Method and device for segmentally preparing sulfuric acid and mineral cotton fibers from ardealite

A technology of slag wool fiber and phosphogypsum, which is applied in chemical instruments and methods, glass manufacturing equipment, sulfur compounds, etc., can solve the problem of low resource utilization rate of phosphogypsum, and achieve fine slag wool fiber, good quality and high concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

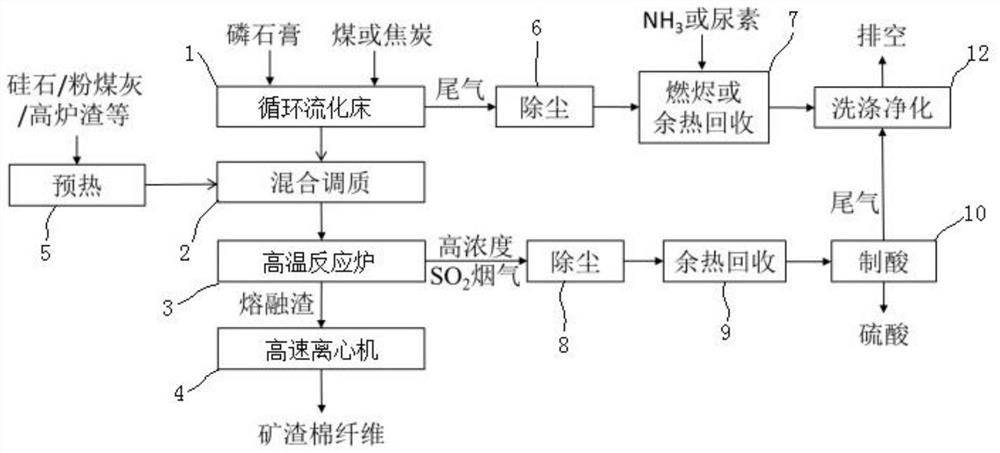

[0051] figure 1 It shows a device for preparing sulfuric acid and slag wool fibers from phosphogypsum through a two-stage process, including a circulating fluidized bed 1, a mixing device 2, a high-temperature reaction furnace 3 and a high-speed centrifuge 4 connected in sequence, and the mixing device 2 is connected with a pre- The heat device 5, the tail gas outlet of the fluidized bed 1 are sequentially connected with the first dust removal device 6, the combustion device 7, and the tail gas washing system 12, and the high temperature reaction furnace 3 is connected with the second dust removal device 8, waste heat recovery device 9 and sulfuric acid production device 10 in sequence , the tail gas outlet of the sulfuric acid plant 10 is connected to the tail gas scrubbing system 12 .

[0052] The preparation method mainly includes the following steps:

[0053] S1. Add carbon-based reducing materials to powdery phosphogypsum; wherein the molar ratio of C in the reducing mat...

Embodiment 2

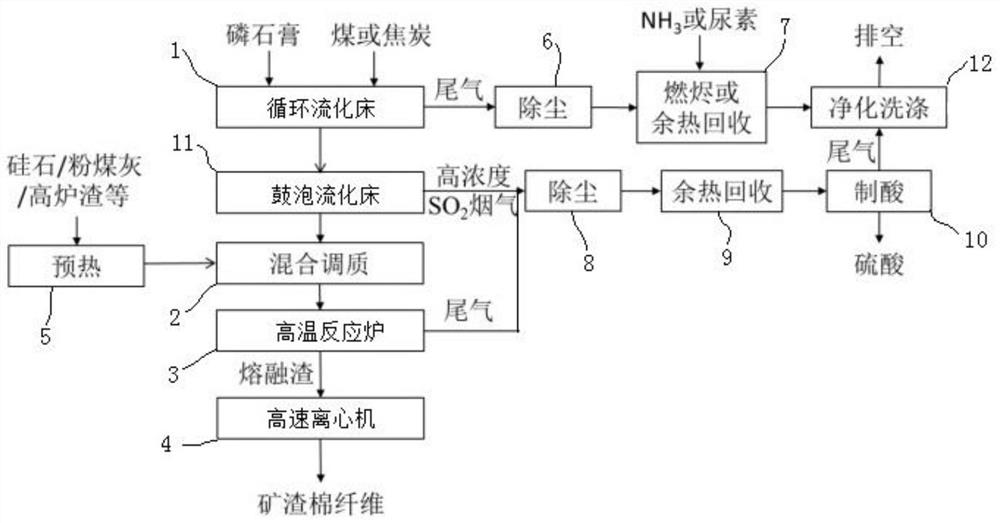

[0058] figure 2 It shows a device for preparing sulfuric acid and slag wool fibers from phosphogypsum through a three-stage process, including a circulating fluidized bed 1, a bubbling fluidized bed 11, a mixing device 2, a high-temperature reaction furnace 3 and a high-speed centrifuge 4 connected in sequence , the mixing device 2 is connected with a preheating device 5, the tail gas outlet of the fluidized bed 1 is connected with the first dedusting device 6, the combustion device 7, and the tail gas washing system 12 in sequence, and the high temperature reaction furnace 3 and the tail gas outlet of the bubbling fluidized bed 11 are connected with each other successively. The second dedusting device 8 , the waste heat recovery device 9 are connected with the sulfuric acid production device 10 , and the tail gas outlet of the sulfuric acid production device 10 is connected with the tail gas washing system 12 .

[0059] The preparation method mainly includes the following st...

Embodiment 3

[0066] The composition of the raw materials used in this example and the following examples is shown in Table 1.

[0067] Raw material composition (mass fraction %) used in the embodiment of table 1

[0068] CaO SiO 2

[0069] With 100 mass parts of phosphogypsum dry base, add 7.5 mass parts of coke (fixed carbon content is 63.62%) according to the molar ratio of carbon (C) and sulfur (S) in phosphogypsum is 0.8, send into circulating fluidized bed, temperature is 850°C, the average residence time of the material is 5.0 minutes, according to the batching requirements of slag wool, the acidity index Mk=1.35, pH=5.0 of the slag, 21.5 parts by mass of fly ash, 10 parts by mass of iron tailings and 15 parts by mass Part of silica is crushed through a 40-mesh sieve, preheated to 800°C, mixed with the hot discharge from the fluidized bed, sent to a high-temperature reaction furnace, and roasted and decomposed and melted in sequence; the temperature of the roasted dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com