Patents

Literature

89 results about "Reflection illumination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

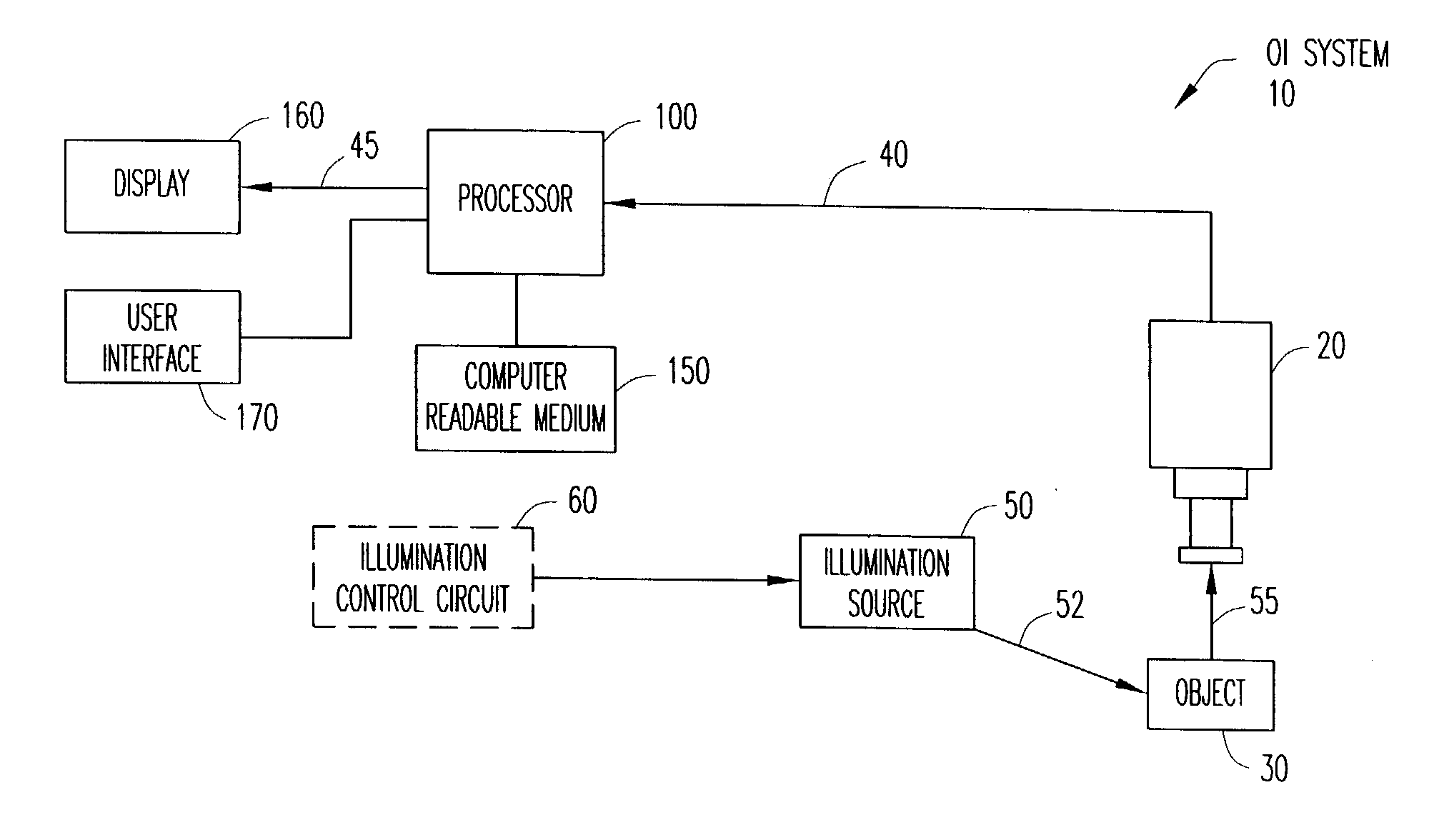

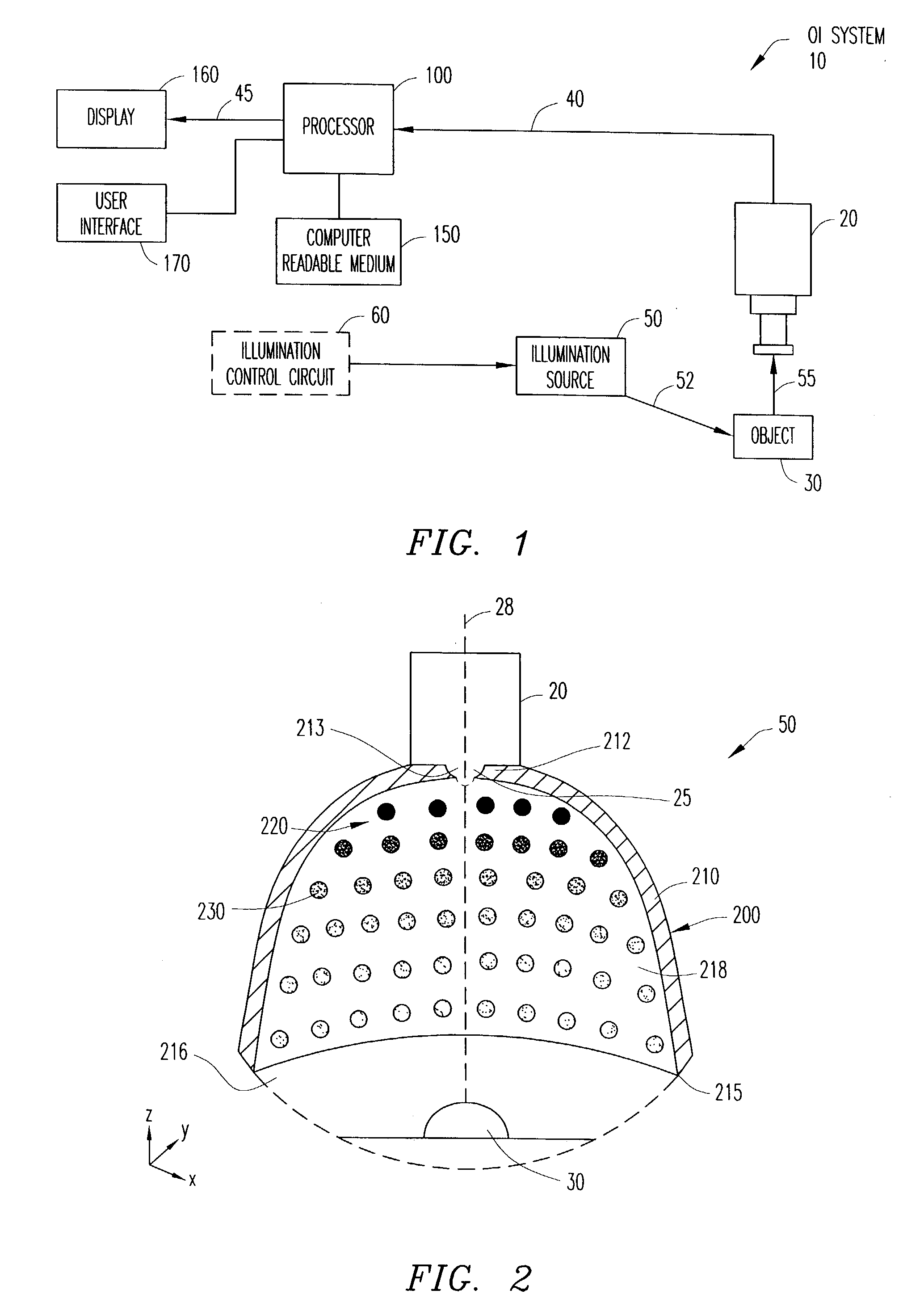

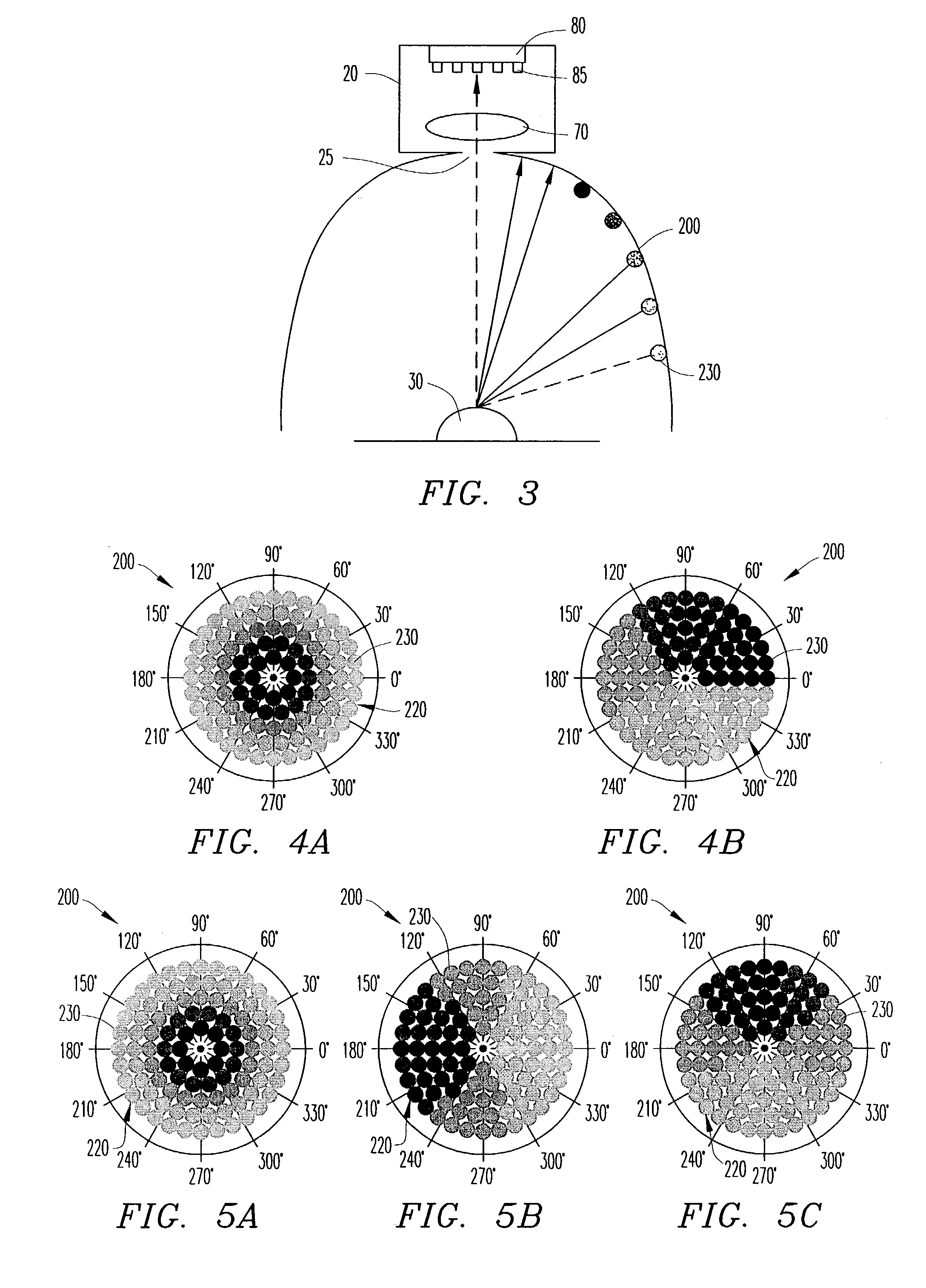

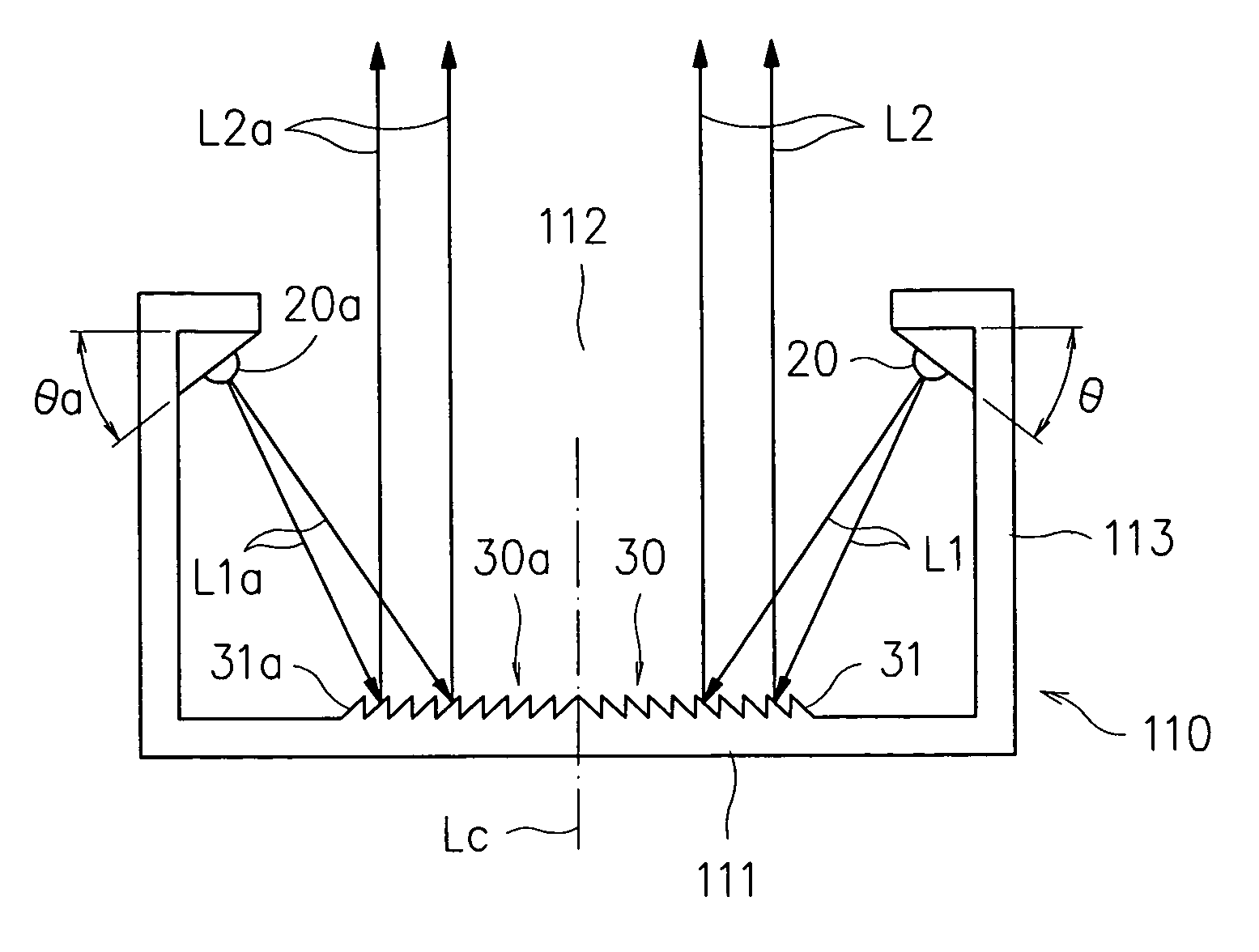

Optical inspection system, illumination apparatus and method for use in imaging specular objects based on illumination gradients

InactiveUS20040184653A1Image analysisCharacter and pattern recognitionLight equipmentSurface gradient

An optical inspection system uses an illumination gradient to gradually spatially vary the intensity and / or specular characteristics of the illumination reflected from the surface of a specular object to determine surface gradients of the object. The surface gradients can be used to reconstruct a three-dimensional image of the object. The illumination gradient can be produced by an illumination apparatus that includes circular arrays of light-emitting elements. The illumination gradient can also be produced using an optical element that gradually alters the illumination intensity of the reflected illumination in accordance with the incidence characteristics of the reflected illumination on the optical element. The illumination gradient enables the use of numerous illumination angles to reduce error in estimated surface gradients without increasing imaging or processing time.

Owner:AGILENT TECH INC

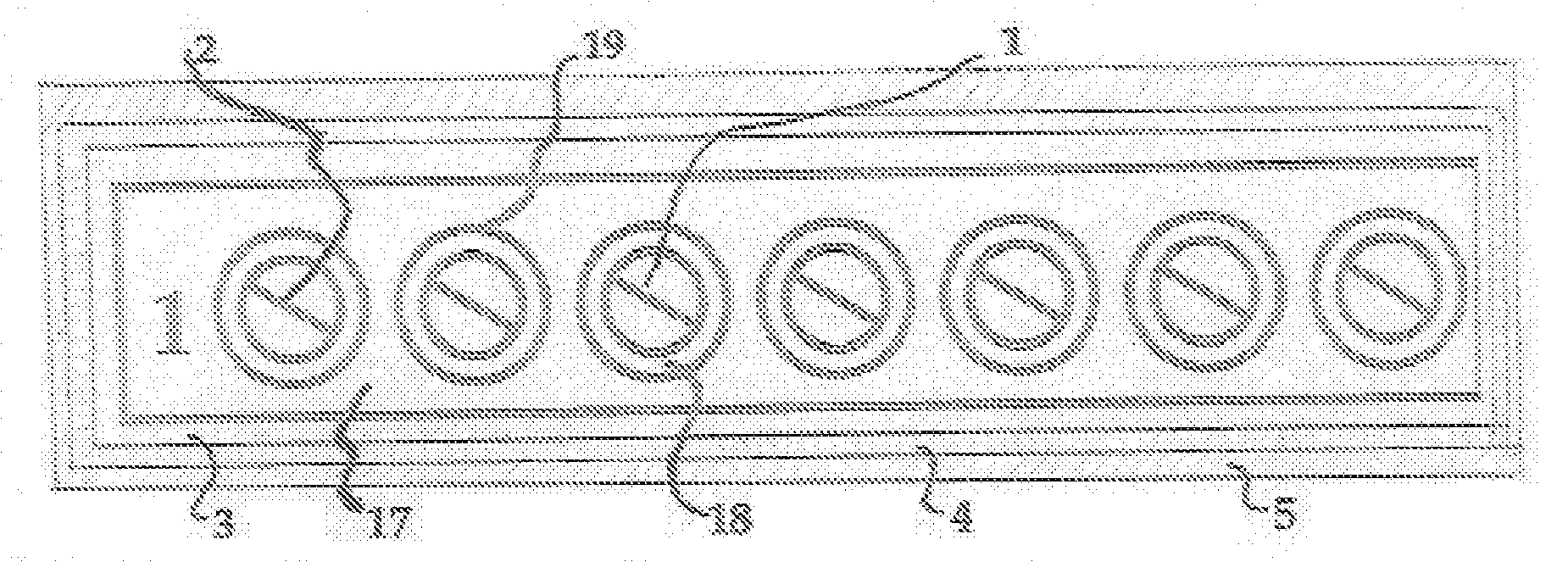

Reflective illumination device

InactiveUS7530712B2Improve efficiencyIncrease illuminationPoint-like light sourceElongate light sourcesFresnel lensReflection illumination

Owner:IND TECH RES INST +1

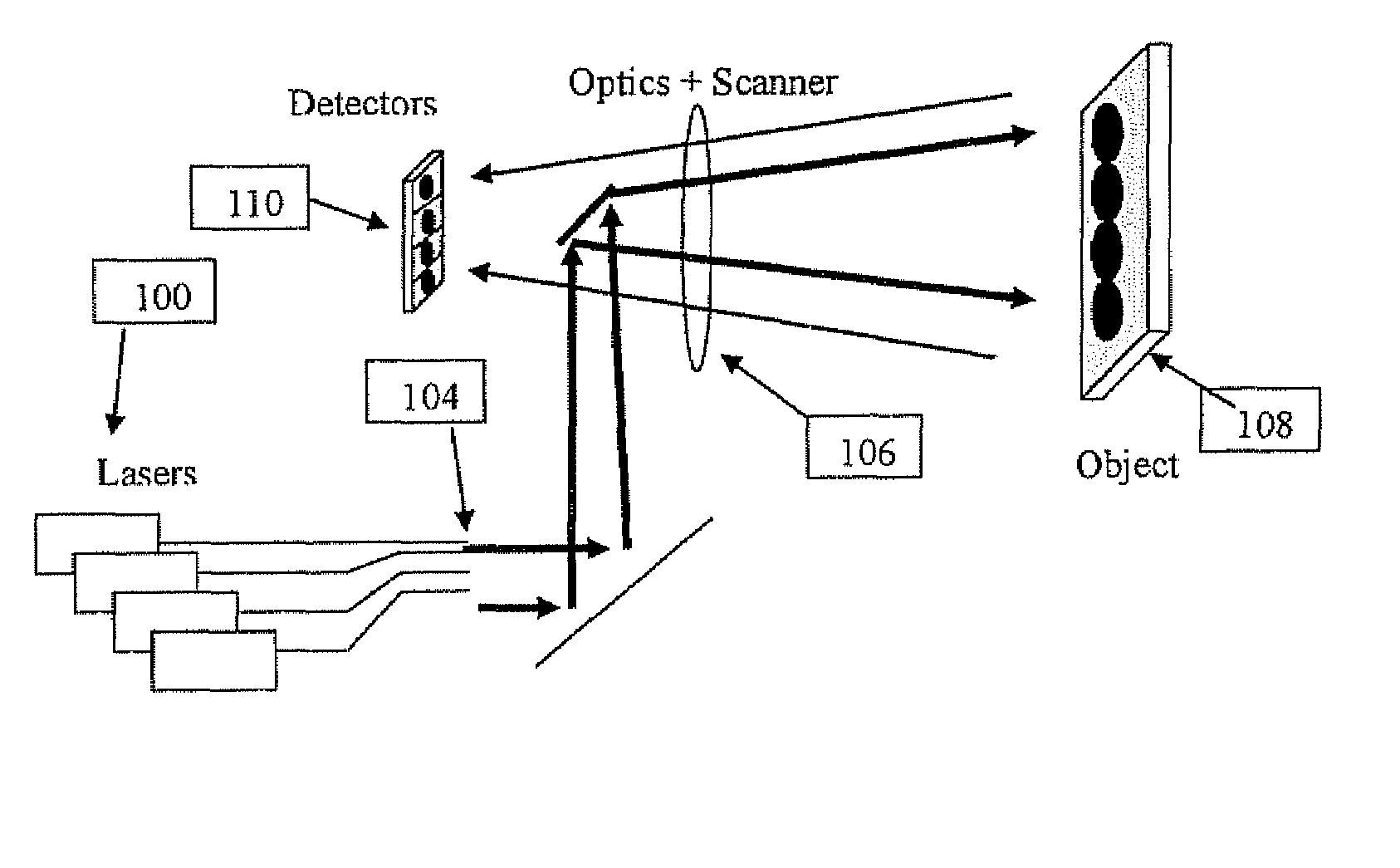

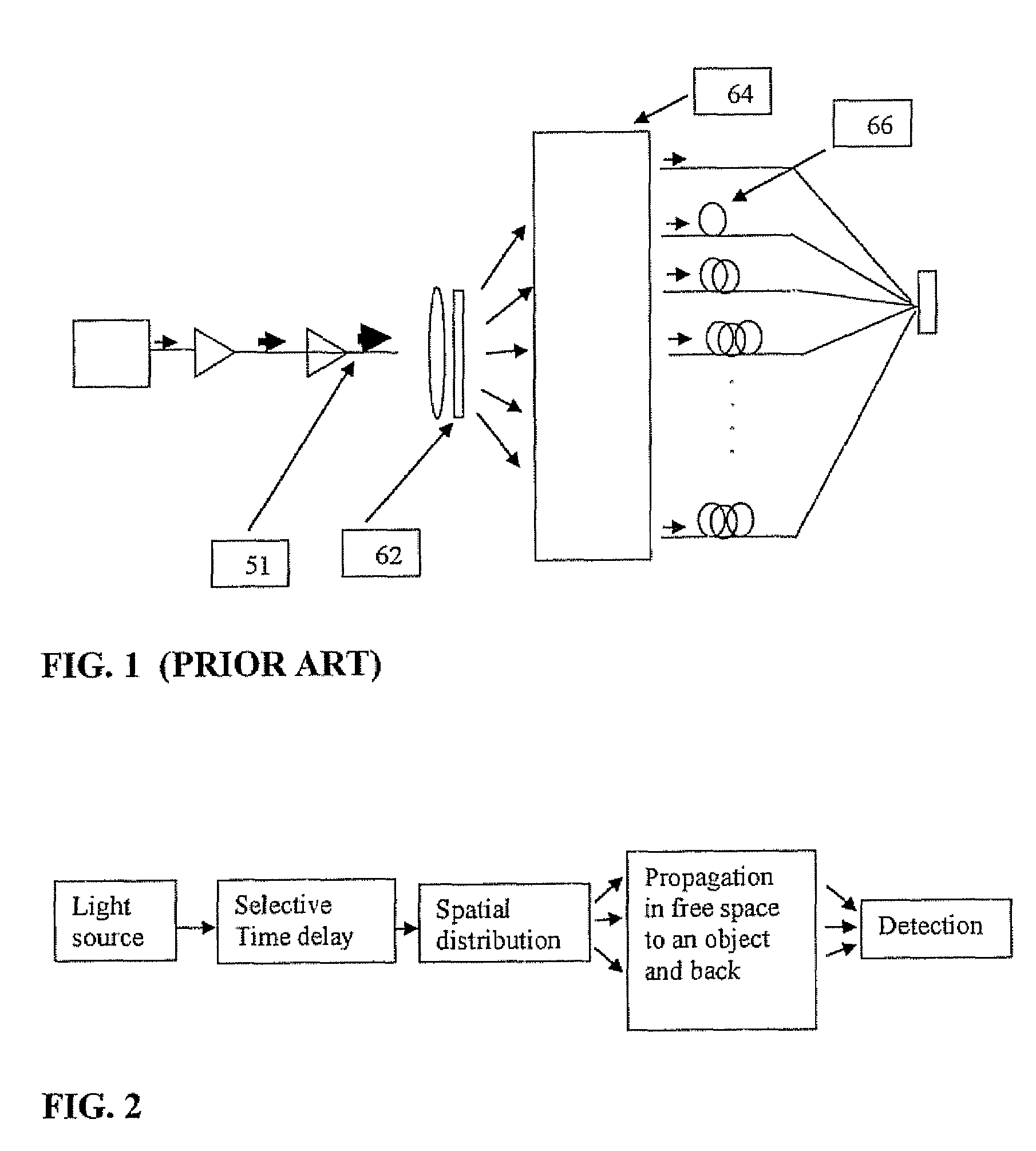

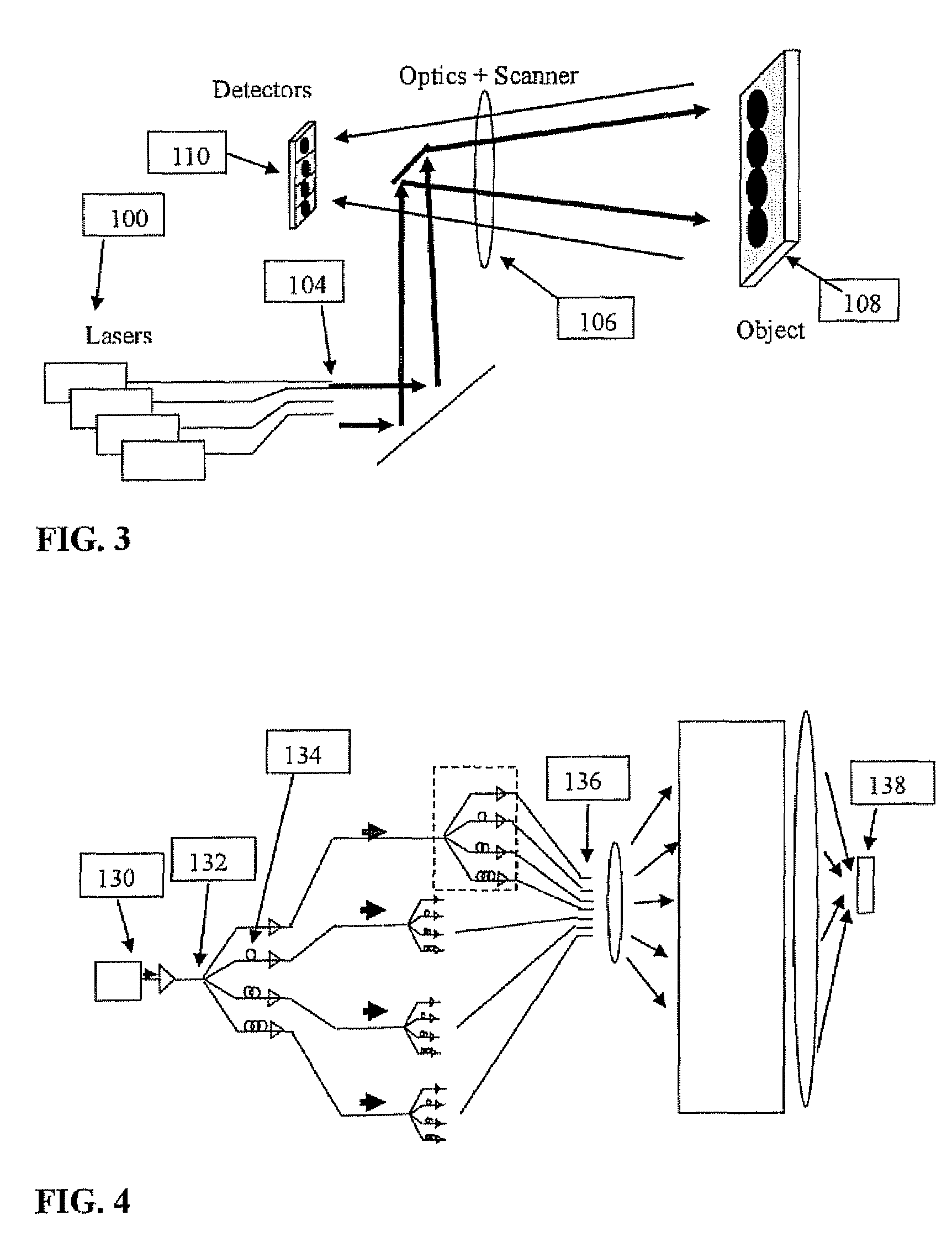

Time-Space Multiplexed LADAR

InactiveUS20070177841A1High refractive indexCoupling light guidesElectromagnetic wave reradiationImage resolutionOptical field

A LADAR system includes a detector optical arrangement defining a current optical field of view. An illumination subsystem without moving parts transmits pulsed illumination at different times to each of a number of illumination sub-regions of the current optical field of view, and a detection subsystem, including one or more detectors, detects reflected illumination from a corresponding one or more detection sub-region of the current optical field of view. Each of the detection sub-regions overlaps illumination sub-regions so that an overlap of each of the illumination sub-regions with the detection sub-region defines a LADAR image pixel of resolution finer than the detection sub-region.

Owner:THE STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG ARO VOLCANI CENT

Sealants for Solar Energy Concentrators and Similar Equipment

InactiveUS20090032088A1Good sealantImprove performance and longevityPV power plantsSynthetic resin layered productsFresnel lensPlastic materials

Owner:RABINOWITZ MARIO

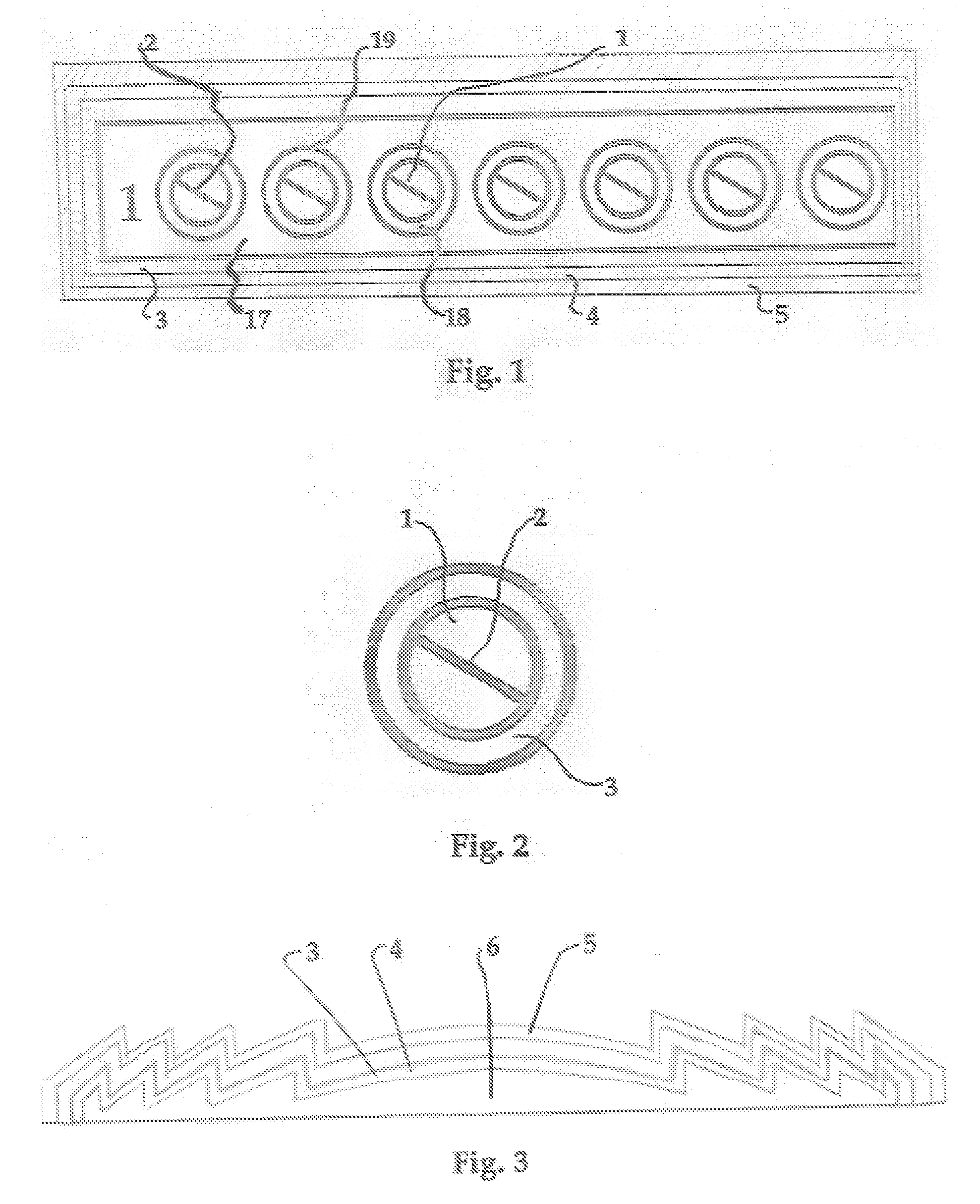

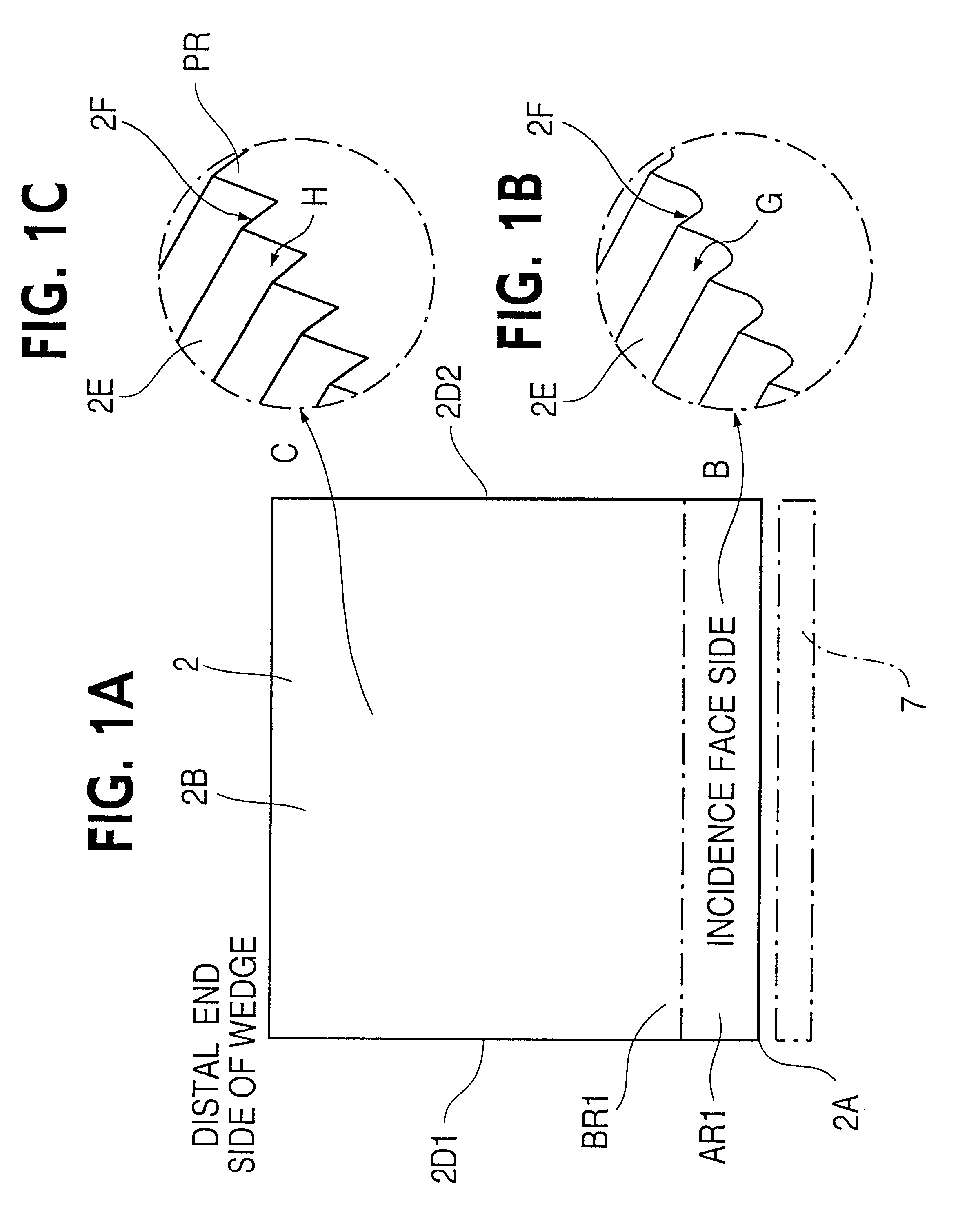

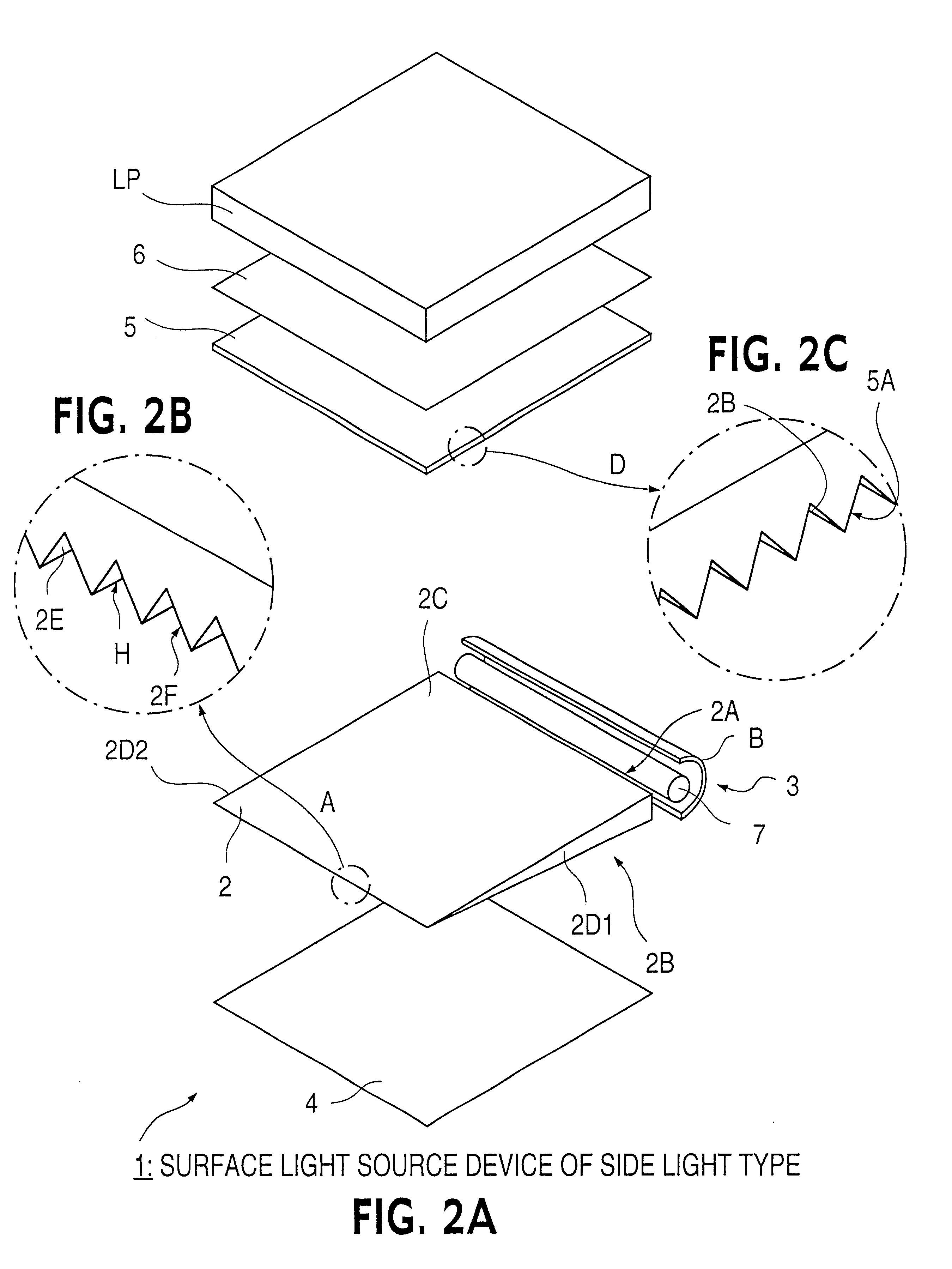

Light guide plate, surface light source device of side light type and liquid crystal display

