Device and method for inspecting unevenness of film thickness

A technology of inspection device and inspection method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of uneven film thickness, uneven pigment dispersion, uneven color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] Embodiments for carrying out the present invention will be described using the drawings.

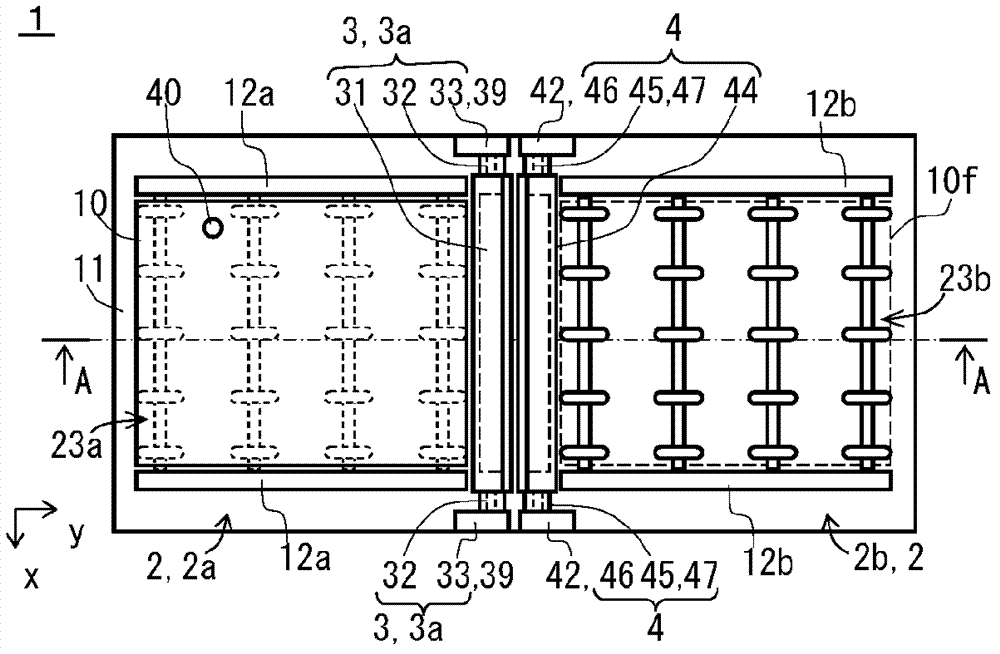

[0117] Figure 1A It is a plan view showing an embodiment for realizing the present invention.

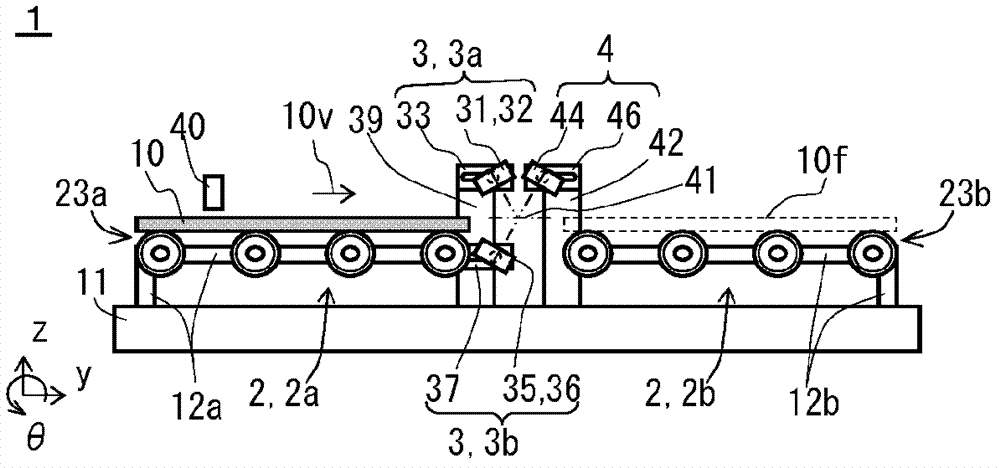

[0118] Figure 1B It is a side view showing an embodiment for realizing the present invention.

[0119] In each figure, let the three axes of the orthogonal coordinate system be X, Y, and Z, let the XY plane be the horizontal plane, and let the Z direction be the vertical direction. In particular, in the Z direction, the direction of the arrow is represented as upward, and the opposite direction is represented as downward. Furthermore, let the rotation direction around the X direction be the θ direction.

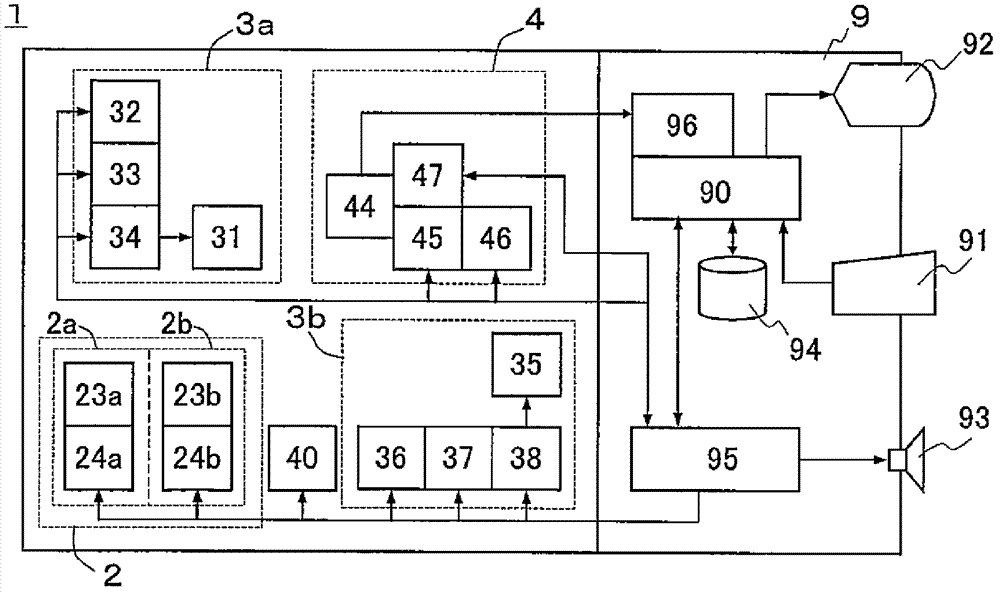

[0120] The film thickness unevenness inspection device 1 includes a substrate moving unit 2 , a light source unit 3 , an imaging unit 4 , an inspection unit, and a control unit 9 . Here, the substrate to be inspected is described as an example of a substrate 10 coated with a colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com