the field of chemical printing and dyeing, can solve the problems of cotton fiber damage, high dosage, and small dosage of acid release agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method for an anti-printing auxiliary agent for reactive dyes, comprising the following steps:

[0020] (1) Take 5-15wt% non-ionic fatty alcohol polyoxyethylene ether surfactant solid and add 15-35wt% water to dissolve it, configure it into a uniform dispersion system, stir it with a mechanical mixer at a speed of 1000-2000r, and mix Adding 50-80wt% of white oil, silicone oil, and kerosene dropwise while stirring to prepare a water-blocking thickener;

[0021] (2) Take 1-3wt% citric acid, tartaric acid, maleic acid, itaconic acid, ammonium sulfate at least one anti-printing acid agent, add 15-20wt% deionized water to dissolve evenly, add 45 -60wt% of the water-blocking thickener prepared in step (1), stir it evenly with a mechanical mixer, then add 20-40wt% anionic polyurethane PU300C to it, stir evenly, and prepare a kind of anti-printing auxiliary for reactive dyes ; Among them, the viscosity of the anti-printing additive is 26000-54000mPa.s.

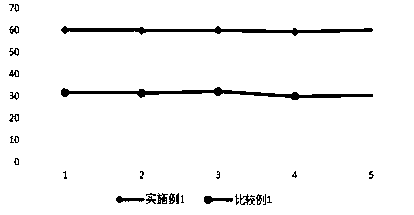

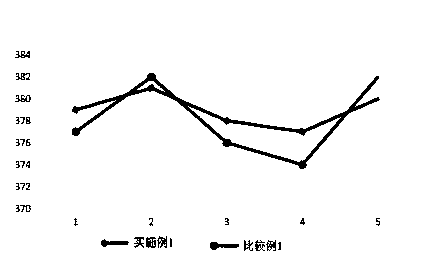

Embodiment 1

[0023] Preparation of anti-printing additives: Take 10wt% nonionic fatty alcohol polyoxyethylene ether type surfactant solid and add 20wt% water to dissolve, stir with a mechanical mixer at a speed of 1500r, and add 70wt% of it dropwise while stirring White oil, prepared as a water blocking thickener; take 3wt% citric acid, add 20wt% deionized water to dissolve evenly, add 45wt% water blocking thickener to this solution and stir evenly with a mechanical mixer, and then add 33wt% anionic polyurethane PU300C; stir evenly to prepare an anti-printing auxiliary for reactive dye printing; wherein the viscosity of the anti-printing auxiliary is 26000-54000mPa.s;

[0024] Preparation of active printing paste: accurately weigh 80wt% deionized water, add 15wt% urea, 2.5wt% baking soda, 0.2wt% anti-staining salt s, 4.5wt% solid sodium alginate in sequence, and stir for 2 hours at high speed with a stirrer , puffed for 6 hours to obtain the original printing paste; accurately weigh 5wt% a...

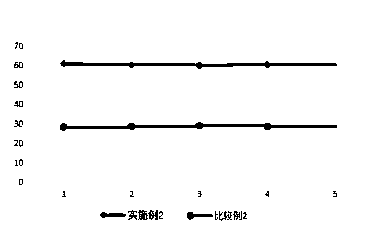

Embodiment 2

[0034] Preparation of anti-printing additives: Take 15wt% nonionic fatty alcohol polyoxyethylene ether type surfactant solid and add 20wt% water to dissolve, stir with a mechanical mixer at a speed of 1000r, and add 65wt% of it dropwise while stirring White oil; prepared as a water blocking thickener; get at least one anti-printing acid agent in 1wt% tartaric acid, maleic acid, itaconic acid, ammonium sulfate, add 40wt% deionized water to dissolve evenly, add to this solution Add 45wt% water-blocking thickener and stir evenly with a mechanical mixer, and then add 20wt% anionic polyurethane PU300C to it; stir evenly, and prepare a kind of anti-printing auxiliary agent for reactive dye printing; wherein the viscosity of anti-printing auxiliary agent At 26000-54000mPa.s;

[0035]Preparation of active printing paste: accurately weigh 80wt% deionized water, add 15wt% urea, 2.5wt% baking soda, 0.2wt% anti-staining salt s, 4.5wt% solid sodium alginate in sequence, and stir for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com