InactiveUS6585356B1Suppress abnormal emissionAvoid display qualityMechanical apparatusElongate light sourcesLiquid-crystal displayLight guide

Cylindrically curved slopes successively inner-reflect illumination light which reaches a back face or emission face of a light guide plate via an upper edge of an incidence face. The curved slopes give the light diverse propagation directions after inner-reflection. This avoids the viewer from observing a strongly irradiated edge, thereby reducing reflective appearance. Inner-reflection by the curved slopes also gives diverse propagation directions to illumination light coming via other edges, thereby reducing reflective appearance. Curved surface profile is given to valleys involved in a great number of projection rows running in a direction approximately perpendicular to the incidence face, and may be further given to the projection rows. The valleys are provided with curved surface profile within a curved-surface-profile-giving-area around the incidence face or, in addition to this, around flank faces of the light guide plate. The curved surface profile varies gradually around a boundary of the curved-surface-profile-giving-area to avoid sudden profile changing which would bring undesirable effects.

Owner:ENPLAS CORP

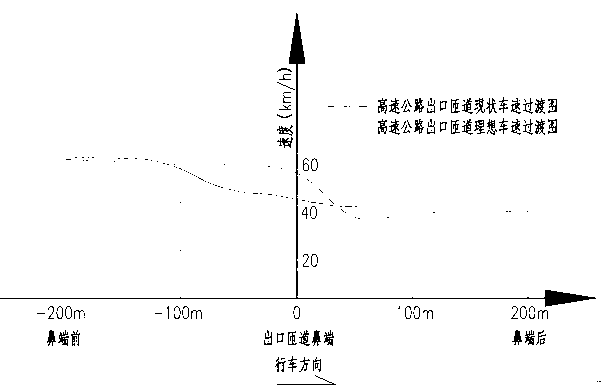

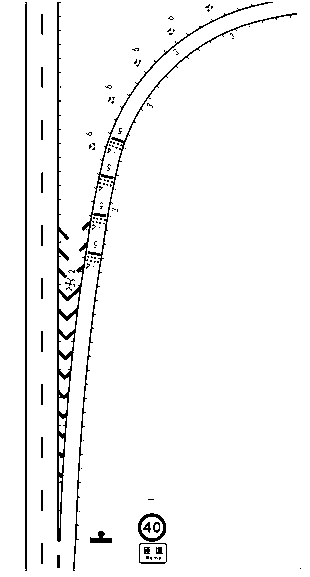

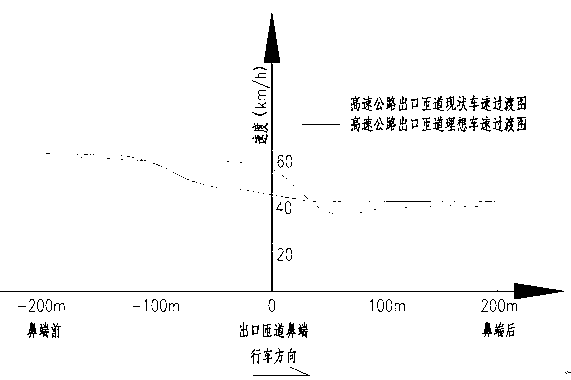

Improving method for dark spot in accident at exit ramp of expressway based on retro-reflection illumination

InactiveCN102912700AFacilitate early decelerationAchieve a reasonable transitionClimate change adaptationTraffic signalsReflection illuminationSimulation

The invention relates to an improving method for a dark spot in an accident at an exit ramp of an expressway based on retro-reflection illumination, wherein ramp grading speed-limit signs are arranged at sight through places in front of the starting point and the nose end of a transition section of a deceleration lane of the exit ramp; a main line single-layer linear induction sign and a ramp double-layer linear induction sign are arranged behind the nose end of the exit ramp; a lane edge line of the exit ramp deviates towards the inner side and reduces the width of a traffic lane, an edge line of a lane at the outer side is set to be a vibration edge line; raised road signs are arranged at the outer sides of a main line and a road edge line of the exit ramp from the end point of the deceleration lane, and a single-side anti-collision bucket is arranged at a guardrail next to the outer side of the ramp from the nose end of the exit ramp, so as to form a high-frequency vision information stream commonly; road-surface lateral deceleration marked lines are arranged in the heading direction of the exit ramp at an interval of 8-12m, so as to form an intermediate-frequency vision information stream commonly with road side linear induction signs; and road side vibration marked lines, anti-collision buckets and the guardrail form road side multi-level protection, and all safety facilities are made of high-strength reflecting materials. The improving method is suitable for realizing the speed limit for a downgrade ramp at an exit of the expressway (40-60km / h).

Owner:WUHAN UNIV OF TECH

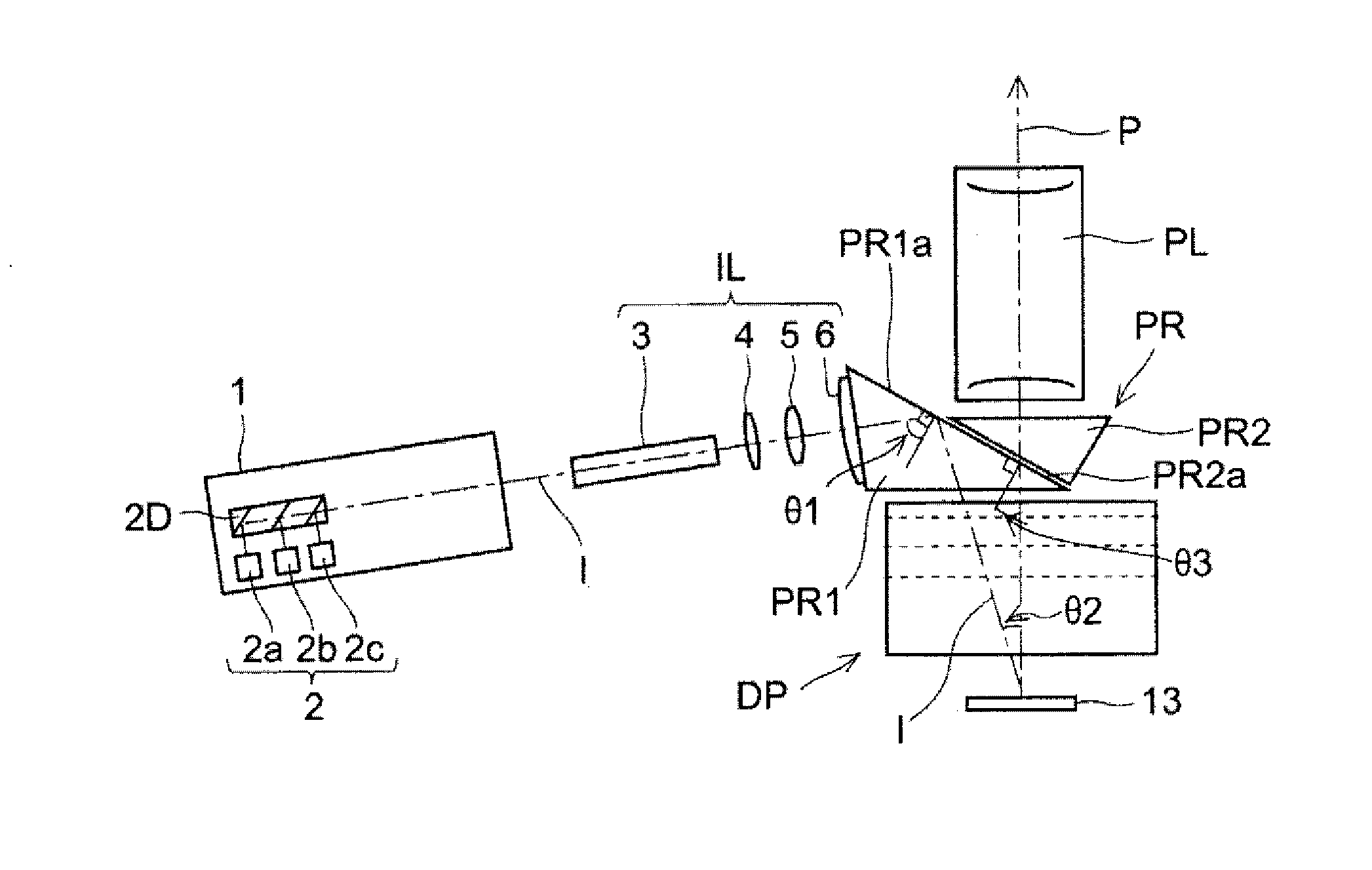

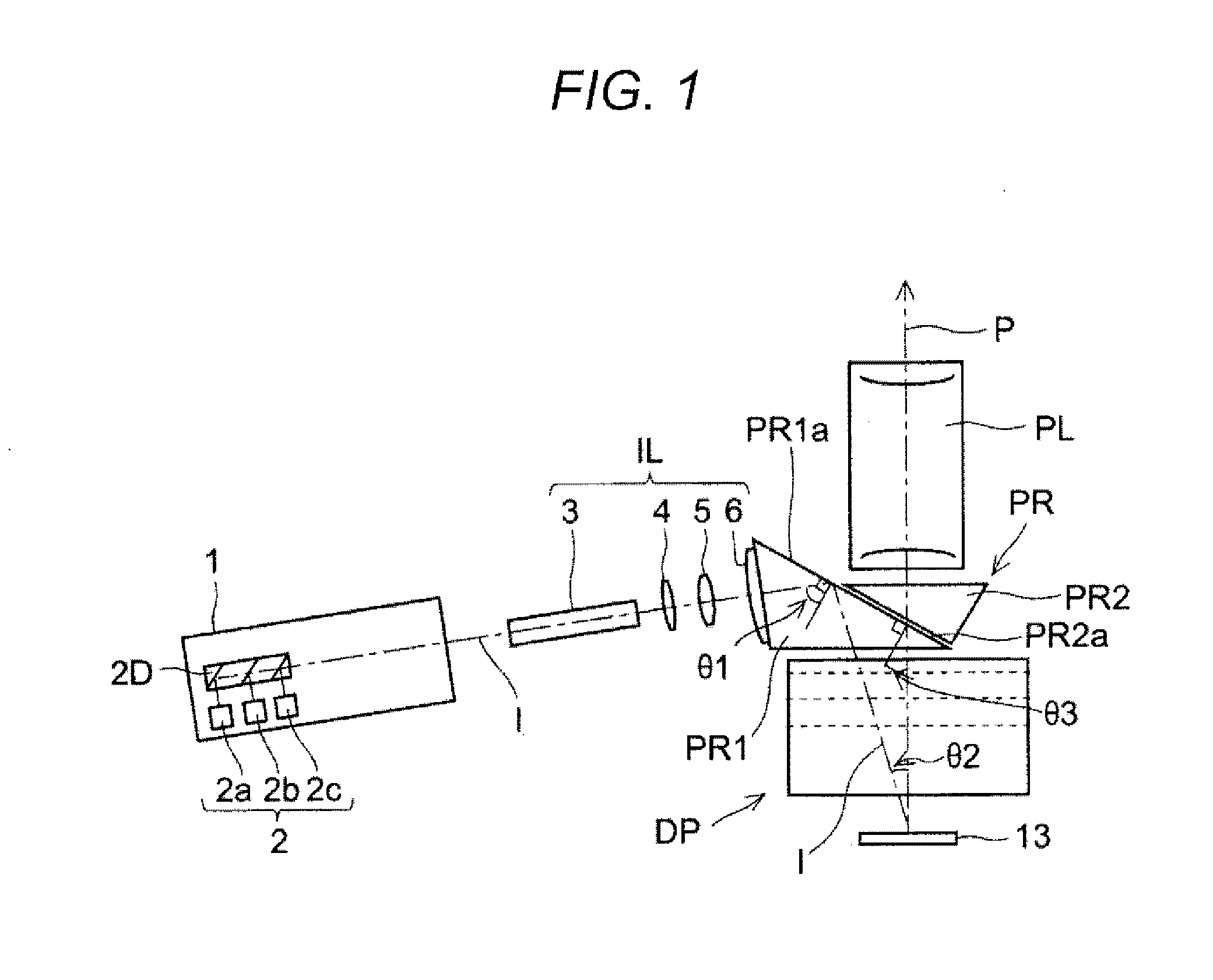

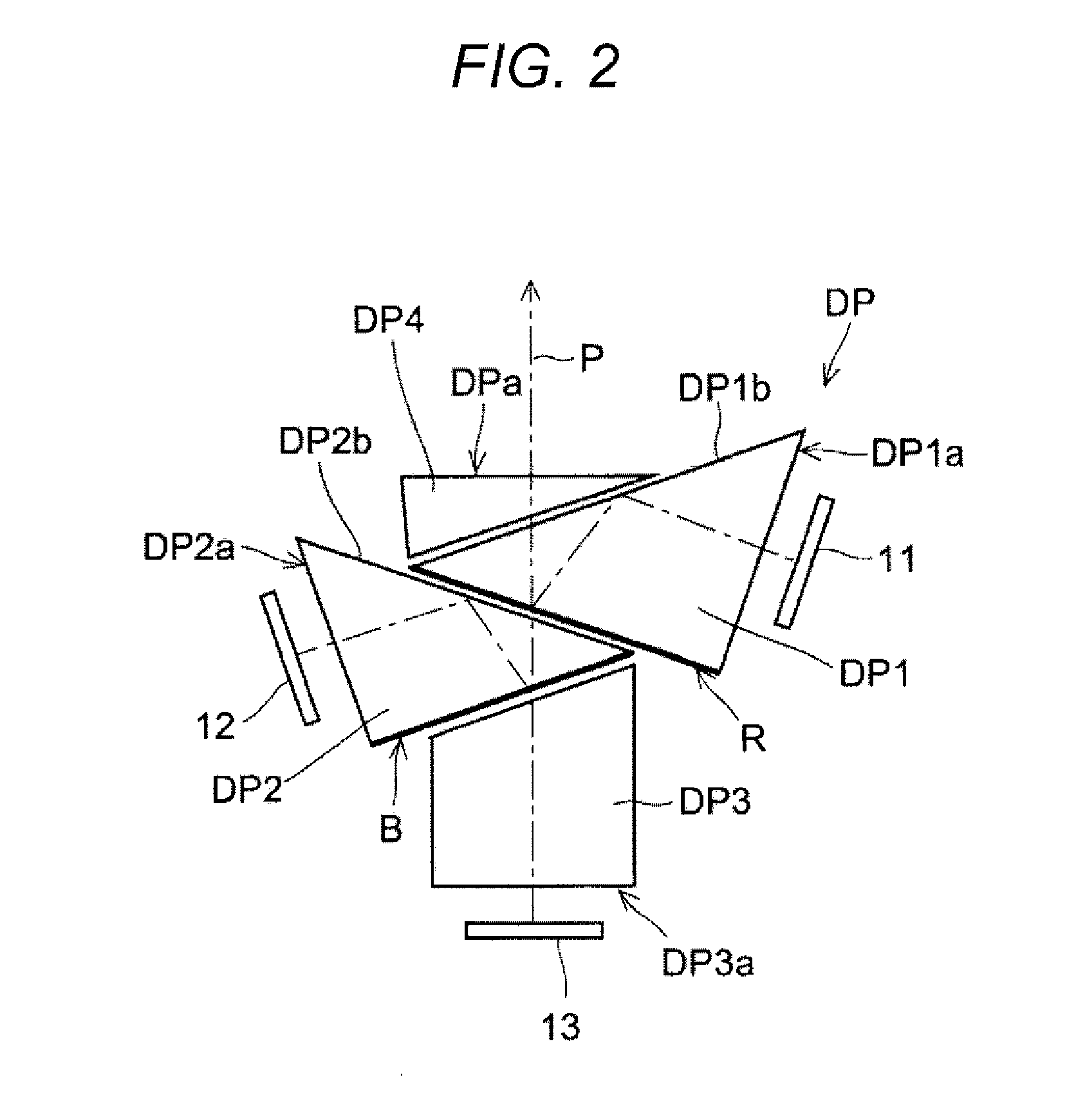

Prism for projection optical system and optical system having same

A prism for a projection optical system included in a projector including an illumination light source, an illumination optical system, and a projection optical system, includes: a first surface that totally reflects a beam of one of the illumination light and the projection light and transmits a beam of the other; and a second surface that is opposed to the first surface with an air gap therebetween and transmits a beam passing through the first surface, wherein the first surface has an antireflective film having an average reflectivity of a s-polarized reflectivity and a p-polarized reflectivity at a center angle of a transmitted beam of 2% or lower in three wavelength ranges including a first wavelength range of blue, a second wavelength range of green, and a third wavelength range of red.

Owner:KONICA MINOLTA INC

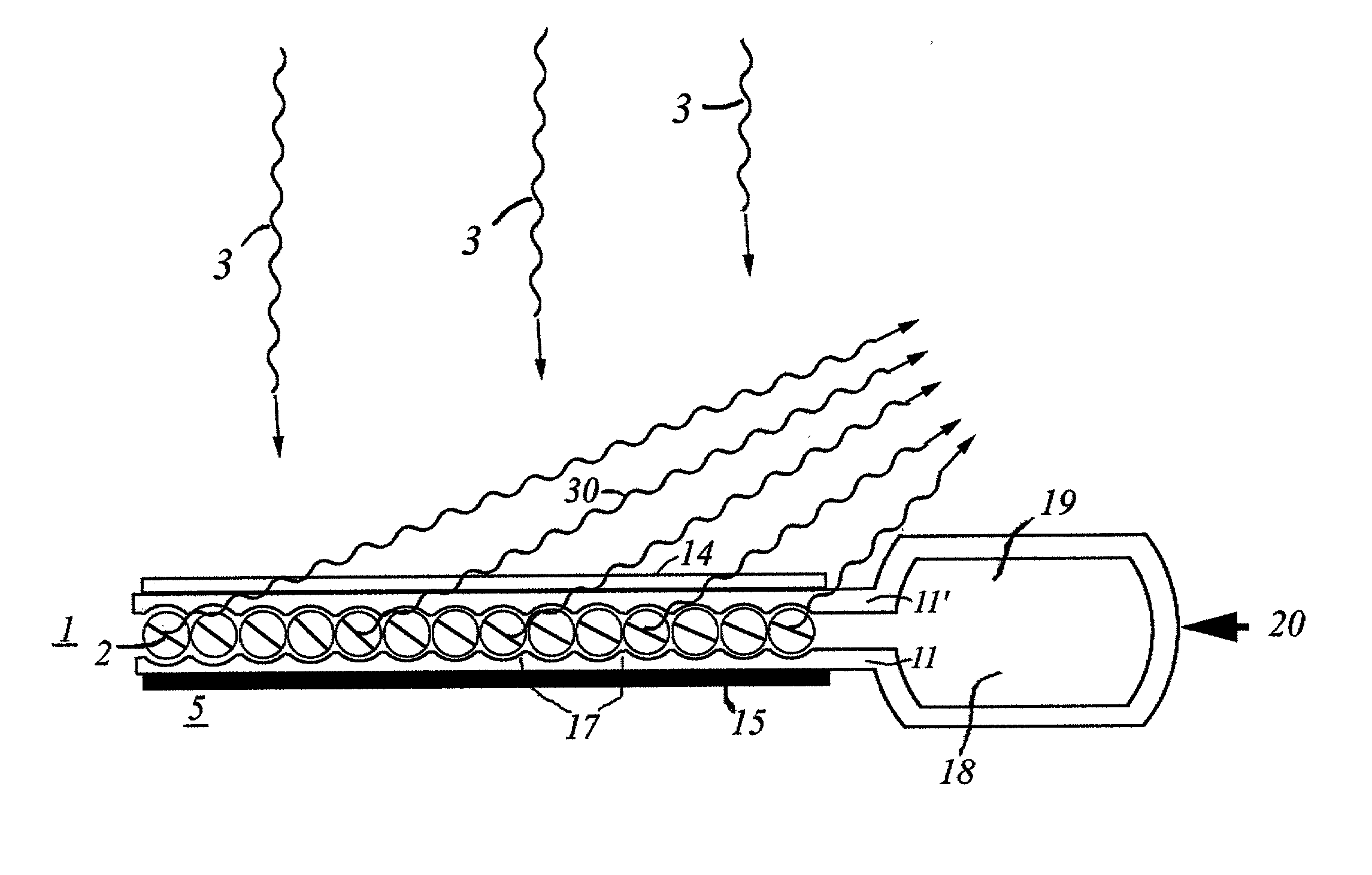

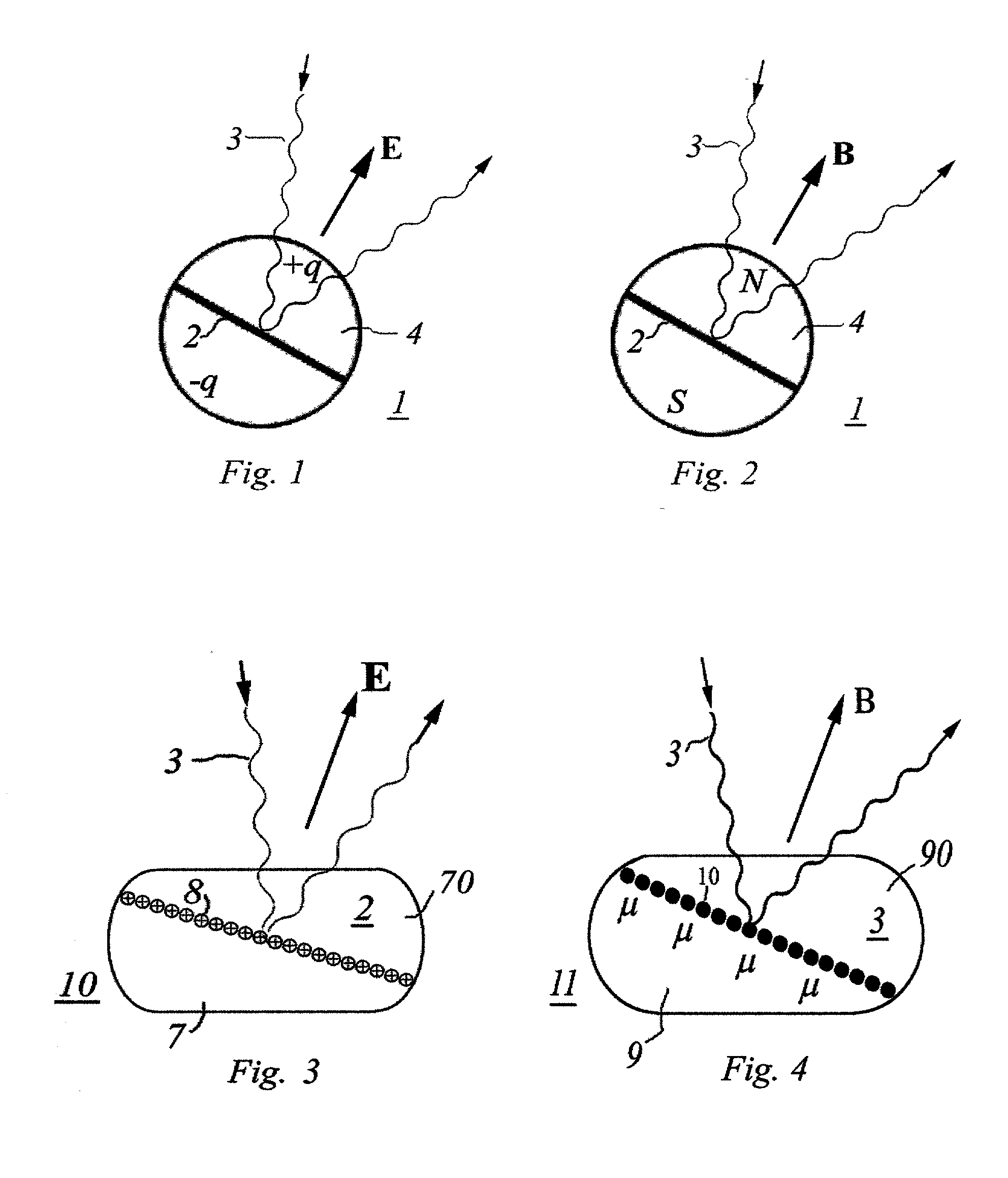

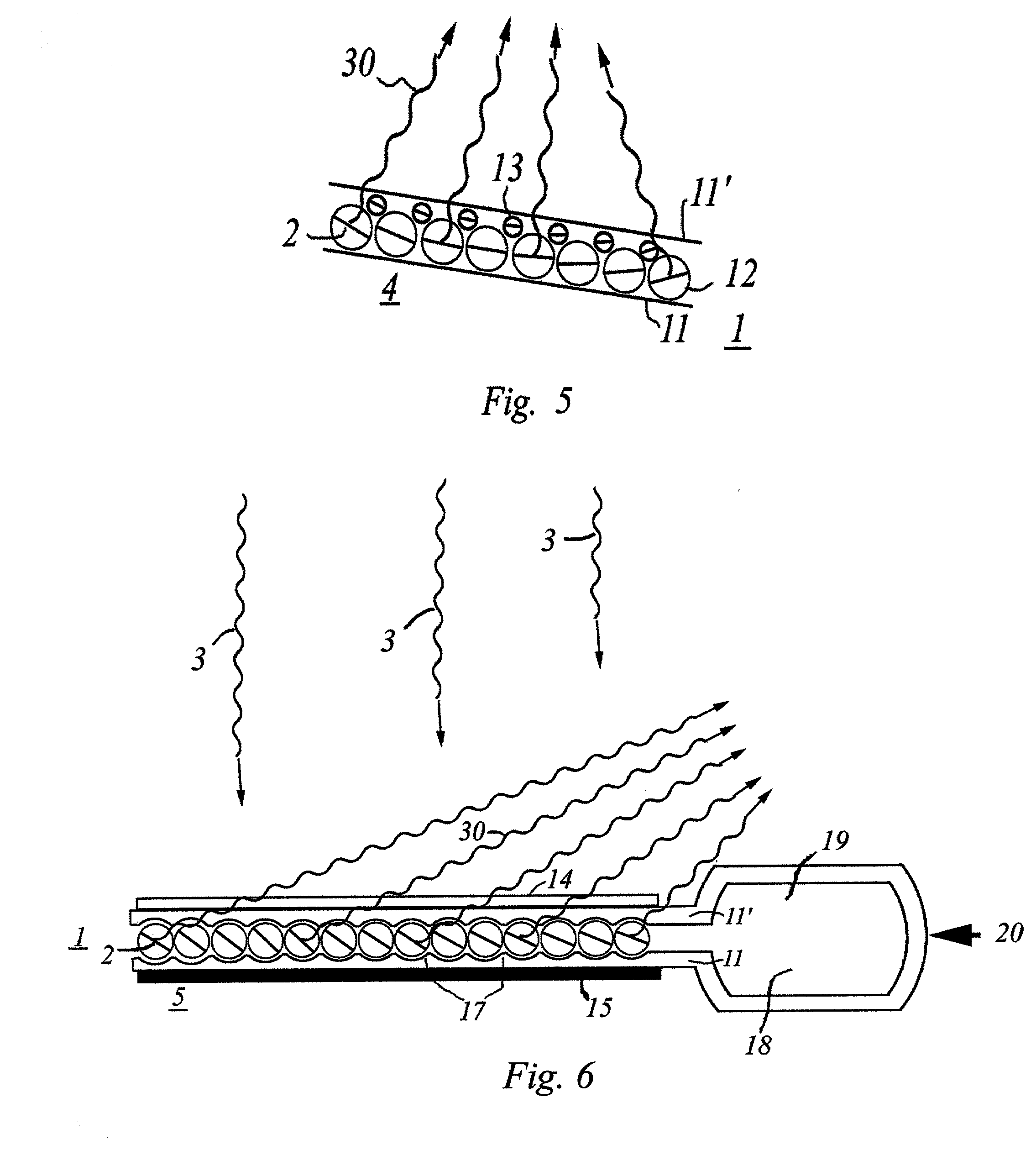

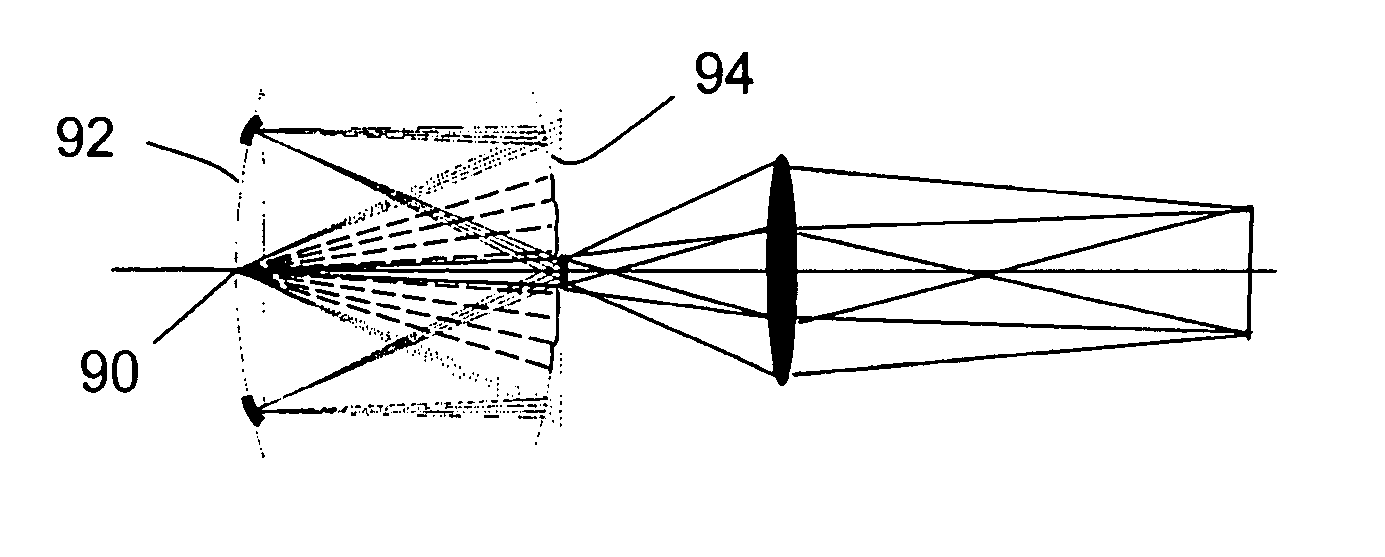

Active reflection illumination and projection

This invention deals with the broad general concept for active reflection or projection illumination and image formation. A mini-optics reflection and focussing system is presented that ranges from interior illumination, to exterior illumination, to large scale space based illumination, to ordinary and to telescopic image formation. It can be used both as a source of illumination, and to project images, figures, and the written word. This novel system is uniquely distinct and different from prior art direct viewing gyricon displays, allowing it to be more versatile, economical, and practical with broader applications such as dynamic full color displays. In most cases it can operate with greater simplicity and efficiency. Furthermore in its capacity as a high altitude active reflector of solar radiation, it can be utilized to supply illumination, energy, and provide climate control.

Owner:DAVIDSON MARK PETER +1

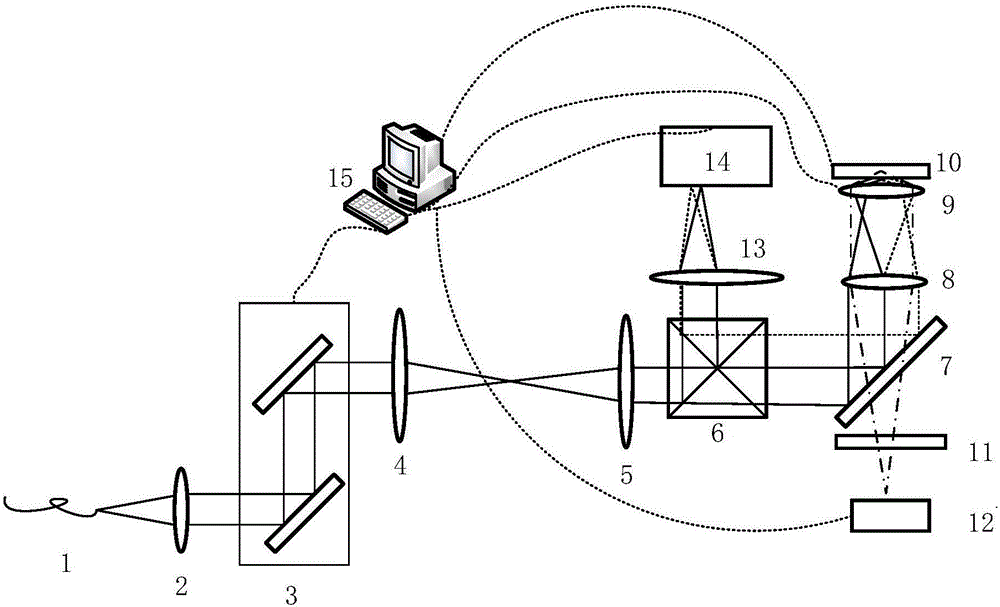

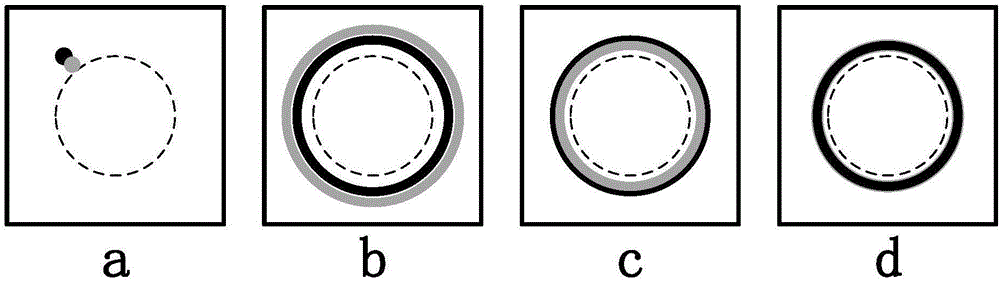

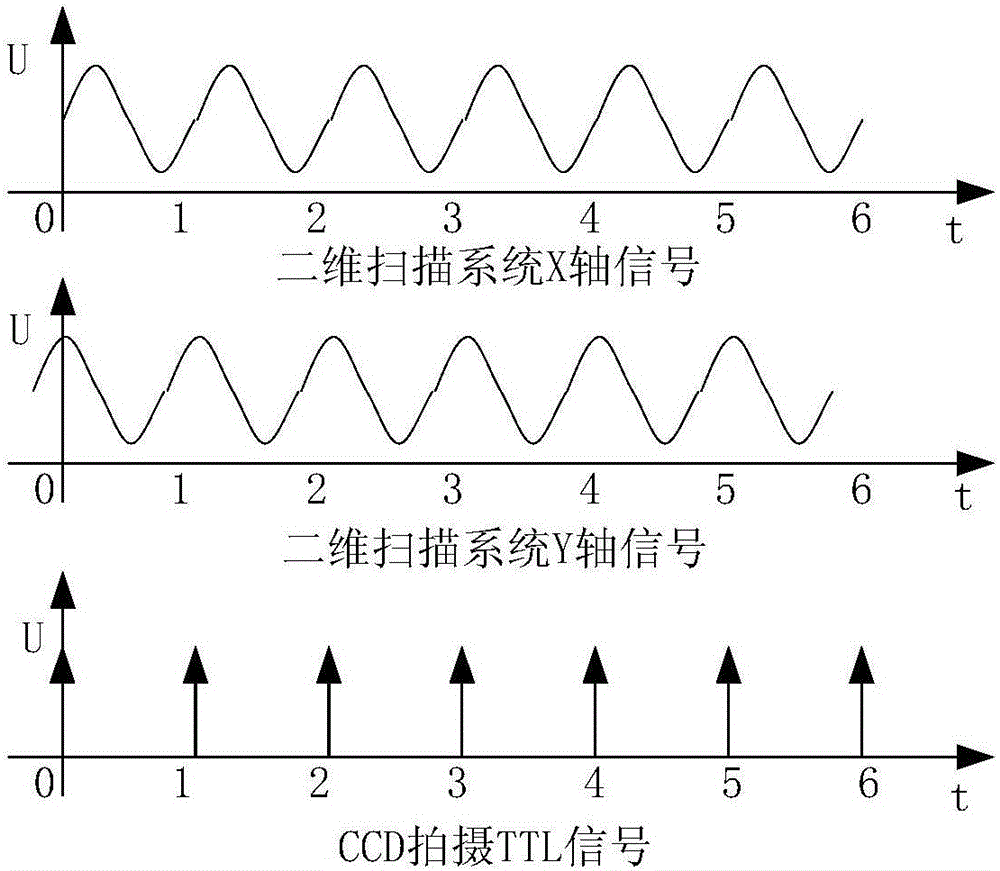

Rotating total internal reflection microscopy method and device with feedback function

ActiveCN106226895AAutomatic adjustment of total reflection angleHigh angle control resolutionMicroscopesBeam splitterLight spot

The invention discloses a rotating total internal reflection microscopy device with a feedback function. The device comprises a laser device, a two-dimensional scanning galvanometer, a scanning lens, a collimating lens, a dichroic mirror, a beam splitter, a dichroic mirror, a microscopic field lens, a total reflection microobjective and a sample which are arranged in sequence along an optical path, a light intensity position detector located on the reflection optical path of the beam splitter, a computer and a CCD used for acquiring the sample and emitting fluorescent light, wherein the light intensity position detector is used for collecting illuminating light which is emitted by the laser device and reflected by the beam splitter to obtain a first light spot and collecting sample light formed after total reflection of the position of the sample to obtain a second light spot, and the computer is used for obtaining total reflection illumination angle and evanescent wave penetration depth through feedback according to the position information of the first light spot and the second light spot. The invention further discloses a rotating total internal reflection microscopy method with the feedback function. Through synchronous feedback control of the sample and the microobjective, it can be guaranteed that the sample is located on the optimal illumination face and the optimal imaging face, and illumination uniformity and imaging resolution are higher.

Owner:ZHEJIANG UNIV

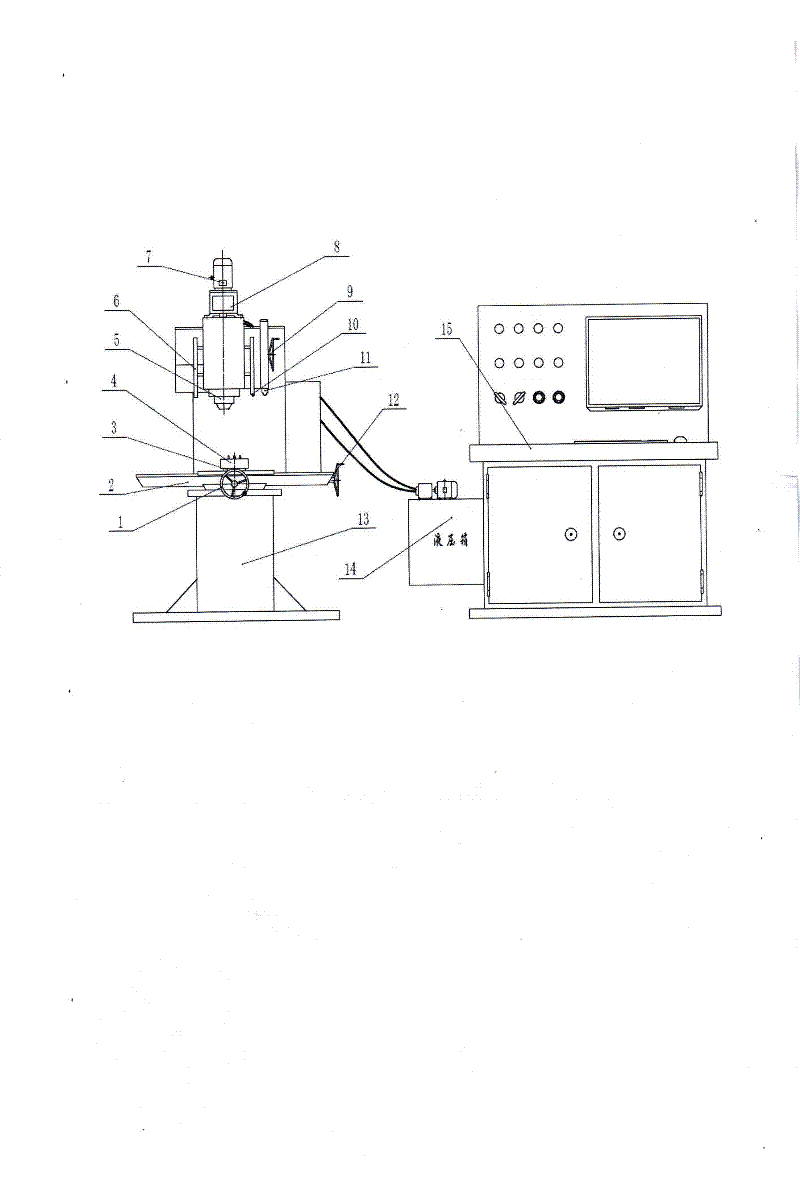

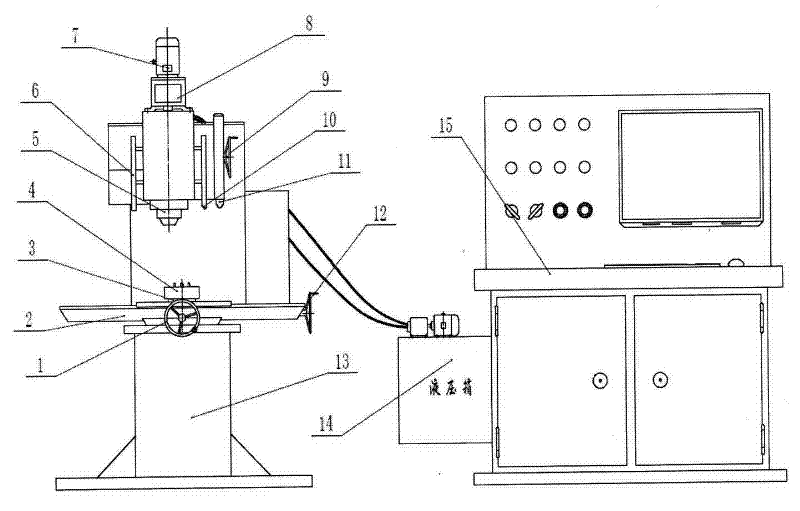

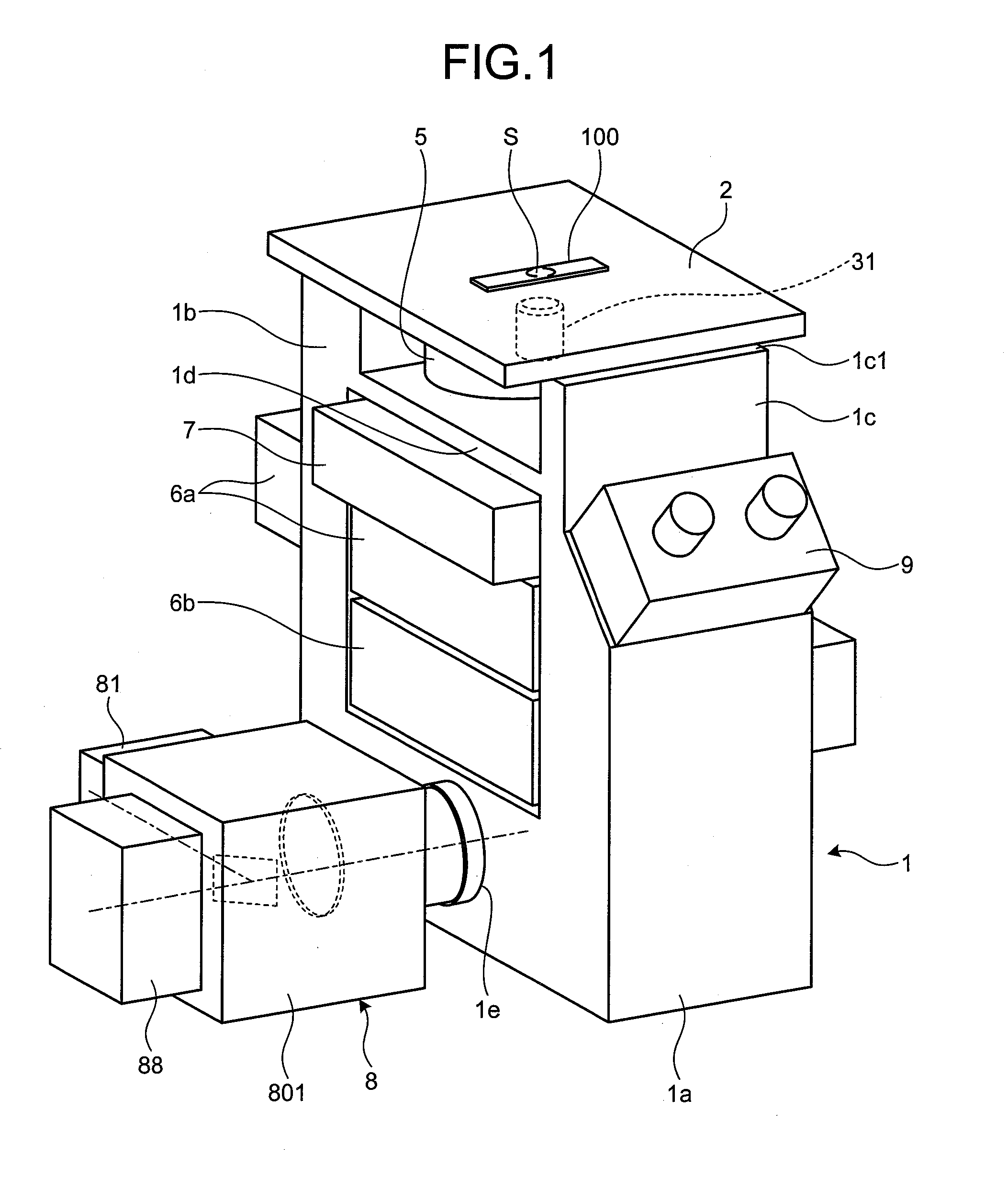

Dedicated automatic rolling riveting fixed machine tool for oscillating bearing

InactiveCN102489986AEasy to assemble and disassembleImproving the quality of rolling rivetingMetal working apparatusReflection illuminationControl system

The invention provides a dedicated automatic rolling riveting fixed machine tool for an oscillating bearing. The machine tool mainly comprises position rough regulating hand wheels in X, Y and Z directions, a working sliding table, an oscillating bearing clamping device, a connecting device of a rolling riveting fixed device, a pressure-torque sensor, an optical ranging machine, a transmission and reflection illumination light source, an optical projection display screen, a load system, a control system and the like. The clamping device adopted by the invention is convenient to assemble and disassemble test pieces, can accurately realize automatic centering and improve the rolling riveting fixed quality of the oscillating bearing; the machine tool can realize the on-line measurement on parameters including rolling riveting pressure, rolling riveting torque, press quantity and the like, has the function of overranging protection, can process the signals and finally generate data, images and curves, and can be beneficial to the preservation and the analysis approach.

Owner:YANSHAN UNIV

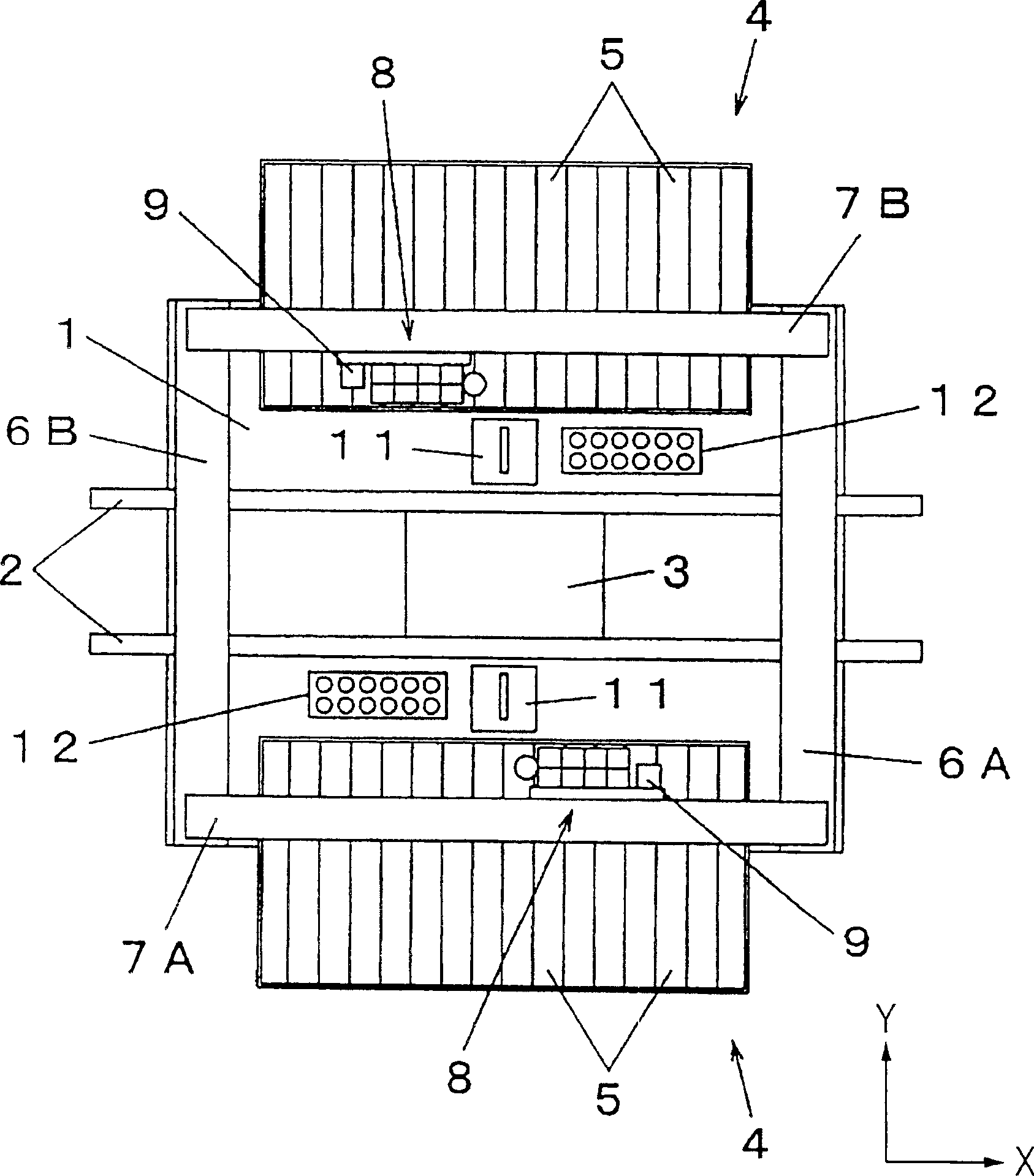

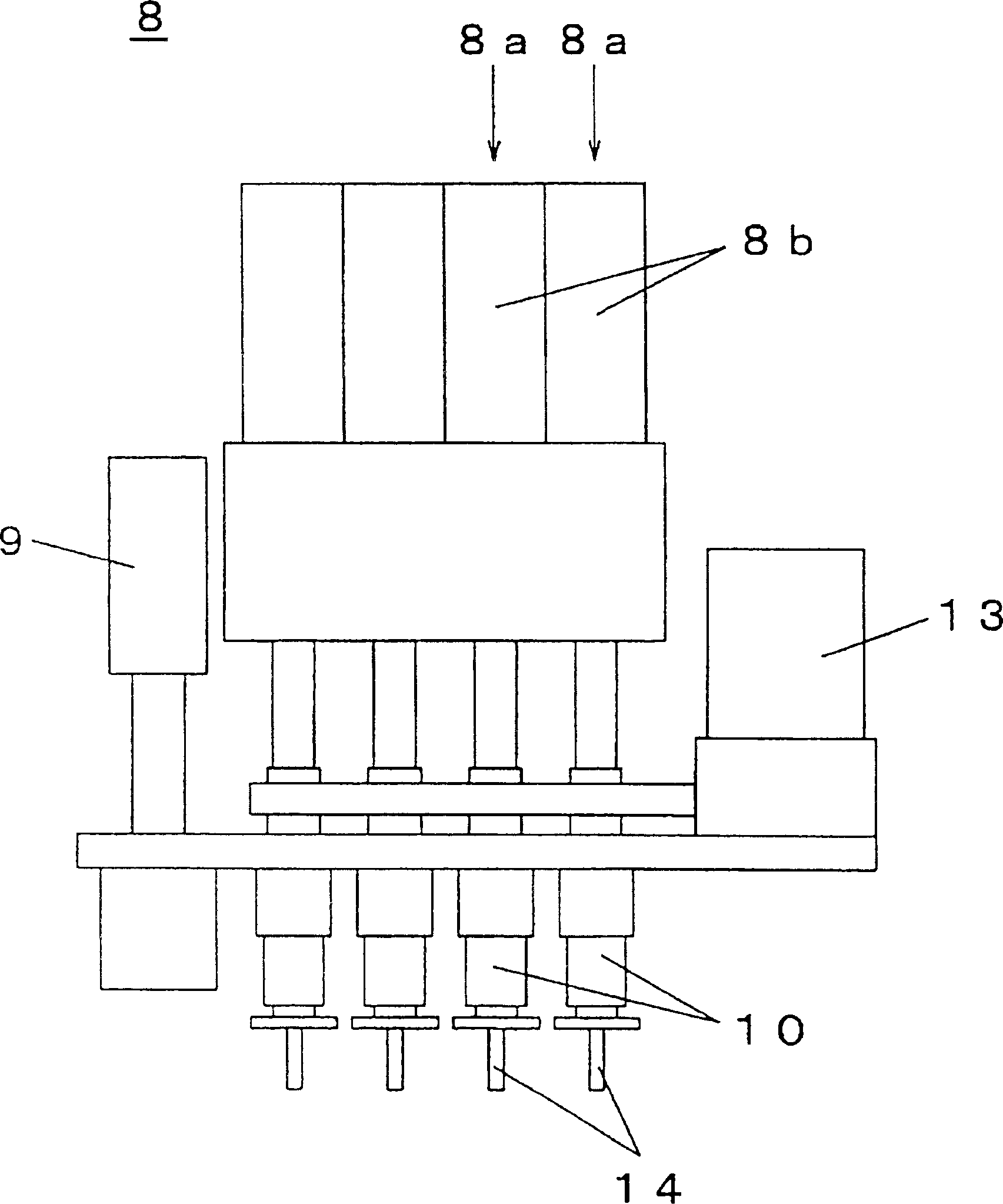

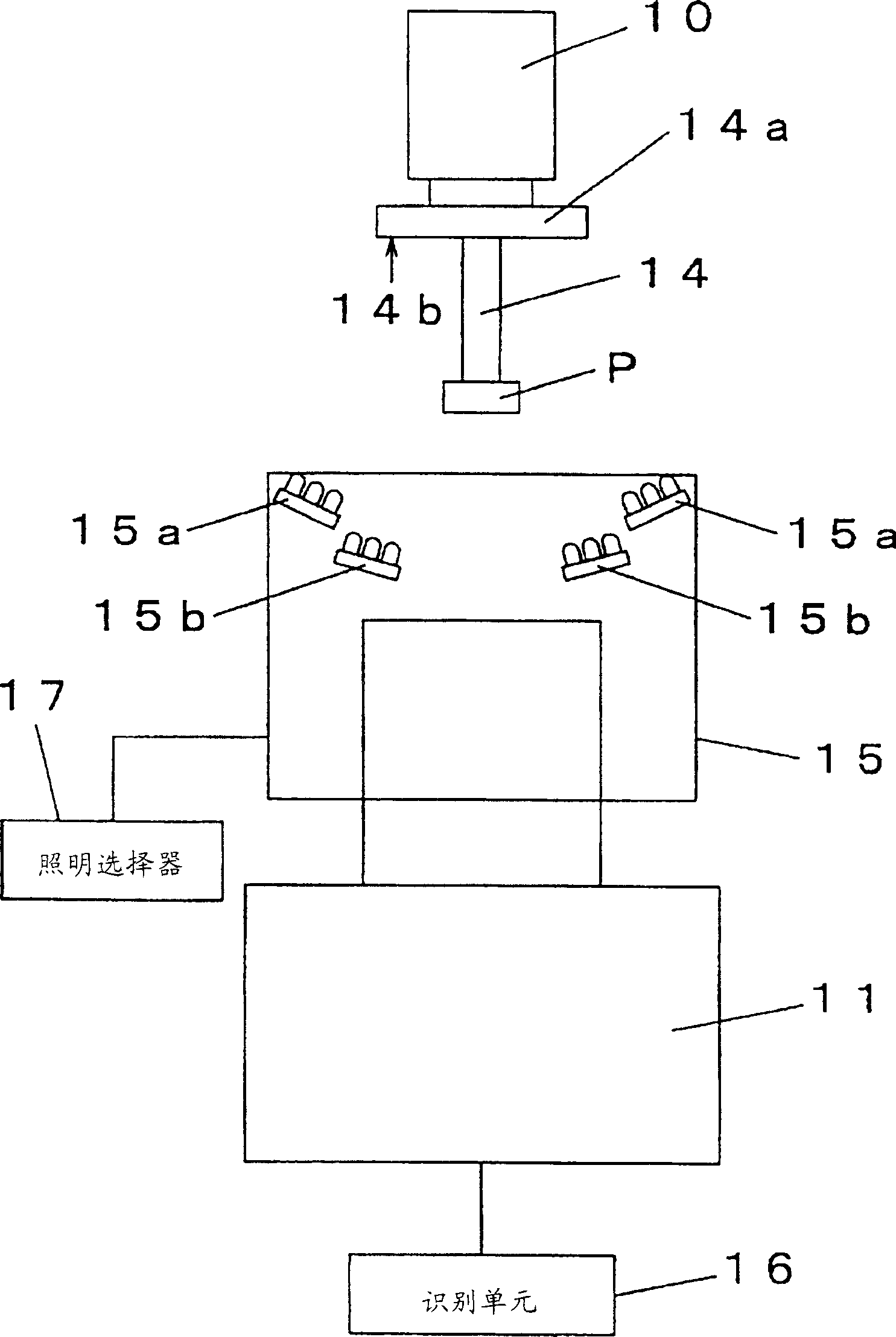

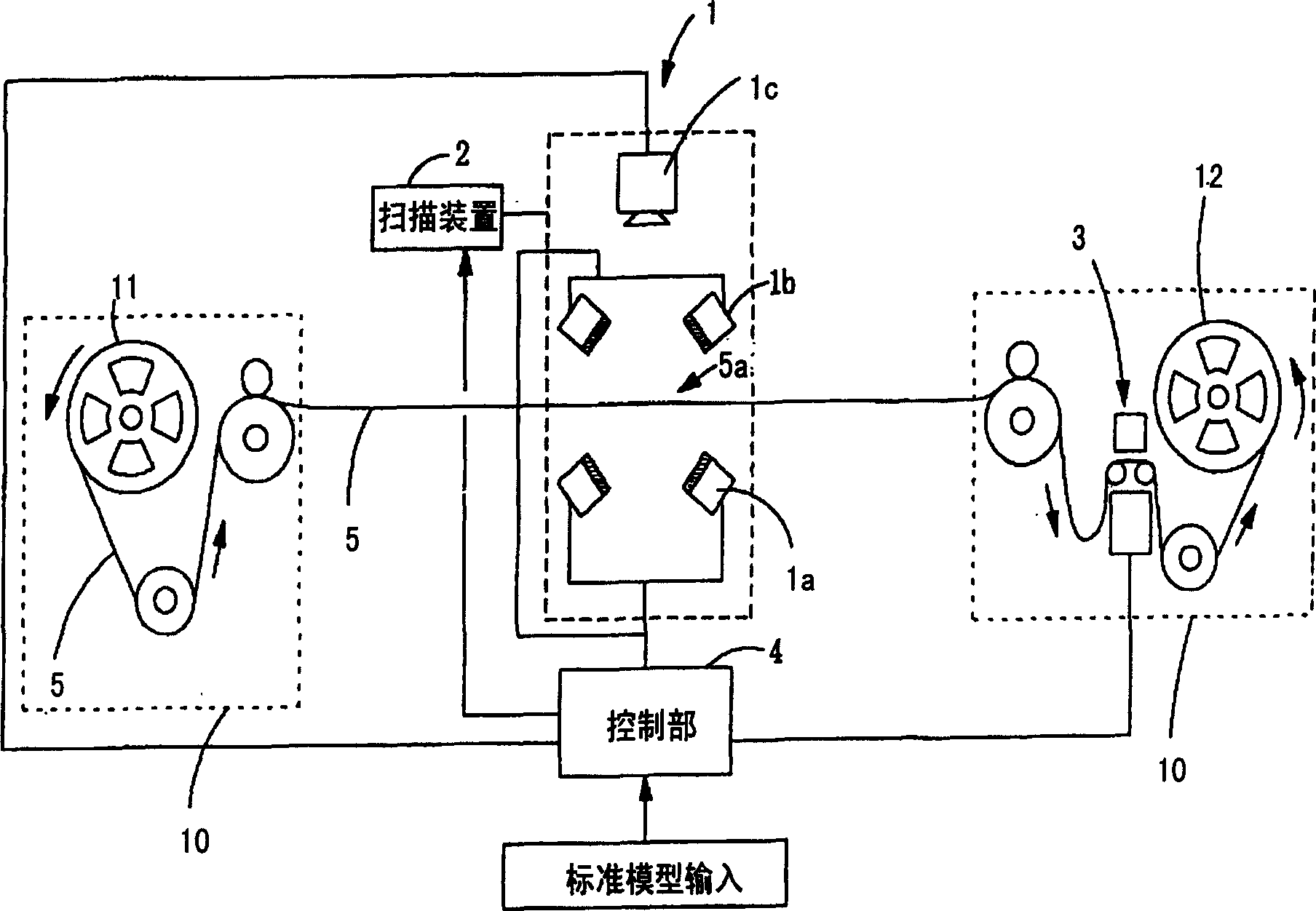

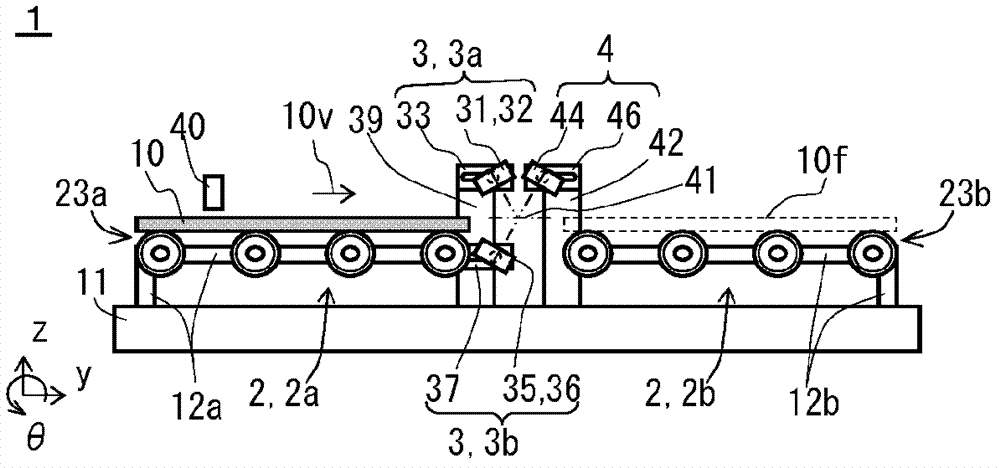

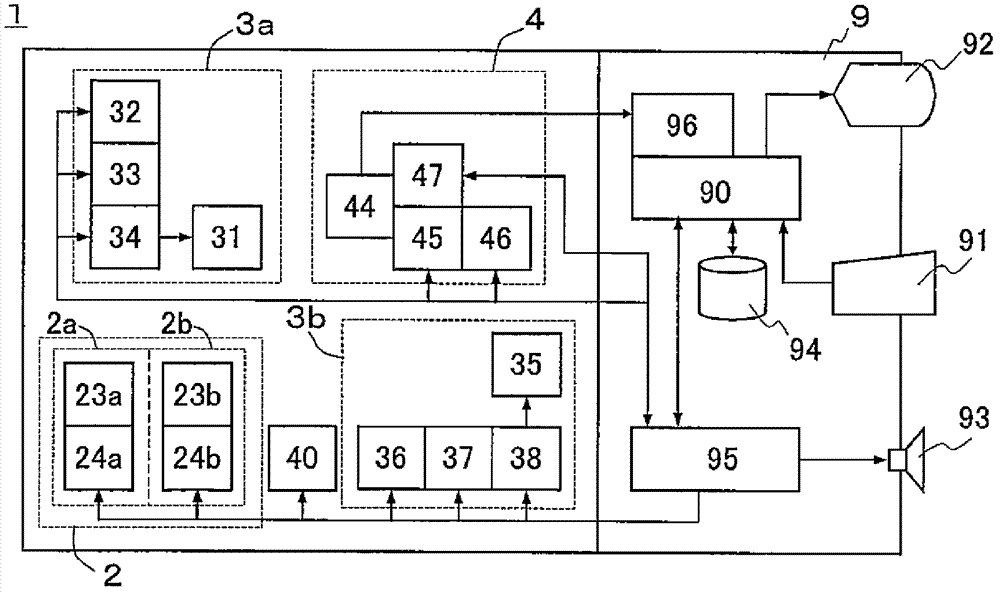

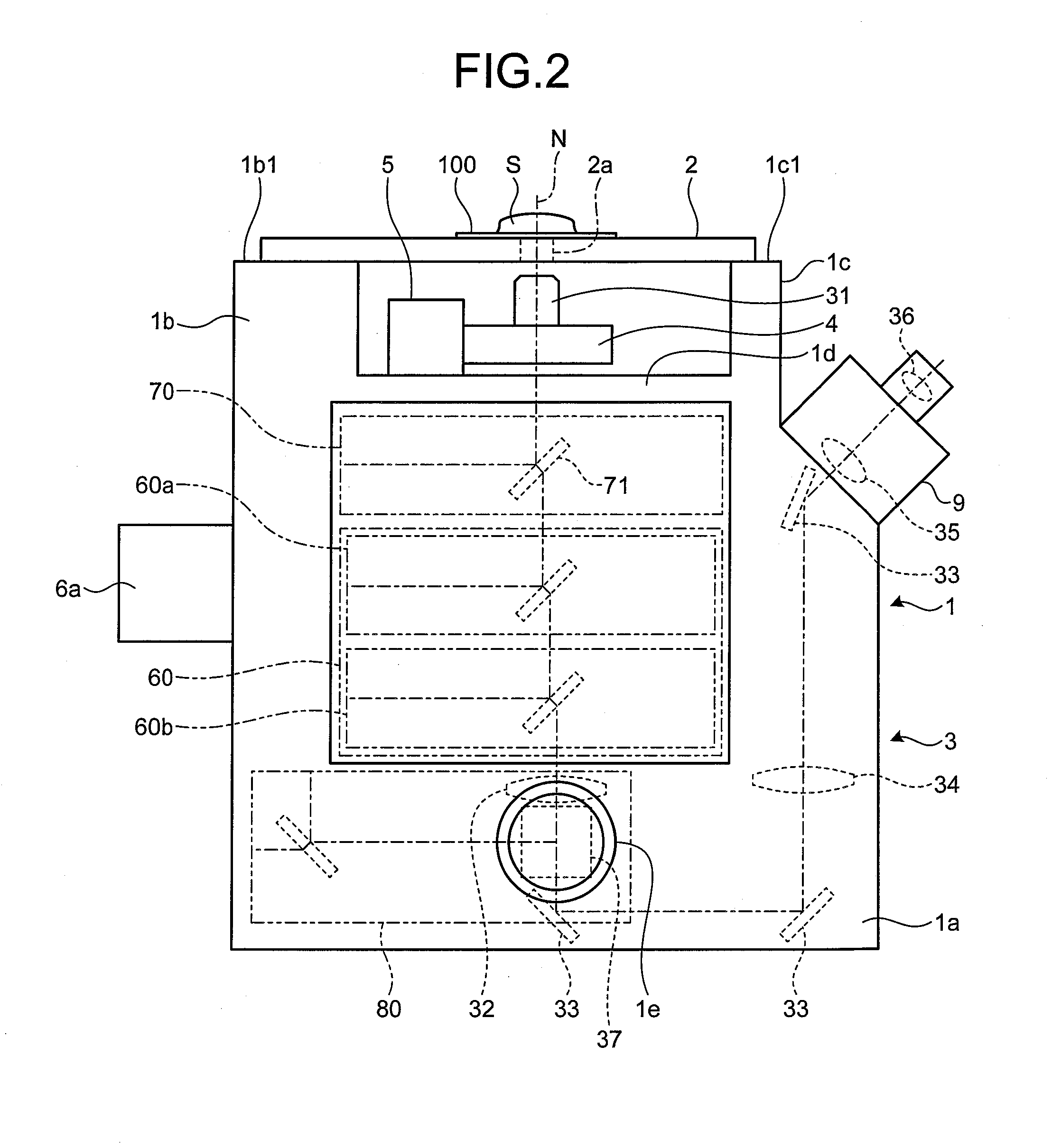

Electronic parts mounting apparatus and method

InactiveCN1711817AGuaranteed installation accuracyUsing optical meansElectrical componentsTransmission illuminationReflection illumination

An electronic component mounting apparatus which uses a mounting head to hold an electronic component, takes a picture of the electronic component by a line camera (11), processes the image of the electronic component taken by the line camera, and identifies the electronic component by using a recognition unit (16) position, positioning the electronic component on the substrate according to the position recognition result, and mounting the electronic component on the substrate. The pre-stored offset for each identification system with its own light source is used for positioning when correcting the position according to the position of the identification result, wherein the light source is a light source for transmitted illumination (15a) or Light source (15b) for reflected lighting. Even in such an electronic component mounting apparatus that selectively uses a plurality of recognition systems, differences in position recognition results caused by use of other types of lighting methods are corrected to secure necessary component mounting accuracy.

Owner:PANASONIC CORP

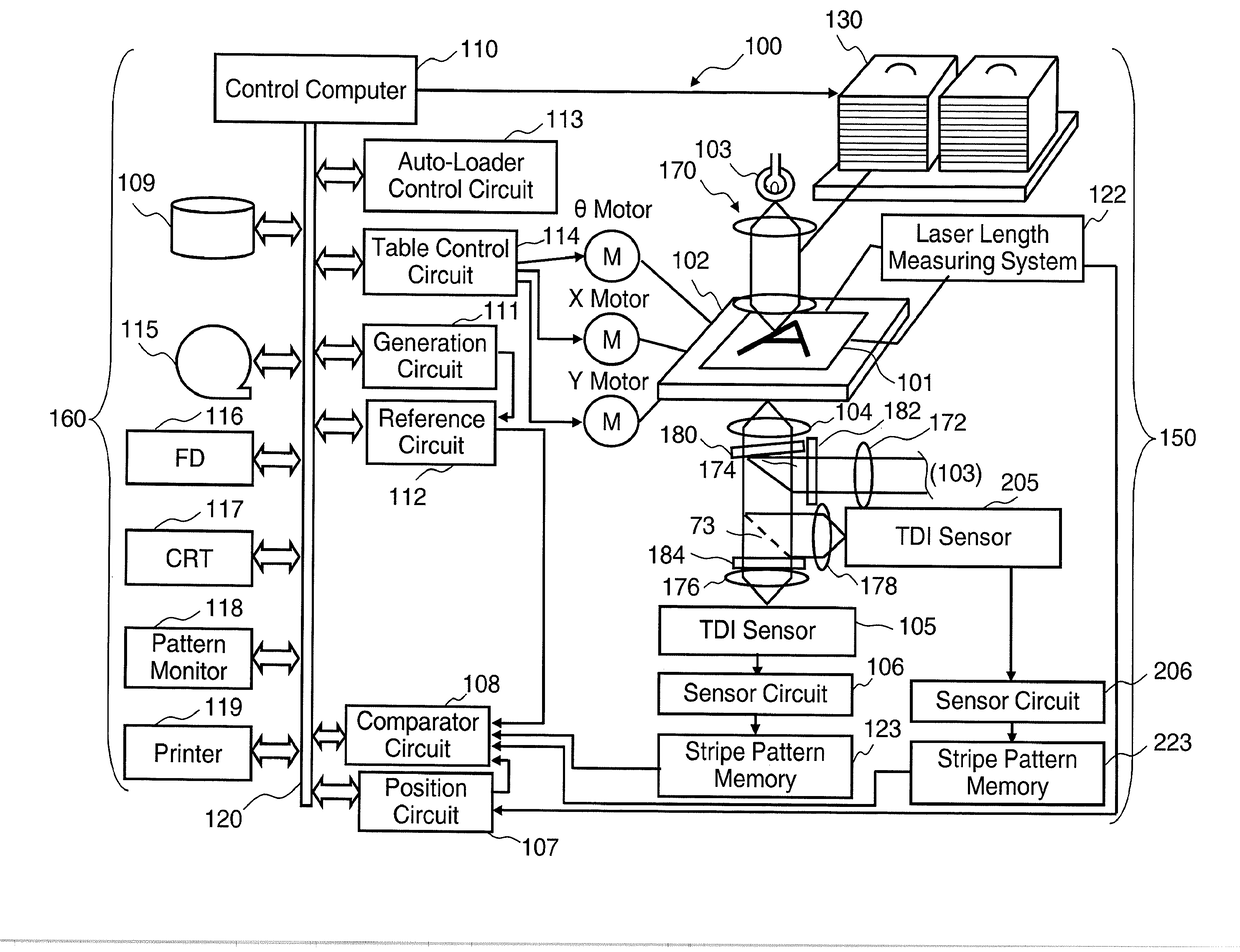

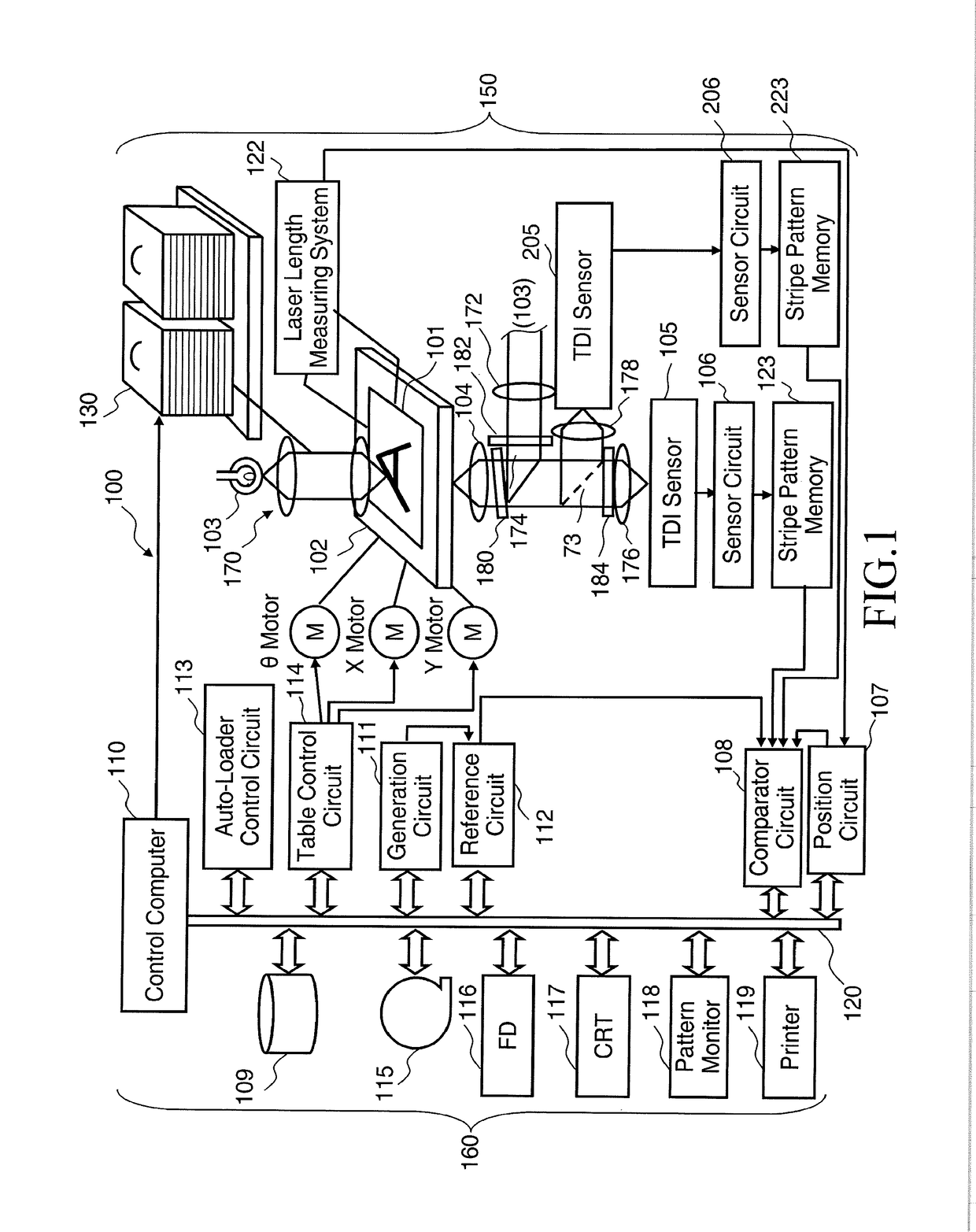

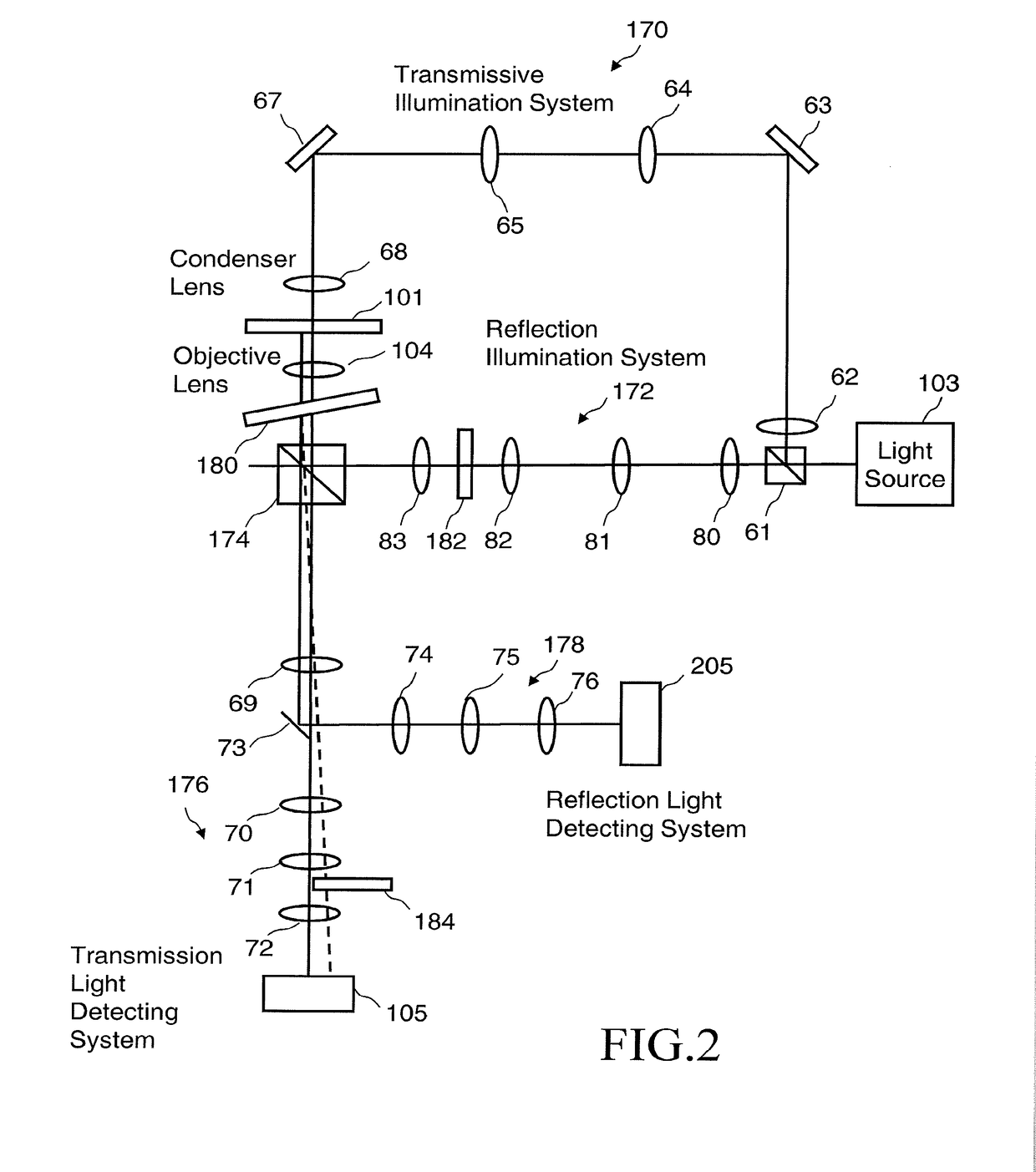

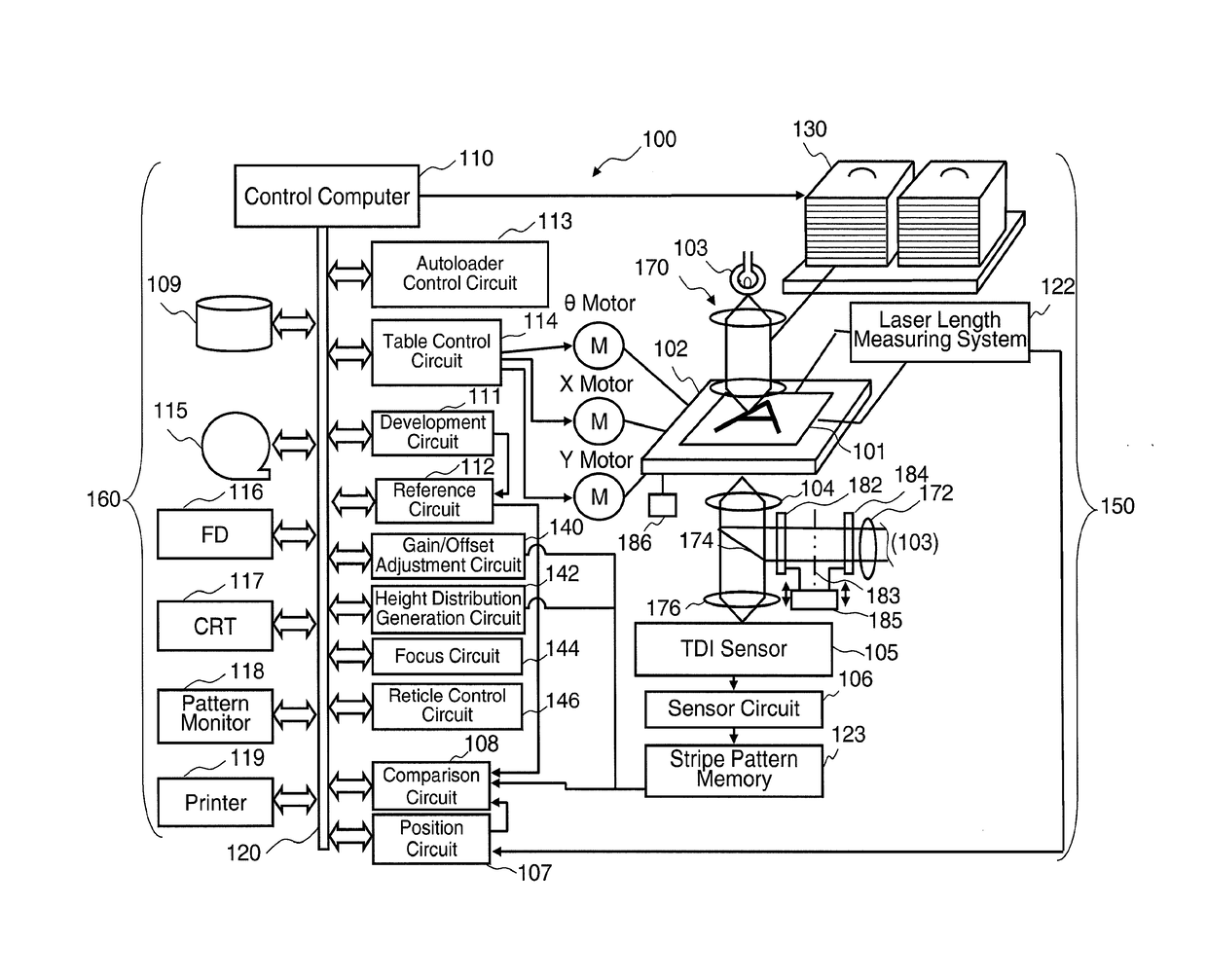

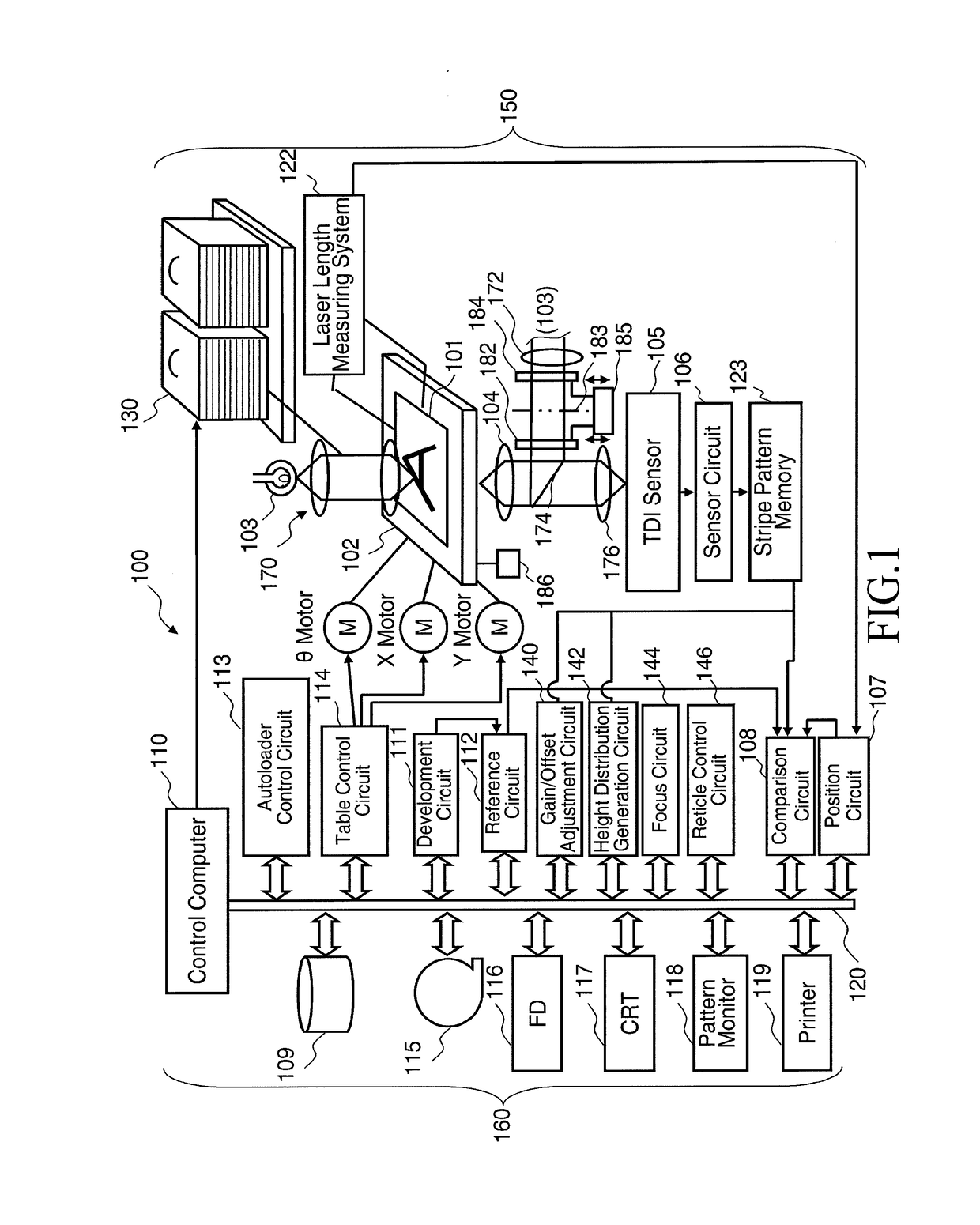

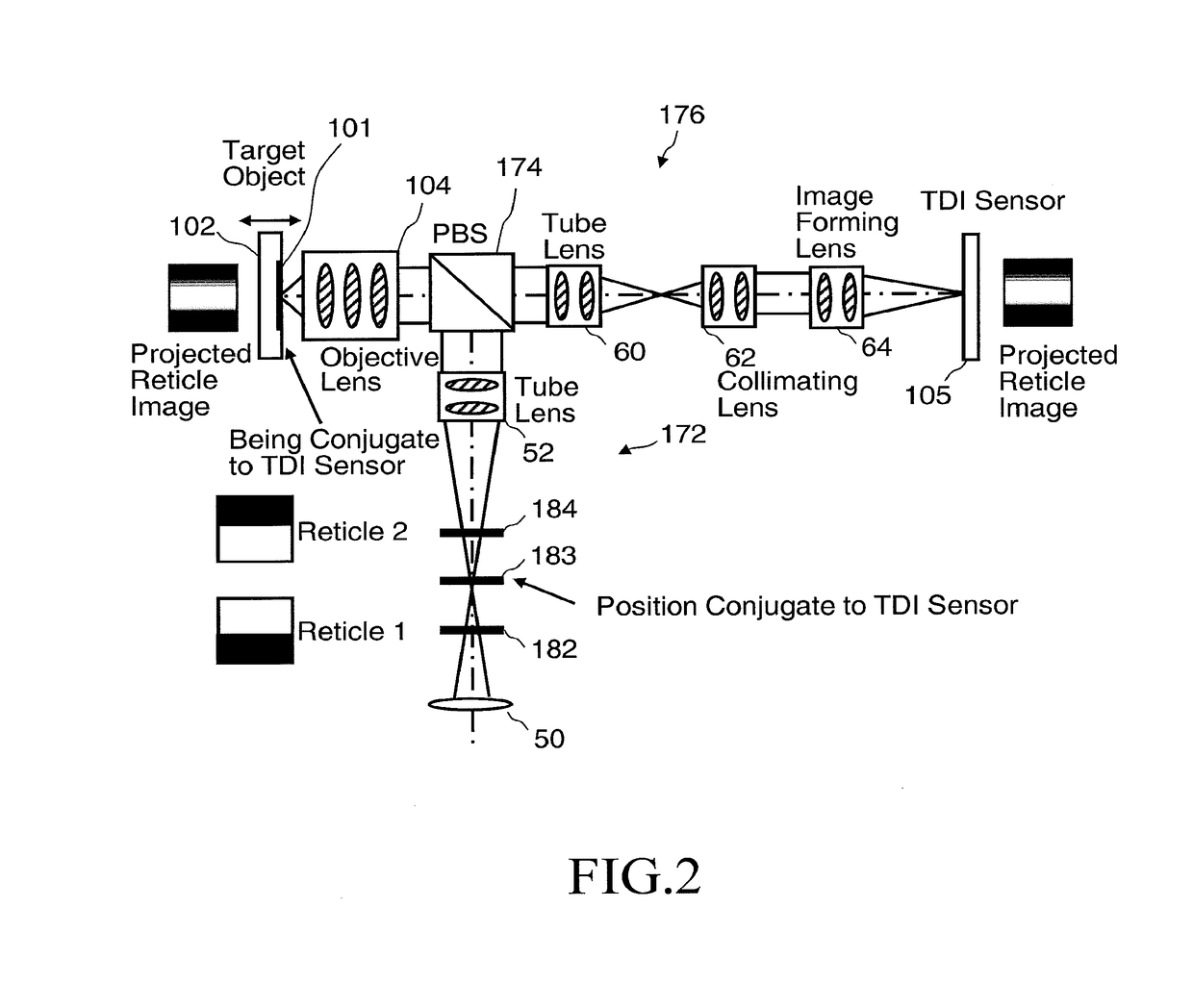

Pattern inspection apparatus

According to one aspect of the present invention, a pattern inspection apparatus includes a first diaphragm that is positioned on an optical path of a reflection illumination optical system and has a first reference pattern of a line-and-space pattern formed thereon; a semi-transmission reflection plate configured to reflect a portion of a reference pattern image that has passed through the first reference pattern; a second diaphragm which is positioned on an optical path of the imaging optical system, on which the portion of the reference pattern image reflected by the semi-transmission reflection plate is projected, and which has a second reference pattern of a line-and-space pattern formed thereon; and a first time delay integration sensor (TDI sensor) configured to receive the portion of the reference pattern image that has passed through the second reference pattern.

Owner:NUFLARE TECH INC

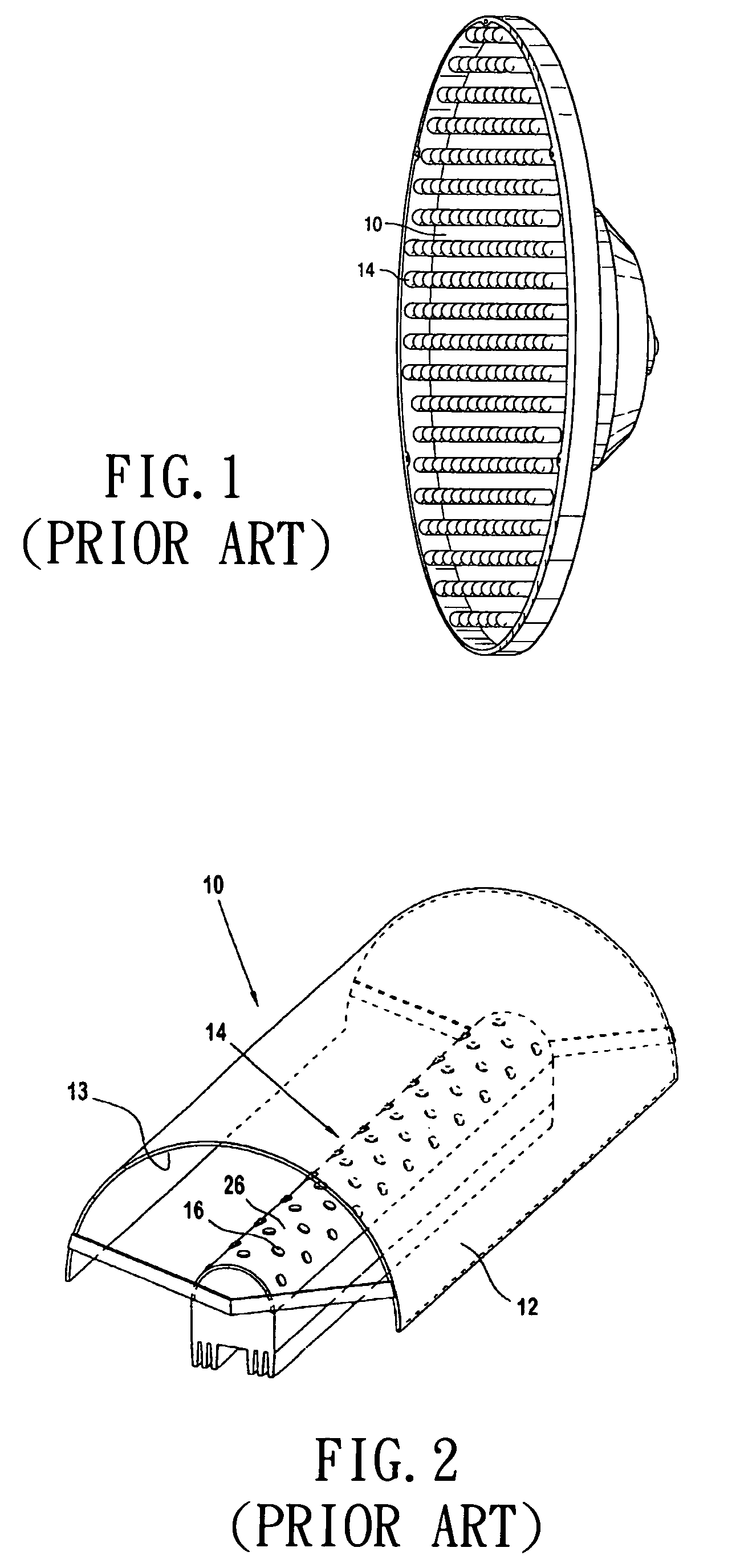

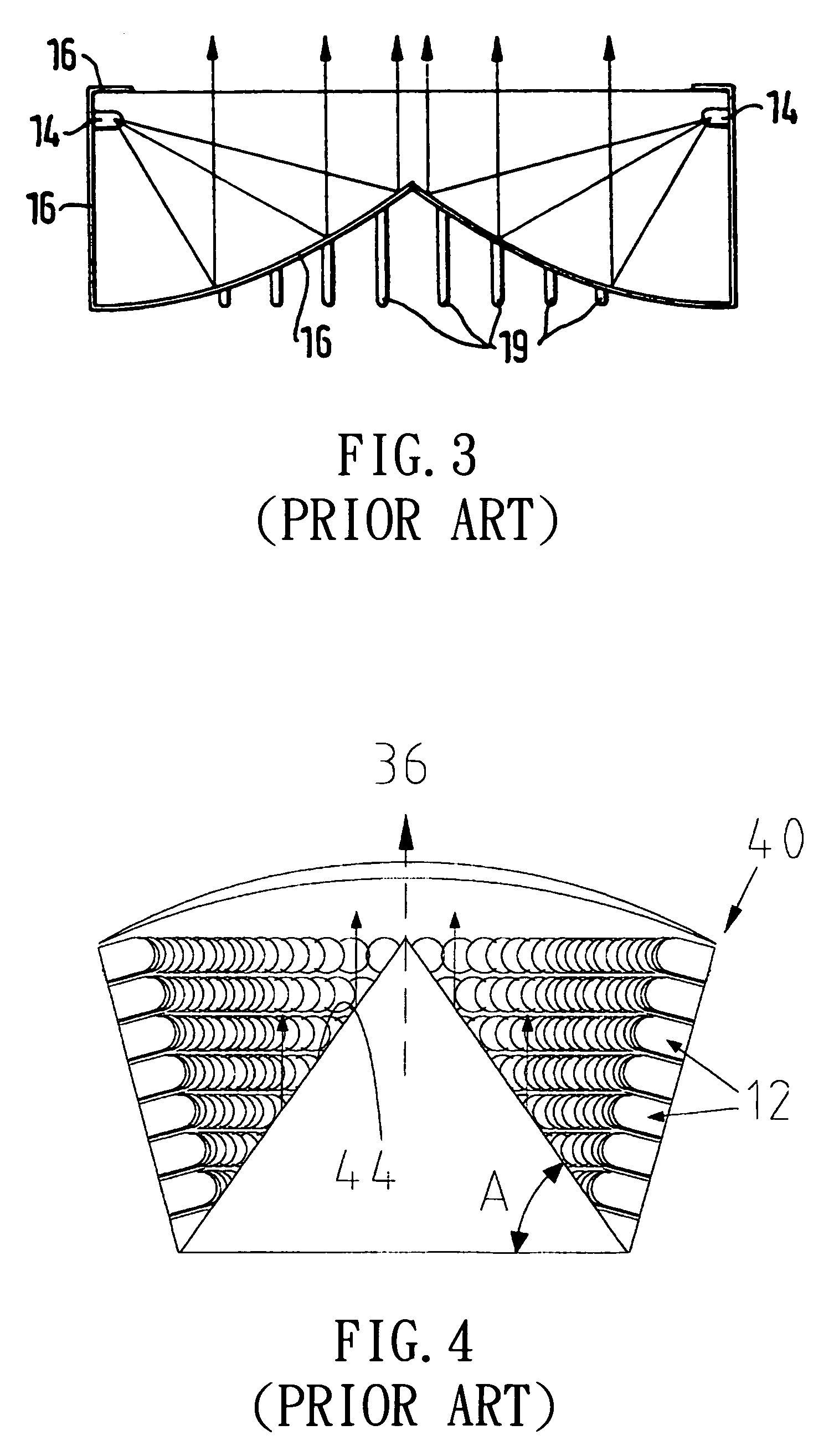

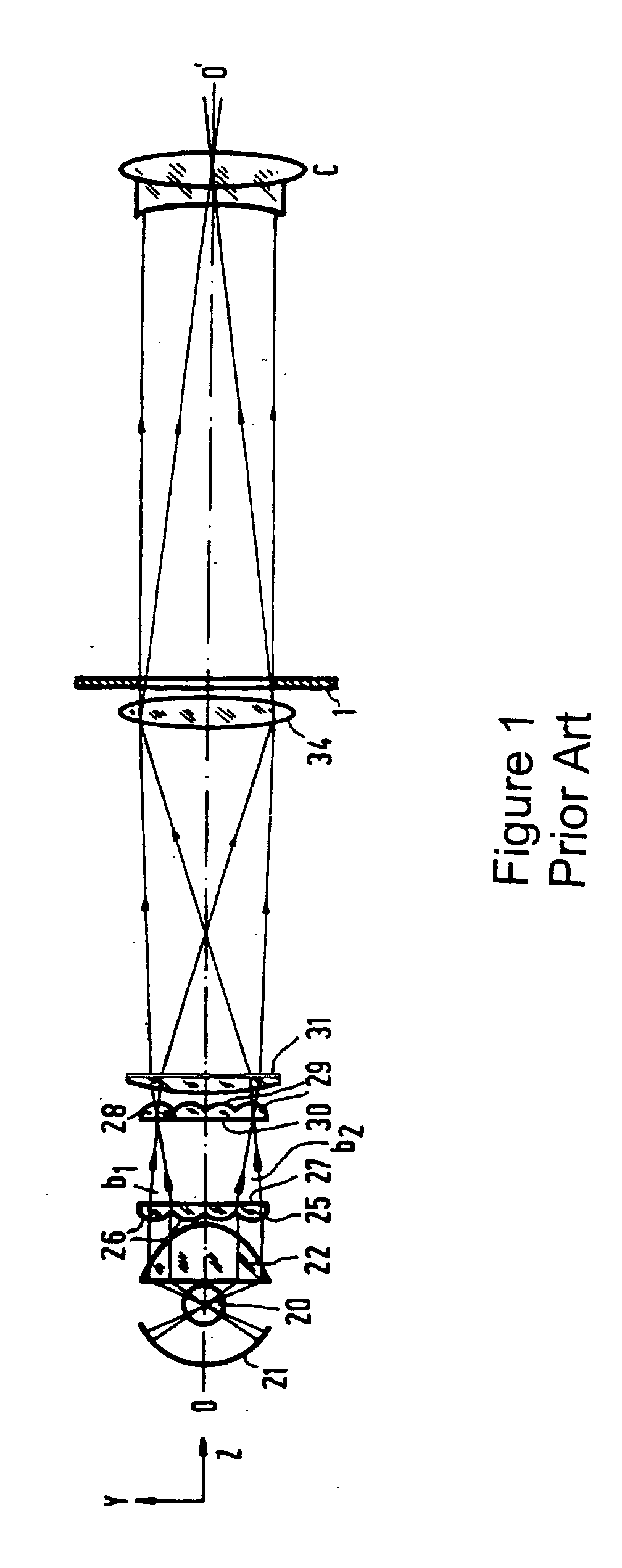

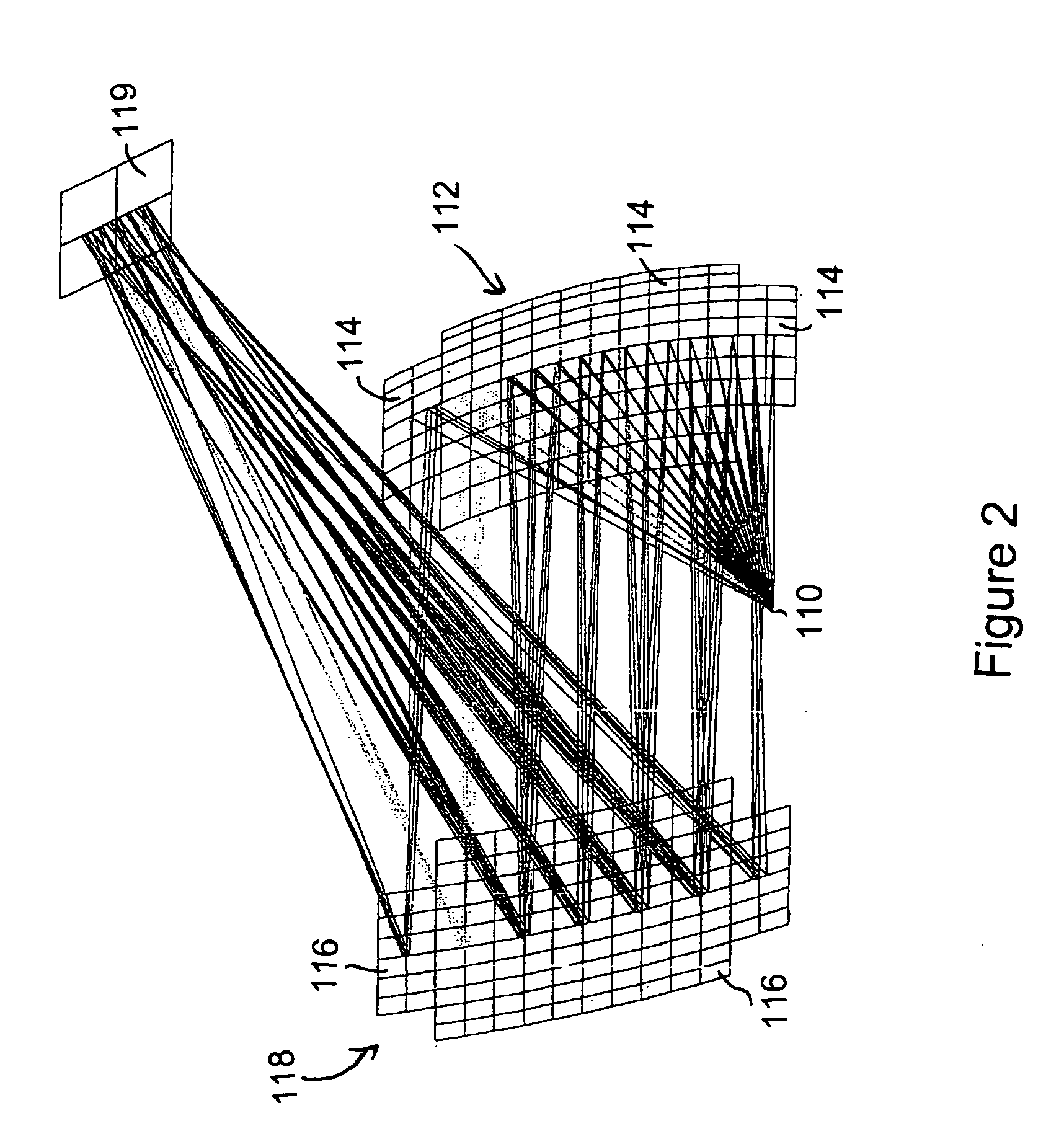

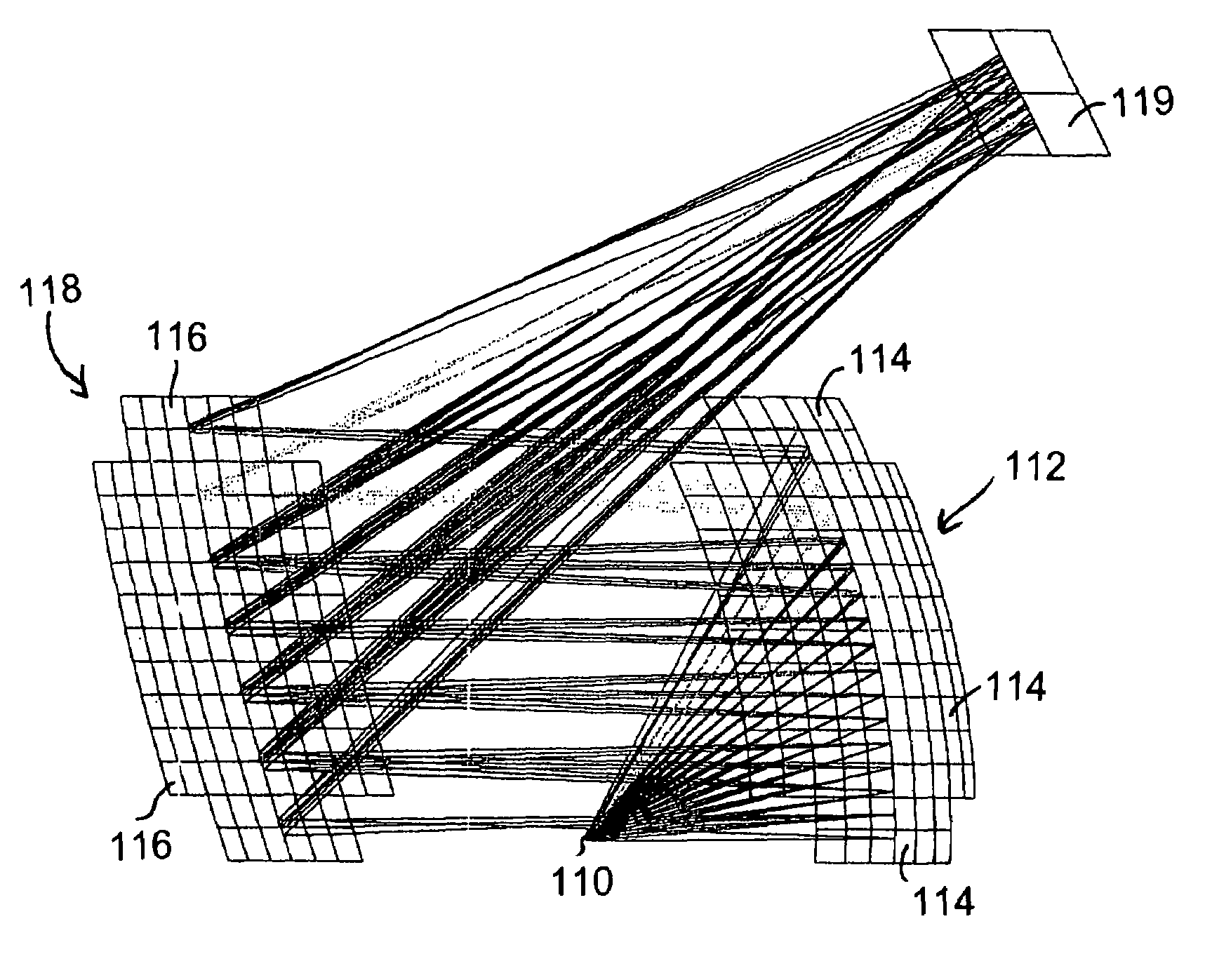

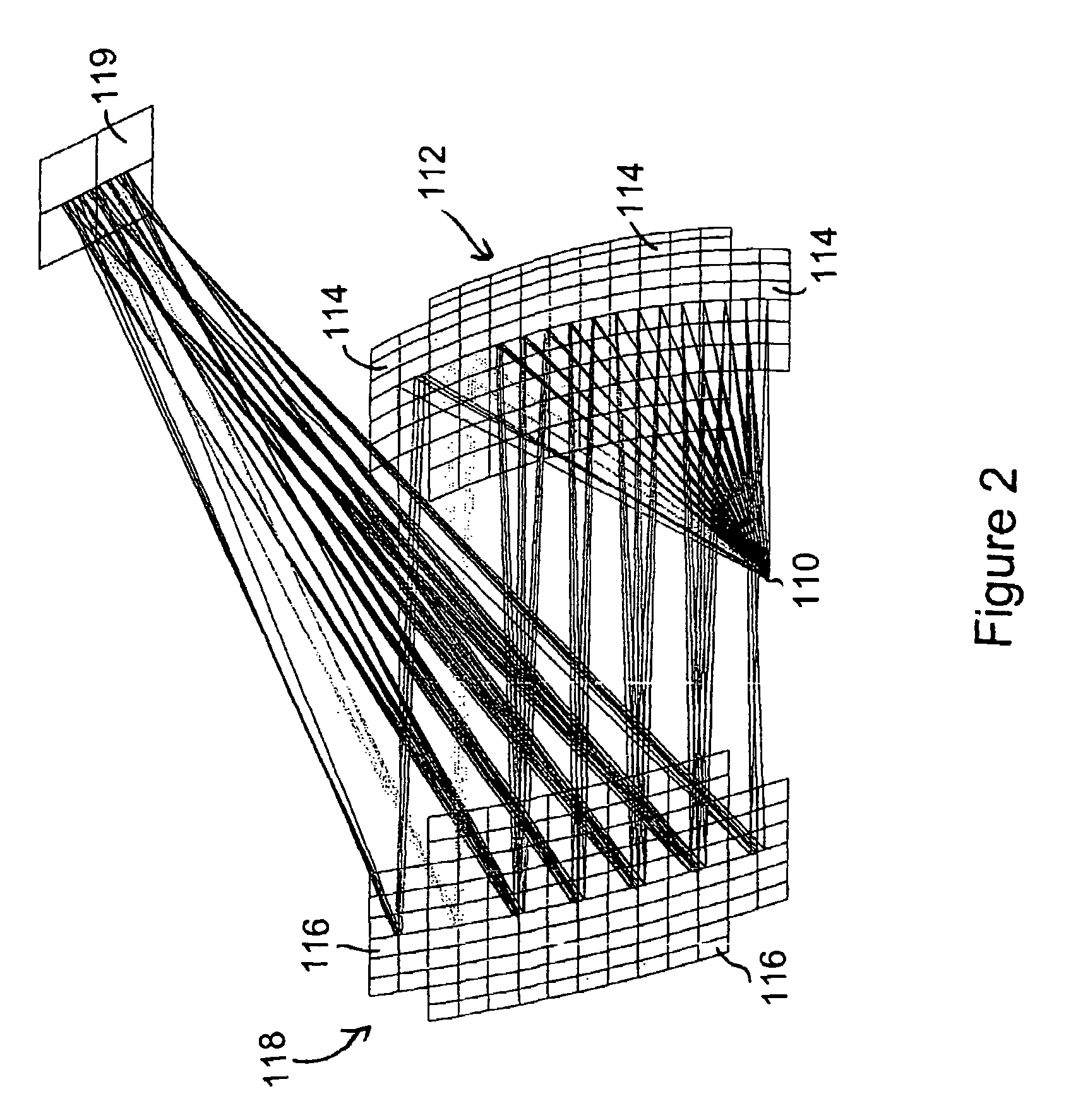

Reflective illumination system

This invention discloses a reflective illumination system for supplying an optical radiation beam along a folded path for illuminating a planar object. The system includes a radiation source, and two facing parabolic dish-shaped arrays of parabolic or dished reflectors. Divergent light received from the light source incident on a first of the arrays is reflected as a larger collimated beam comprising plural separated sub-beams. Each of the reflectors or facets from the first array directs one of the sub-beams to a facet on the second array. The second array reflects the light it receives with a substantially uniform intensity onto a rectangular target location.

Owner:JDS UNIPHASE CORP

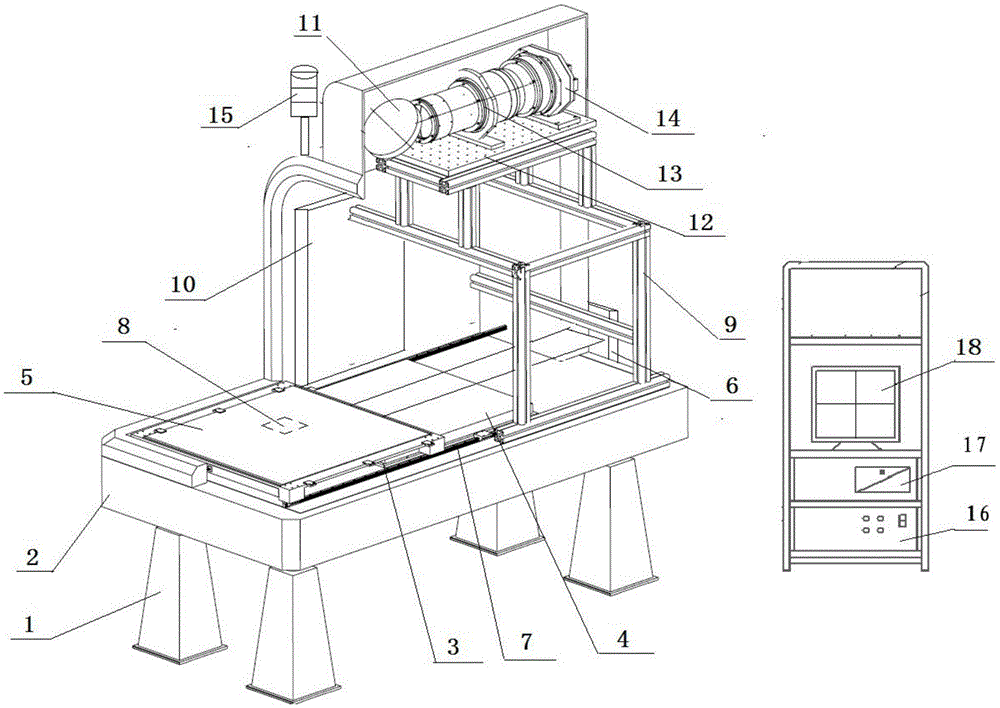

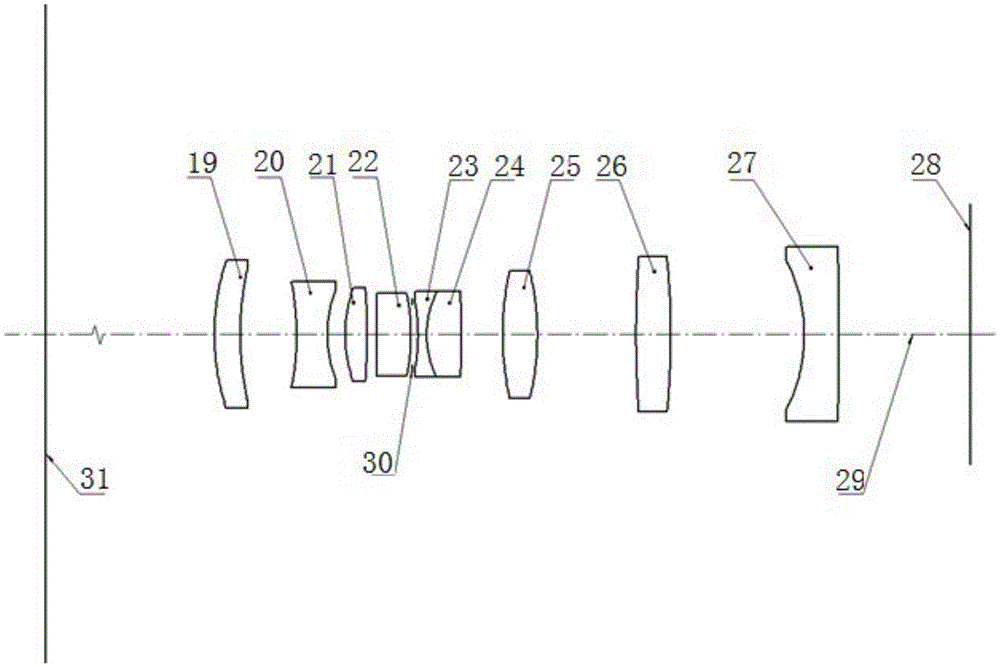

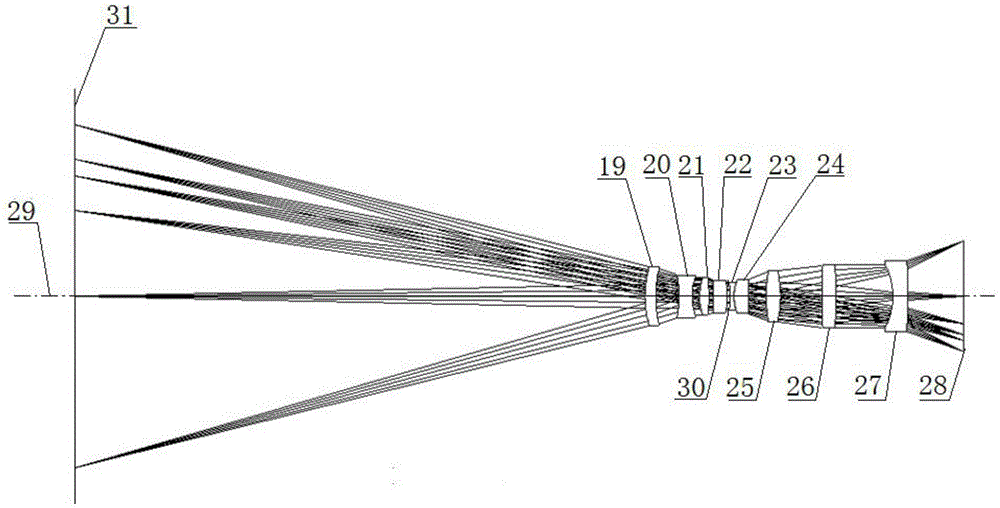

Large-format high-speed high-precision automatic optical detector

ActiveCN105486341AOvercome limitationsOvercome deficienciesMeasurement devicesGratingTransmission illumination

The invention relates to a large-format high-speed high-precision automatic optical detector, belongs to the field of automatic optical detection, and solves the problem that the detection precision tends to be influenced by different errors when a mobile small-view-field lens is moved in a present automatic optical detector. The detector comprises a support platform, damping supports, a translation guide rail pair, a workbench on the translation guide rail pair, a transmission illumination light source, a precise driver, a control system, a grating ruler, a lens support, a reflection illumination light source, a reflector, a precise focusing platform, a large-view-field high-precision lens and a splicing detector focal plane assembly. The imaging view field of the large-view-field high-precision lens is greater than 750mm, an imaging focal plane is composed of a triangularly spliced detector array, and part or all spliced detectors are controlled to work in different frame frequencies to match the movement speeds of different workpieces. The large-view-field high-precision lens is combined with the multi-detector spliced focal plane, the problem that a single lens cannot realize large-view-field imaging but multiple lenses are inconsistent in imaging is overcome, and the detection precision and efficiency are improved.

Owner:CHANGCHUN YITIAN TECH CO LTD

Intrusion warning system

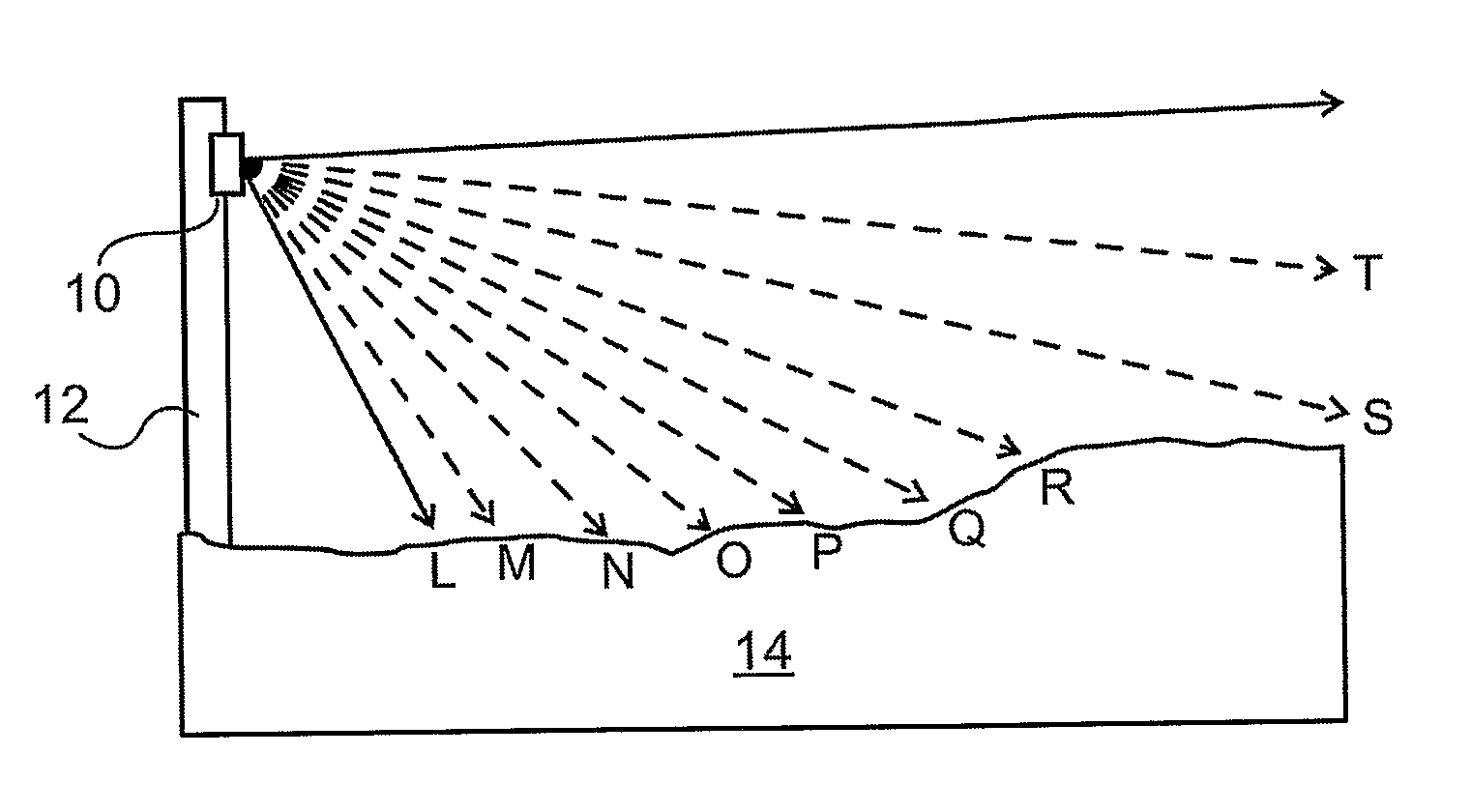

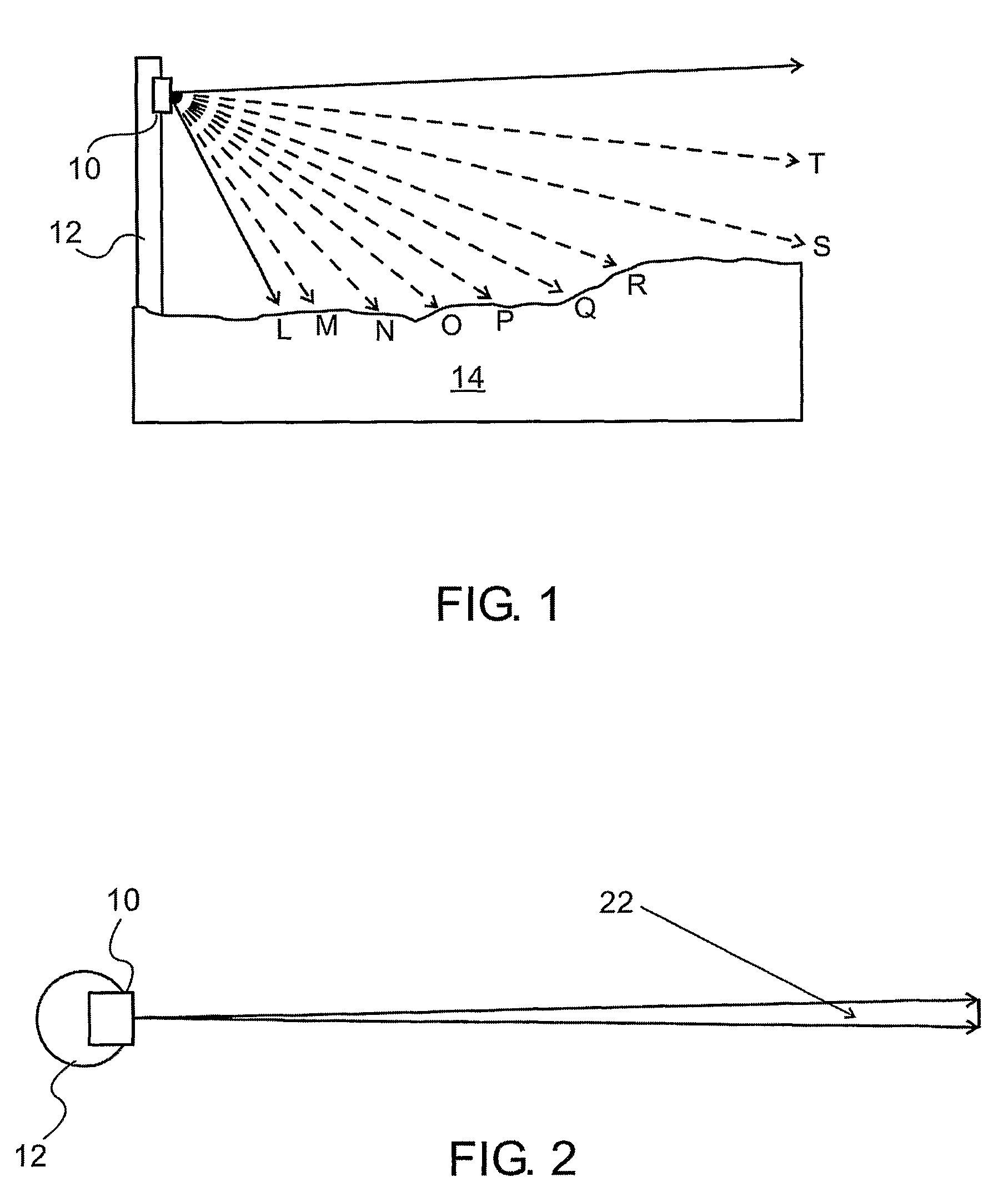

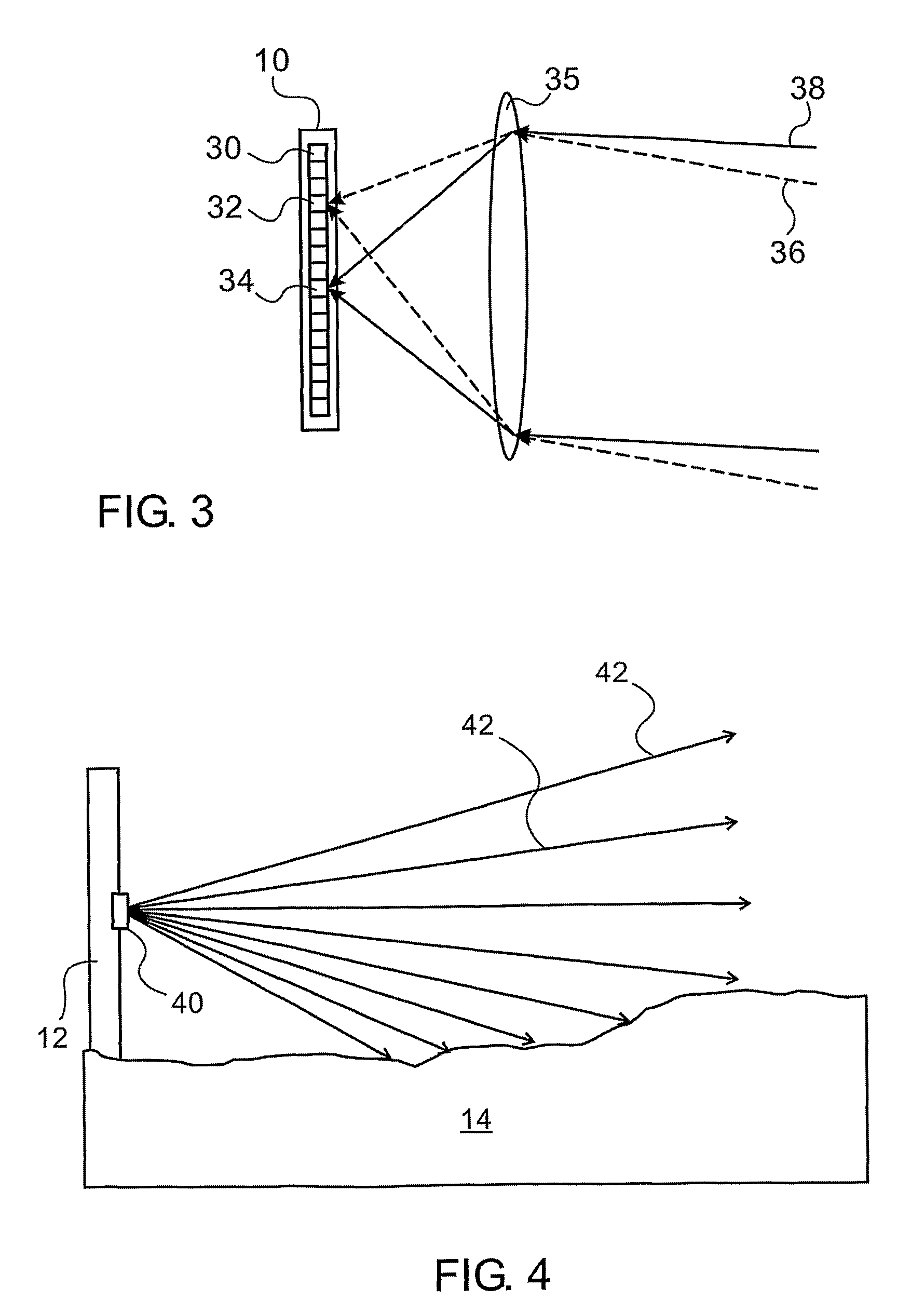

InactiveUS8970374B2Low costHigh sensitivityRadiation pyrometryOptical rangefindersReflection illuminationLight beam

A system for detecting intrusion across a surface, comprising a plurality of light sources projecting an array of illuminating beams along different optical paths in the surface and a detector array system directed such that it detects along a plurality of fields of view in the surface, illumination reflected from the illuminating beams. A signal processing system detects changes along the array of fields of view, in the reflected illumination level detected by the detector system. An increase greater than a predefined level in the reflected illumination level from any field of view provides an indication of an intrusion across the surveilled surface along that field of view, at the crossing point of the direction of that field of view with the optical path whose illuminating beam generated the increase in reflected illumination from that field of view.

Owner:SHILAT OPTRONICS

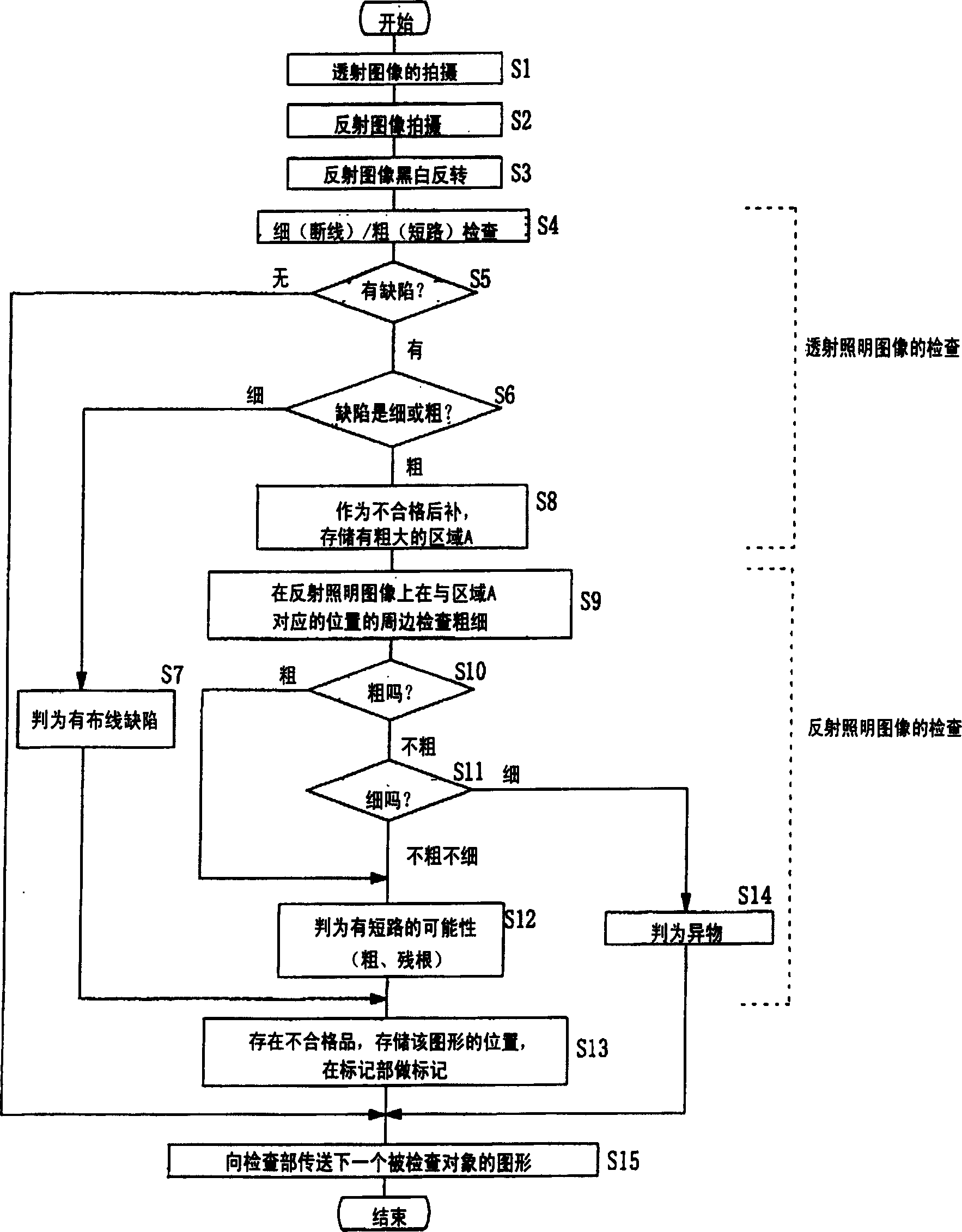

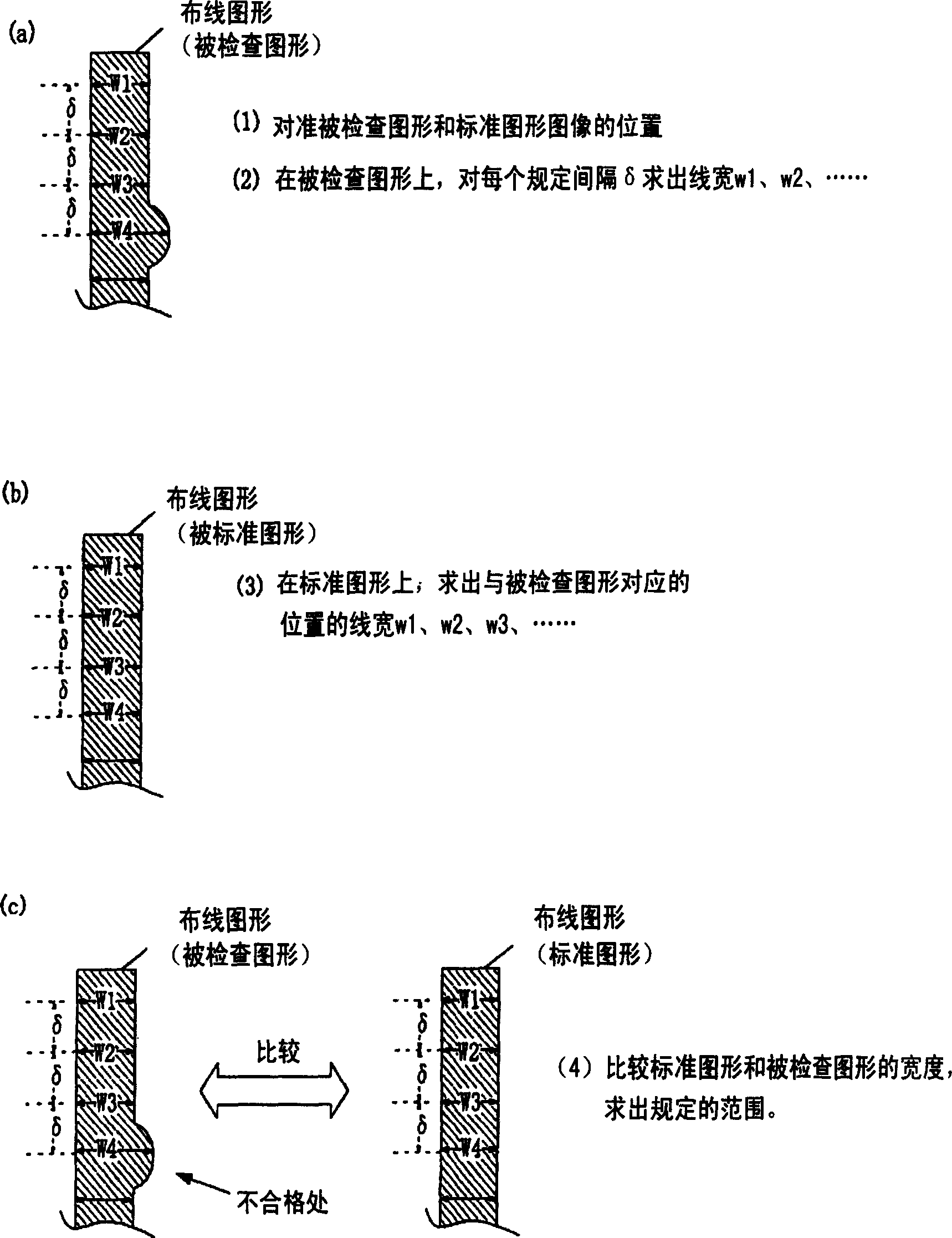

Wiring pattern check up apparatus

InactiveCN1576831AReduce inspectionReduce bulkMaterial analysis by optical meansSemiconductor/solid-state device manufacturingLine sensorTransmission illumination

Provided is an inspection apparatus of a wiring pattern that has a small number of false detections and can reduce inspection time by combining an inspection by vertical illumination and that by reflection illumination. A pattern 5a on a TAB tape 5 is carried to an inspection section 1 by a tape conveyance mechanism 10, illumination light is applied from a transmission illumination means 1a, the transmitted illumination image of the pattern 5a is imaged by a CCD line sensor 1c, illumination light is applied from a vertical illumination means 1b, and the vertical illumination image from the pattern 5a is imaged. The captured image is sent to a control section 4. The control section 4 compares the pattern of the transmission illumination image with a first reference pattern, inspects the pattern 5a, compares the pattern of the vertical illumination image at a position corresponding to a faulty section with a second reference pattern regarding the pattern 5a that is determined to be a faulty candidate, and determines whether the pattern 5a is conforming or not.

Owner:USHIO DENKI KK

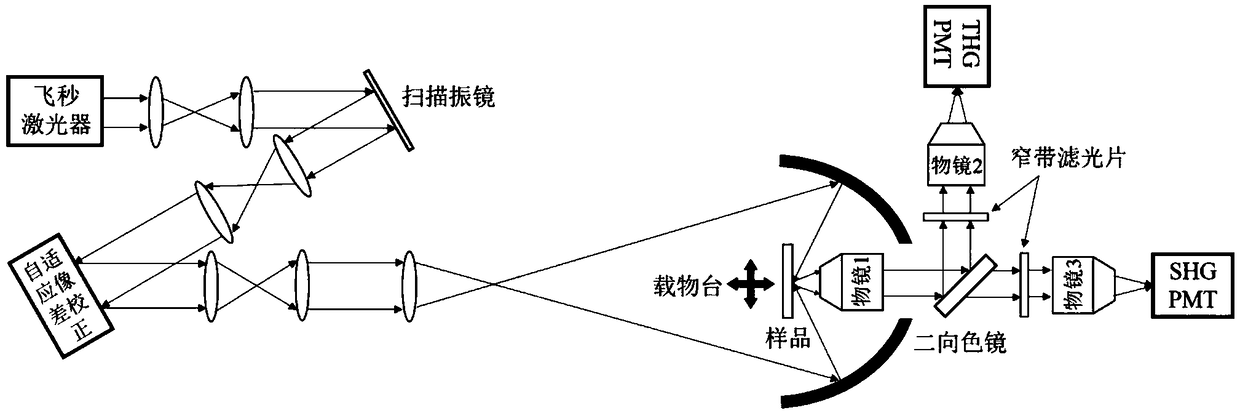

Self-adaption harmonic wave confocal microscopic measurement method for illumination of ellipsoidal reflector

InactiveCN108982428AHigh measurement resolutionScattering properties have little effectAnalysis by material excitationLight spotOptical measurements

The invention relates to a self-adaption harmonic wave confocal microscopic measurement method for the illumination of an ellipsoidal reflector, belonging to the non-linear optical measurement. According to the method, an ellipsoidal reflection illumination system, a confocal microscopic measurement method, a self-adaption optical aberration correction method and a harmonic wave microscopic methodare organically combined, so that the harmonic wave microscopic measurement resolving power can be improved. A femtosecond laser pulse is subjected to beam shaping and scanning galvanometer reflection, enters the self-adaption optical aberration correction method and is subjected to phase modulation and aberration correction to generate illumination beams, and the illumination beams enter an ellipsoidal reflection mirror system and are assembled into a sample so as to generate stimulation focus light spots required by the generation of harmonic signals. The sample is stimulated by stimulationlight to simultaneously generate second and third harmonic signal, and the second and third harmonic signals are collected and analyzed by a double-path composited confocal microscopic measurement system on the right side. After being collected by a large-numerical aperture objective lens, the harmonic signals are separated into two wavelength signals by a bidirectional color selective mirror, are focused by a narrow band pass filter and an imaging objective lens, are transmitted through a needle hole and are received by a photomultiplier (PMT). An adopted harmonic wave collection module adopts a confocal collection mode. By virtue of an apodization effect of a confocal needle hole, the interference caused by aliasing signal noise to the analysis of the harmonic signals can be effectivelyinhibited, and the measurement resolving power of the microscopic system can be greatly improved.

Owner:HARBIN INST OF TECH

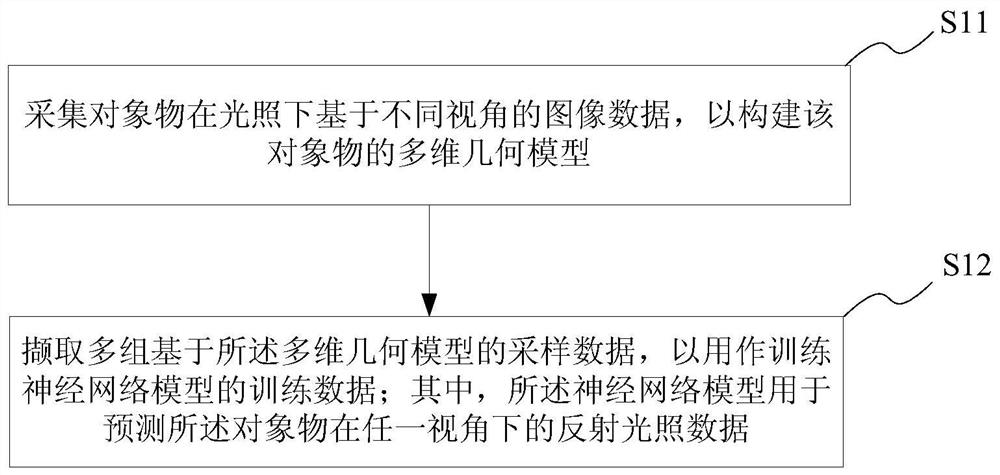

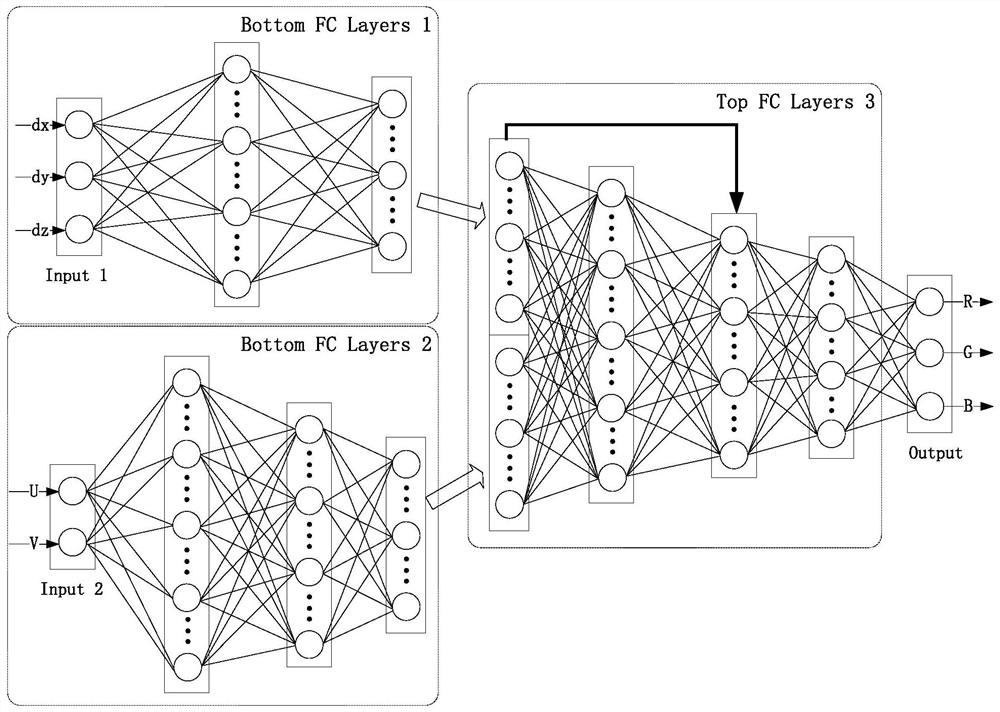

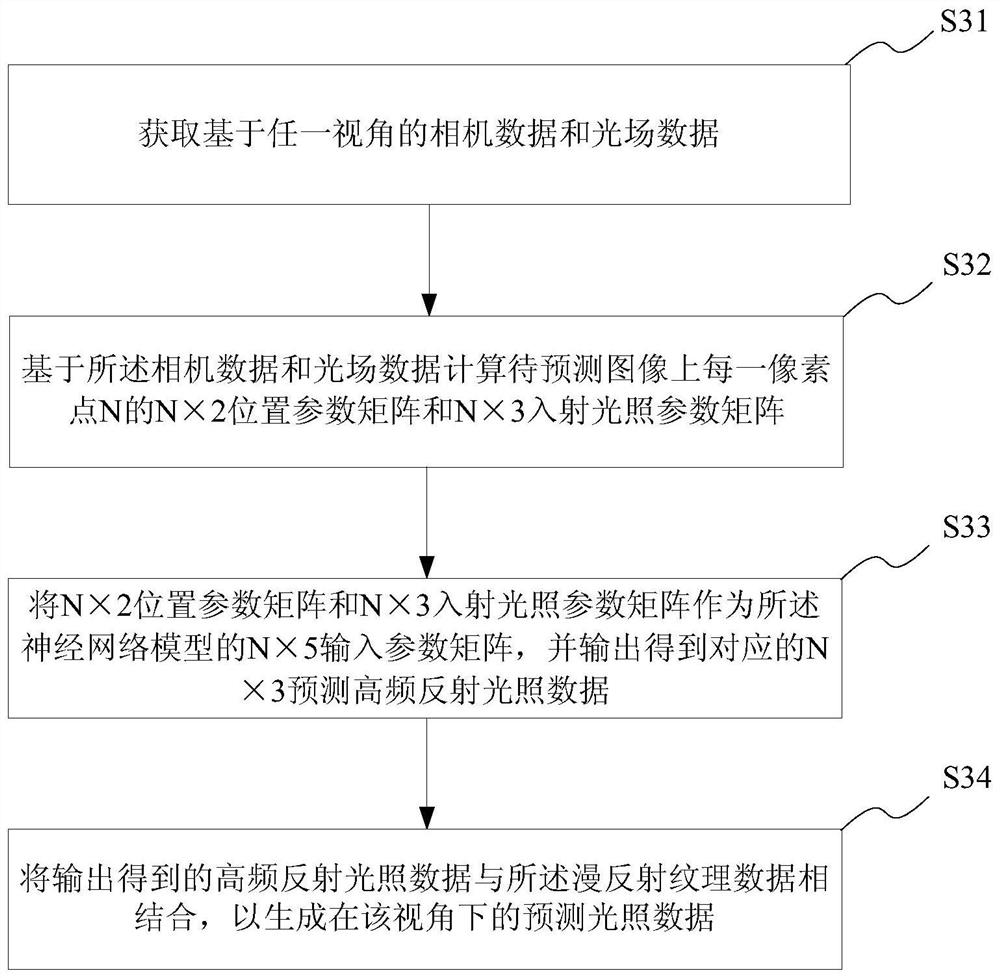

Illumination data prediction method and system based on neural network, terminal and medium

ActiveCN111833430AImprove fidelityHigh Rendering CompressionNeural architecturesNeural learning methodsPattern recognitionReflection illumination

The invention provides an illumination data prediction method and system based on a neural network, a terminal and a medium. The method comprises the steps: collecting the image data of an object under illumination based on different visual angles, so as to construct a multi-dimensional geometric model of the object; capturing a plurality of groups of sampling data based on the multi-dimensional geometric model to serve as training data for training a neural network model; wherein the neural network model is used for predicting reflected illumination data of the object at any visual angle. According to the technical scheme provided by the invention, the neural network used for predicting the illumination data is established based on the sampling data, and the reflection illumination data under any visual angle is predicted through the neural network, so that the high-fidelity rendering image is obtained, Meanwhile, a very high rendering compression ratio and high efficiency of real-time rendering can be achieved.

Owner:SHANGHAI TECH UNIV

Reflective illumination system

This invention discloses a reflective illumination system for supplying an optical radiation beam along a folded path for illuminating a planar object. The system includes a radiation source, and two facing parabolic dish-shaped arrays of parabolic or dished reflectors. Divergent light received from the light source incident on a first of the arrays is reflected as a larger collimated beam comprising plural separated sub-beams. Each of the reflectors or facets from the first array directs one of the sub-beams to a facet on the second array. The second array reflects the light it receives with a substantially uniform intensity onto a rectangular target location.

Owner:JDS UNIPHASE CORP

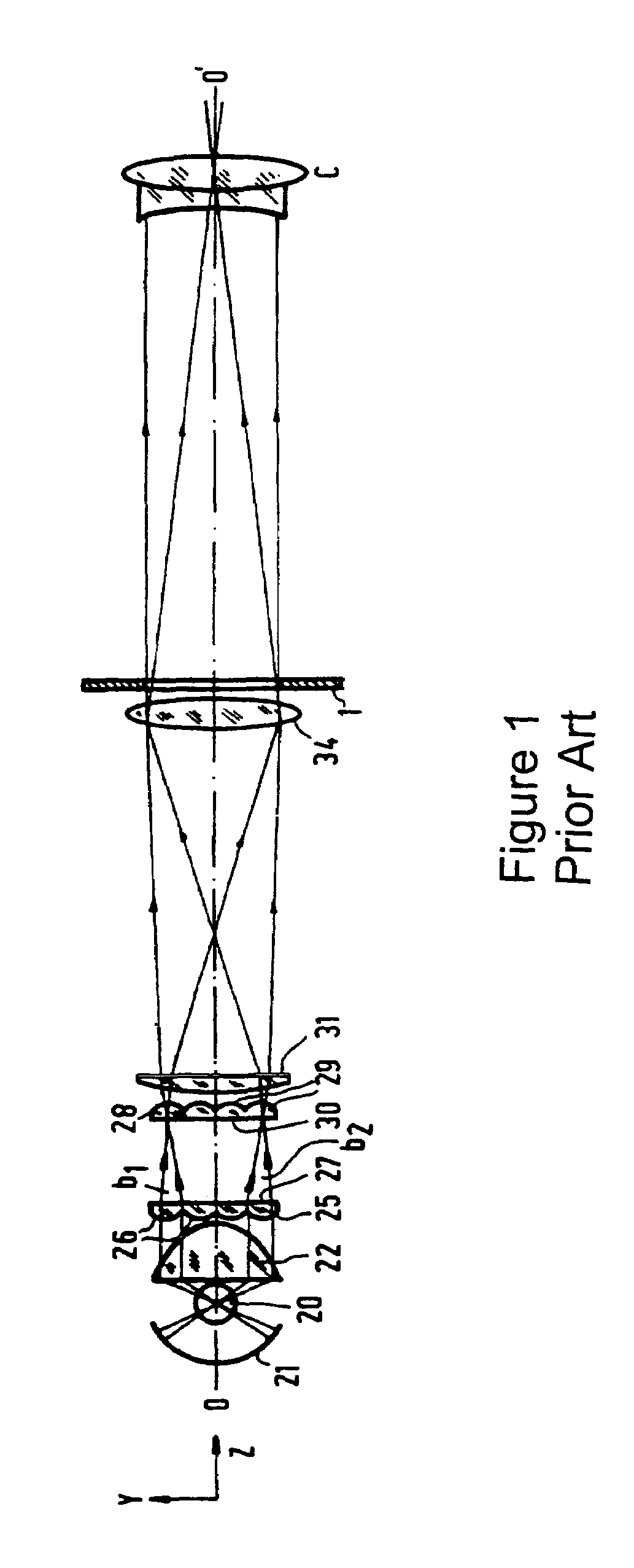

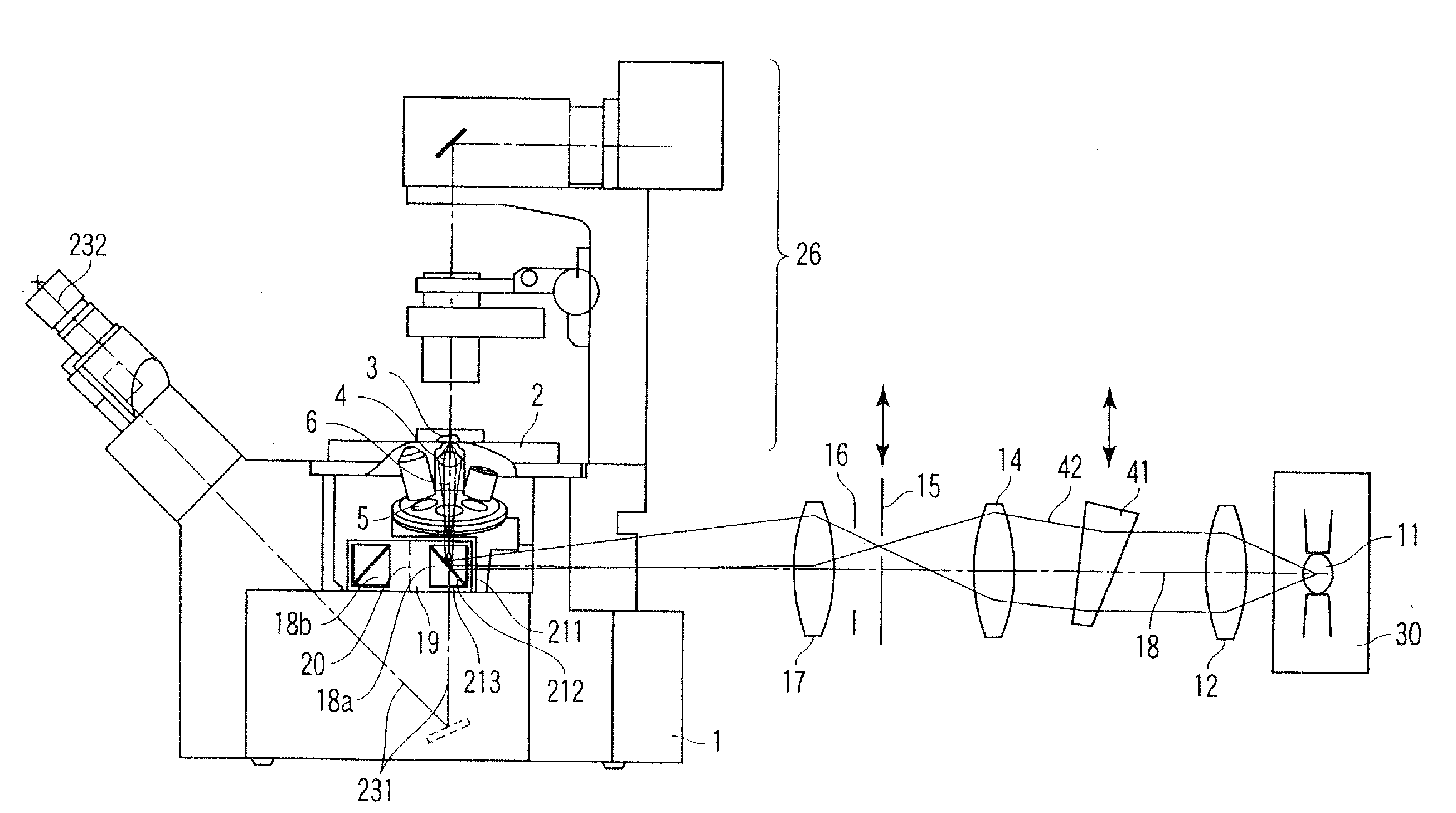

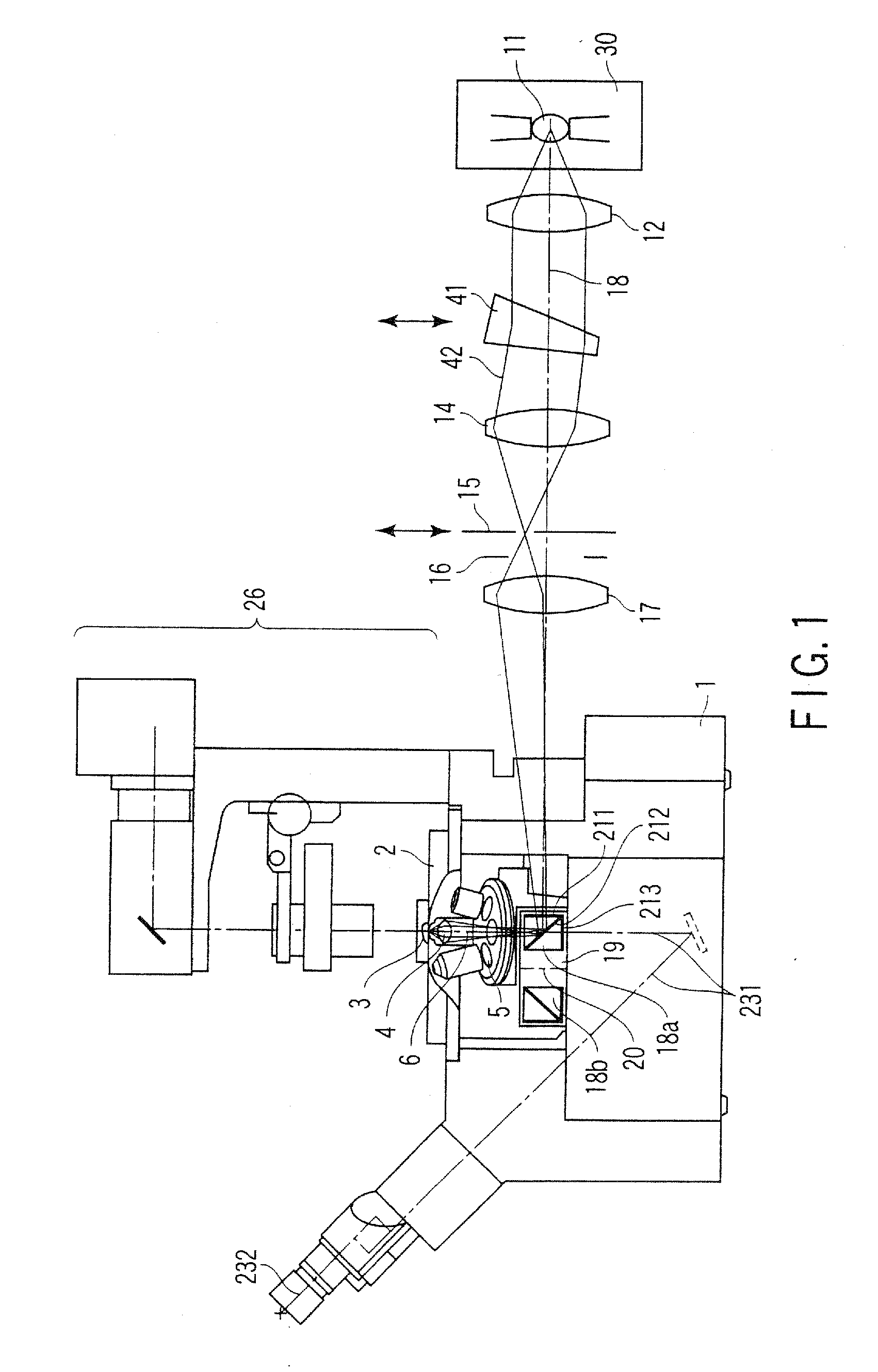

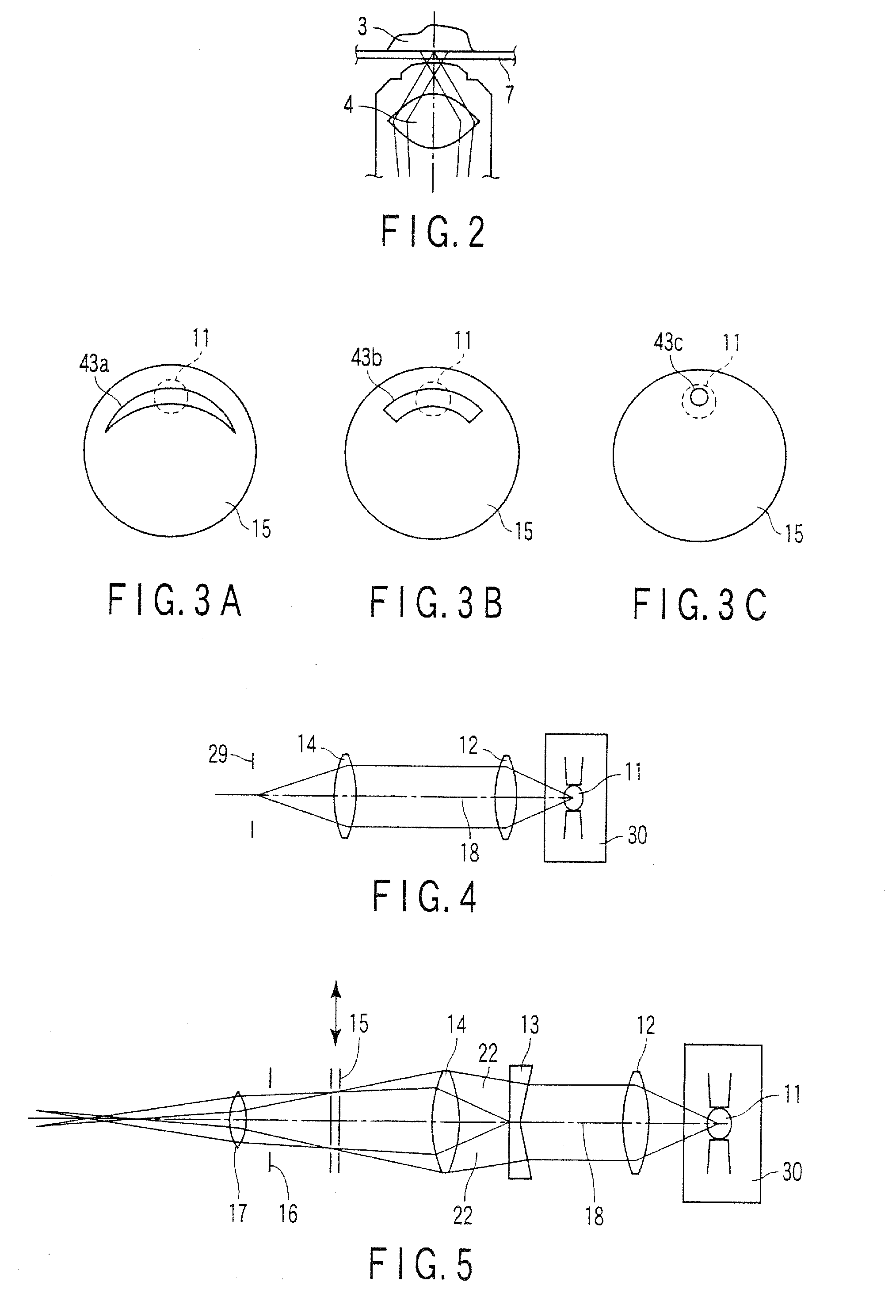

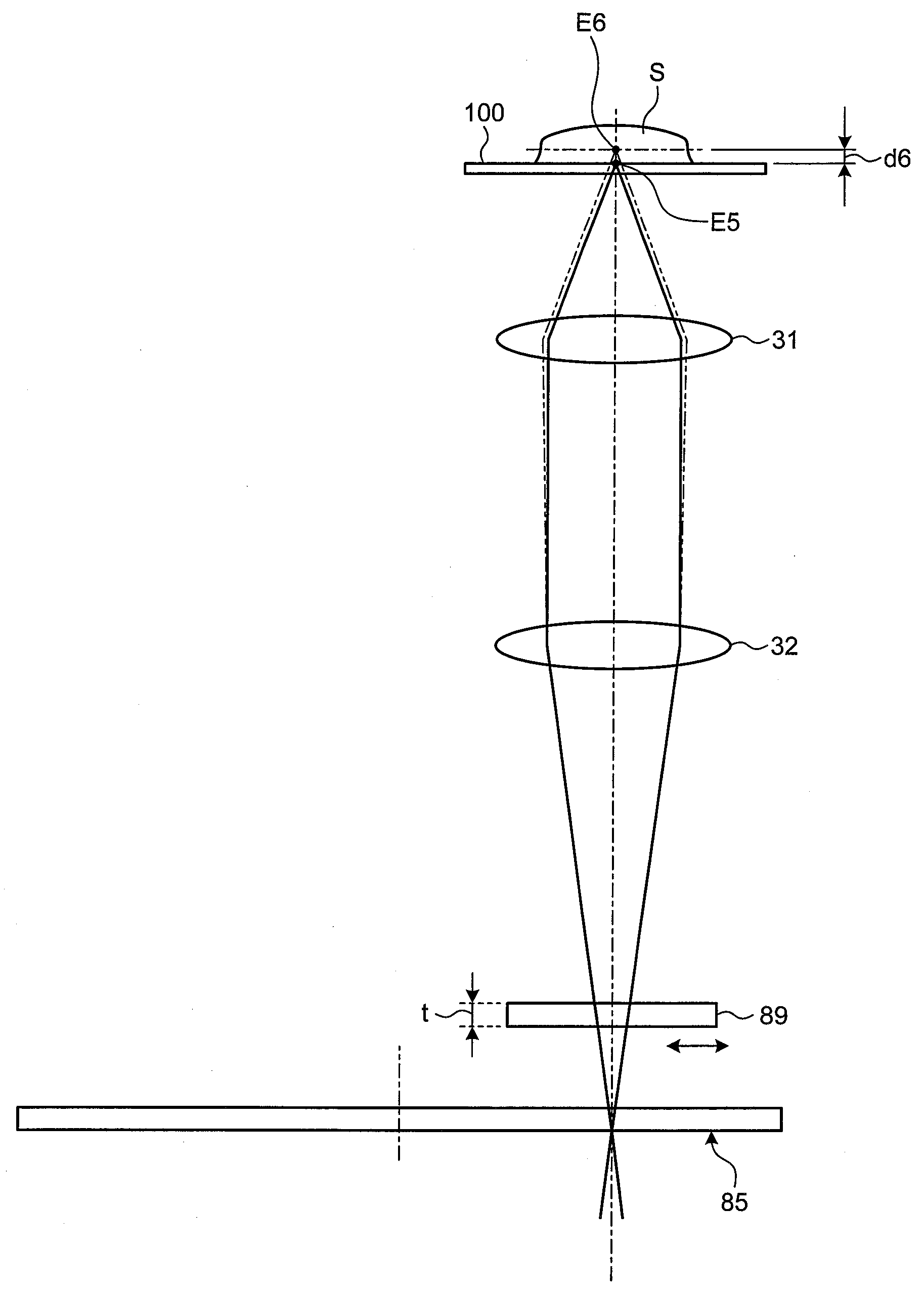

Total reflection fluorescent microscope

A fluorescent microscope comprises a light source, an optical illumination system which forms an optical path to irradiate a specimen with a light beam from the light source, an objective lens which condenses the light beam of the optical illumination system onto the specimen, an optical device which is disposed on the optical path of the optical illumination system and which decenters the light beam by decentering an optical axis of the optical path, and a slit which passes the light beam decentered by the optical device through a total reflection illumination region on an emission pupil surface of the objective lens.

Owner:OLYMPUS CORP

Illumination aperture diaphragm

ActiveUS9175831B2Raise the ratioImage can be preventedElectrode and associated part arrangementsEndoscopesFluorescenceReflection illumination

Owner:VS TECH CORP

Device and method for inspecting unevenness of film thickness

InactiveCN102967266AAutomatic inspection of film thickness unevennessAccurate inspection results of uneven film thicknessMaterial analysis by optical meansSemiconductor/solid-state device manufacturingTransmission illuminationReflection illumination

The present invention provides a film thickness unevenness inspection device and method capable of acquiring an image with brightness and contrast suitable for inspection, so as to obtain an accurate inspection result. The present invention discloses a film thickness unevenness inspection device and method, characterized in moving a substrate with a surface formed thereon a coating film along a direction and, at the same time, inspecting film thickness unevenness of the coating film formed on the substrate. A film thickness inspection portion is provided for inspecting a thickness of the coating film. A light source portion comprises a reflection illumination portion installed in one side of an image capturing portion, and a transmission illumination portion installed in a location opposite to the image capturing portion with the substrate installed in-between. The image capturing portion comprises an image capturing portion angle adjustment mechanism for adjusting a relative angle with respect to the substrate. The reflection illumination portion comprises a reflection illumination angle adjustment mechanism for adjusting a relative angle between the reflection illumination portion and the substrate. The transmission illumination portion comprises a transmission illumination angle adjustment mechanism for adjusting a relative angle between the transmission illumination portion and the substrate. The film thickness unevenness inspection device comprises a control portion. According to film thickness information from the film thickness inspection portion, the control portion controls the reflection illumination angle adjustment mechanism and the transmission illumination angle adjustment mechanism to regulate a light quantity of reflection illumination and a light quantity of transmission illumination.

Owner:TORAY ENG CO LTD

Control grid for solar energy concentrators and similar equipment

InactiveUS7967457B2Increased longevityImprove performanceSolar heating energyMirrorsCost effectivenessIndium tin oxide

Owner:RABINOWITZ MARIO

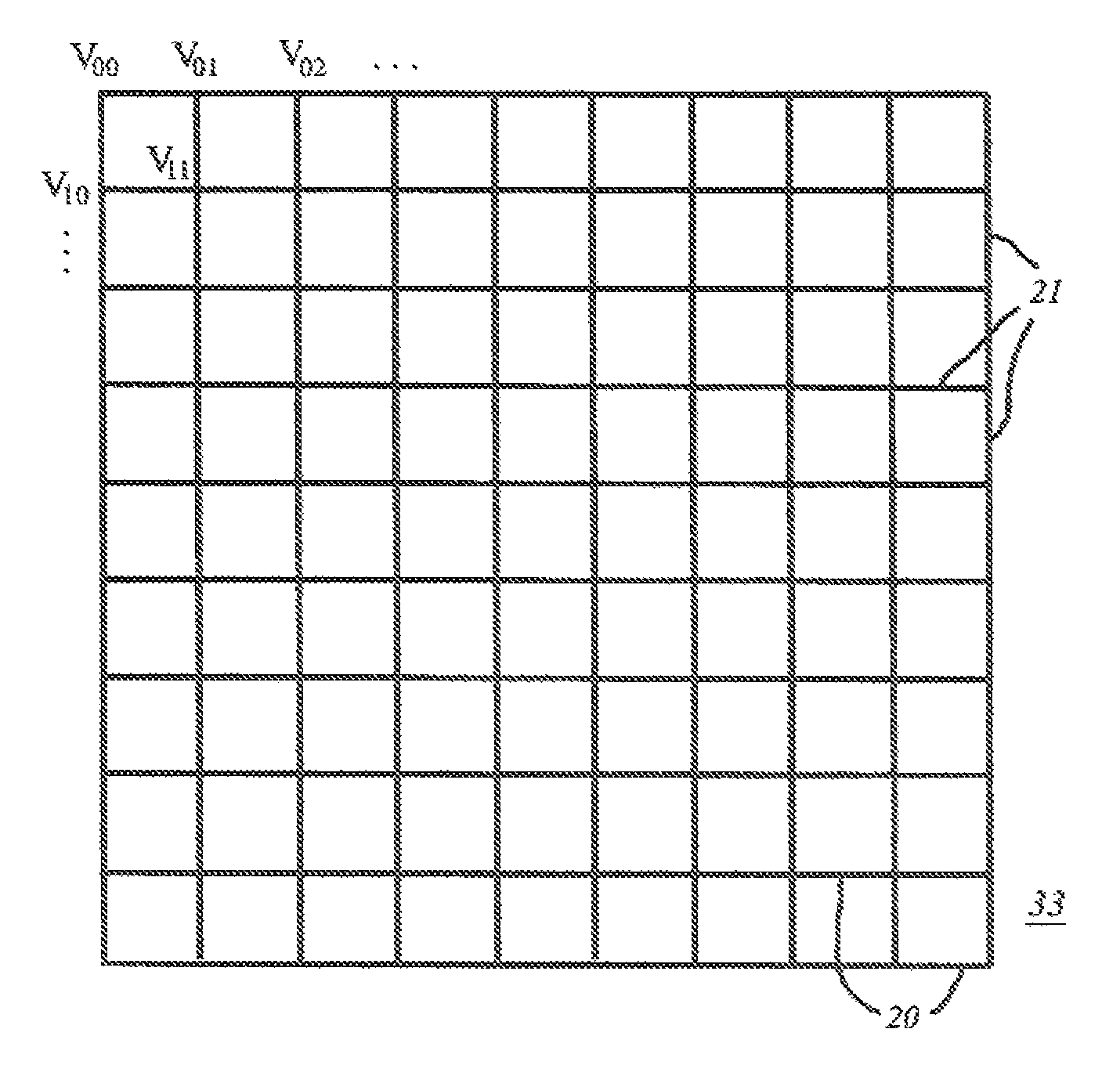

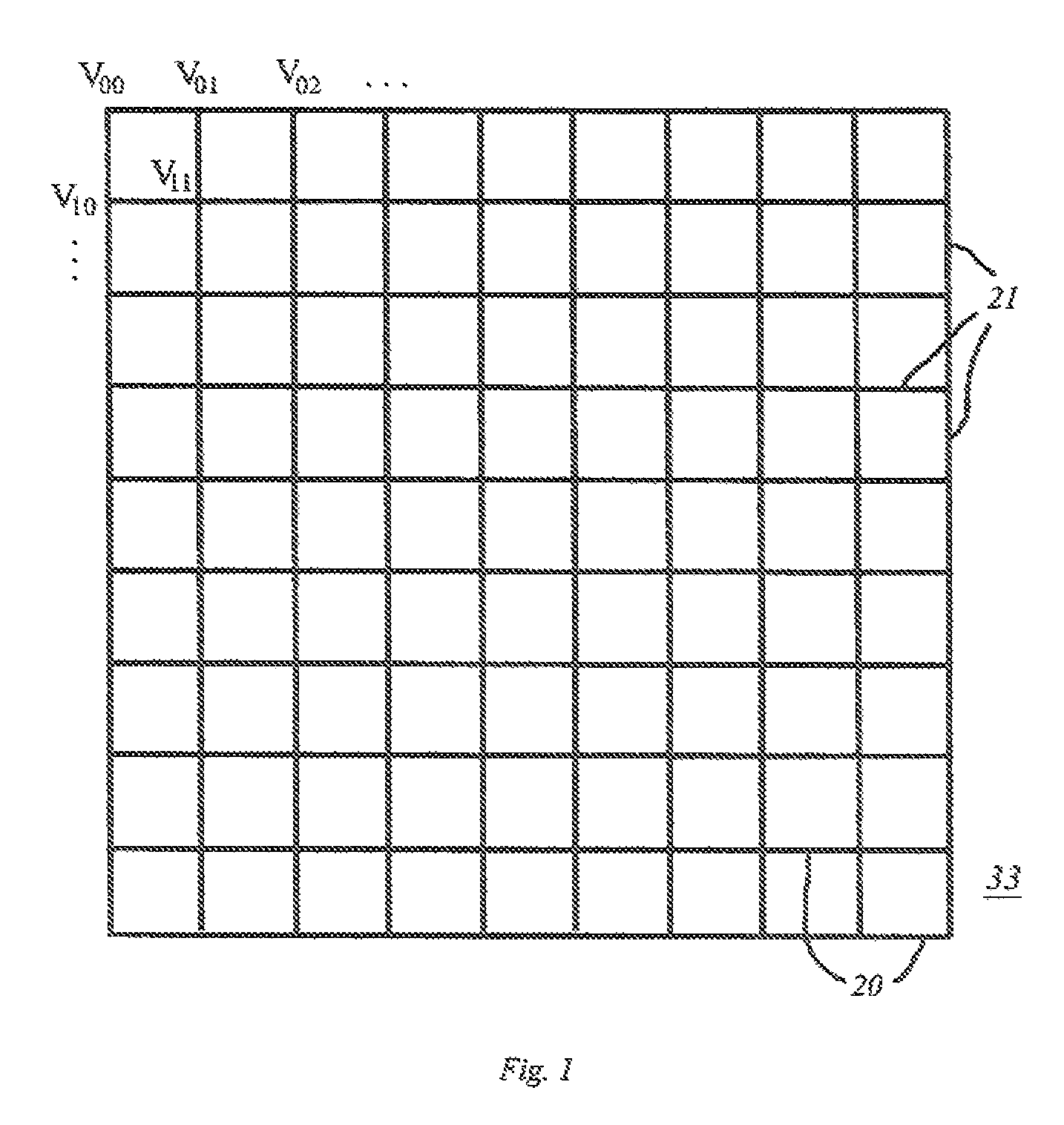

Focusing apparatus, focusing method, and pattern inspection method

ActiveUS20180003649A1Television system detailsSemiconductor/solid-state device testing/measurementReflection illuminationOptoelectronics

A focusing apparatus includes a first reticle, arranged at the front side of a conjugate position of a TDI sensor; a second reticle, arranged at the back side of the conjugate position; an equalizing circuit to perform gray scale value equalization by using a gray scale value output by the TDI sensor which received the pattern image by illumination light not passing through the first and second reticles; and a distance change / move amount calculation circuit to calculate, in a state where the gray scale value equalization has been performed, a distance change / move amount of a relative distance, for focusing the pattern image of the substrate, between the substrate and the conjugate position of the TDI sensor by using a first derivative value of a gray scale value output by the TDI sensor which received the pattern image by the reflection illumination light having passed through the first and second reticles.

Owner:NUFLARE TECH INC

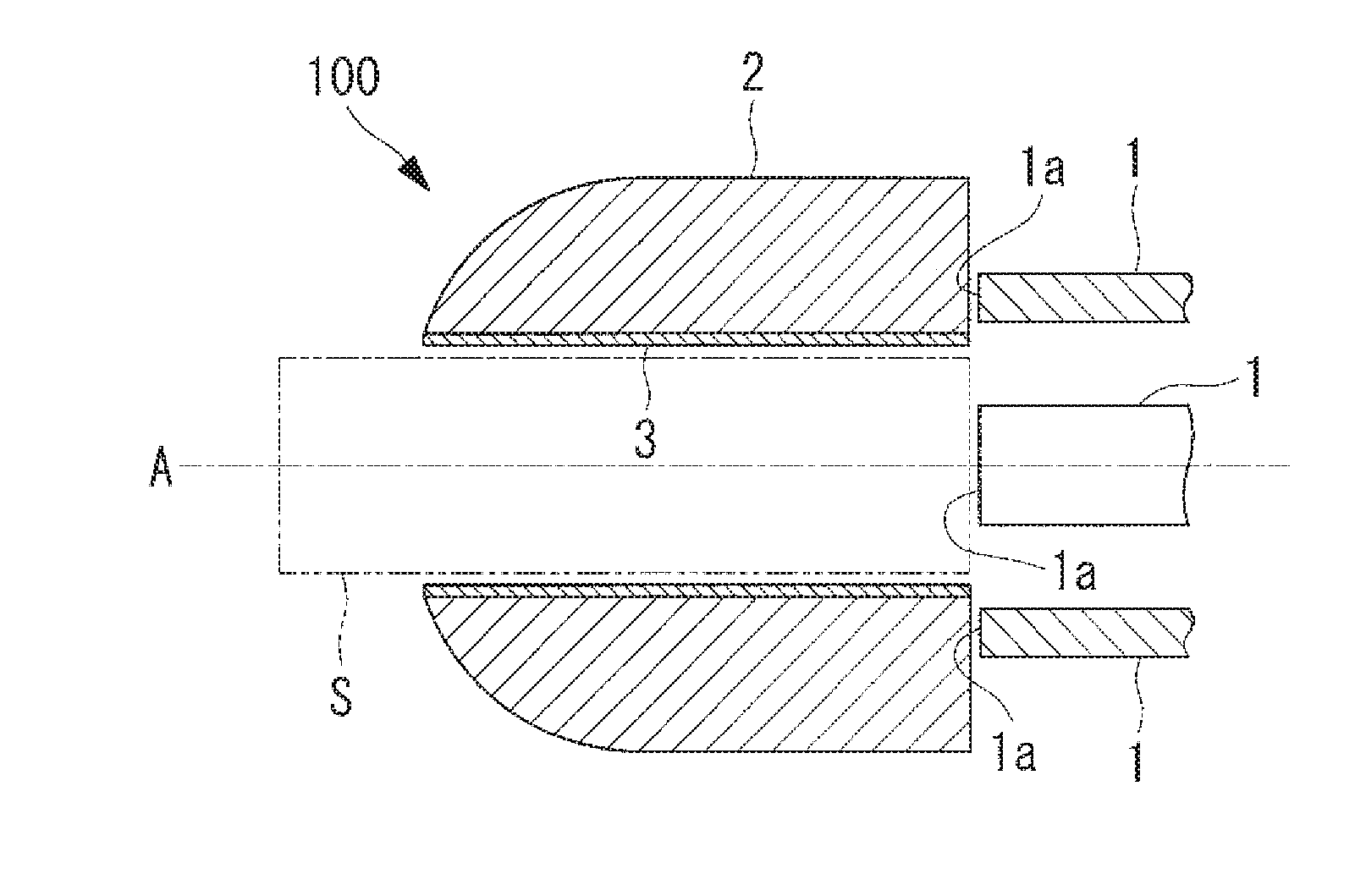

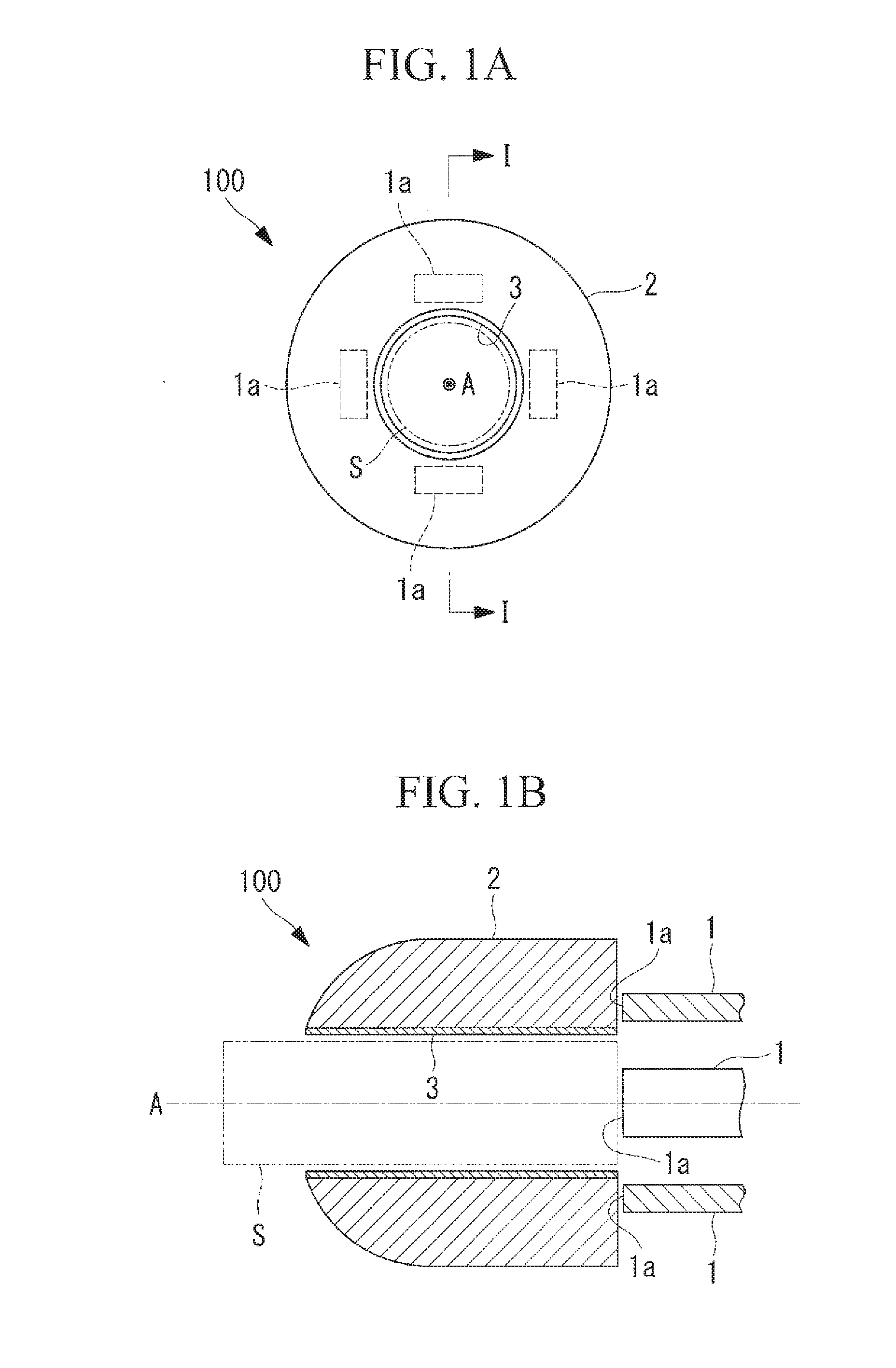

Inverted microscope system

ActiveUS20140293407A1Material analysis by optical meansMicroscopesTotal internal reflectionReflection illumination

An inverted microscope system includes an objective lens holding unit that holds an objective lens configured to collect at least observation light from a specimen, a tube lens configured to form an image using the observation light collected by the objective lens, a total internal reflection fluorescence microscopy optical system provided between the objective lens and the tube lens and configured to observe the observation light from the specimen using a total reflection illumination, and a disk scanning confocal optical system including a rotary disk on which a confocal opening is formed, the confocal opening being placed at a position substantially conjugate to a focus position of the objective lens. A relative distance between the focus position of the objective lens and the substantially conjugate position is changeable along an optical path of the observation light.

Owner:EVIDENT CORP

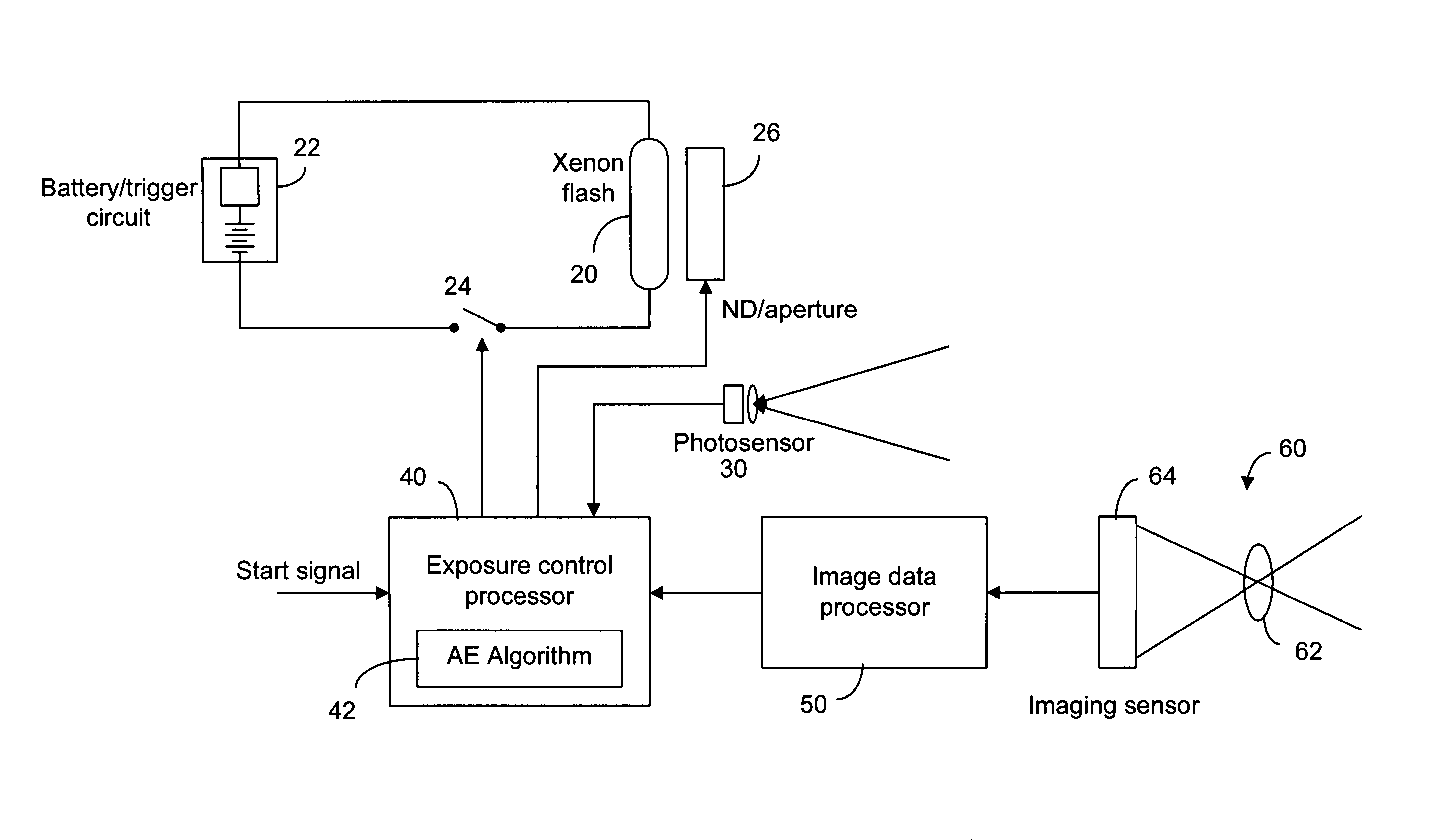

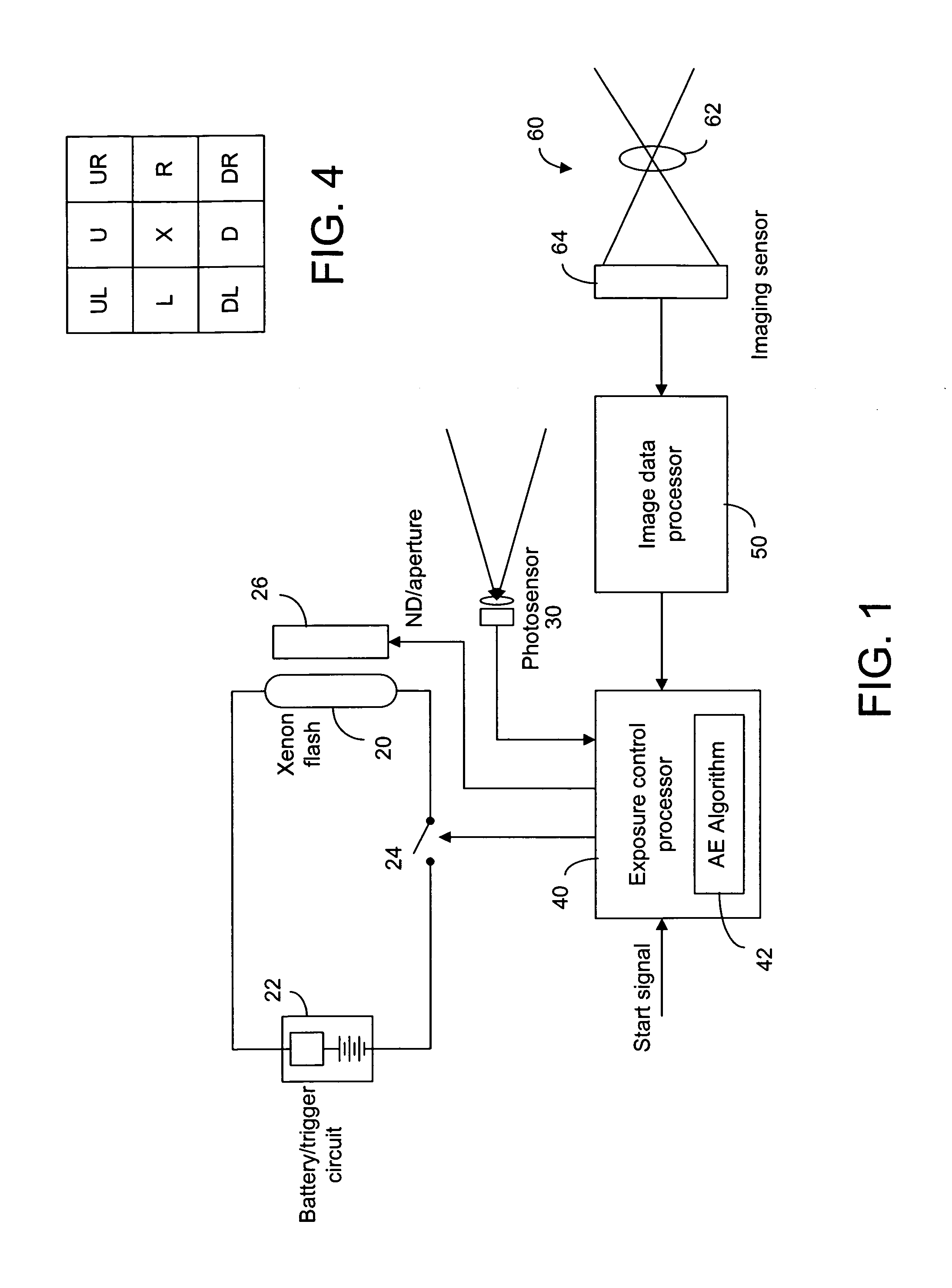

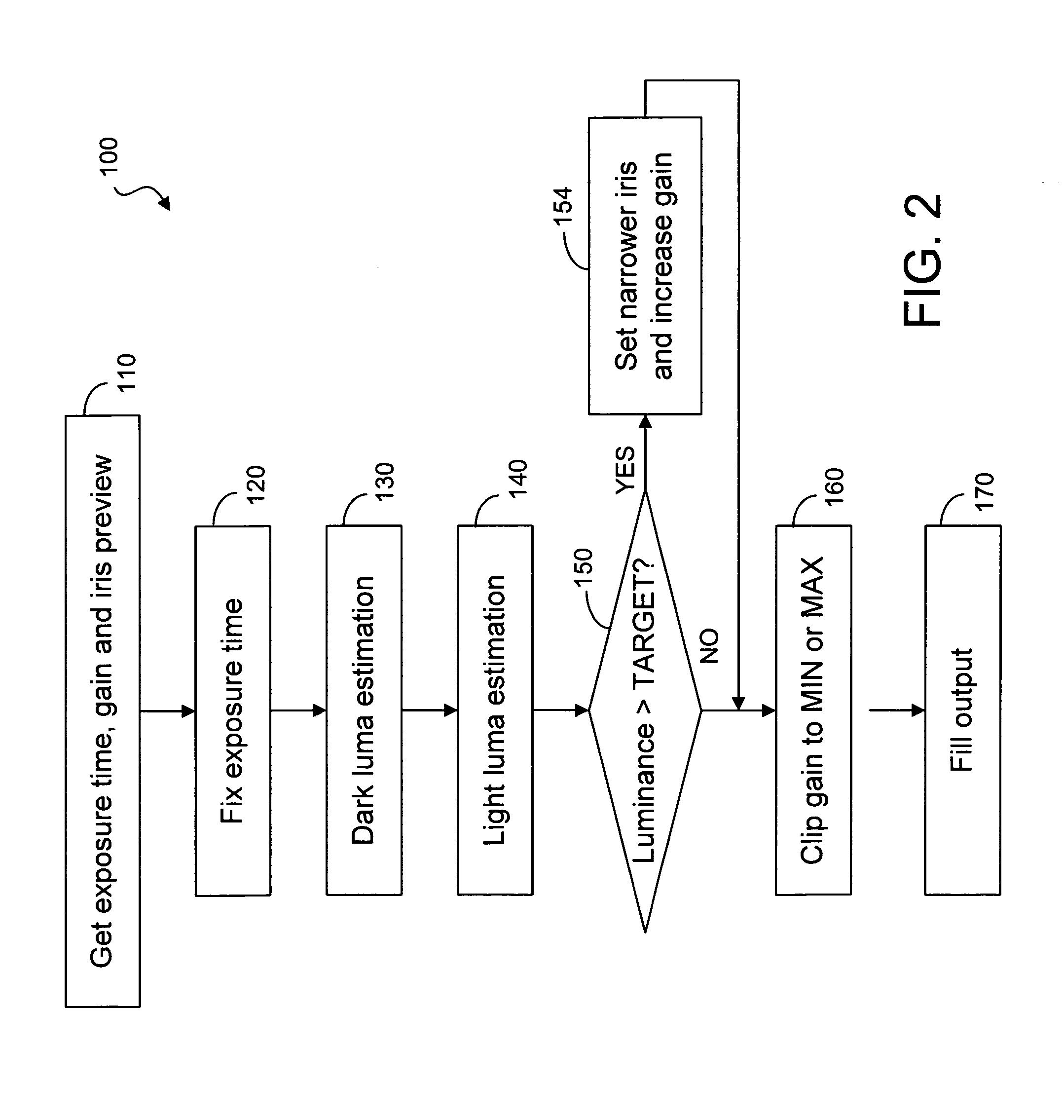

Camera flash module and method for controlling same

InactiveUS8018525B2Television system detailsColor signal processing circuitsImaging processingImage resolution

An auto-exposure algorithm for controlling a camera flash uses image processing to identify important areas of the image affected by the flash, while disregarding highly reflective / illuminated areas and uses a ND filter to linearize the flash triggering with highly reflective scenes. The camera flash is controlled by the auto-exposure algorithm in two stages:a pre-flash stage followed by a main-flash stage. In the pre-flash stage, two images are captured under the same camera settings regarding the exposure time, gain, iris and resolution. One image is captured with flash and one without. From the difference between the two images, a reference pixel is used to determine the flash intensity in the main-flash stage.

Owner:NOKIA TECHNOLOGLES OY

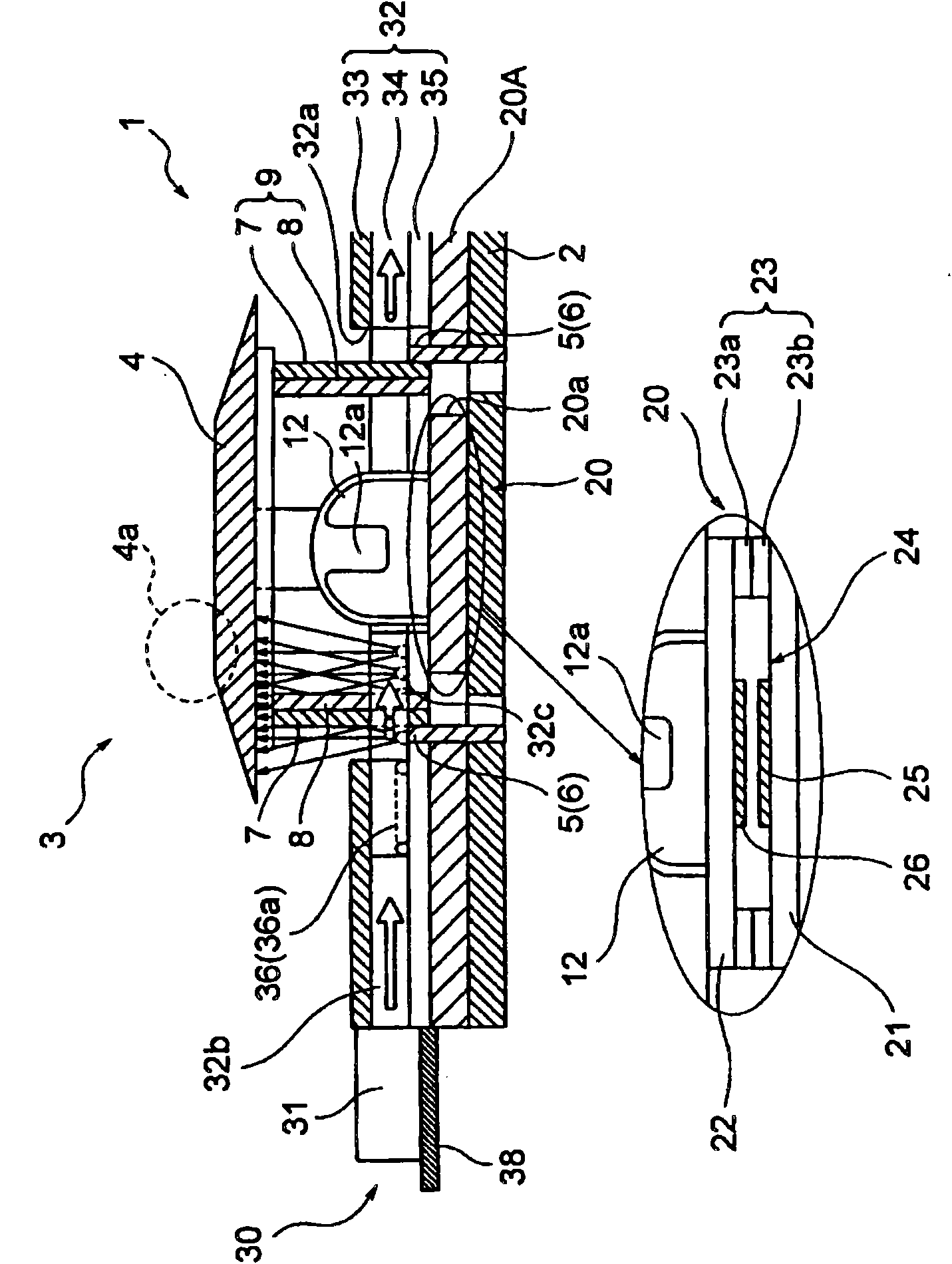

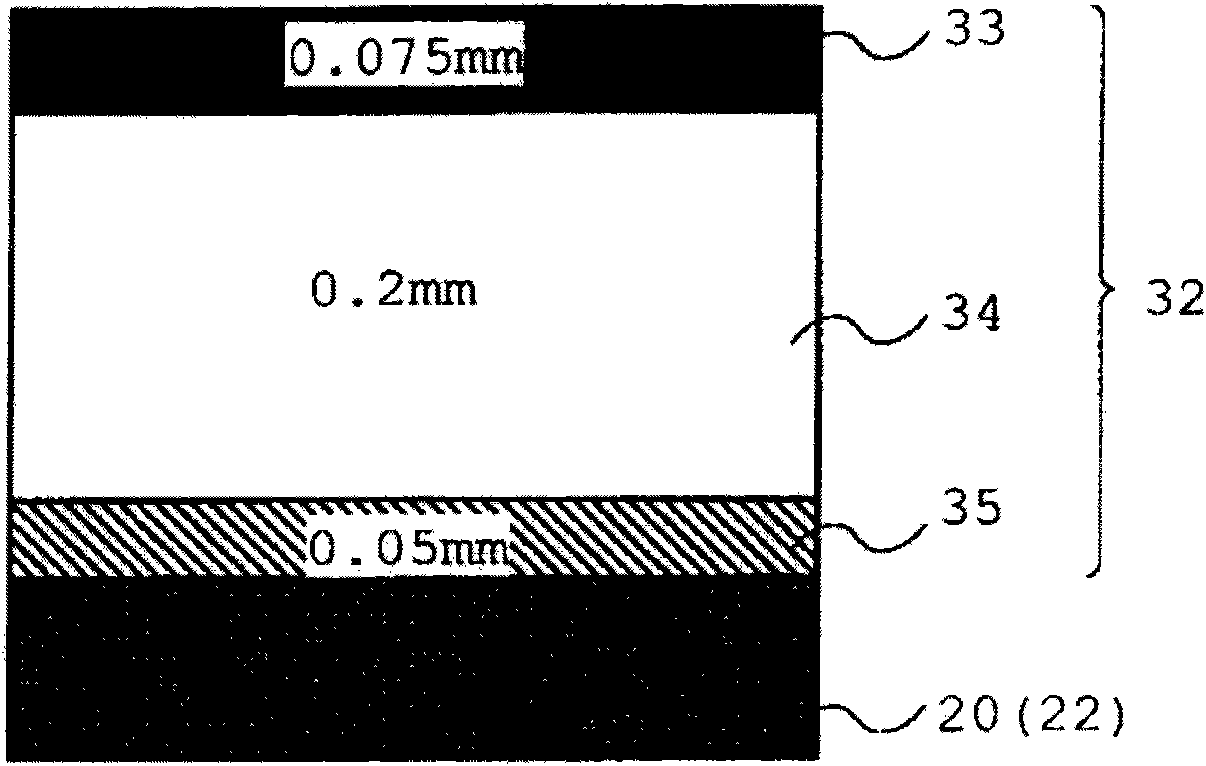

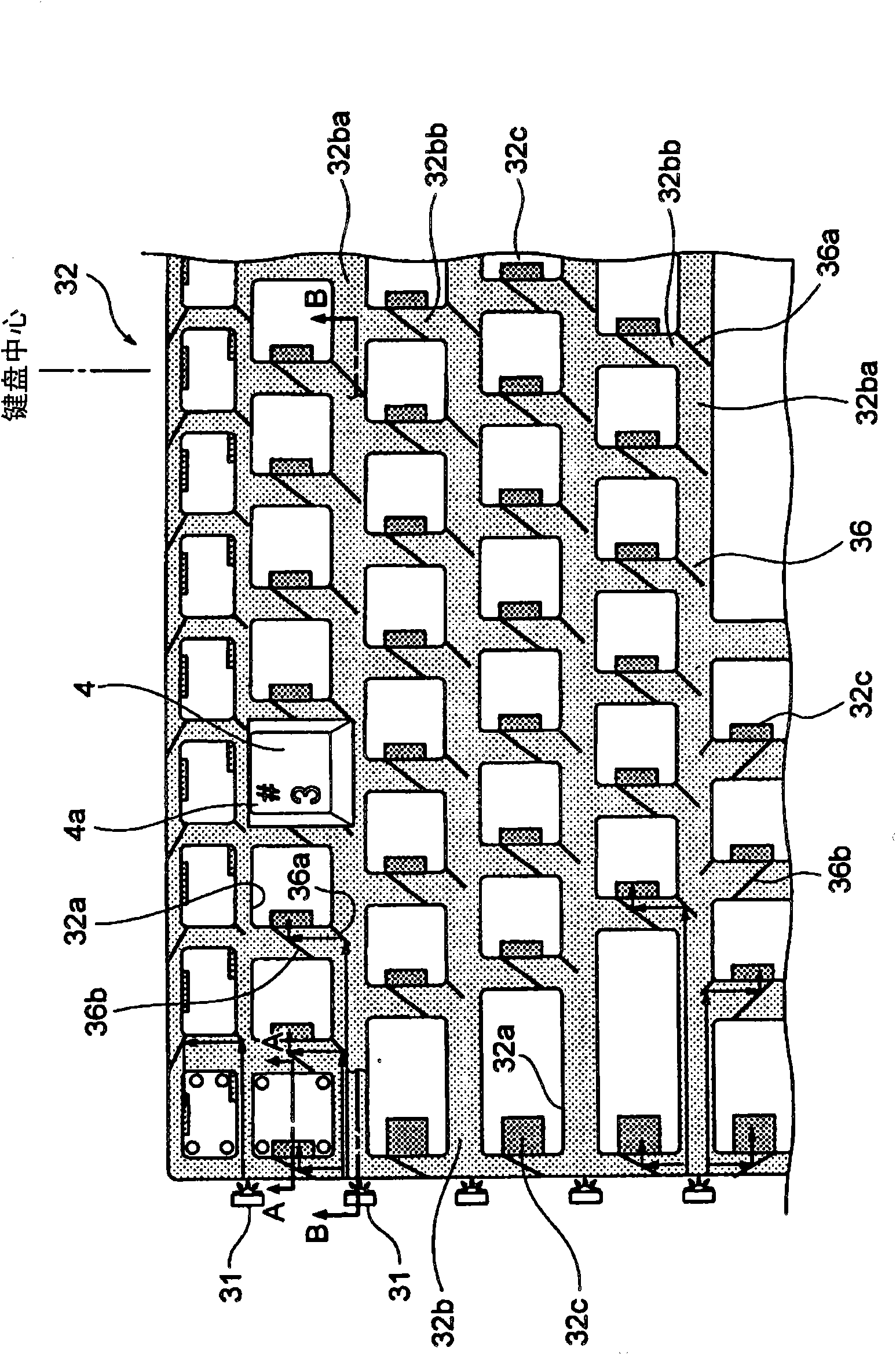

Keyboard device

InactiveCN101894697AImprove utilization efficiencyRealize thinner and lighterLegendsElectric switchesReflection illuminationLight guide

The light guiding member includes: a light guiding member body which is provided with a light propagating portion which extends in the length and width directions within the surface of the light guiding member body so as to open switch openings at positions corresponding to the arrangement positions of the key tops and to propagate the light to the inside of the light guiding member body, and reflection illumination portions, each of which extends from the light propagating portion to the inside of each of the switch openings so as to be interposed in a space between the key top and the membrane switch; a light shielding member which is disposed on the upper surface of the light guiding member body so as to interrupt light leaking upward from the light propagating portion; and a reflection member which is disposed on the lower surface of the light propagating portion and the reflection illumination portions so as to reflect the light, leaking downward from the light guiding member body, toward each key top.

Owner:ALPS ALPINE CO LTD

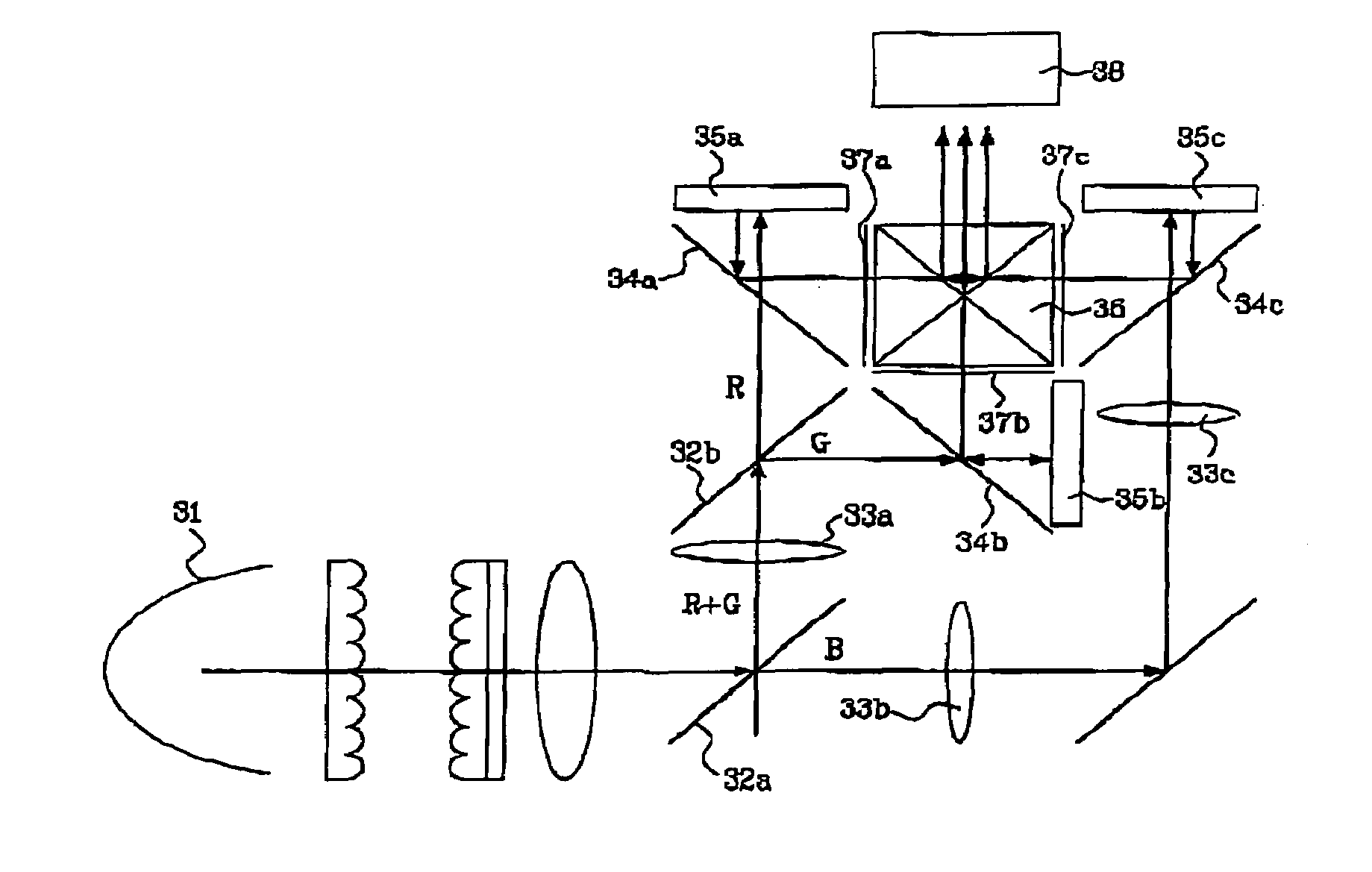

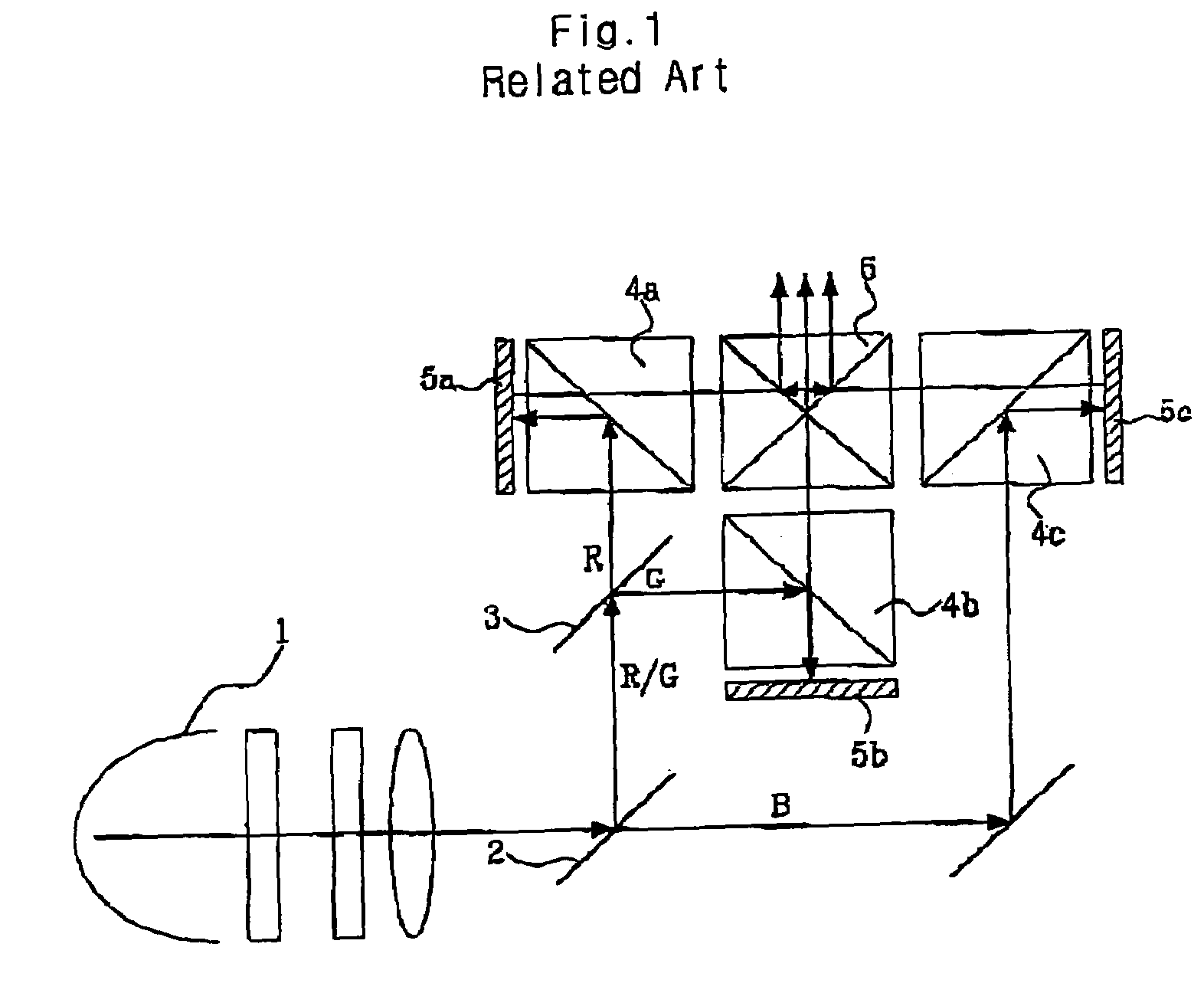

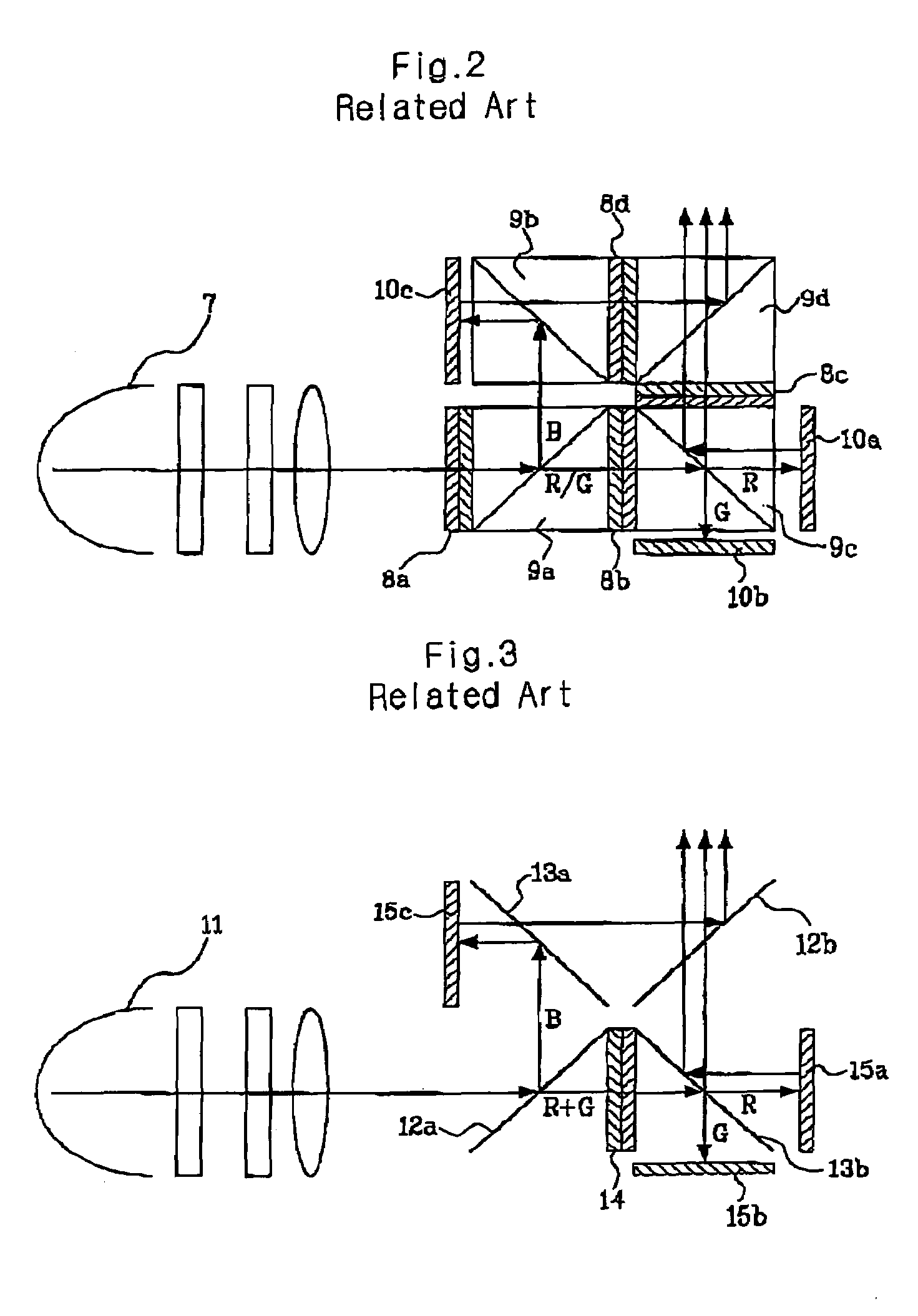

Reflective illuminating optical system

InactiveUS7172287B2Astigmatism is suppressedImprove efficiencyTelevision system detailsProjectorsBeam splitterWire grid

A reflective illuminating optical system on silicon, more particularly, to an illuminating optical system is provided, in which R, G, and B signals reflected from a LCoS panel (Liquid Crystal on Silicon panel) in a projection system do not pass through wire grid type PBSs (Polarized Beam Splitters) but are reflected by the wire grid type PBSs (Polarized Beam Splitters) so that astigmatism is suppressed and illuminating efficiency is improved.

Owner:LG ELECTRONICS INC

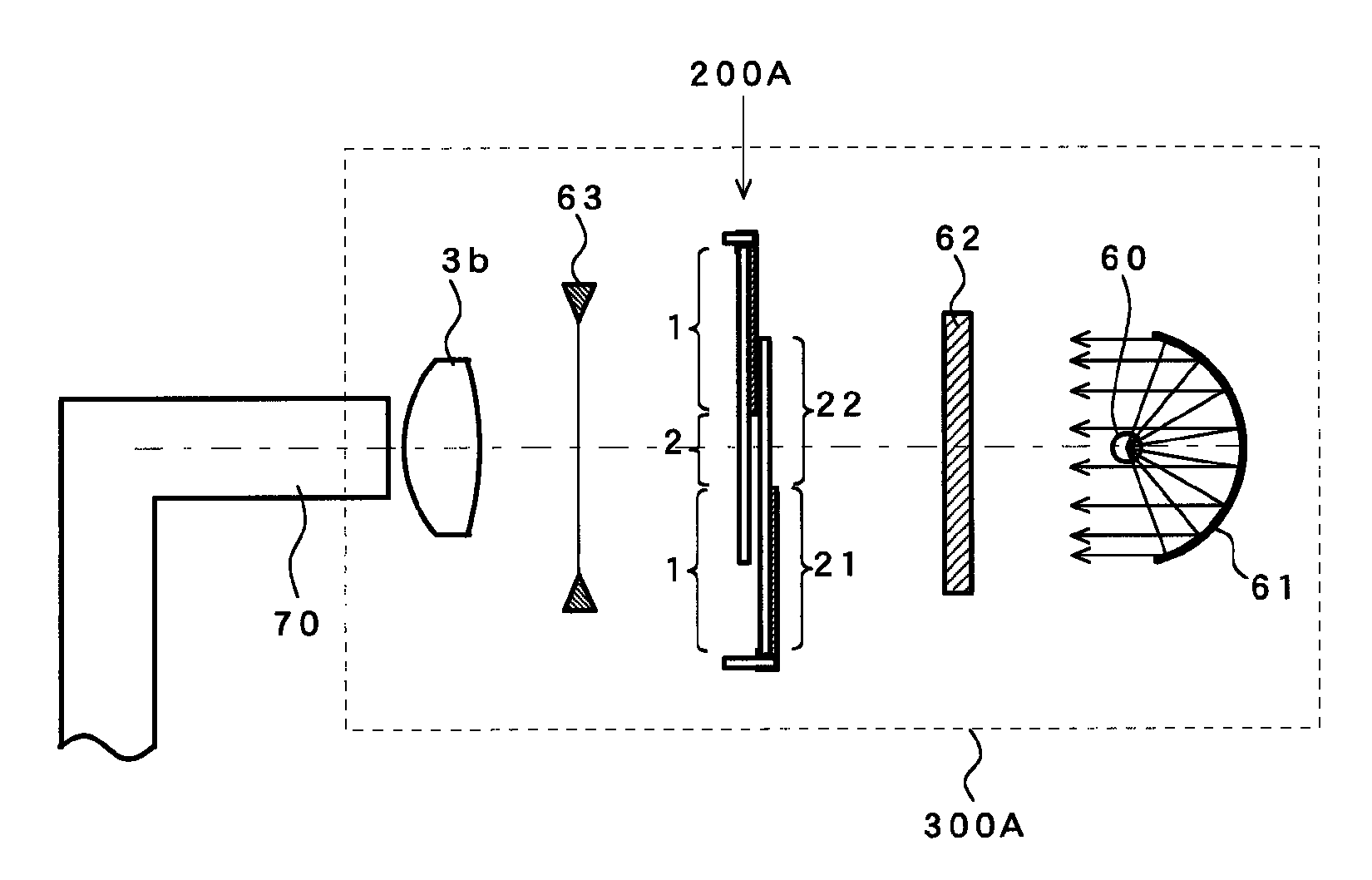

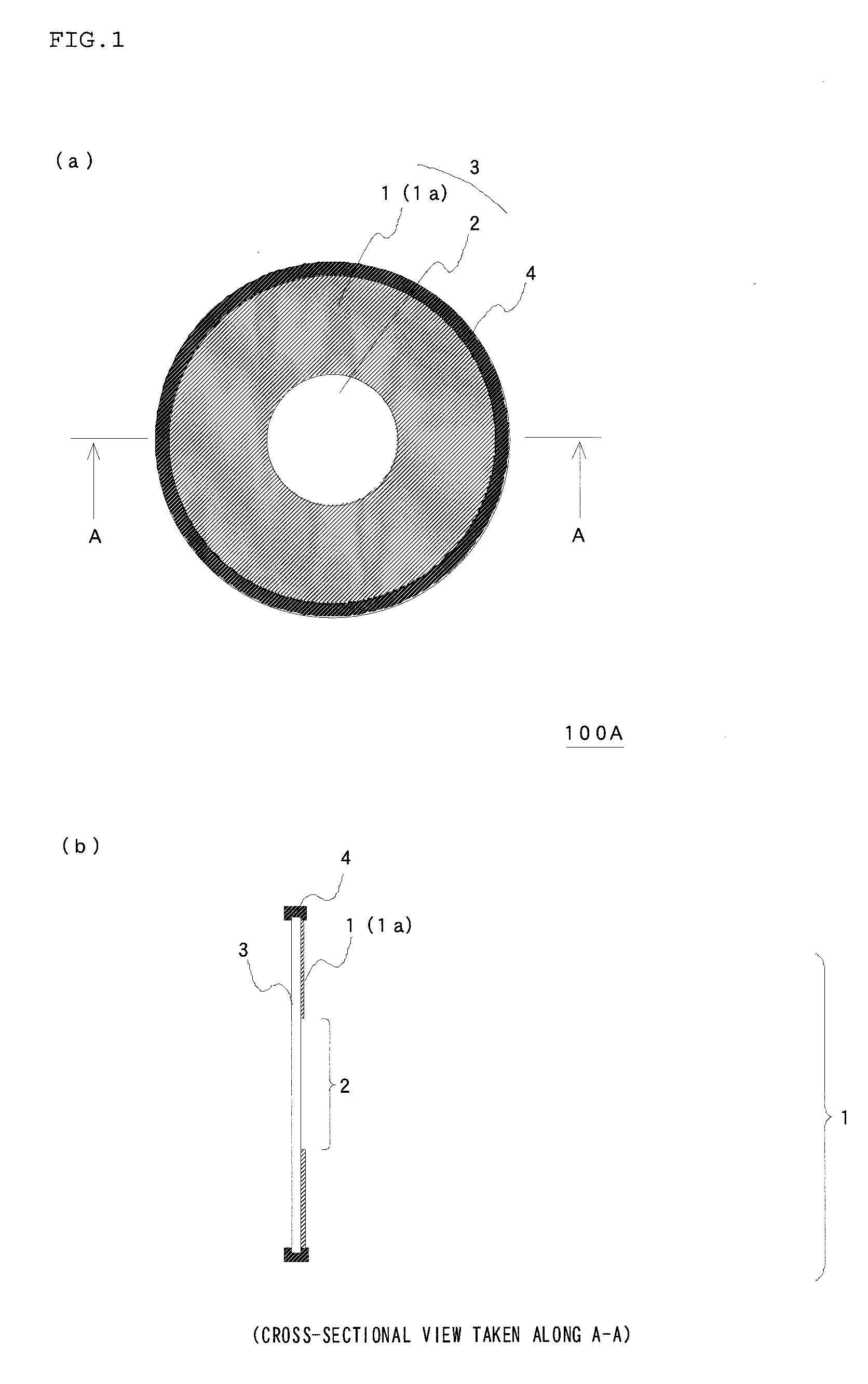

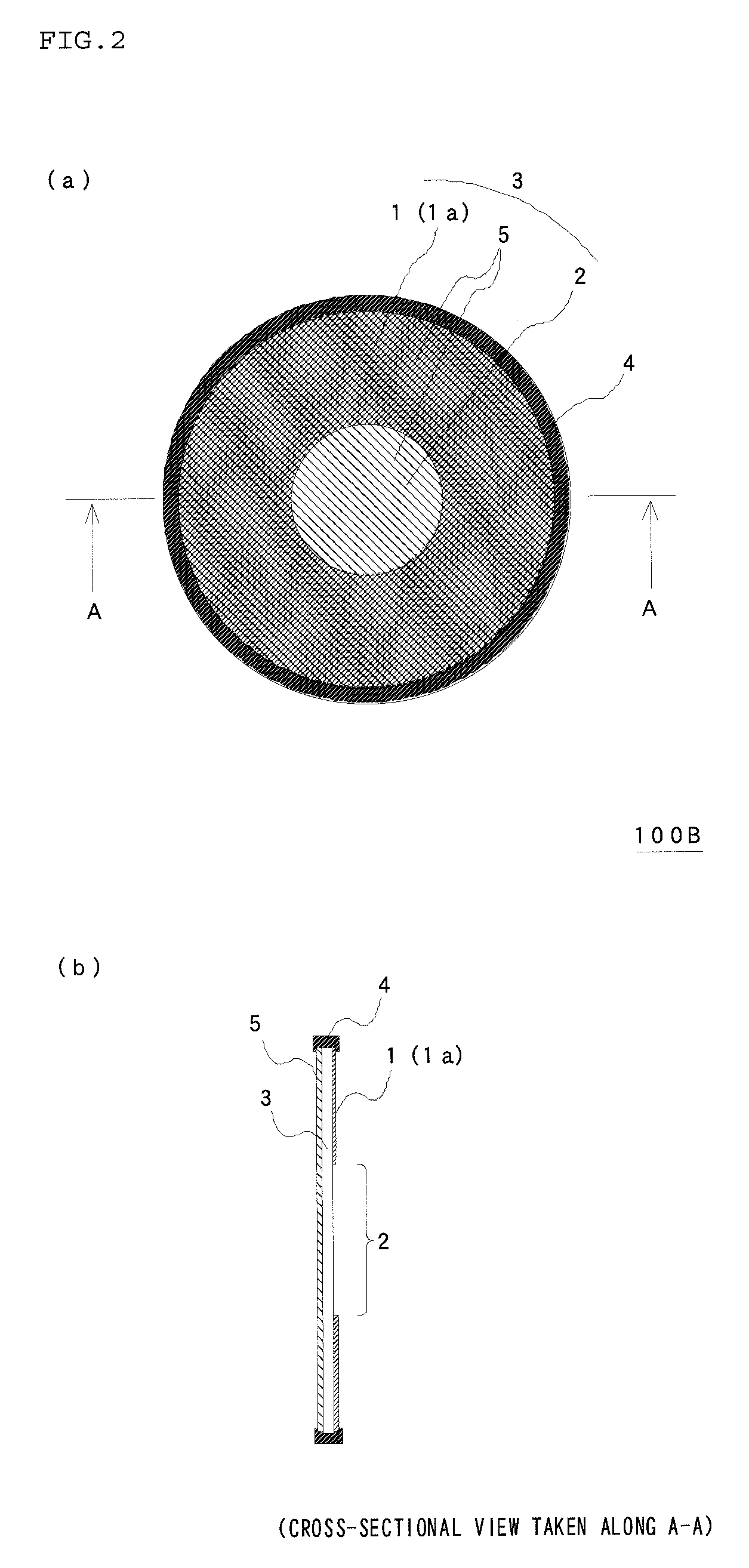

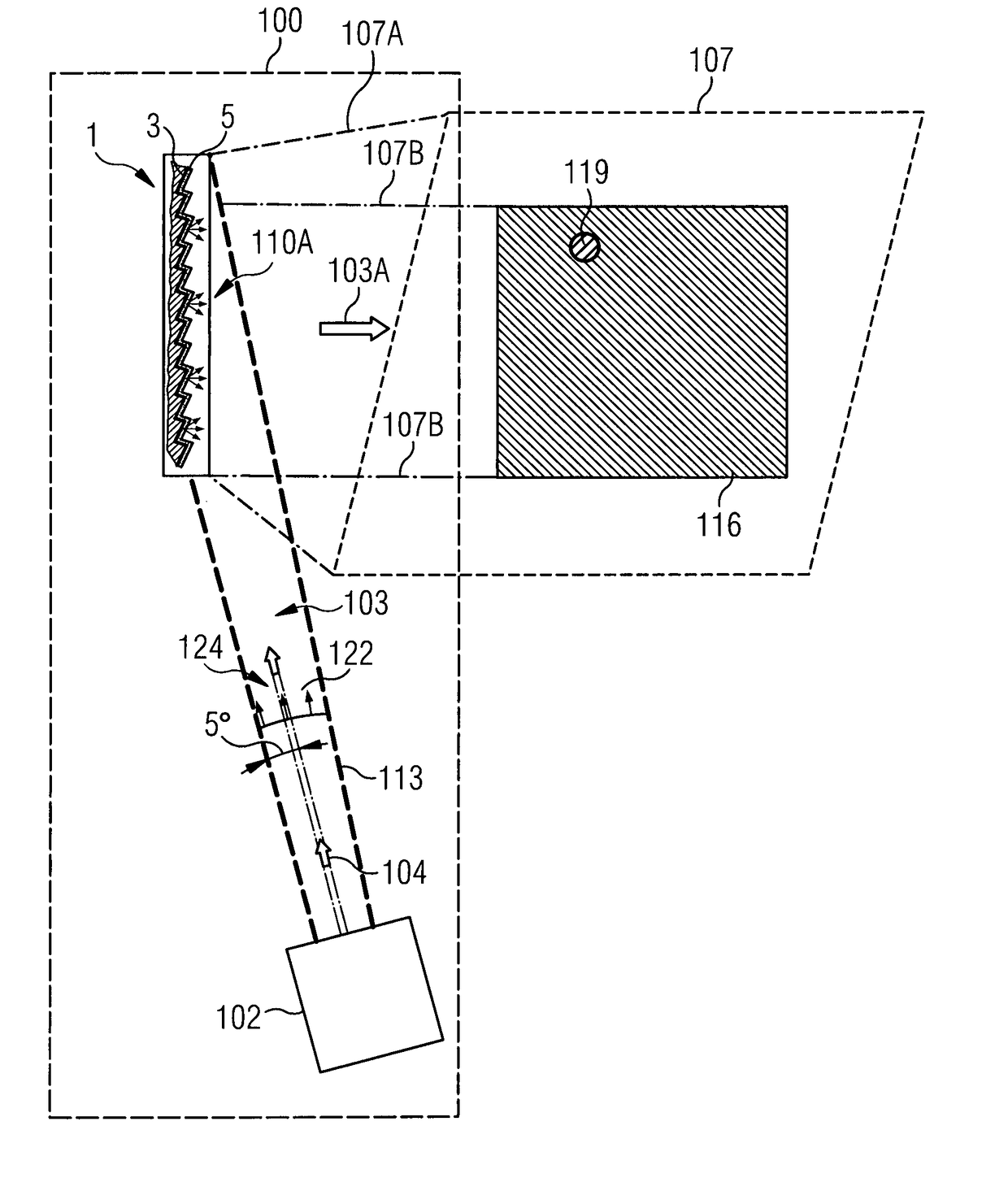

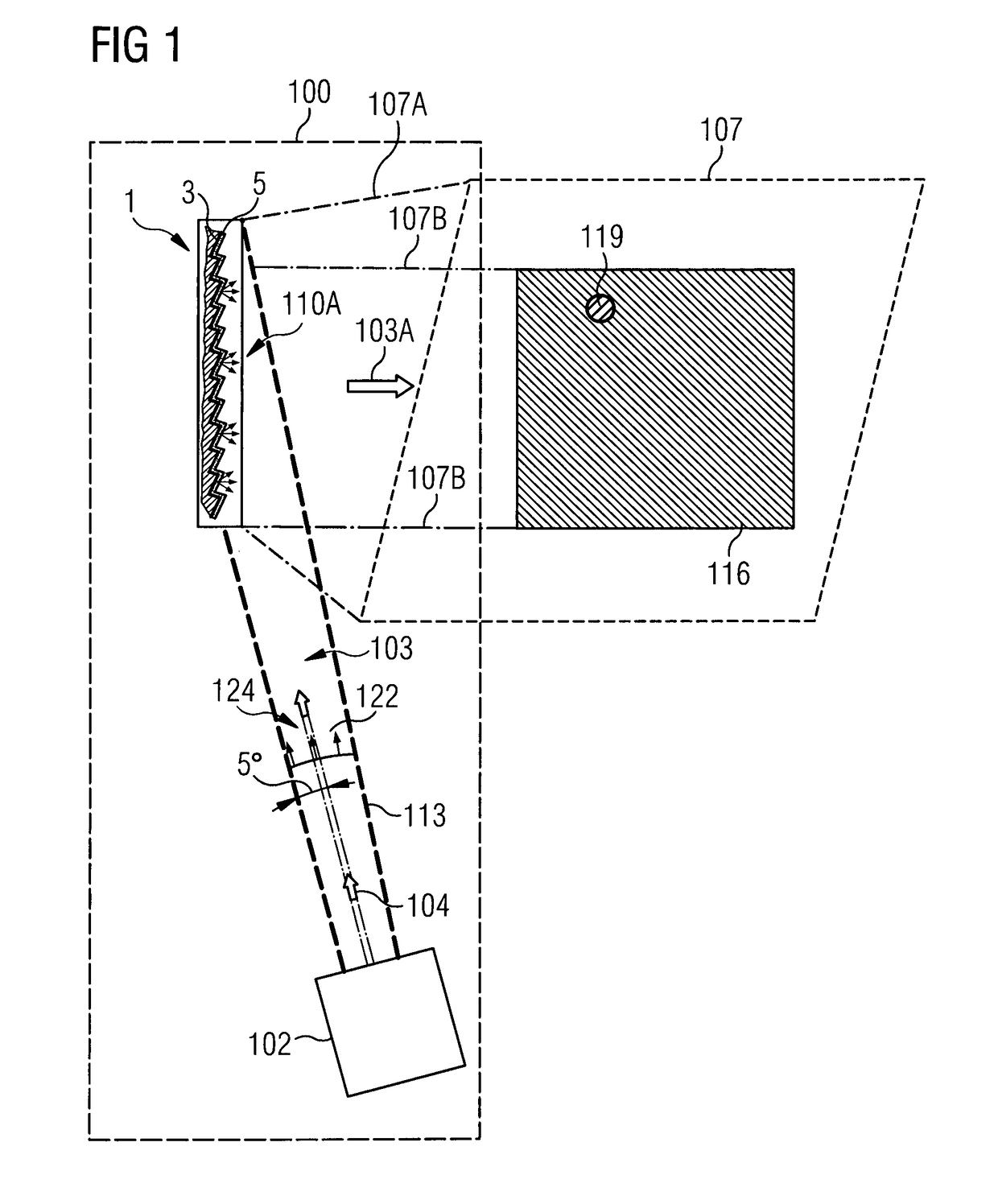

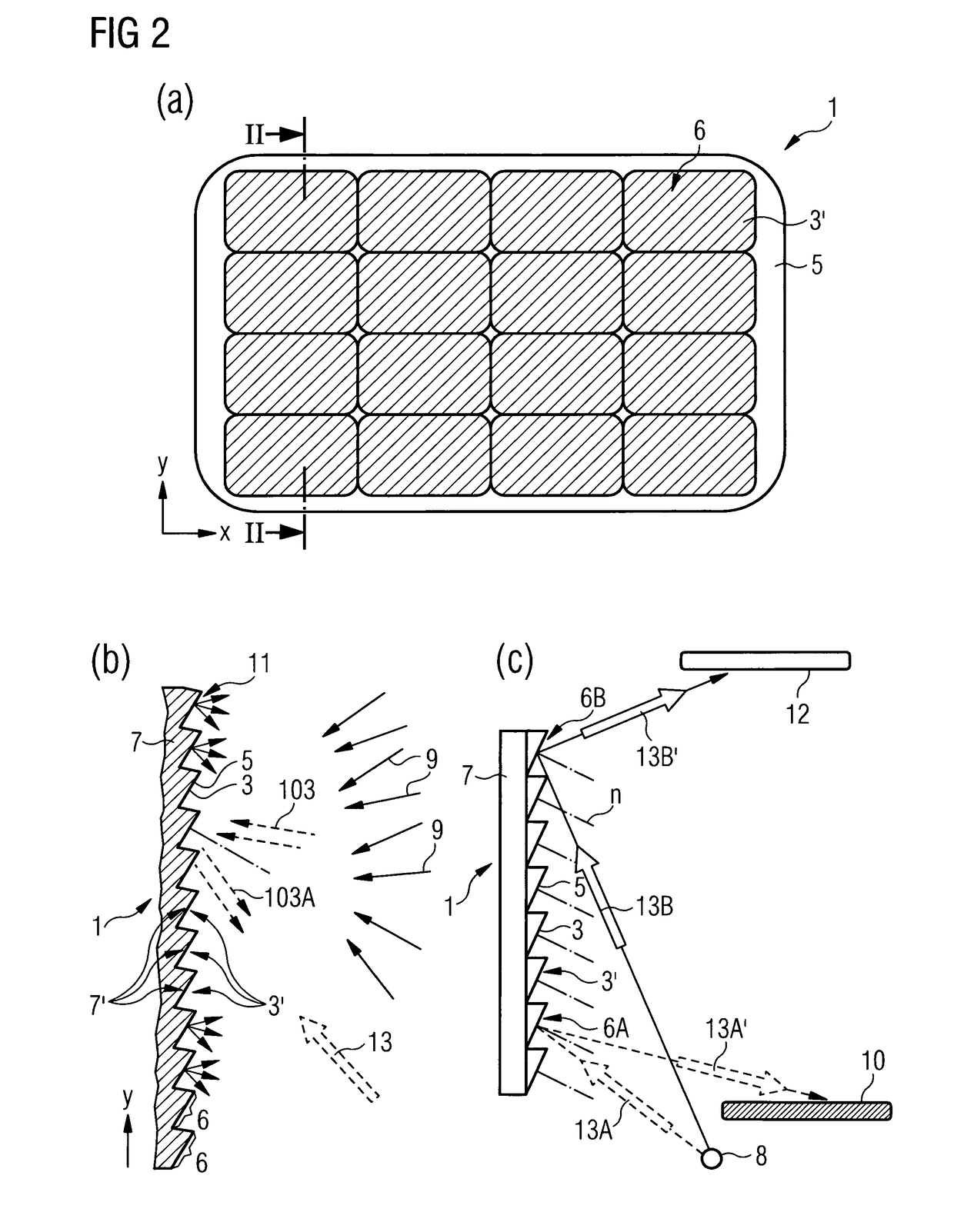

Reflective illumination systems for optically widened perception

ActiveUS20180210120A1Increase beamMinimizing contributionDiffusing elementsReflectorsNanoparticleLight beam

In an aspect, an illumination system (100) is disclosed to comprise a light source (102) configured to generate a light beam (103), and a chromatic reflective unit (1) for being illuminated by the light beam (103). The chromatic reflective unit (1) comprises a plurality of non-coplanar reflective surface sections (3′), and a chromatic diffusing layer (5) comprises a plurality of nanoparticles (37) embedded in a matrix (39), wherein the chromatic diffusing layer (5) is provided upstream of the plurality of reflective surface sections (3′) such that at least a portion of the light beam (103) passes through the chromatic diffusing layer (5) before and after being reflected by the plurality of non-coplanar reflective surface sections (3′). Chromatic diffusing layer (5) is further configured to provide for—together with non-coplanar reflective surface sections (3′)—a specular reflectance that is larger in the red than in the blue and for a diffuse reflectance that is larger in the blue than in the red.

Owner:COELUX

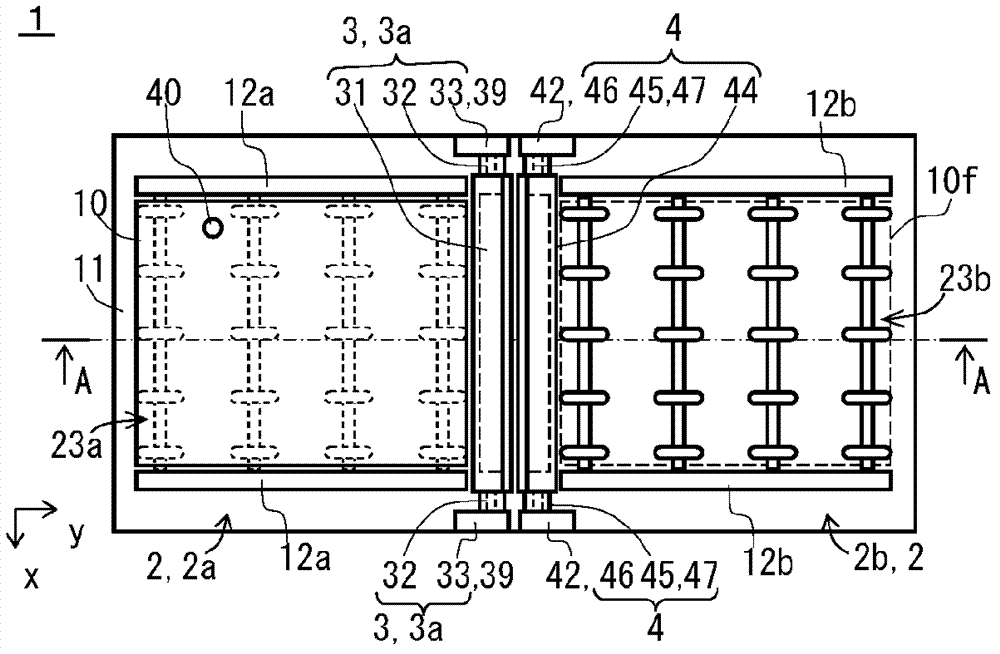

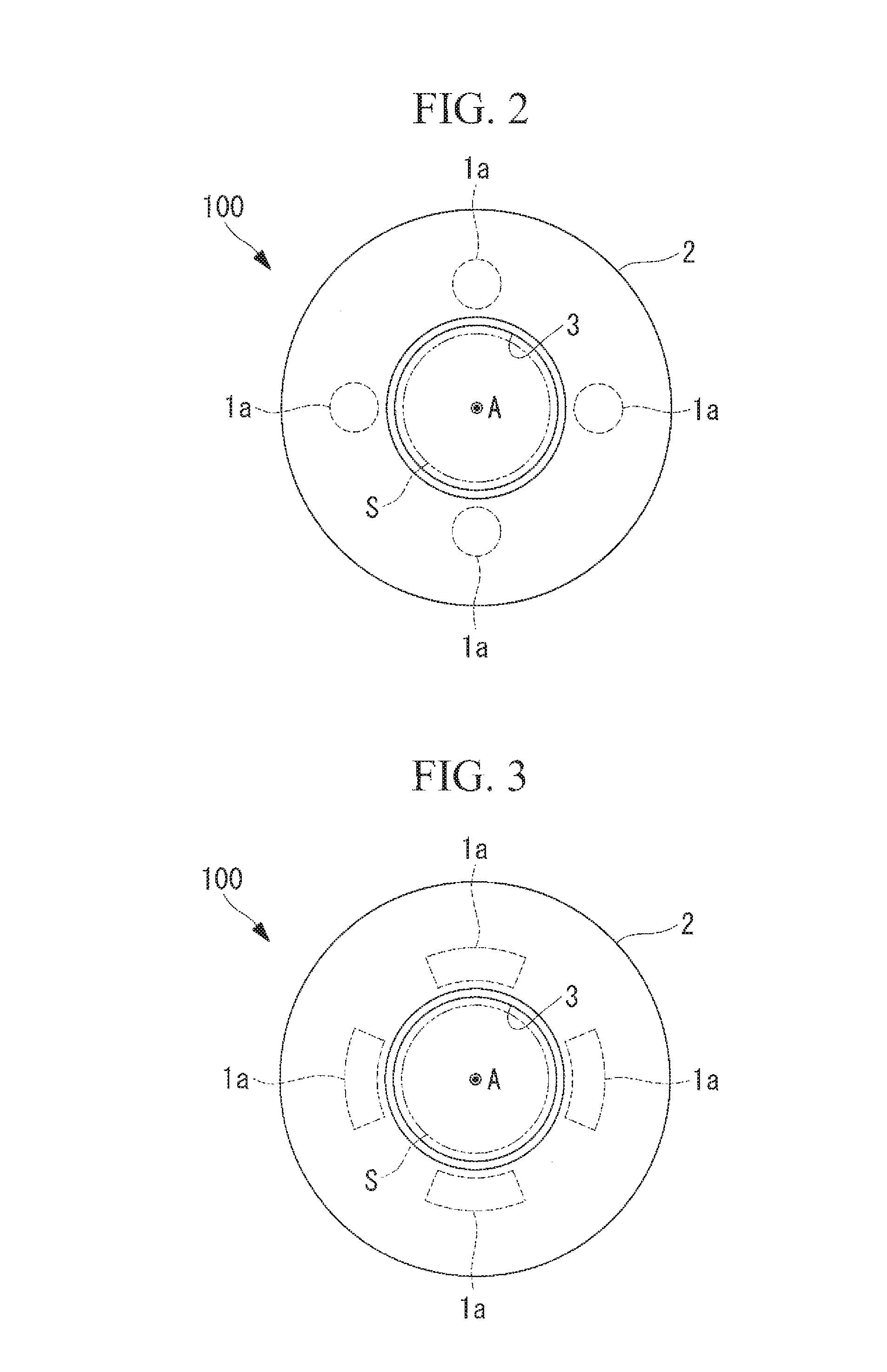

Illumination device

An illumination device according to the present invention includes a light output unit having an output end that outputs illumination light; a diffusion layer that is disposed in a circumferential direction centered on a predetermined axis and that receives the illumination light from the output end, guides the illumination light while diffusing the illumination light, and outputs the illumination light from a surface thereof; and a reflective layer that is provided adjacent to a surface of the diffusion layer at an inner side in a radial direction and that reflects the illumination light outward in the radial direction. The diffusion layer contains a light guide material that guides the illumination light and a diffusion material dispersed and supported in the light guide material.

Owner:OLYMPUS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com